CNC PCB milling

-

@NeverDie

Ah yes the artwork comes on top of that.I measured the paint thickness with a topcraft caliper. It shows 0,05mm or around 2 mils.

Even if you do manage to get that perfect layer thickness. There might still be the problem of the paint sticking to the artwork more than to the PCB.

This might be different though if the layer is thinner.

I think I can live with how fuzzy it is.

https://youtu.be/T56wuO43lW4

The linked video shows how to make a rod.@Joerideman said in CNC PCB milling:

I measured the paint thickness with a topcraft caliper. It shows 0,05mm or around 20 mils.

By my rekoning, 0.05mm equals about 2 mils, not 20, since 1 mil = 0.001" by definition. Given how you got there, that's pretty close to the target! Did it cure all the way through? Maybe the 0.5mil spec quoted by Altium is just a minimum value.

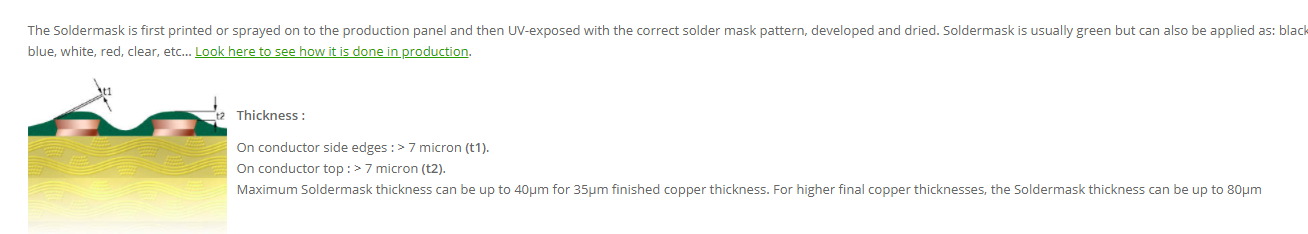

It looks as though PCB fabs may actually spray it on:

https://www.eurocircuits.com/sm-solder-mask/

and so they spray it on thicker if the copper laminate is thicker. On top of that, being an industrial process they're probably tuned to spray on the least amount that will still get the job done (to save material cost), so I'm not sure how much we can extrapolate from their metrics.Without other references, but recognizing their profit motive, I'm inclined to take their 0.5 mil as a minimum thickness. The question then is: what can be the maximum thickness and have it still work out well? i.e. still cure all the way through. If the troughs were deep enough, maybe you wouldn't even need a solder paste template: perhaps you could just squeegee on the solder paste to fill the voids left in the solder mask and squeege off the rest? Since with our process we're screeding it on rather than spraying it on, maybe that's an option we have that the professional fabs can't match. If it were possible, it would be a nice two-for-one bonus: solder mask and solder paste template all-in-one!

Edit: As another datapoint, dynamask comes in a 3mil and 4 mil thickness. In their case, though, it says they use a polyethelene release film instead of the polypropylene you're having good luck with:

Dynamask 5000 series film is a transparent, high gloss forest green material which is supplied in

thicknesses of 75 microns (3mils) and 100 microns (4 mils) the film is supplied in several widths and a roll

length of 100 mtrs.

Like most other dry film products the photopolymer is sandwiched between a 25 micron(1.0mil) polyester

support sheet and a 25 micron (1mil) polyethylene release sheet..

https://www.ebay.com/itm/Dry-film-solder-Dynamsk-5000-0-3m-x-1m-/282595757649I ordered some dynamask yesterday just to give it a try, but it will take 2 or 3 weeks to get here.

Lots of interesting recommendations in their instructions. Definitely worth a read. For instance, it looks as though they recommend the copper should be cleaned with hydrochloric acid, and then they want you to scratch it up with pumice. so that the scratches score to a depth of 2 to 4 microns. I presume the aim is to clear away corrosion and to give the dynamask something to key into and help it stick. Maybe the same would also help with getting the Mechanics uv paint to stick to the copper in preference to whatever release sheet is being used, so that it's less likely to peel off with the release sheet. Assuming the mask is fully cured, then if it's a tug-of-war, the stronger bond wins.

They also recommend vacuum lamination over rolled lamination to avoid air bubbles. Of course, they're stating an ideal. Maybe putting it into a vacuum chamber for a while before roller laminating it would be a compromise. Or maybe I should sell my vacuum chamber and use the money to buy a vacuum laminator from aliexpress. On first look there are quite a few which aren't super expensive, although they're still multiples of what a cheap hot roller laminator would cost. @Joerideman It's hard to tell from your photos: did you find that air bubbles were a problem at all using the Mechanics uv solder mask paint?

Edit: Inspired by @Joerideman I ordered a couple different polypropylene sleeves:

https://smile.amazon.com/gp/product/B083LN26WD/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

which advertise being "non-stick"and some much thicker:

https://smile.amazon.com/gp/product/B07C28PPL6/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1Unfortunately, they aren't due to arrive until Monday.

Meanwhile I'll try to figure out if there are any easily available abrasives or grits that are the equal of the "3F brush pumice" recommended by dynamask for scratching up a PCB's copper.

Edit: looks as though 2000-3000 grit sand paper would be roughly equivalent. Due to the unfortunate way grits are defined (where 20% of the particles can be larger than the nominal grit size), it's probably better to start with 3000 or 2500 grit. Maybe better would be to use something like 3M Trizact, where the abrassive particles are of a more uniform size.

-

In my experiments the best results I got were using a rubber roller with a handle, the film is 0.1-0.2mm thick but that is no problem for the home made led uv exposure box to cure. Here is something similar, unfortunetly mine got lost a while ago when moving out.

I clean the boards after milling with some Scotch Brite metal sponge and the abrasive part of a dish washing Scotch Brite sponge, this also removes the small burs along milled traces. Wash with some IPA in the end and the paint gets good adhesion to the board.The hurdles of getting the uv mask aligned, printed dark enough (damn these new eco printers) makes me want to build a laser for doing this kind of curing. I've just saw a great video of a UV laser using a spinning mirror from a printer, that would make the scanning of the board so much faster.

-

In my experiments the best results I got were using a rubber roller with a handle, the film is 0.1-0.2mm thick but that is no problem for the home made led uv exposure box to cure. Here is something similar, unfortunetly mine got lost a while ago when moving out.

I clean the boards after milling with some Scotch Brite metal sponge and the abrasive part of a dish washing Scotch Brite sponge, this also removes the small burs along milled traces. Wash with some IPA in the end and the paint gets good adhesion to the board.The hurdles of getting the uv mask aligned, printed dark enough (damn these new eco printers) makes me want to build a laser for doing this kind of curing. I've just saw a great video of a UV laser using a spinning mirror from a printer, that would make the scanning of the board so much faster.

@executivul Do you put down something over the paint (such as plastic, for instance) before rolling over it, or do you roll directly over the wet paint with the roller itself?

-

@executivul Do you put down something over the paint (such as plastic, for instance) before rolling over it, or do you roll directly over the wet paint with the roller itself?

@NeverDie I put a piece of clear "document wrap foil"

-

It makes sense. AFAIK, the uv solder mask paint isn't benefited from the laminator heat, just the uniform squeezing from the rollers.

-

The stack goes like this:

-glass

-normal printer paper made transparent to UV light (https://www.amazon.co.uk/Kontakt-chemie-Transparent-21-Spray-200ml/dp/B00ID6KY4K)

-toner (the image is mirrored and placed toner face down)

-transparent film from "document wraps"

-UV solder mask paint

-pcb

-glassThe top and bottom glass pieces are held tight by some binder clips.

-

That's an interesting spray. I'll have to do some hunting to see if I can find a US distributor for that.

-

That's an interesting spray. I'll have to do some hunting to see if I can find a US distributor for that.

@NeverDie or just try some canola oil spilled on normal laser printer paper ;)

-

@NeverDie or just try some canola oil spilled on normal laser printer paper ;)

@executivul

Is it better to use that spray with regular printer paper than just printing to a transparency? -

@executivul

Is it better to use that spray with regular printer paper than just printing to a transparency?@NeverDie My printer has a problem with transparencies (jams) and also the high cost for transparencies made me go the paper route, if the toner is facing down the distance is the same as when using transparency printed artwork, also the paper "softens" the uv led light and makes it more uniform I guess.

-

@NeverDie My printer has a problem with transparencies (jams) and also the high cost for transparencies made me go the paper route, if the toner is facing down the distance is the same as when using transparency printed artwork, also the paper "softens" the uv led light and makes it more uniform I guess.

I use the same kind of plastic folder. They are dirt cheap. And yesterday I used the same one twice.

@NeverDie it was late in the night already. I meant 2 mils :-).

Yes the laminator is only rolling, there is no heat involved.

-

Note sure if it's overkill or actually a good idea, but it looks as though so-called "cold" laminators exist, where you can adjust the pressure:

https://www.amazon.com/dp/B07Z4VSTZC/ref=sspa_dk_detail_1?psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEzUTk5WjRINjJVWTRDJmVuY3J5cHRlZElkPUEwNDE5MTk5MUpSUE1QTzQ3UEkzRyZlbmNyeXB0ZWRBZElkPUEwMzk5OTIxMjY5NUkyQkI2SFVLQyZ3aWRnZXROYW1lPXNwX2RldGFpbDImYWN0aW9uPWNsaWNrUmVkaXJlY3QmZG9Ob3RMb2dDbGljaz10cnVl

You could dial in a uniform pressure. -

Note sure if it's overkill or actually a good idea, but it looks as though so-called "cold" laminators exist, where you can adjust the pressure:

https://www.amazon.com/dp/B07Z4VSTZC/ref=sspa_dk_detail_1?psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEzUTk5WjRINjJVWTRDJmVuY3J5cHRlZElkPUEwNDE5MTk5MUpSUE1QTzQ3UEkzRyZlbmNyeXB0ZWRBZElkPUEwMzk5OTIxMjY5NUkyQkI2SFVLQyZ3aWRnZXROYW1lPXNwX2RldGFpbDImYWN0aW9uPWNsaWNrUmVkaXJlY3QmZG9Ob3RMb2dDbGljaz10cnVl

You could dial in a uniform pressure.@NeverDie for $99.99 I would roll the s#it out of it with my hand roll, heck I would even step on it with my pressure controlled 200 lbs weight in pink slippers.

-

Note sure if it's overkill or actually a good idea, but it looks as though so-called "cold" laminators exist, where you can adjust the pressure:

https://www.amazon.com/dp/B07Z4VSTZC/ref=sspa_dk_detail_1?psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEzUTk5WjRINjJVWTRDJmVuY3J5cHRlZElkPUEwNDE5MTk5MUpSUE1QTzQ3UEkzRyZlbmNyeXB0ZWRBZElkPUEwMzk5OTIxMjY5NUkyQkI2SFVLQyZ3aWRnZXROYW1lPXNwX2RldGFpbDImYWN0aW9uPWNsaWNrUmVkaXJlY3QmZG9Ob3RMb2dDbGljaz10cnVl

You could dial in a uniform pressure.@NeverDie you might as well buy those specialized springloaded engraving bits from Wegstr. If you are willing to invest this money.

These hot/cold laminators cost 15 euro here.

-

I'll try it both ways. I've already own roughly the same kind of roller as executivul, so I'll try that first. My wife has a laminator that takes 20 minutes to warm up, so I could pass it through that before it gets hot.

I was leaning toward the screed approach, but not sure if would still work well if there's going to be artwork placed on top. Meh, maybe just flatten it in a press. That would do it for sure (well, if the plates are parallel that is).

-

I'll try it both ways. I've already own roughly the same kind of roller as executivul, so I'll try that first. My wife has a laminator that takes 20 minutes to warm up, so I could pass it through that before it gets hot.

I was leaning toward the screed approach, but not sure if would still work well if there's going to be artwork placed on top. Meh, maybe just flatten it in a press. That would do it for sure (well, if the plates are parallel that is).

@NeverDie oh btw, I have not seen air bubbles.

-

I just now stumbled across this, which is actually kinda interesting:

https://www.youtube.com/watch?v=pf7S5KXng6o&list=PLcVGA0RegYfzAcEsDU7aBQKMtvXU8rd19&index=43Basically it shows that with very little time or effort you can create a print screen. If you were to create a print screen for solder mask, you could squeegee the solder mask through the print screen onto the PCB and the solder mask paint would be printed just exactly where you wanted it to be and nowhere else. Then all you would have to do is UV cure it, and you'd be done.

To illustrate, here's a video of what looks like wretchedly impoverished people making PCB's, but it illustrates print screening of solder mask:

https://www.youtube.com/watch?v=zw0H5-OlRs0(Prior to this scene, the same poor souls used the same screen print method to lay down the copper mask. They then etched the copper, which led directly to this scene). The quality seems consistent with a lot of the cheap boards one might come across on aliexpress.

It also opens the door to the possibility of having real "silk screen" printing of artwork onto the final PCB as well. which so far I haven't seen any other discussion regarding how to do.

In terms of cost, it's more expensive than the techniques we've so far been discussing, but the cosumables are less costly than, say, sending off to JLPCB with rapid DHL return shipping, and you obviously get the results far faster than JLPCB would ever be able to deliver them to your doorstep. Plus, for small PCB's it seems likely that you could cut down the fabric to only the amount needed, and thus the material costs could be stretched out over possibly many different design iterations.

-

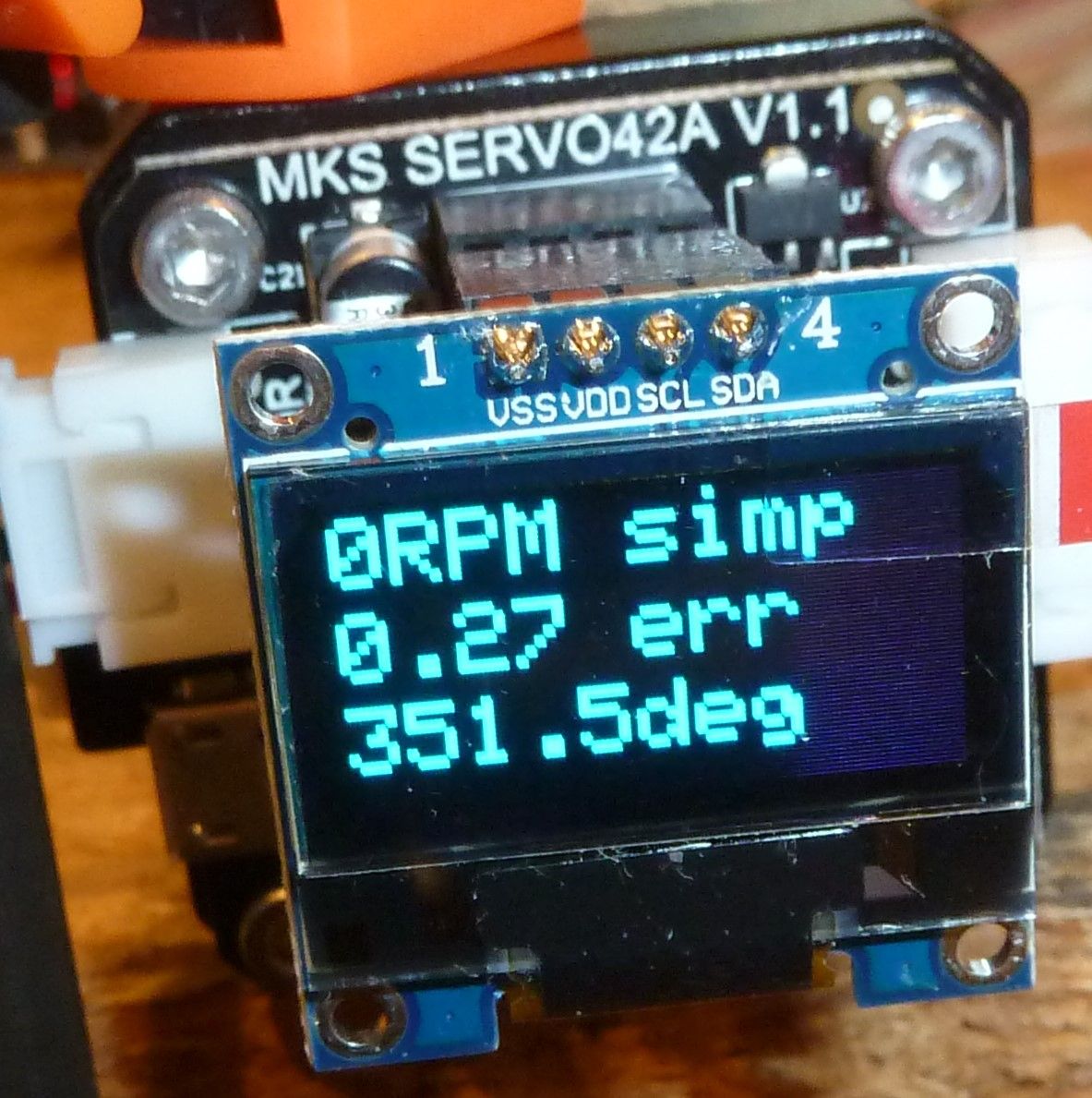

"Houston, we have closed the loop."

It's up and running. In 256 step mode, it is barely even audible.

However, given that, for a closed loop system the picture seems to represent a anomaly. Can you guess what it is? After jogging the motor around a bit, I stopped and let the stepper idle at what it thinks should be 351.5deg, based on the steps that I sent to it, but which the encoder measures as being 0.27 degree different than that. Well, we know that a full step would be 1.8 degrees, so if it is truly microstepping at 256 ,that means that each microstep should be able to advance the motor by 1.8/256=0.007 degree. Right? So, here's the rub: if the motor is idling, why hasn't it corrected, or at least significantly reduced, the 0.27 degree error? 0.007 degree is much less than 0.27 degree, so it should have adjusted the stepper's true position to be much closer to what its theoretical position should be. Yet, it isn't. Why not?

Well, maybe it can't actually do 256 microsteps. Maybe it can do only 128. That would mean that it should be able to make each microstep be 0.14 degree. Right? But, if that were true, then being closed loop it again should have moved the stepper to bring it closer to what it should be. But it didn't.

So, here's my theory: it's can't actually do 128 microsteps either. Maybe the most it can do is 64 microsteps. In that case, each microstep would be 0.28 degree. Right? But the error is 0.27 degree, which is less than 0.28 degree. Maybe that's where their algorithm gives up and stops. However, if it were me writing the code, I would have made it so that it moves one microstep closer to where it should be, even if that means overshooting by 0.01 degree. That's because being off by 0.01 degree is better than being off by 0.27 degree. But it didn't do that.

However, if we assume that whoever wrote the code actually did the best job that could be done at closing the loop in this scenario, then the obvious conclusion is that this stepper driver can actually do at most 32 microstepping and nothing more. Why? Because in that case each microstep would be 0.56 degree, and so trying to close the loop by moving the stepper one microstep toward the position it ideally should have would mean overshooting by an amount greater than 0.27 degree, and so it's actually better to do nothing in this particular situation.

But if that's the case, why advertise it to have more microstepping than what it's actually capable of?

Anyhow, that's as far as I've gotten with it so far. I guess the next step will be to open up a terminal window to view its output over the usb connection. Perhaps that will shed more light on the mystery.

Edit: Whooops. 1.8 degree divided by 32 is 0.056, not 0.56, so my calculations above are off. Well, I'm heading off to bed right now, so I'll look into that discrepancy tomorrow. Meanwhile, if anyone has thoughts on the 0.27 degree anomaly, feel free to post.

That's it for today. Signing off. :sleeping: :sleeping_accommodation:

-

I just now stumbled across this, which is actually kinda interesting:

https://www.youtube.com/watch?v=pf7S5KXng6o&list=PLcVGA0RegYfzAcEsDU7aBQKMtvXU8rd19&index=43Basically it shows that with very little time or effort you can create a print screen. If you were to create a print screen for solder mask, you could squeegee the solder mask through the print screen onto the PCB and the solder mask paint would be printed just exactly where you wanted it to be and nowhere else. Then all you would have to do is UV cure it, and you'd be done.

To illustrate, here's a video of what looks like wretchedly impoverished people making PCB's, but it illustrates print screening of solder mask:

https://www.youtube.com/watch?v=zw0H5-OlRs0(Prior to this scene, the same poor souls used the same screen print method to lay down the copper mask. They then etched the copper, which led directly to this scene). The quality seems consistent with a lot of the cheap boards one might come across on aliexpress.

It also opens the door to the possibility of having real "silk screen" printing of artwork onto the final PCB as well. which so far I haven't seen any other discussion regarding how to do.

In terms of cost, it's more expensive than the techniques we've so far been discussing, but the cosumables are less costly than, say, sending off to JLPCB with rapid DHL return shipping, and you obviously get the results far faster than JLPCB would ever be able to deliver them to your doorstep. Plus, for small PCB's it seems likely that you could cut down the fabric to only the amount needed, and thus the material costs could be stretched out over possibly many different design iterations.

@NeverDie The UV laminator just gave me the craziest idea: Why don't we take a normal laminator, remove the heating coils and add a strip of UV leds to it??? The expected result: perfect pressing of the artwork to the board and curing at the same time, speed it travels through sets the hardening level. I can get rid of all those glass panels and stuff.

I'm going out hunting for a cheap laminator :) -

@NeverDie The UV laminator just gave me the craziest idea: Why don't we take a normal laminator, remove the heating coils and add a strip of UV leds to it??? The expected result: perfect pressing of the artwork to the board and curing at the same time, speed it travels through sets the hardening level. I can get rid of all those glass panels and stuff.

I'm going out hunting for a cheap laminator :)@executivul good luck.

I noticed that I really have to hold the board and the plastic together, otherwise the rolls will pull the foil off the board.

So that might make aligning the artwork a bit difficult. Perhaps some form of holder for the PCB could prevent the shifting.