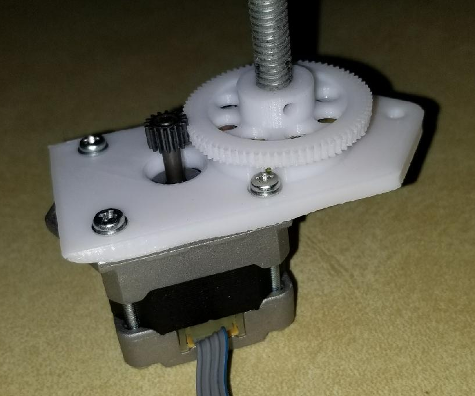

DIY CNC mill from mainly salvaged and 3D printed parts

-

I believe the flexible couplers are for when the stepper axis isn't co-linear with the threaded rod.

-

I believe the flexible couplers are for when the stepper axis isn't co-linear with the threaded rod.

-

@neverdie I still may buy another set. I think the clamping style would be the best, but as I said, not sure how that would be on the D shaft.

-

BTW, I suspect that using longer linear bearings will lead to less slop:

http://a.co/0yWkPgi -

BTW, I suspect that using longer linear bearings will lead to less slop:

http://a.co/0yWkPgi@neverdie said in DIY CNC mill from mainly salvaged and 3D printed parts:

@dbemowsk Are these not something you can 3D print? Then you could customize to the D shaft if you like.

I guess I hadn't thought about 3D printing them. I did order a pack of two though.

https://www.amazon.com/uxcell-Encoder-Coupler-Coupling-8mmx5mm/dp/B01E0CTI42/ref=sr_1_14?ie=UTF8&qid=1522050398&sr=8-14&keywords=5mm+8mm+coupler

@neverdie said in DIY CNC mill from mainly salvaged and 3D printed parts:

BTW, I suspect that using longer linear bearings will lead to less slop:

I would tend to agree. Does your CNC use linear bearings? -

@neverdie said in DIY CNC mill from mainly salvaged and 3D printed parts:

@dbemowsk Are these not something you can 3D print? Then you could customize to the D shaft if you like.

I guess I hadn't thought about 3D printing them. I did order a pack of two though.

https://www.amazon.com/uxcell-Encoder-Coupler-Coupling-8mmx5mm/dp/B01E0CTI42/ref=sr_1_14?ie=UTF8&qid=1522050398&sr=8-14&keywords=5mm+8mm+coupler

@neverdie said in DIY CNC mill from mainly salvaged and 3D printed parts:

BTW, I suspect that using longer linear bearings will lead to less slop:

I would tend to agree. Does your CNC use linear bearings?@dbemowsk said in DIY CNC mill from mainly salvaged and 3D printed parts:

Does your CNC use linear bearings?

Yes.

-

Just a note to everyone. These style couplers are NOT good for the X axis, or Z axis if the motor is vertical and facing down.

The problem is that the spiral part is actually quite springy. When say the X axis motor spins to pull the X axis to one side, the springy part seems to really stretch. Pushing the X axis works fine. Since my Z axis motor is mounted on top with the weight of the axis being downward, this will cause the coupler to stretch even more. My 3D printer uses these on it's Z axis which works fine because the motors face up with the pressure of the Z axis down on the couplers.The only thing about the ones that I got that I liked was the way that it clamps to the shaft. I think the clamping action is better because you get more surface area grabbing the shaft.

Something like this may be the best because it is solid and there is no stretching. It also has the clamping action.

-

Just a note to everyone. These style couplers are NOT good for the X axis, or Z axis if the motor is vertical and facing down.

The problem is that the spiral part is actually quite springy. When say the X axis motor spins to pull the X axis to one side, the springy part seems to really stretch. Pushing the X axis works fine. Since my Z axis motor is mounted on top with the weight of the axis being downward, this will cause the coupler to stretch even more. My 3D printer uses these on it's Z axis which works fine because the motors face up with the pressure of the Z axis down on the couplers.The only thing about the ones that I got that I liked was the way that it clamps to the shaft. I think the clamping action is better because you get more surface area grabbing the shaft.

Something like this may be the best because it is solid and there is no stretching. It also has the clamping action.

@dbemowsk they should work if used as intended. These couplings are supposed to be stiff in only one direction of freedom: Rotation of the axis (=transfer the torque of the motor to the axis). The other 5 degrees of freedom should be of low stiffness to absorb misalignment between motor and axis. So the correct type of bearings should actually constrain the axis to only rotate in one DoF and not translate into the coupling.

-

@dbemowsk they should work if used as intended. These couplings are supposed to be stiff in only one direction of freedom: Rotation of the axis (=transfer the torque of the motor to the axis). The other 5 degrees of freedom should be of low stiffness to absorb misalignment between motor and axis. So the correct type of bearings should actually constrain the axis to only rotate in one DoF and not translate into the coupling.

@technovation DIDn't think about that when I bought them. I will save them for spares for my 3D printer.

-

I notice that the kit from CNCrouterParts does appear to use the springy couplers:

https://www.youtube.com/watch?v=EiOOrOfwKvwSo, I guess it can't be bad, because they seem to make very nice kits.