Board and hardware failures

-

Hello everyone:

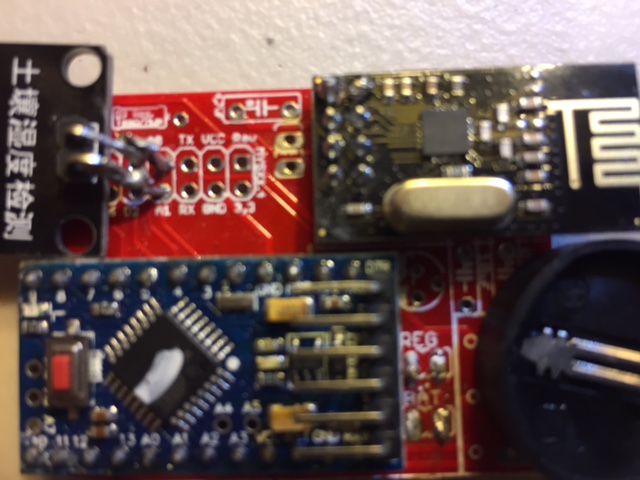

I took Gohan's advice and did the continuity tests. On two of the boards I tested, there was a lack of connectivity to pins 10 and 11. (Pins 9,13, and 12 were fine).

These boards were from two different batches.Below is a picture of a board that was actually working for weeks. Then I get the same !TSM:INIT:TSP FAIL failures rolling out. Since this was a plant moisture sensor, I assumed it was because I got some water on it - but maybe not.

On one of the boards, I de-soldered the radio. Then the continuity was even worse. I don't even want to show a picture of it :)

So - does this provide more clues? Any idea on the best way to salvage parts now? I have a feeling the pro-mini is just fine.

Thanks again!

@ileneken3 said in Board and hardware failures:

Since this was a plant moisture sensor, I assumed it was because I got some water on it.

I'll bet on (galvanic) corrosion as a root cause. Protect the pcb or use wires between pcb and sensor.

-

OK, I started over again with the moisture sensor -taking all the advice I got.

- Used female headers, to allow for easily swapping hardware.

- No longer cutting pins on back of the board.

- No longer cutting right side of board off (in case damage is done).

- New soldering iron tip.

- Soldering with a magnifying glass, and being careful.

- Checking continuity.

- Checking pro-mini and radio separately.

- Separating the "fork" so no soil or moisture touches the PCB (avoiding corrosion).

I turned it all on , and got the same !TSM:INIT failures. Just when I was about to throw the board against the wall, I took a shot at shorting the REG (in addition to the BAT). Then everything worked great!

I guess I don't understand why that worked. I figured I'd write myself a spreadsheet, and fill in the combinations. Attached is my start.

Comments/Corrections? -

OK, I started over again with the moisture sensor -taking all the advice I got.

- Used female headers, to allow for easily swapping hardware.

- No longer cutting pins on back of the board.

- No longer cutting right side of board off (in case damage is done).

- New soldering iron tip.

- Soldering with a magnifying glass, and being careful.

- Checking continuity.

- Checking pro-mini and radio separately.

- Separating the "fork" so no soil or moisture touches the PCB (avoiding corrosion).

I turned it all on , and got the same !TSM:INIT failures. Just when I was about to throw the board against the wall, I took a shot at shorting the REG (in addition to the BAT). Then everything worked great!

I guess I don't understand why that worked. I figured I'd write myself a spreadsheet, and fill in the combinations. Attached is my start.

Comments/Corrections?@ileneken3 First and foremostm, don't get discouraged. We are here to help. Can you show us a set of fresh pics of both sides of your board so we can see what's going on? The easy newbie board can have several configurations and depending on how you have things connected with your incoming power will determine what BAT and REG jumpers need to be in place for things to work properly.

-

OK, I started over again with the moisture sensor -taking all the advice I got.

- Used female headers, to allow for easily swapping hardware.

- No longer cutting pins on back of the board.

- No longer cutting right side of board off (in case damage is done).

- New soldering iron tip.

- Soldering with a magnifying glass, and being careful.

- Checking continuity.

- Checking pro-mini and radio separately.

- Separating the "fork" so no soil or moisture touches the PCB (avoiding corrosion).

I turned it all on , and got the same !TSM:INIT failures. Just when I was about to throw the board against the wall, I took a shot at shorting the REG (in addition to the BAT). Then everything worked great!

I guess I don't understand why that worked. I figured I'd write myself a spreadsheet, and fill in the combinations. Attached is my start.

Comments/Corrections?@ileneken3 as @dbemowsk said, there are some configurations you can use which is tested (see openhardware for details). If you have some insight and imagination thought there are probably a 100 different combination you can do... but also 100 different combination that won't work! (100 might be exaggerated but you get the picture).

First rule - the board is not designed to short both bat and reg at the same time.

BAT and REG as dependent on which input you use and if you use a booster/regulator or not.

About your spreadsheet:- Correct! Should work - what kind of problems did you experience?

- Correct! Should work - what kind of problems did you experience?

- Not possible. Using BAT you can not cut the PCB because the trace runs through the booster module. If you dont want to use the booster you can bypass it with a wire but its not possible using 3x5cm cut pcb.

- I dont know, I have to have a schematics because it depends in which input you use and how you put the regulator. This will feed the 3.3v pro mini with 3.7v directly and only regulate the power to the radio.

You always connect your power source to VCC and never RAW - right?

When you had this issue:

I turned it all on , and got the same !TSM:INIT failures. Just when I was about to throw the board against the wall, I took a shot at shorting the REG (in addition to the BAT). Then everything worked great!

What kind of hardware and power supply did you use? Did you use a tested radio (to exclude radio failure).

Another tip is to solder the basic components first (not any sensor or accuator) and test the board with a easy sketch like timeaware sensor. If that works you can continue to include the sensor to exclude its a sensor error.

The easiest way is to follow the guidelines on openhardware or ask what you want to achieve.

-

OK, I started over again with the moisture sensor -taking all the advice I got.

- Used female headers, to allow for easily swapping hardware.

- No longer cutting pins on back of the board.

- No longer cutting right side of board off (in case damage is done).

- New soldering iron tip.

- Soldering with a magnifying glass, and being careful.

- Checking continuity.

- Checking pro-mini and radio separately.

- Separating the "fork" so no soil or moisture touches the PCB (avoiding corrosion).

I turned it all on , and got the same !TSM:INIT failures. Just when I was about to throw the board against the wall, I took a shot at shorting the REG (in addition to the BAT). Then everything worked great!

I guess I don't understand why that worked. I figured I'd write myself a spreadsheet, and fill in the combinations. Attached is my start.

Comments/Corrections?@ileneken3 said in Board and hardware failures:

@gohan

!TSM:INIT failures.TSM INIT means radio was not initialized, in that case only 2 possibilities:

- connection problem with one of the radio pins

- radio doesn't get power (it seems that was the case for you)

-

@ileneken3 as @dbemowsk said, there are some configurations you can use which is tested (see openhardware for details). If you have some insight and imagination thought there are probably a 100 different combination you can do... but also 100 different combination that won't work! (100 might be exaggerated but you get the picture).

First rule - the board is not designed to short both bat and reg at the same time.

BAT and REG as dependent on which input you use and if you use a booster/regulator or not.

About your spreadsheet:- Correct! Should work - what kind of problems did you experience?

- Correct! Should work - what kind of problems did you experience?

- Not possible. Using BAT you can not cut the PCB because the trace runs through the booster module. If you dont want to use the booster you can bypass it with a wire but its not possible using 3x5cm cut pcb.

- I dont know, I have to have a schematics because it depends in which input you use and how you put the regulator. This will feed the 3.3v pro mini with 3.7v directly and only regulate the power to the radio.

You always connect your power source to VCC and never RAW - right?

When you had this issue:

I turned it all on , and got the same !TSM:INIT failures. Just when I was about to throw the board against the wall, I took a shot at shorting the REG (in addition to the BAT). Then everything worked great!

What kind of hardware and power supply did you use? Did you use a tested radio (to exclude radio failure).

Another tip is to solder the basic components first (not any sensor or accuator) and test the board with a easy sketch like timeaware sensor. If that works you can continue to include the sensor to exclude its a sensor error.

The easiest way is to follow the guidelines on openhardware or ask what you want to achieve.

"100 different combinations"

Yes, I meant the spreadsheet to be a list of typical examples - not a comprehensive list. For a "newbie", having a cookbook style recipe is useful.- Works, no problems.

- Works, no problems.

- This is a big surprise. I thought I might have been doing something wrong, but nobody caught that from the pictures I sent! For a plant monitor, where the sensor needs almost no voltage, I didn't think it made sense to use a booster. I also wanted a nice compact device to stick in the plant pot. So, given my "illegal" configuration, I suppose it's no surprise there would be some erratic behavior?

- This works great for me. The board (and most sensors) work fine in the voltage range of a LIPO - only the radio needs to be regulated down to 3.3V. The mcp1700 needs its pins crossed over to work (since the board is designed for a LE33 regulator). A correction to the BOD column would be "2.8V (default)" or "N/A".

I have never used RAW.

Regarding:

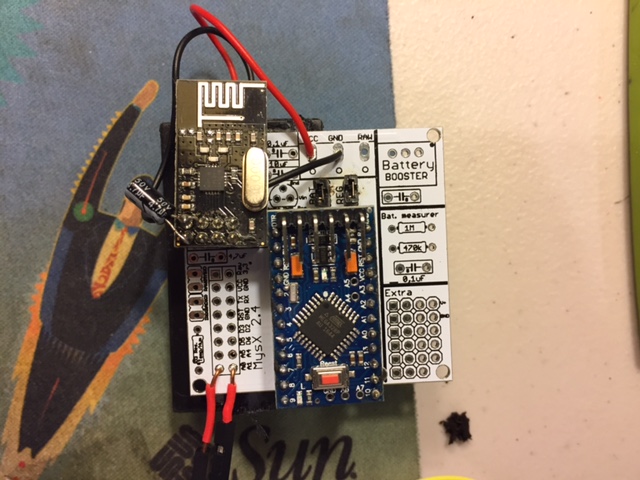

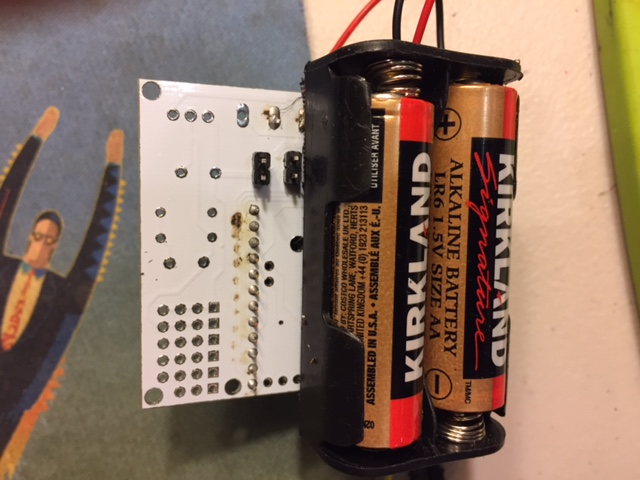

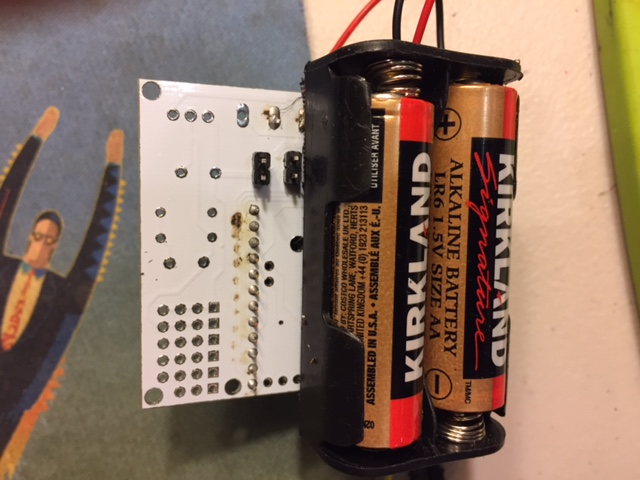

What kind of hardware and power supply did you use? Did you use a tested radio (to exclude radio failure).I used 2 AA , a 3.3V pro mini with no BOD. I tested the radios, and even tried different ones. I can send a picture - but there's nothing interesting with it. So, the existing mystery is: why do I need to short both BAT and REG (which I know now is illegal)? I tried all combinations of shorting/not shorting jumpers - that is the only one that worked.

-

@ileneken3 First and foremostm, don't get discouraged. We are here to help. Can you show us a set of fresh pics of both sides of your board so we can see what's going on? The easy newbie board can have several configurations and depending on how you have things connected with your incoming power will determine what BAT and REG jumpers need to be in place for things to work properly.

@dbemowsk

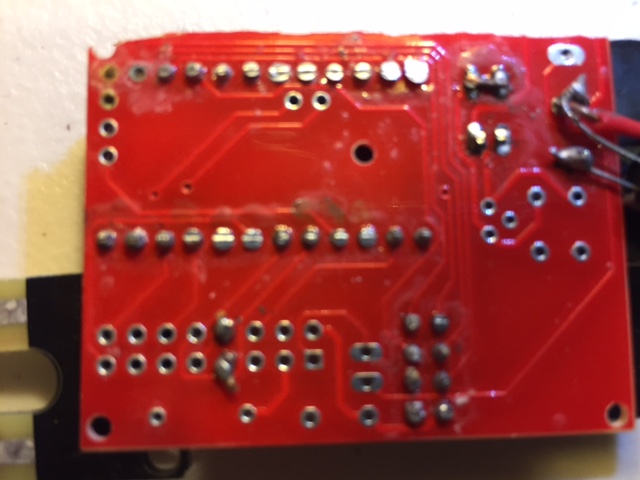

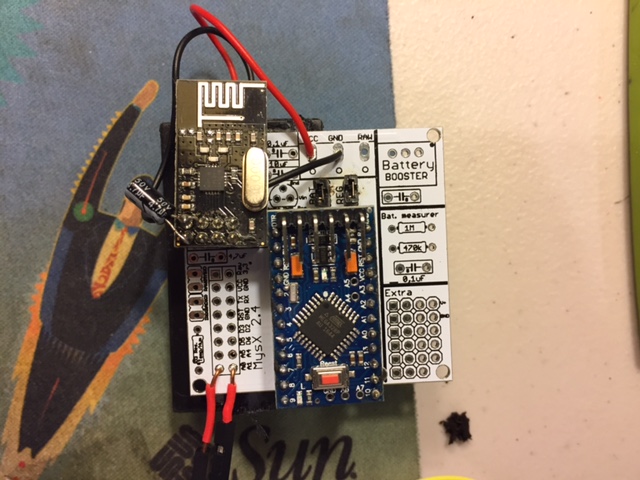

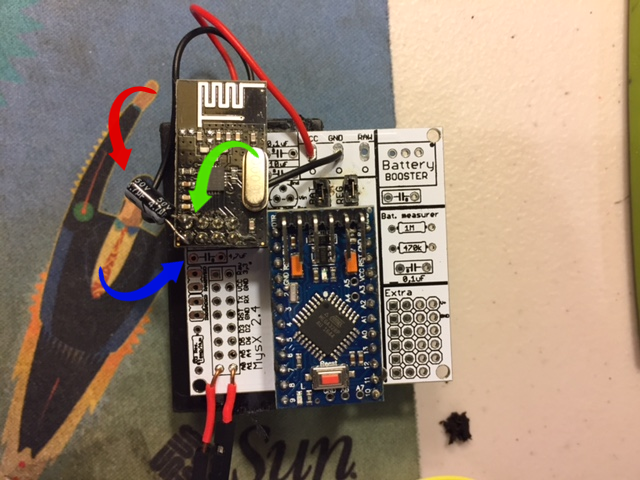

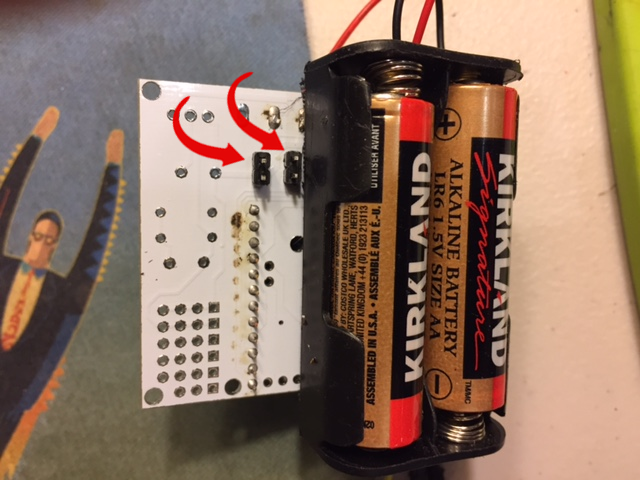

Yes, I appreciate the help! I am hoping others are learning from my adventures. It wouldn't be a fun hobby without a bit of frustration here and there :)I am attaching fresh pictures. The sensor attached is a "fork" for plant moisture monitoring.

-

"100 different combinations"

Yes, I meant the spreadsheet to be a list of typical examples - not a comprehensive list. For a "newbie", having a cookbook style recipe is useful.- Works, no problems.

- Works, no problems.

- This is a big surprise. I thought I might have been doing something wrong, but nobody caught that from the pictures I sent! For a plant monitor, where the sensor needs almost no voltage, I didn't think it made sense to use a booster. I also wanted a nice compact device to stick in the plant pot. So, given my "illegal" configuration, I suppose it's no surprise there would be some erratic behavior?

- This works great for me. The board (and most sensors) work fine in the voltage range of a LIPO - only the radio needs to be regulated down to 3.3V. The mcp1700 needs its pins crossed over to work (since the board is designed for a LE33 regulator). A correction to the BOD column would be "2.8V (default)" or "N/A".

I have never used RAW.

Regarding:

What kind of hardware and power supply did you use? Did you use a tested radio (to exclude radio failure).I used 2 AA , a 3.3V pro mini with no BOD. I tested the radios, and even tried different ones. I can send a picture - but there's nothing interesting with it. So, the existing mystery is: why do I need to short both BAT and REG (which I know now is illegal)? I tried all combinations of shorting/not shorting jumpers - that is the only one that worked.

So, given my "illegal" configuration, I suppose it's no surprise there would be some erratic behavior?

Exactly, there are multiple way for the current to flow.

2 AA , a 3.3V pro mini with no BOD, why do I need to short both BAT and REG (which I know now is illegal)?

Because you shorted BAT first and if you do you have to have a booster or jump this. When you added REG you started feeding the rest of the circuit and it worked. Using BAT you cant cut the PCB or not use the booster.

You said 1 and 2 "Works, no problems."

Du you have it working now, because im not 100% sure what you are trying to achieve. -

So, given my "illegal" configuration, I suppose it's no surprise there would be some erratic behavior?

Exactly, there are multiple way for the current to flow.

2 AA , a 3.3V pro mini with no BOD, why do I need to short both BAT and REG (which I know now is illegal)?

Because you shorted BAT first and if you do you have to have a booster or jump this. When you added REG you started feeding the rest of the circuit and it worked. Using BAT you cant cut the PCB or not use the booster.

You said 1 and 2 "Works, no problems."

Du you have it working now, because im not 100% sure what you are trying to achieve.@ileneken3 the board was not designed tgat way you have it in the picture in post above.

If you feed 2xAA and jump BAT you need a booster (or jump this with a wire and lower BOD) .Another way is to use REG jumper, lower BOD and jump the voltage regualtor with a wire (recommended because then you can cut the PCB)

Edit: I updated openhardware.io with this information (look for 3.3V without booster (advanced users!))

Edit2: Might be that jumping both creates the same effect as wire jump booster!! I will look more into that... as I said, the pcb was not designed that way so I have never thought about it but if it works that great! -

@ileneken3 the board was not designed tgat way you have it in the picture in post above.

If you feed 2xAA and jump BAT you need a booster (or jump this with a wire and lower BOD) .Another way is to use REG jumper, lower BOD and jump the voltage regualtor with a wire (recommended because then you can cut the PCB)

Edit: I updated openhardware.io with this information (look for 3.3V without booster (advanced users!))

Edit2: Might be that jumping both creates the same effect as wire jump booster!! I will look more into that... as I said, the pcb was not designed that way so I have never thought about it but if it works that great!According to the new documentation, my build is now officially approved by you! Of course, it would be interesting to hear what the exact effect of jumping both jumpers is. All I know is that it works. There seem to be a lot of sensors that work fine down to 1.9V, so I would think that this configuration would be useful. (Assuming that reprogramming the bootloader is not too hard - I didn't think so).

So did you consider making the LIPO configuration "official"? So far, it seems that it works fine for me. It is good for when you really want a small footprint and/or your sensor needs 3.3V. Unfortunately, not as long a life as 2 AA, but you don't have to deal with the booster's expense and possible radio interference.

-

According to the new documentation, my build is now officially approved by you! Of course, it would be interesting to hear what the exact effect of jumping both jumpers is. All I know is that it works. There seem to be a lot of sensors that work fine down to 1.9V, so I would think that this configuration would be useful. (Assuming that reprogramming the bootloader is not too hard - I didn't think so).

So did you consider making the LIPO configuration "official"? So far, it seems that it works fine for me. It is good for when you really want a small footprint and/or your sensor needs 3.3V. Unfortunately, not as long a life as 2 AA, but you don't have to deal with the booster's expense and possible radio interference.

@ileneken3 - what i always consider is the Newbie/Easy effect. Im not going to make any harder build instructions because that might scare people off. I want it easy and understandable. Thats the reason im not going to add tutorial how to change bod and stuff like that. I just mention it so people knows it possible.

exact effect of jumping both jumpers is

Well, Its a long story but here it goes (keep along in the schematics maybe?).

BAT activated the circuit to the radio, but not the arduino (if the booster isnt soldered). The reason for that is that the radio works down to 1.9v. The radio is also noice sensitive and 2xAA could be considered very low noice. When you didnt soldered the booster you did not activate the rest of the circuit. REG activates the arduino pro mini circuit and the sensors. This will output 3.3v from VCC to the voltage regulator but since you didnt have any regulator in place the radio didnt get any power. Two different circuit which activated both together via the jumpers and BOD is disabled will work together. Whats important to know is that if you have had a booster or any voltage regulator this setup may have failed!Thank you for adding this discussion so we could find out this way to use the EasyPCB!

-

@dbemowsk

Yes, I appreciate the help! I am hoping others are learning from my adventures. It wouldn't be a fun hobby without a bit of frustration here and there :)I am attaching fresh pictures. The sensor attached is a "fork" for plant moisture monitoring.

@ileneken3 A couple things that I should note. I will reference the image below. First, with the capacitor for the radio (red arrow), though it should work the way you have it, there is a designated spot on the board for that cap. That is the spot where the blue arrow is pointing. The right pad has a G marked next to it. That tells where the negative (-) lead for the cap goes. Then you don't have to have it sticking out the side of your board. If you do plan to keep it the way you have it, watch out for the lead marked with the green arrow. It looks like it is close to bridging the terminal next to it.

The next thing I will reference is your BAT and REG jumpers. Looking at the image below, you have the black spacers for your header connections on the bottom side of the board.

These are designed to be on the top of the board. If you look at the pic of the 2 pin header connector, the two short side leads are what go through the top of the board and the black spacer rests on the top and then it gets soldered from the bottom.

When I do my boards, I just take a piece of wire and bridge the BAT and REG as needed for the board I am building since I am typically building a more permanent circuit. You would typically use jumpers like that if you are planning at some point of changing the configuration and may need to remove that cross connect for one reason or another.

O ther than that, it looks like that setup should work, but I cannot see one row of pins from your pro mini as the battery holder is blocking it in the image.

Keep with it. With help you will get better and gain more knowledge.

-

Make sure to doublecheck the G on the 4.7uF cap if you have rev 7 or 8 because it may be wrong. (this is fixed in rev 9)