DIY CNC mill from mainly salvaged and 3D printed parts

-

@dbemowsk said in DIY CNC mill from mainly salvaged and 3D printed parts:

I figure that way I have a matched set and I am not fighting things like too slow speed on one axis that is fighting the others when milling a job.

From what I've read, your GRBL controller would compensate, as it knows the speed of each motor (well, after you tell it, that is).

@neverdie said in DIY CNC mill from mainly salvaged and 3D printed parts:

From what I've read, your GRBL controller would compensate, as it knows the speed of each motor (well, after you tell it, that is).

I figured that, but I was having trouble with a couple of the steppers that I was trying to use. Couldn't seem to get them to run reliably from the GRBL controller. The other part would have been figuring out a drive system for them as they all had geared heads. I would have had to figure out a gearing and mounting system. The motors I got were only $33 US, so basically $11/motor, so not a bad price, and I can direct couple them to the threaded rods making things easier.

-

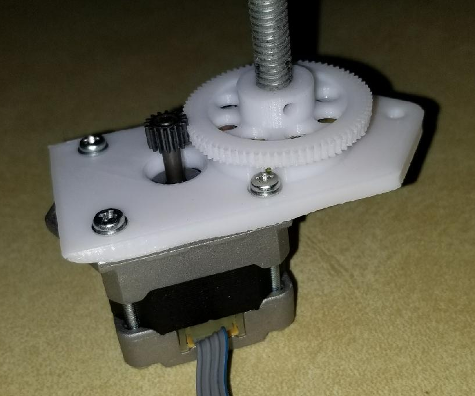

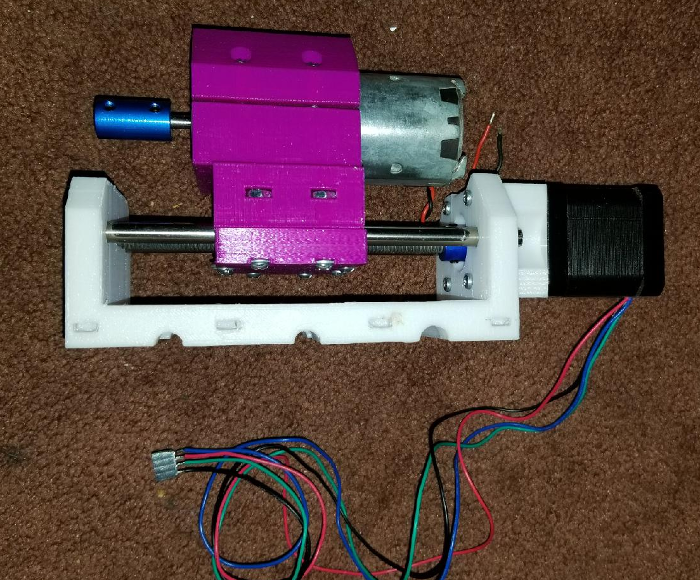

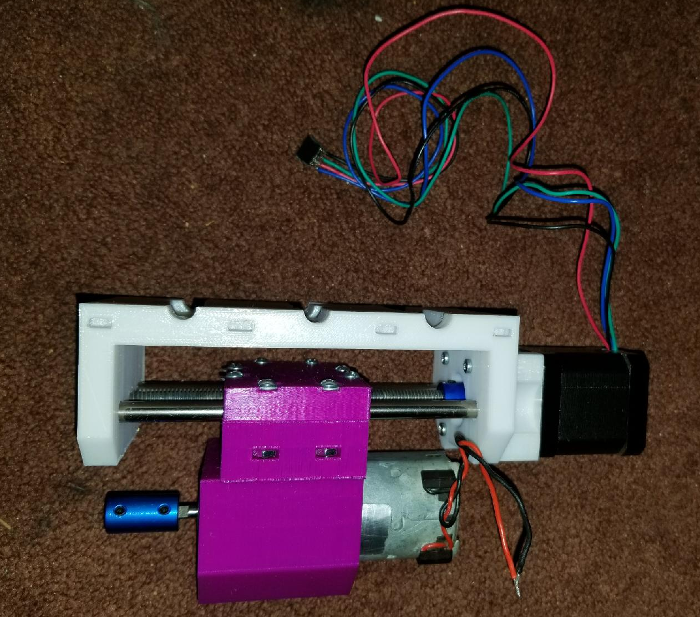

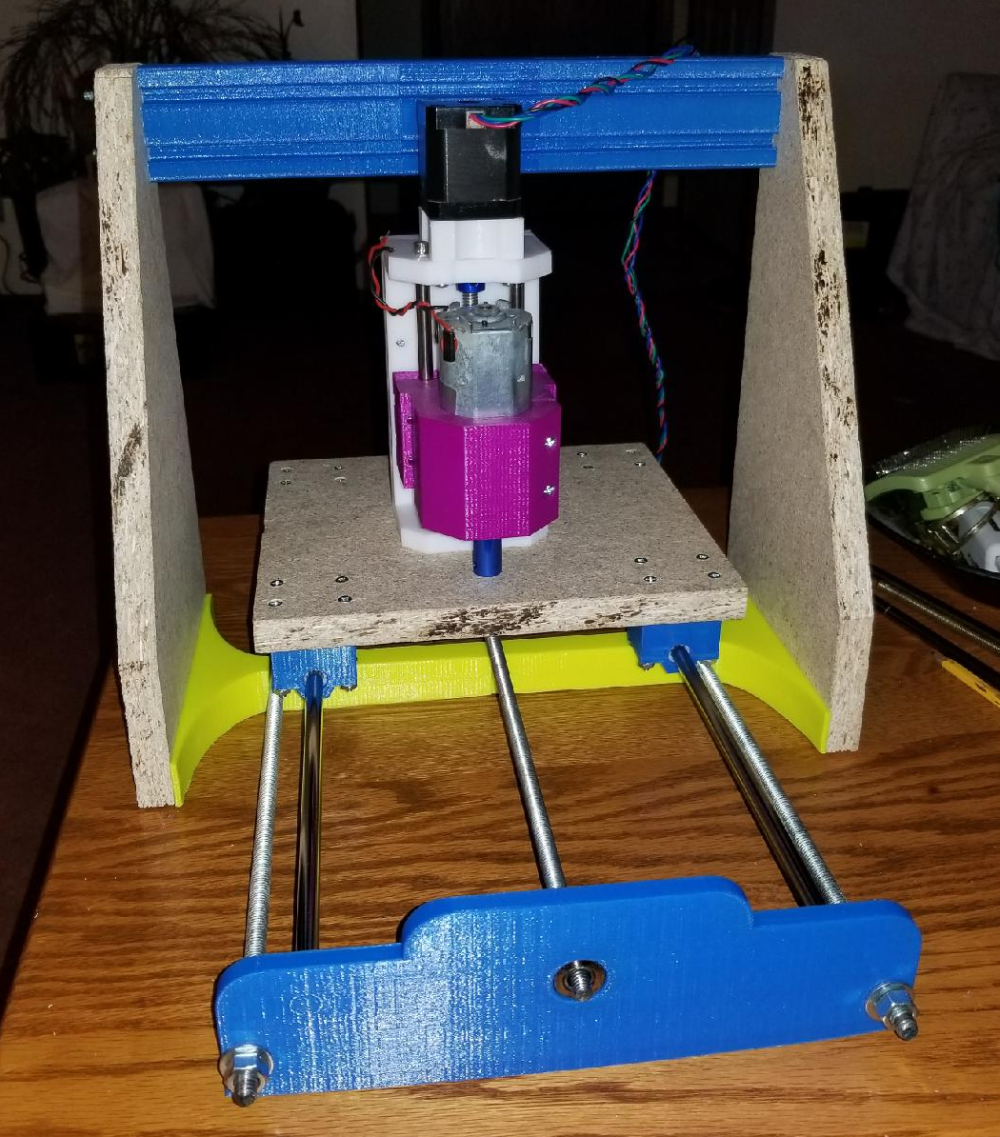

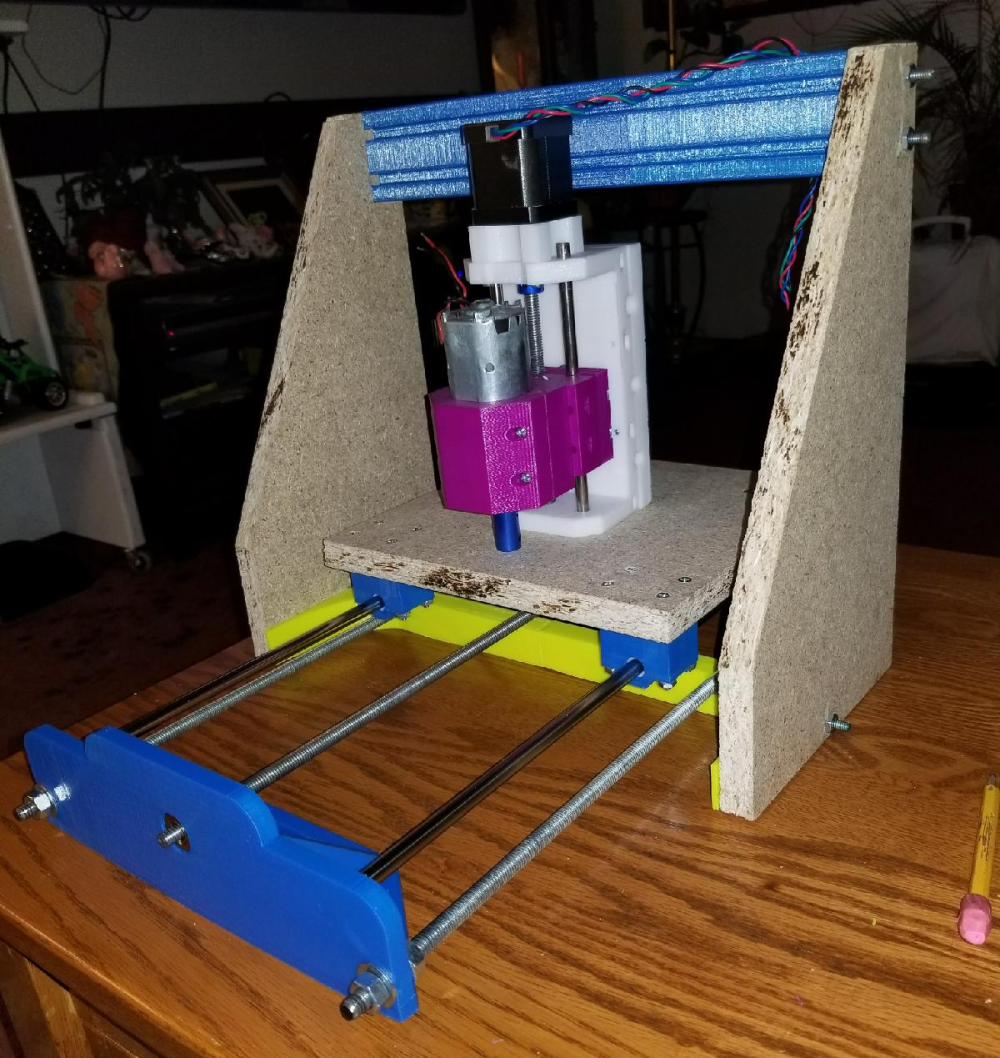

So I would call today's part of the build pretty significant. I have the Z axis mostly assembled and did a drive test. Below are some pics of the assembly.

Here is the assembly taking it's first steps. It still needs some adjustment, but from what I am seeing, things should work. The next part of the build is going to be getting the uprights made that will hold the X axis rods and drive assembly. Once that is done, I should be able to do some more solid testing and calibration.

https://www.youtube.com/watch?v=XR7zPx8NVN8 -

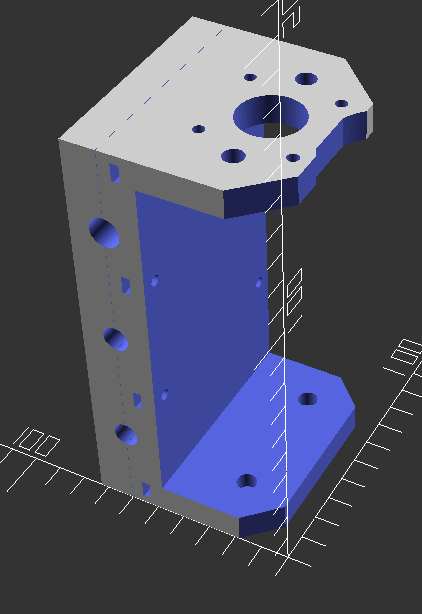

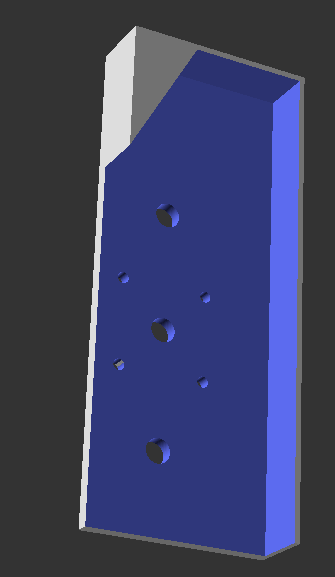

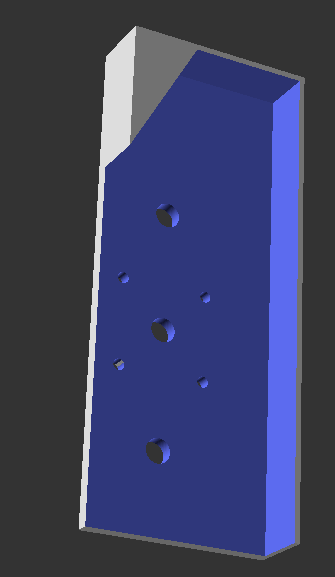

As some of you may have noticed, based on the earlier cad drawing, I had to make some adjustments to the large white bracket. The adjustments were there to let the spindle motor pass by the bracket. On the first attempt, the back of the spindle motor was hitting the bracket restricting travel. Also, the lower lip of the spindle motor assembly was hitting the lower part of the bracket. A few tweaks later and this was born.

-

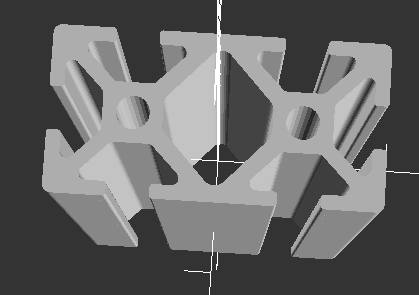

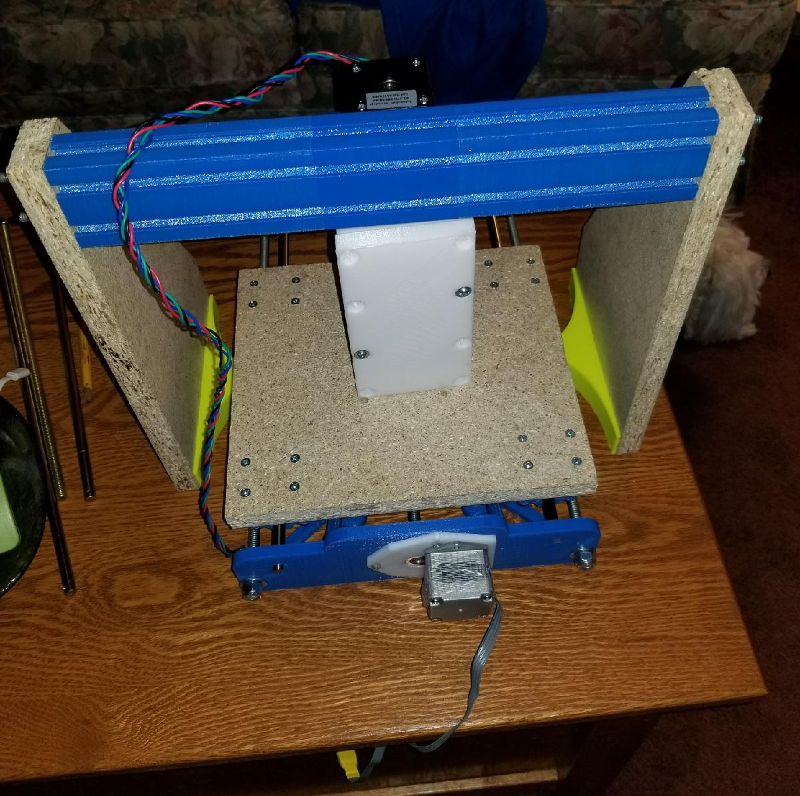

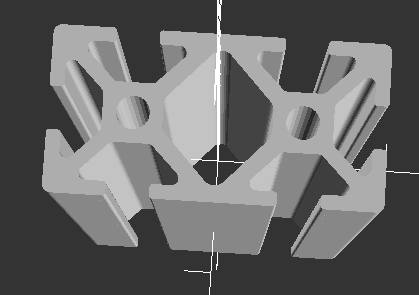

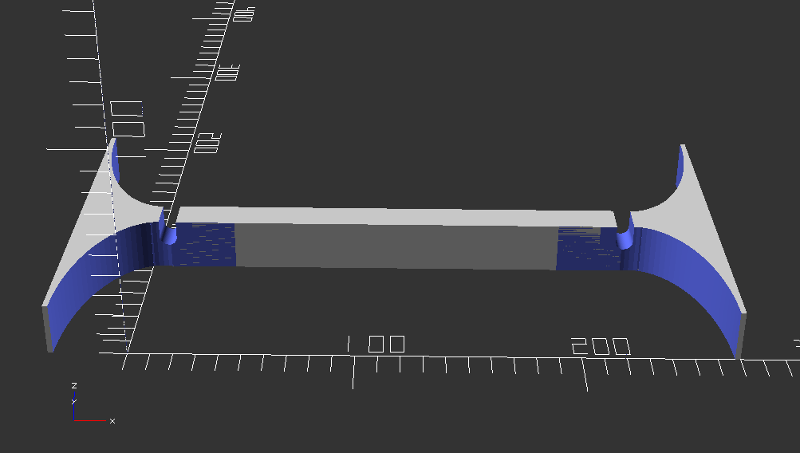

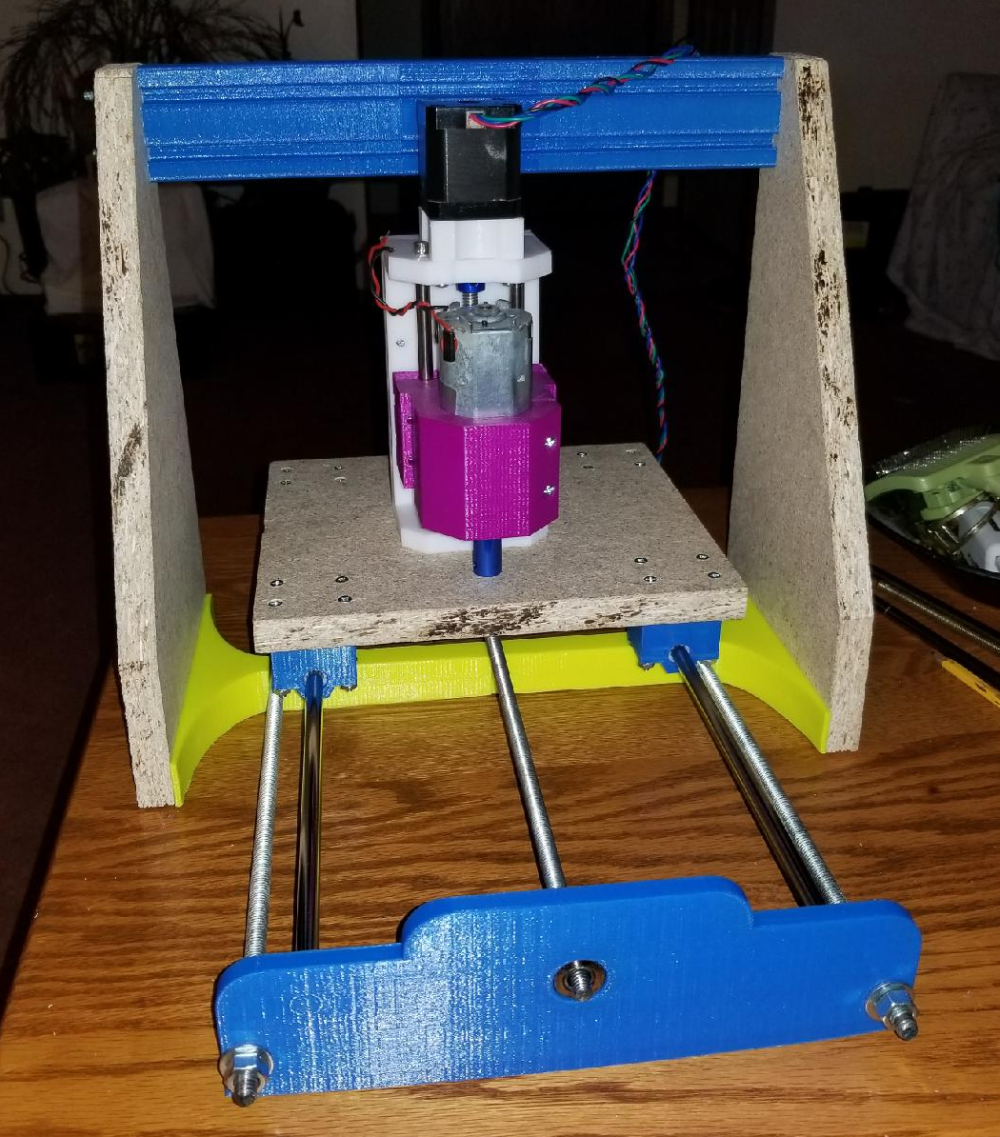

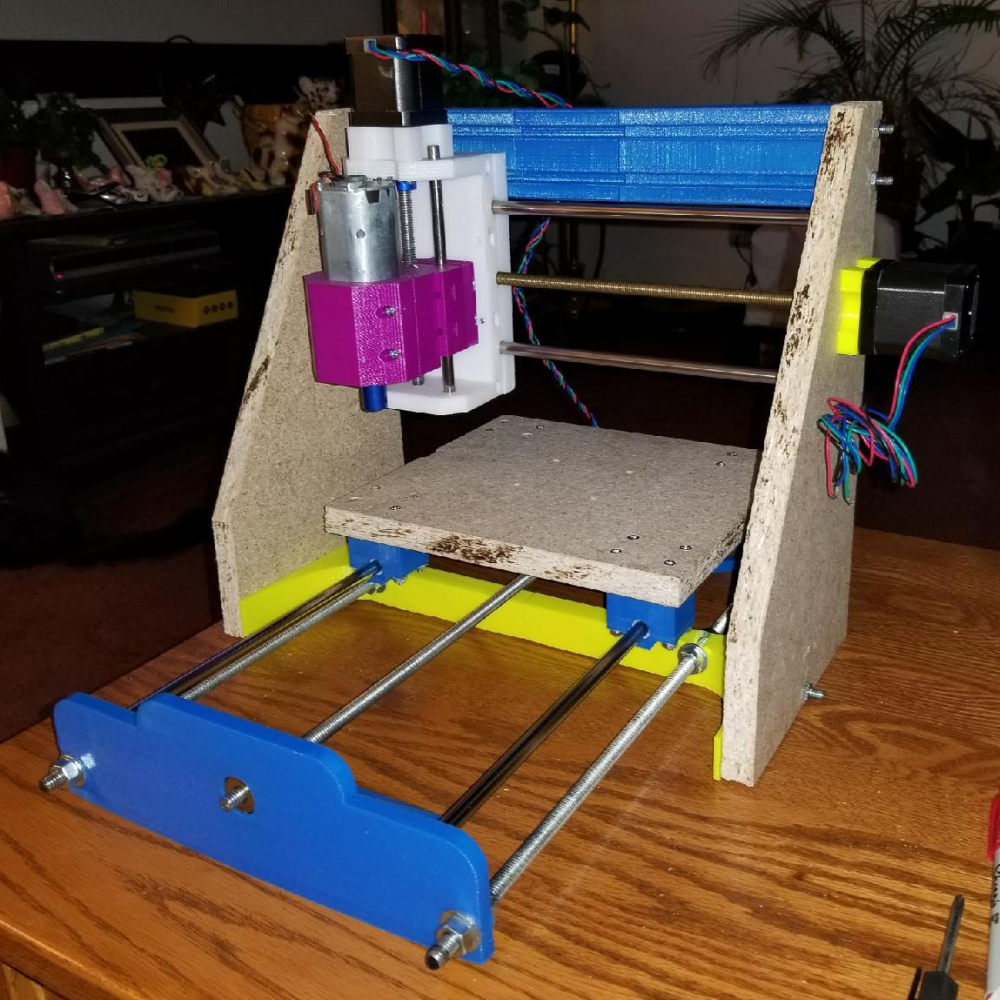

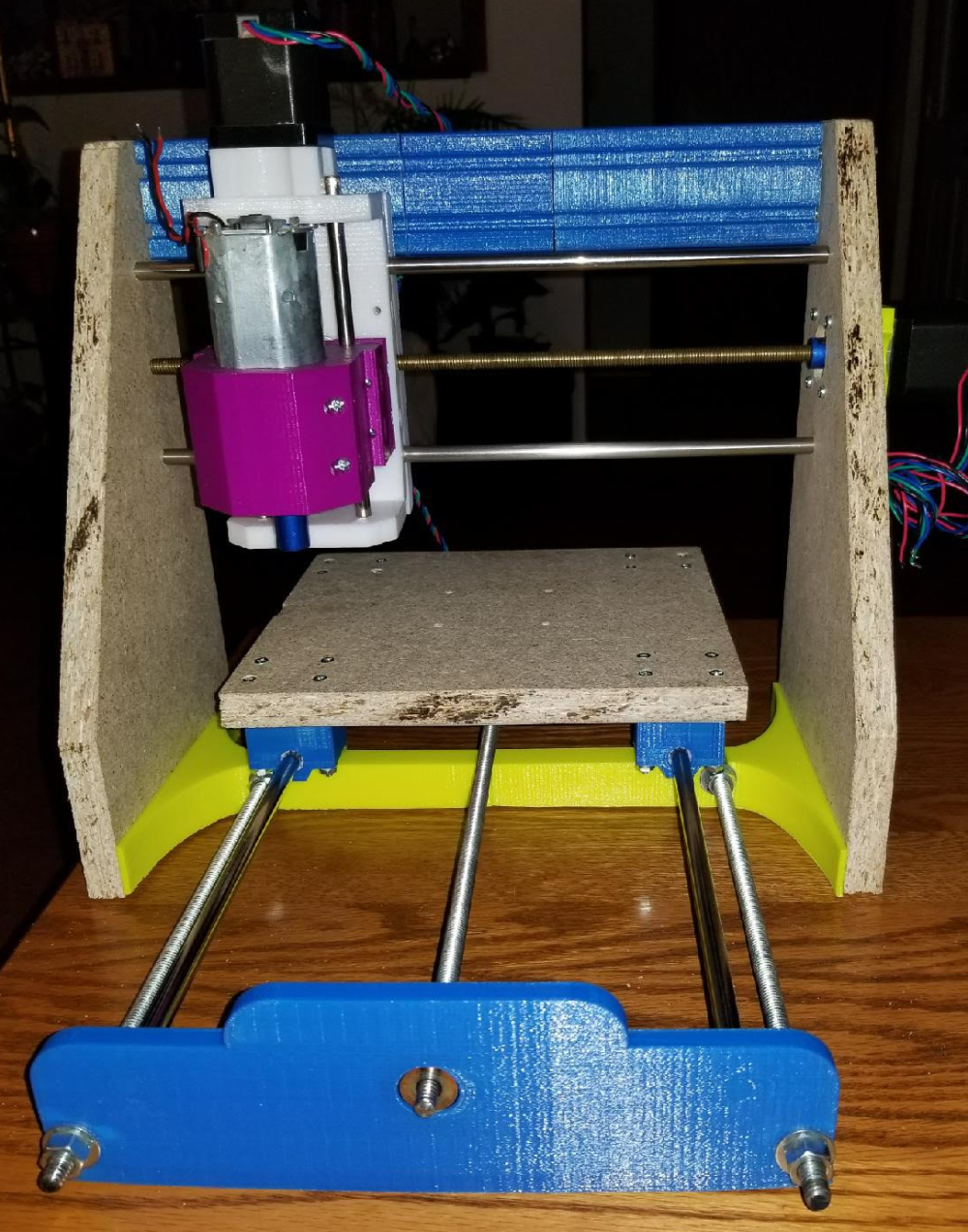

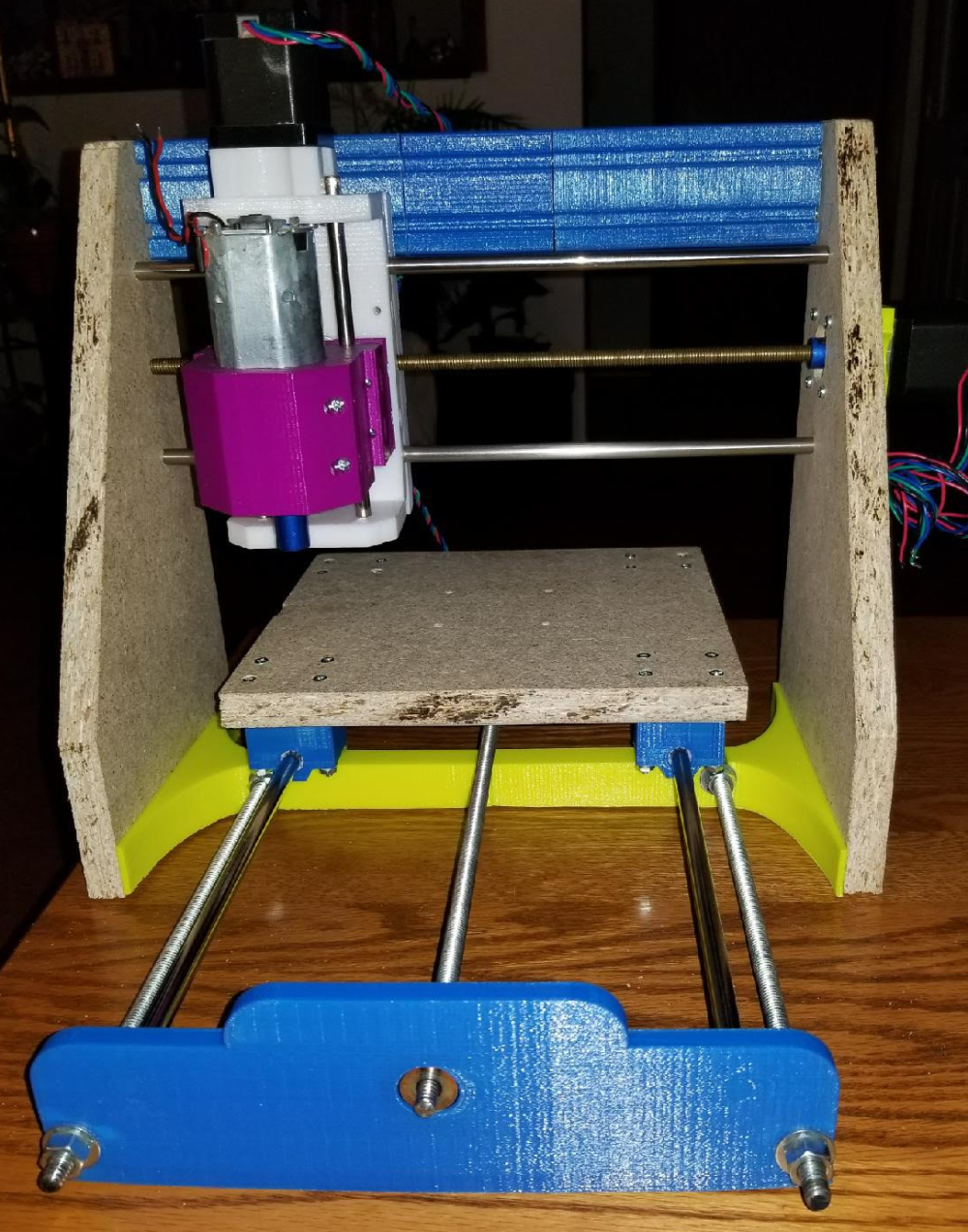

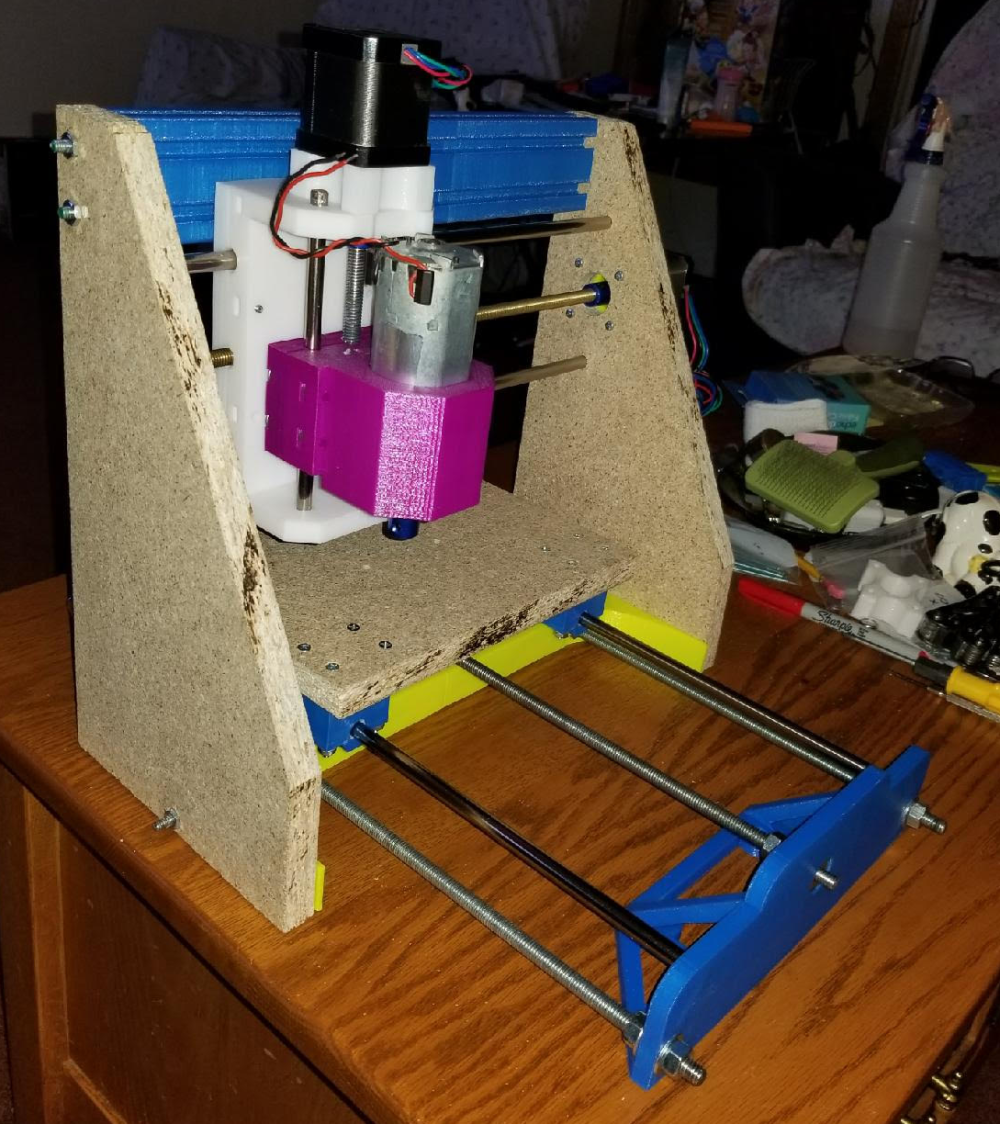

So, the project is nearing completion. I have an amalgam of colors used in the setup as I was trying to use up some rolls of plastic that I had on hand. I now have a gantry assembly that is held together at the top with some 3D printed T-Slot channel that was part of a failed print. There are 3 pieces strung together with some 10-24 threaded rods run through the center holes.

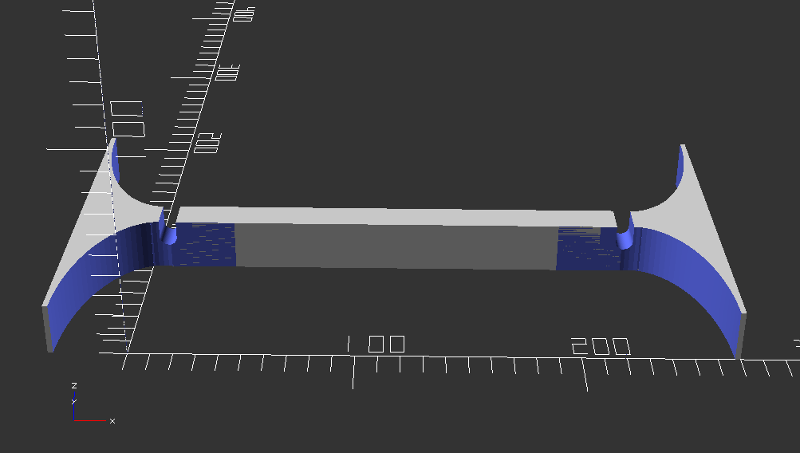

The bottom is strung together with a custom 3D printed I support that also has a piece of 10-24 threaded rod through it. That too was done in two pieces because I could not fit the whole thing on my print bed.

I am in the process of printing the drill guides to drill the holes in the MDF sides that will hold the smooth rods and the X axis stepper.

Here are the latest pics of the assembly so far.

Once I have the gantry X axis rods in place with the Z axis carriage, I will then be able to do a full test of the electronics. I opted for now to keep the salvaged Y axis motor assembly since I had that working. Once I have everything working, I will post a video.

-

So, the project is nearing completion. I have an amalgam of colors used in the setup as I was trying to use up some rolls of plastic that I had on hand. I now have a gantry assembly that is held together at the top with some 3D printed T-Slot channel that was part of a failed print. There are 3 pieces strung together with some 10-24 threaded rods run through the center holes.

The bottom is strung together with a custom 3D printed I support that also has a piece of 10-24 threaded rod through it. That too was done in two pieces because I could not fit the whole thing on my print bed.

I am in the process of printing the drill guides to drill the holes in the MDF sides that will hold the smooth rods and the X axis stepper.

Here are the latest pics of the assembly so far.

Once I have the gantry X axis rods in place with the Z axis carriage, I will then be able to do a full test of the electronics. I opted for now to keep the salvaged Y axis motor assembly since I had that working. Once I have everything working, I will post a video.

@dbemowsk MDF? That is chipboard or particle board, no?

I very much doubt you will get sufficient rigidity even were you to glue/screw ribs on those side plates, and as a material it behaves badly with vibrating bolts etc... -

If it doesn't work out, maybe you will want to build an MPCNC instead?

-

@dbemowsk MDF? That is chipboard or particle board, no?

I very much doubt you will get sufficient rigidity even were you to glue/screw ribs on those side plates, and as a material it behaves badly with vibrating bolts etc...@zboblamont I'll see how it goes. It is a big experiment at this point. If it doesn't work out I may be able to have a frame milled pretty cheap. I work for our local school district and I know the shop teachers at our high school that run the large CNC mill that they have. I may be able to have them mill me some parts. I do have all the needed steppers and things, I may just need a frame, worst case.

-

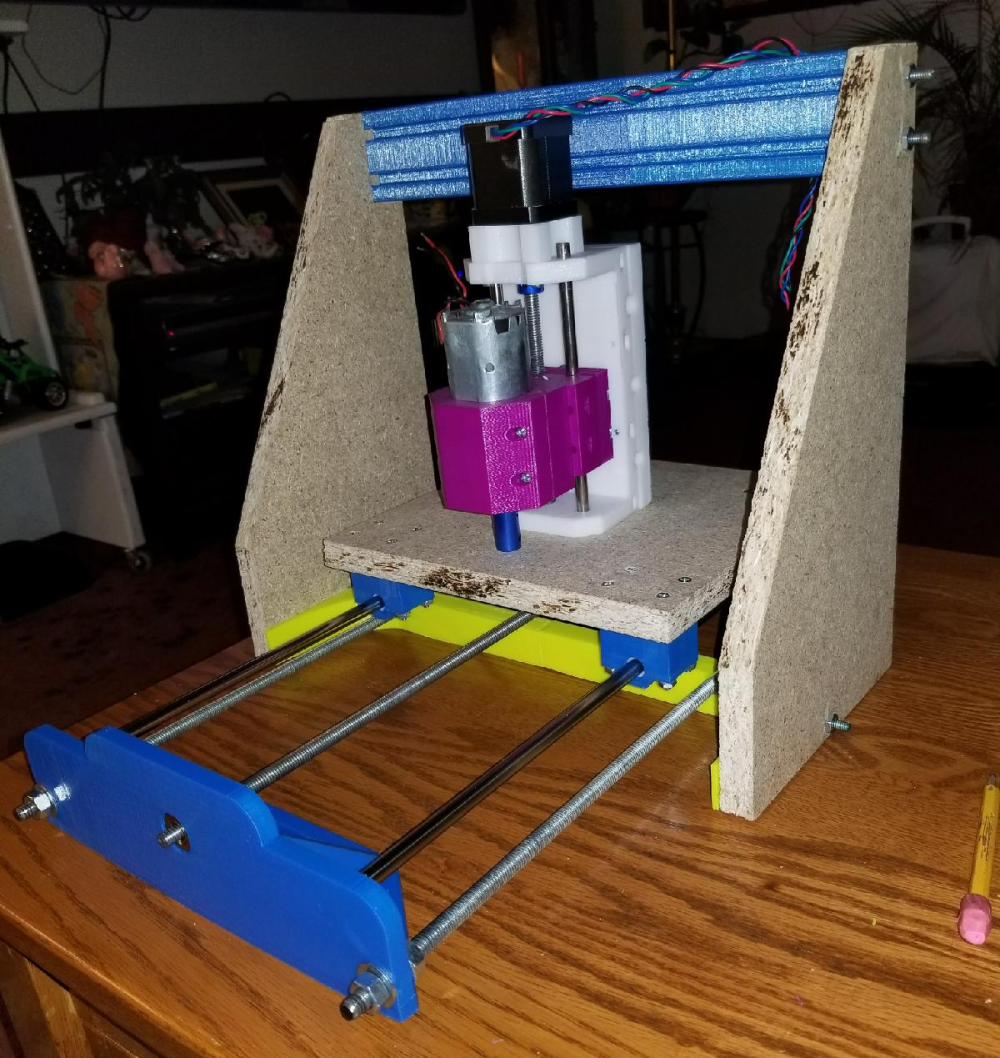

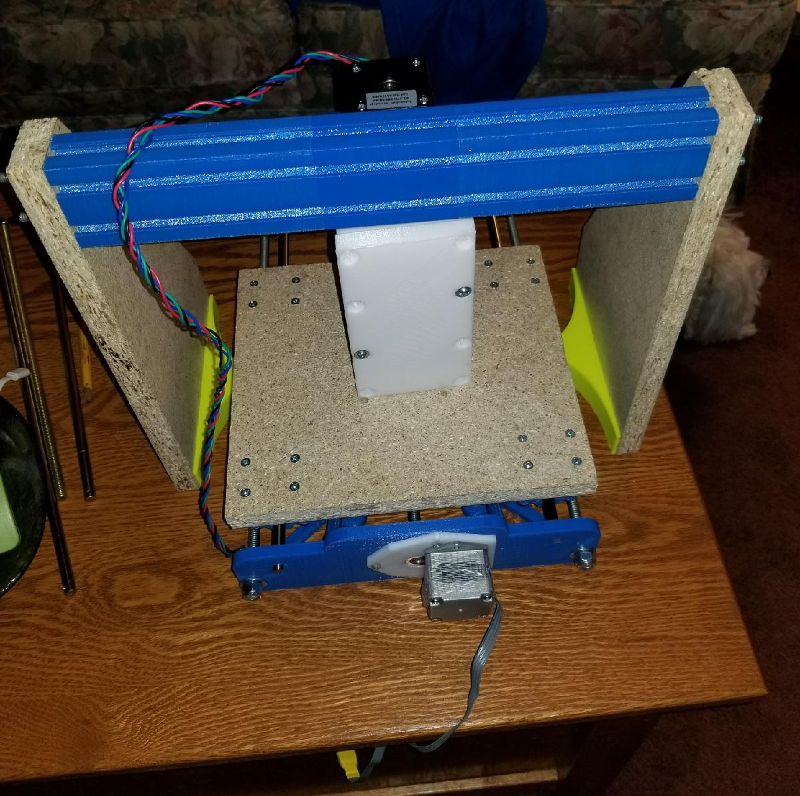

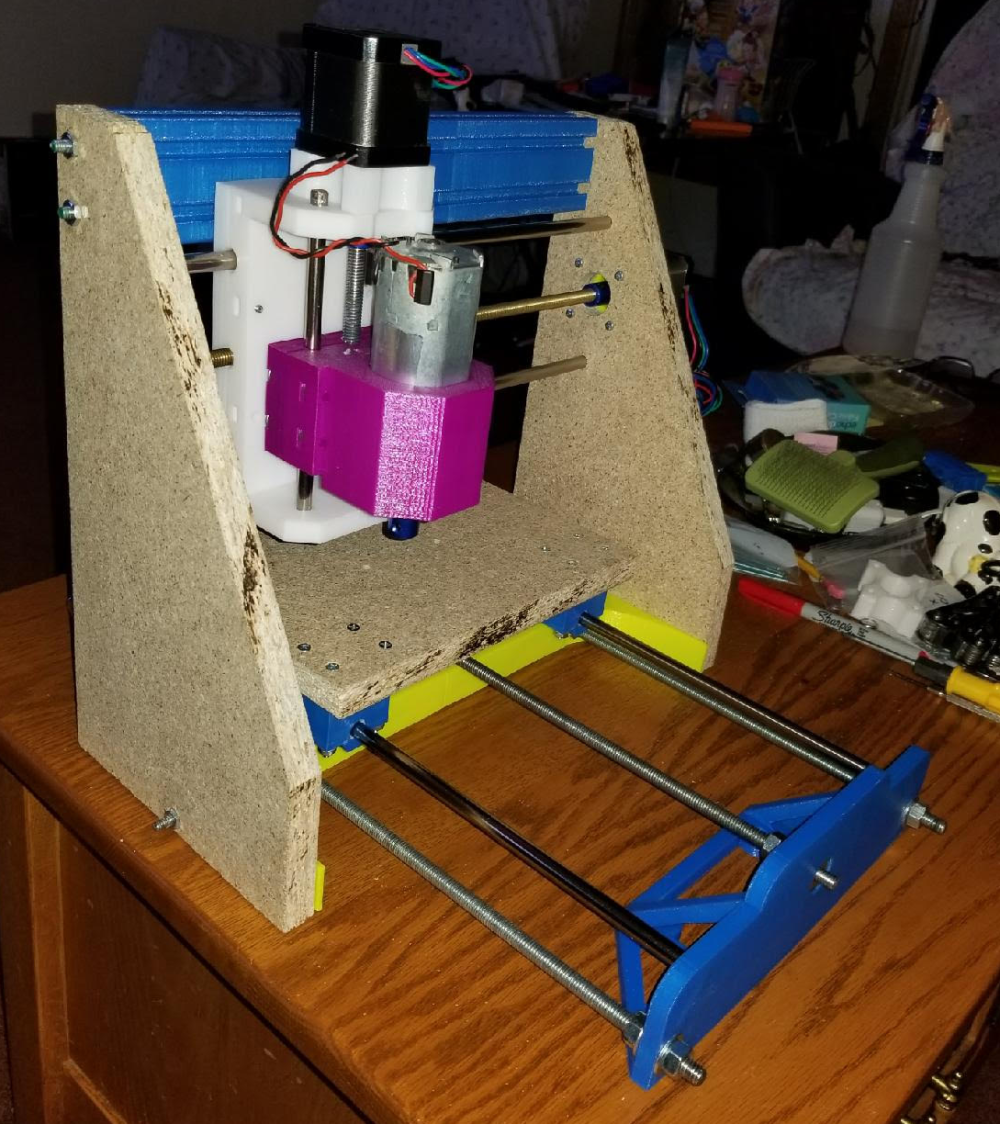

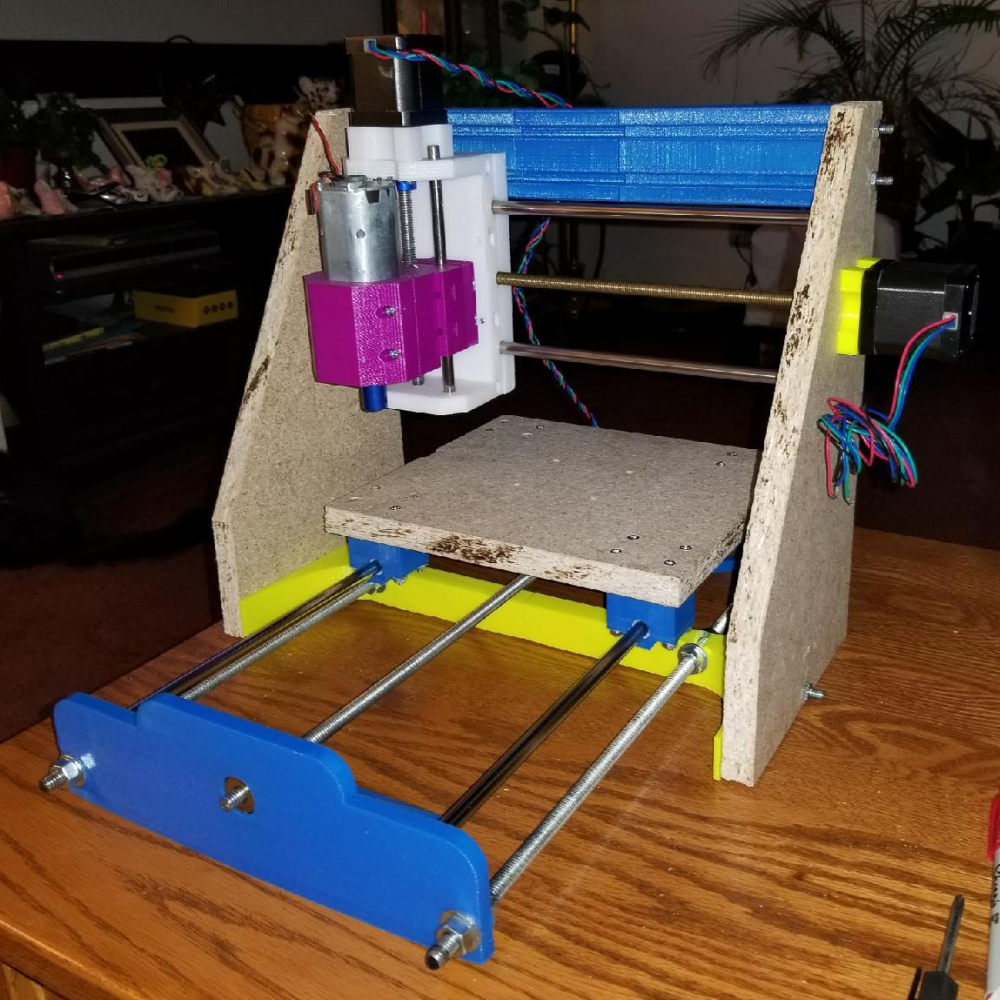

So the CNC is near ready for testing. I need to solder a connector on to the X axis stepper and I should be able to run some tests. I think the next step is going to be figuring out how to calibrate the GRBL controller.

Here are some pics of the build so far.

-

So the CNC is near ready for testing. I need to solder a connector on to the X axis stepper and I should be able to run some tests. I think the next step is going to be figuring out how to calibrate the GRBL controller.

Here are some pics of the build so far.

-

@dbemowsk A+ for sticking with it all the way to completion.

The main calibration number will probably be the revolutions per inch for each of the axises (axi?). From there you can start air carving.

@neverdie Thanks. I appreciate the tip and the compliment. Are you sure it is revolutions per inch and not steps per inch? The larger black motors I have for the X and Z axes are 400 steps per rev, but I think the Y axis motor is only 200 steps per rev. The Y axis is running on the large geared assembly though, so that should help more with both torque and revolution step count.

There is the talk about the rigidity of it. I am thinking if I run it a bit slower, the rigidity will matter a little bit less, but I'll see once I get it going. The MDF I used is 3/4", and it feels pretty rigid, but only tests will tell. I have my spindle chuck, a set of 7 coletts and some bits on order from amazon. Those should be here tomorrow I am thinking, since everything was prime.

-

@dbemowsk A+ for sticking with it all the way to completion.

The main calibration number will probably be the revolutions per inch for each of the axises (axi?). From there you can start air carving.

@neverdie said in DIY CNC mill from mainly salvaged and 3D printed parts:

@dbemowsk A+ for sticking with it all the way to completion.

The main calibration number will probably be the revolutions per inch for each of the axises (axi?). From there you can start air carving.

I'm just going from memory. I think you're right, though: steps per inch. Or something like that. ;)

-

So here is it's maiden voyage... It's first simultaneous run of all axes, AKA the initial X, Y and Z axis test.

https://www.youtube.com/watch?v=8diihXJwMj0 -

I believe these are the settings that I need to change: https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.9

I will be trying to configure things tonight. From the tracking information, I should have my chuck, coletts and the drills tonight, but the V bits won't be here til Monday. I am wondering if there are any test files that I can try to test my calibration? I will try to set up software on my WIndows laptop for now, but may migrate to a laptop running linux for the final setup. -

I haven't had a chance to test the accuracy of the machine yet, but I did find a web page that has a VERY useful calculator for figuring out your steps per mm for a lead screw type system.

https://www.prusaprinters.org/calculator

Scroll down to the section labeled "Steps per millimeter - leadscrew driven systems". You just enter the parameters of your motor, microstepping, gear ratio (if any) and lead screw type/size. From that it calculates the steps per mm that is needed to configure your X, Y and Z axes for your GRBL controller.Figured this may be useful to others.

-

Or use a dial gauge and get an exact measurement.

-

That should work. Here's what I meant though:

-

That should work. Here's what I meant though:

-

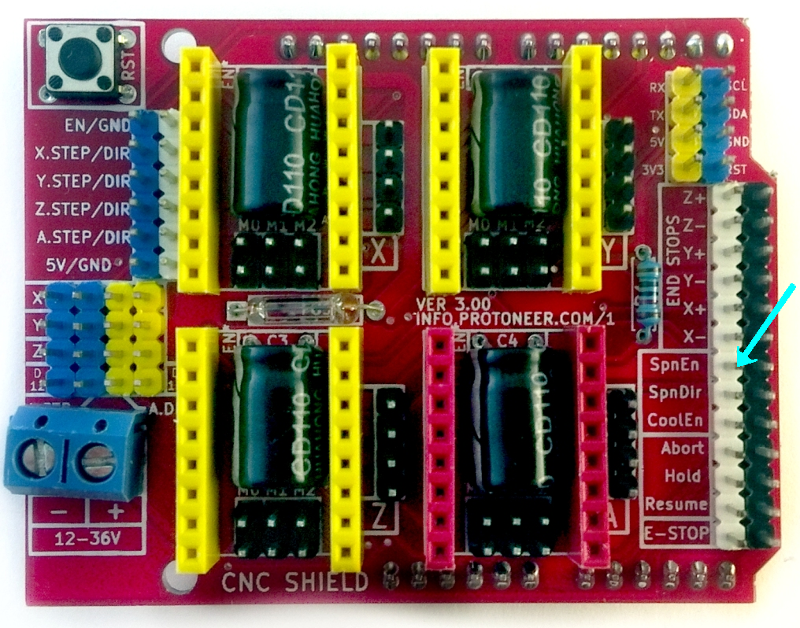

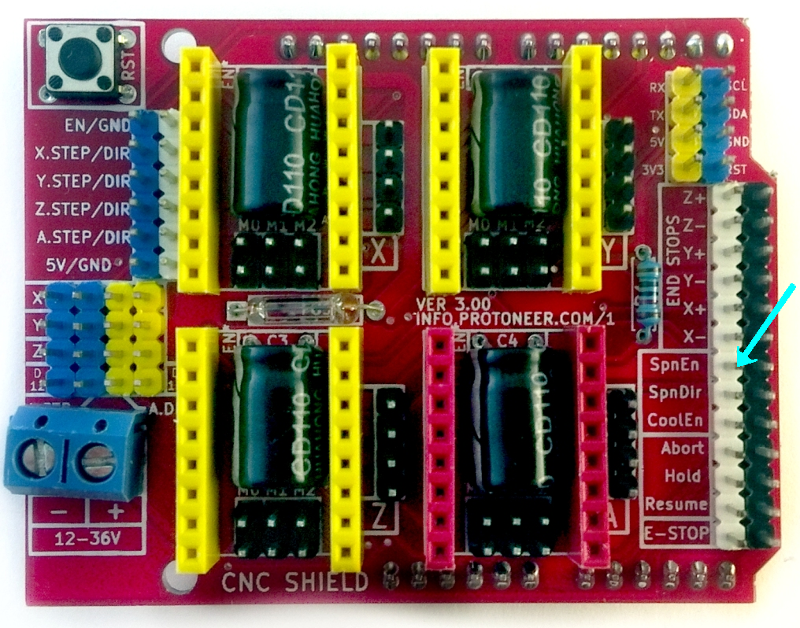

So I am trying to get my spindle control set up and I am having an issue. I am checking with a volt meter between the spindle enable (SpnEn) and ground and I am reading 5v. No matter what spindle commands I am sending (M03, M04 or M05) I am always reading 5v. Is there a different command for spindle enable? If I check the spindle direction pin (SpnDir), I read 5v when I send M03, and 0v when I send M04. So that appears to be working.

-

So I am trying to get my spindle control set up and I am having an issue. I am checking with a volt meter between the spindle enable (SpnEn) and ground and I am reading 5v. No matter what spindle commands I am sending (M03, M04 or M05) I am always reading 5v. Is there a different command for spindle enable? If I check the spindle direction pin (SpnDir), I read 5v when I send M03, and 0v when I send M04. So that appears to be working.

@dbemowsk

On my board,

M3 SP1000

spins the spindle at maximum speed. Just M3 by itself doesn't.

It's not obvious from looking at your board where the spindle OUT voltage is. Maybe on the opposite side? I guess you'll have to probe around to find it.