💬 Power Meter Pulse Sensor

-

Done that... reset everything..still the same

here is my code

#define DIGITAL_INPUT_SENSOR 3 // The digital input you attached your light sensor. (Only 2 and 3 generates interrupt!)

#define PULSE_FACTOR 1000 // Nummber of blinks per KWH of your meeter

#define SLEEP_MODE false // Watt-value can only be reported when sleep mode is false.

#define MAX_WATT 10000 // Max watt value to report. This filetrs outliers.

#define CHILD_ID 1 // Id of the sensor childunsigned long SEND_FREQUENCY = 5000; // Minimum time between send (in milliseconds). We don't wnat to spam the gateway.

double ppwh = ((double)PULSE_FACTOR)/1000; // Pulses per watt hour

bool pcReceived = true;

volatile unsigned long pulseCount = 0;

volatile unsigned long lastBlink = 0;

volatile unsigned long watt = 0;

unsigned long oldPulseCount = 0;

unsigned long oldWatt = 0;

double oldKwh;

unsigned long lastSend;

MyMessage wattMsg(CHILD_ID,V_WATT);

MyMessage kwhMsg(CHILD_ID,V_KWH);

MyMessage pcMsg(CHILD_ID,V_VAR1);void setup()

{

// Fetch last known pulse count value from gw

request(CHILD_ID, V_VAR1);// Use the internal pullup to be able to hook up this sketch directly to an energy meter with S0 output

// If no pullup is used, the reported usage will be too high because of the floating pin

pinMode(DIGITAL_INPUT_SENSOR,INPUT_PULLUP);attachInterrupt(digitalPinToInterrupt(DIGITAL_INPUT_SENSOR), onPulse, RISING);

lastSend=millis();

}void presentation() {

// Send the sketch version information to the gateway and Controller

sendSketchInfo("Energy Meter", "1.0");// Register this device as power sensor

present(CHILD_ID, S_POWER);

}void loop()

{

unsigned long now = millis();

// Only send values at a maximum frequency or woken up from sleep

bool sendTime = now - lastSend > SEND_FREQUENCY;

if (pcReceived && (SLEEP_MODE || sendTime)) {

// New watt value has been calculated

if (!SLEEP_MODE && watt != oldWatt) {

// Check that we dont get unresonable large watt value.

// could hapen when long wraps or false interrupt triggered

if (watt<((unsigned long)MAX_WATT)) {

send(wattMsg.set(watt)); // Send watt value to gw

}

Serial.print("Watt:");

Serial.println(watt);

oldWatt = watt;

}// Pulse cout has changed if (pulseCount != oldPulseCount) { send(pcMsg.set(pulseCount)); // Send pulse count value to gw double kwh = ((double)pulseCount/((double)PULSE_FACTOR)); oldPulseCount = pulseCount; if (kwh != oldKwh) { send(kwhMsg.set(kwh, 4)); // Send kwh value to gw oldKwh = kwh; } } lastSend = now;} else if (sendTime && !pcReceived) {

// No count received. Try requesting it again

request(CHILD_ID, V_VAR1);

lastSend=now;

}if (SLEEP_MODE) {

sleep(SEND_FREQUENCY);

}

}void receive(const MyMessage &message) {

if (message.type==V_VAR1) {

pulseCount = oldPulseCount = message.getLong();

Serial.print("Received last pulse count from gw:");

Serial.println(pulseCount);

pcReceived = true;

}

}void onPulse()

{

if (!SLEEP_MODE) {

unsigned long newBlink = micros();

unsigned long interval = newBlink-lastBlink;

if (interval<10000L) { // Sometimes we get interrupt on RISING

return;

}

watt = (3600000000.0 /interval) / ppwh;

lastBlink = newBlink;

}

pulseCount++;

}@asgardro Thanks for your nice prompt feedback.

-

Pulse Power Measurement: Measuring Instantaneous Power of a Short Pulse. ... Thermopile sensors are often used to measure single shot pulse energy;

-

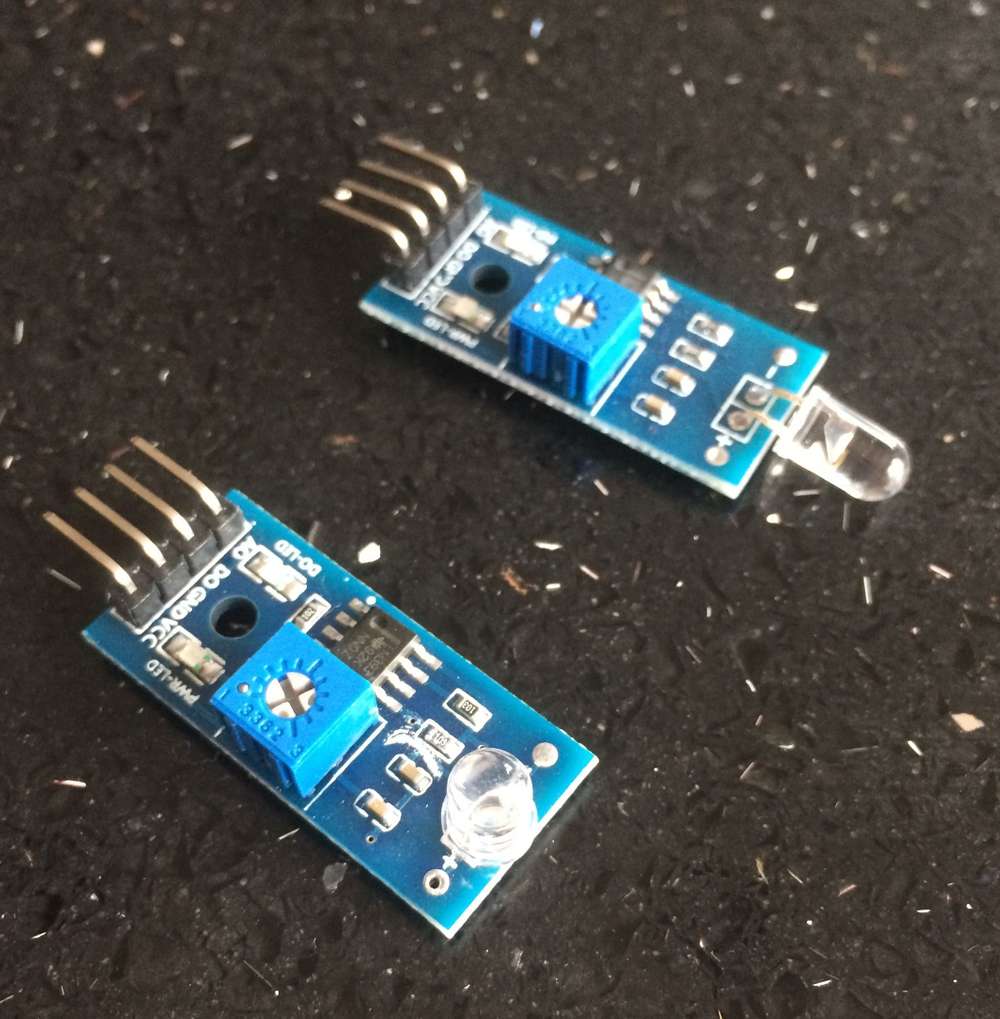

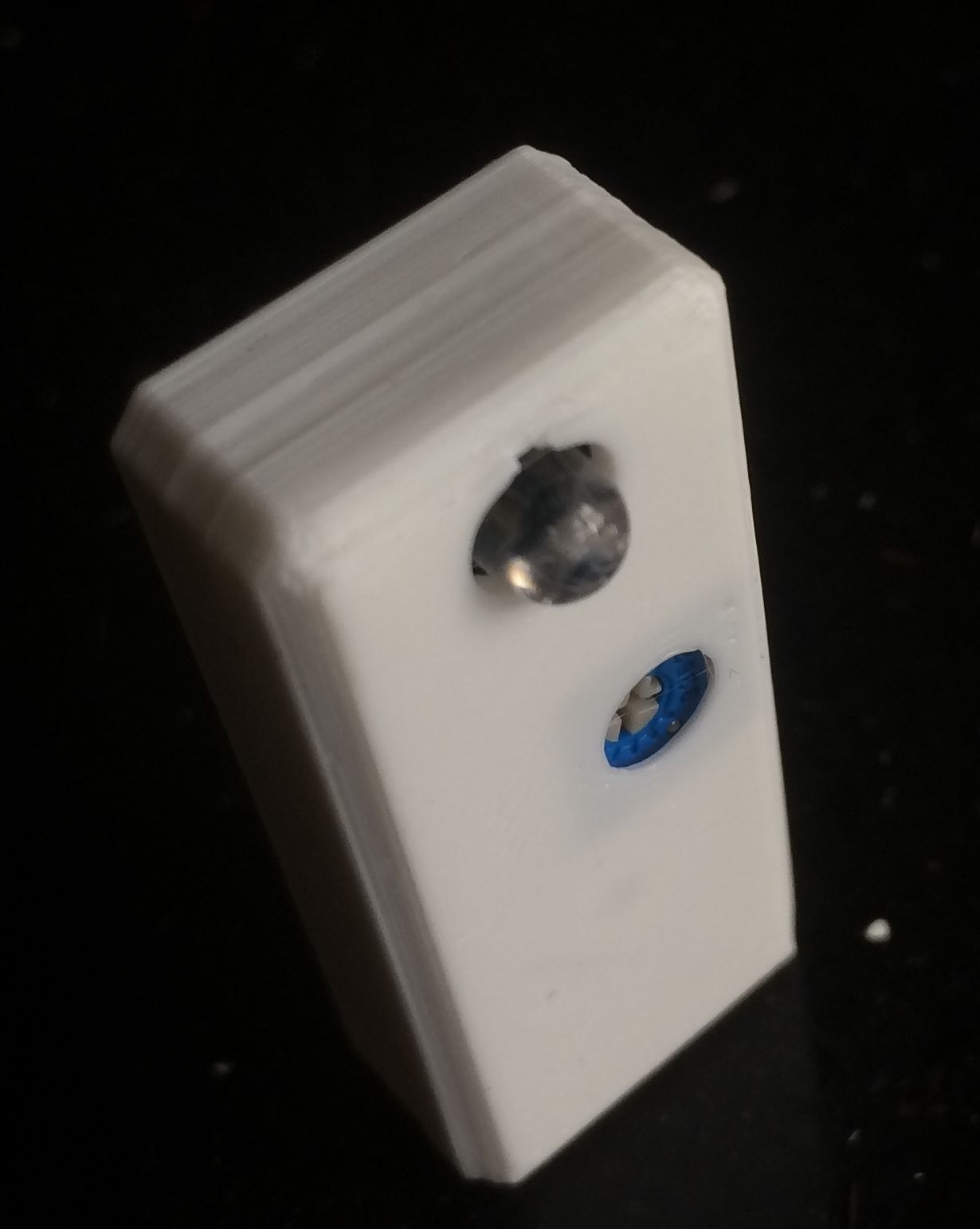

I've been building one of these pulse meters up, it seems to be working on the bench very nice. Just got to build a case and get a power supply of the Arduino. But I have designed a case to hold the LM393 sensor onto the meter. I removed the light sensor and re-soldered it flush to the board making it easier to mount on the meter. Its a simple box but works quite well.

The files are on thingiverse here

Hope this is useful.

@keithellis Lovely idea.

I've followed suit and knocked up one but with the sensor facing the other way, so that it faces the meter, and the preset pot is and LEDs are facing away from the meter.That way the sensor side of the case can be stuck to the face of the meter, and the pot adjusted without removing it from the meter. The flashing light on DO flashes in sync with the LED on the meter. Theres a little ring that holds the sensor flush with the face of the case so it can lie flat on the front of the meter.

Also, its a good idea to use black / dark coloured PLA so as to block out the any stray light that may illuminate the sensor (such as when the meter man comes to read it and shines a bright torch to see the dials).