CNC PCB milling

-

I have been working on gathering parts to build either another 3D printer or CNC machine like this. I think I am sold on a CNC. A question I have on this is what kind of control board does this use? Is it just a standard RAMPS 1.4 board like ones used in 3D printers? Also, is that just a piece of MDF mounted for the build plate? Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

-

I have been working on gathering parts to build either another 3D printer or CNC machine like this. I think I am sold on a CNC. A question I have on this is what kind of control board does this use? Is it just a standard RAMPS 1.4 board like ones used in 3D printers? Also, is that just a piece of MDF mounted for the build plate? Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

@dbemowsk said in CNC PCB milling:

Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

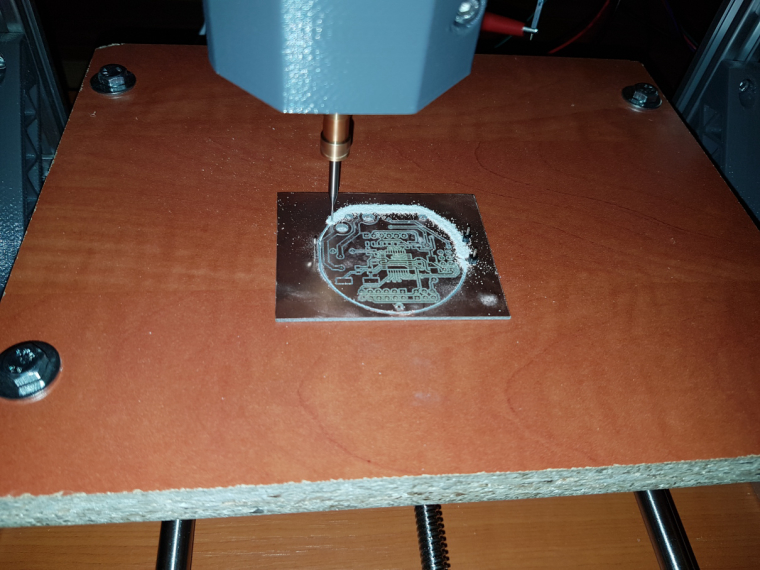

Without the sacrificial MDF material (where, presumably, MDF is flatter than ordinary wood), then when you drill through the PCB material, wouldn't you also be drilling into the v-slot support metal? i.e. presumably you need some kind of sacrificial layer, and the flatter the better.

-

I have been working on gathering parts to build either another 3D printer or CNC machine like this. I think I am sold on a CNC. A question I have on this is what kind of control board does this use? Is it just a standard RAMPS 1.4 board like ones used in 3D printers? Also, is that just a piece of MDF mounted for the build plate? Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

@dbemowsk said in CNC PCB milling:

A question I have on this is what kind of control board does this use?

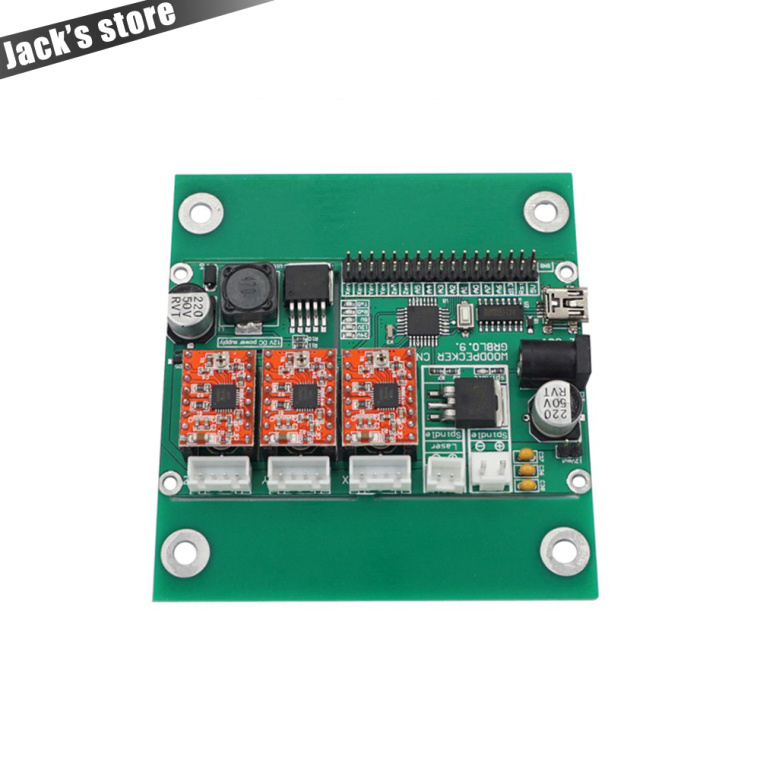

One WoodPecker GRBL 0.9 controller and 3 stepper motor drivers:

https://www.aliexpress.com/store/product/Freeshipping-USB-port-cnc-engraving-machine-control-board-3-axis-control-laser-engraving-machine-board-GRBL/424291_32809235879.html?spm=2114.12010615.0.0.6d908f98CJc2us -

I have been working on gathering parts to build either another 3D printer or CNC machine like this. I think I am sold on a CNC. A question I have on this is what kind of control board does this use? Is it just a standard RAMPS 1.4 board like ones used in 3D printers? Also, is that just a piece of MDF mounted for the build plate? Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

@dbemowsk that is just a simple laminated MDF, but other materials could also work. the only advantage it has is that it is not a very strong material (when the drill or milling bit go into that) and it is flat.

I used T-nuts at the bottom, but I did not receive clamps, so this is why I drilled the MDF and fixed like this. my original screws were longer than necessary, so later I replaced them with a shorter version (see the picture below), so it is not disturbing now.

you can use clamps, but if you would like to drill or mill as well and not just isolation routing on the top layer, then you need a sacrificial layer between the PCB and the cnc bed. this could be also fixed with the clamps, so it is basically up to you how to solve this.

I went for this solution as it is flat, fix and very stable. for the double sided PCBs I can (and have to) use alignment holes with an additional tool in the holes to position the PCB, then a simple double sided adhesive tape makes the job to fix the PCB.

this cnc comes with the controller board which is mentioned by @NeverDie, it is basically a GRBL compatible board. you can also use different controllers such as arduino based ones, Pi CNC Hat, TinyG and others. it uses Pololu drivers like the RAMPS, but for the RAMPS I'm not sure in the communication protocol.

-

@dbemowsk said in CNC PCB milling:

Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

Without the sacrificial MDF material (where, presumably, MDF is flatter than ordinary wood), then when you drill through the PCB material, wouldn't you also be drilling into the v-slot support metal? i.e. presumably you need some kind of sacrificial layer, and the flatter the better.

-

If you are doing only 1 pcb or 2 it is oke to use a cnc milling machine,

i needed a bunch of boards for my home automation project and it took way to long.

Changing bits for engraving/drilling etc and then the costs of the pcb itself.I went to https://www.itead.cc/open-pcb/pcb-prototyping.html , double sided smaller circuits then with your milling machine and coating , looks like factory pcbs.

it is fun to see the machine working though, made some timelapse videos.

click for the video -

@andrew Thanks for all the links. I've ordered everything on your list. Which software will be the first I use? Maybe I can start learning a bit about it while I wait for the deliveries to arrive.

@neverdie cool, you will have a nice Christmas then :)

I guess you have experience with EDA tools, such as KiCAD or Eagle. this should be the first point. you should export your PCB related gerber and excellon files (top and bottom copper layers, edge cuts) from the given EDA software, then flatcam is the next one.

in flatcam you have to import the exported files and do all of the necessary preparation work, to create the necessary G codes for every tasks, including isolation routing, milling and drilling.

this will be your main tool, so discover it as much as possible, including the double sided pcb handling part. most of the manual preparation happens here. maybe this tool is the most important in the whole process.after this, you just have to use a G code sender tool which will control the CNC based on the G code, but this is the easy part. you need a CNC for that, so let's get back to this once you have a working setup. maybe in the meantime you can check e.g. bCNC's and chilipeppr's general howtos.

without a working cnc you can also visualise and simulate the G code, e.g. with CAMotics.

-

If you are doing only 1 pcb or 2 it is oke to use a cnc milling machine,

i needed a bunch of boards for my home automation project and it took way to long.

Changing bits for engraving/drilling etc and then the costs of the pcb itself.I went to https://www.itead.cc/open-pcb/pcb-prototyping.html , double sided smaller circuits then with your milling machine and coating , looks like factory pcbs.

it is fun to see the machine working though, made some timelapse videos.

click for the video@vince I think it's meant for prototyping, not production. At least for that purpose, the reduction in turnaround time should be huge. If, instead, you send everything to the fab at every step, then you need the patience of a saint to iteratively evolve a PCB design.

-

@neverdie cool, you will have a nice Christmas then :)

I guess you have experience with EDA tools, such as KiCAD or Eagle. this should be the first point. you should export your PCB related gerber and excellon files (top and bottom copper layers, edge cuts) from the given EDA software, then flatcam is the next one.

in flatcam you have to import the exported files and do all of the necessary preparation work, to create the necessary G codes for every tasks, including isolation routing, milling and drilling.

this will be your main tool, so discover it as much as possible, including the double sided pcb handling part. most of the manual preparation happens here. maybe this tool is the most important in the whole process.after this, you just have to use a G code sender tool which will control the CNC based on the G code, but this is the easy part. you need a CNC for that, so let's get back to this once you have a working setup. maybe in the meantime you can check e.g. bCNC's and chilipeppr's general howtos.

without a working cnc you can also visualise and simulate the G code, e.g. with CAMotics.

-

@yveaux I bought mine from "rattmotor" seller on ebay (https://www.ebay.com/usr/rattmmotor), but I basically just limited the item location filter to Europe when I searched for cnc2418 on ebay, then I made my choice based on the price and seller ratings.

-

@yveaux Even Amazon.com sells them. Some even have 1-day Prime shipping, so you could have one tomorrow if you wanted.

-

@yveaux Even Amazon.com sells them. Some even have 1-day Prime shipping, so you could have one tomorrow if you wanted.

-

@neverdie Amazon still doesn't ship to the Netherlands and all eBay sellers seem to ship from China...

-

@yveaux search for "cnc 2418" with space separated, then you can find some one from Germany.

-

@andrew ok, I'll give it another try, but suggested rattmotor also seems to ship from China (despite all the American flags in the pictures...)

-

-

@andrew ok, thanks! It was probably the mobile searching then that hid them.

Probably better not having the link though... Must resist to click.... -

@yveaux If you do a fair amount of PCB prototyping, then it pays for itself pretty rapidly (as compared to using a Fab that is).