Anyone tried the Creality CR-10 3D printer?

-

there are so much settings, and "little" things to know that's not easy to explain everything :)

Volcano is simply an extended e3dv6, maybe 1cm taller. You could just buy the volcano heatblock and nozzles and update an e3d. I have a lot of spares parts for hotends, handy.

It has a bigger heatblock=you can push more filament in it, and if you don't need a 0.2mm and very fine details, that can save a lot of time, like divide by 2 print timeAbout printers, well, I already exposed my points. When i started, I hesitated to build an i3 Steel (i wanted something sturdy, I prefer sturdy/fast/precise CNC's machines, makes sense to me for a good start). Remember the first commercial slow color ink printers 20-25 years ago??

So I was going back&forth, read a lot, asked for advices to a few gurus on reprap forums, and finally I thank them and am happy with my choice. But this a choice by a "maker" (not "afraid" to build/study new things) + I like good stuff.. and it cost me less than an original prusa! approx 350, 2years ago.imho, what I "don't like" in the hypercube is:

- rods and LMUU : I prefer vwheels like on the dbot printer (cheap vwheel on ali). With the slots acting as linear guides and replacing rods, it gets more sturdy

- the X axis with its vertical rods which is the same on prusa though.. not the best if you have weight on your gantry. Here, I use bowden setup, so it's lighter&faster to move. but I'm not fan of this vertical rods strategy especially for direct drive. that can work, but can be limiting too at a moment.

-

@neverdie I use XT60 and JST connectors on my hotends, 2 minutes job to replace, including heating and removing filament.

You seem to get the strong points of a cube design, speed, sturdiness and "enclosability".

The kinematics can be corexy or simple cartesian (flsun cube) or even wicked gantrys like the ultimaker.

As long as you are near the 30-35mm^3(cubic)/sec melting limit of the Volcano heatblock you are maxed out and can't go any faster in speed. Knowing that usual layer height is nozzle diameter/2 and layer width is 1.2nozzle diameter, divide the more realistic 30mm^3/sec to the widthheight and see the max speed you can achieve. That should determine the type of printer you use. Also remember the max speed is achieved only at long straight moves, acceleration plays a huge role, and accelerating a big heated bed with glass on top is not easy, while throwing around a light bowden hotend on a corexy is a breeze. Like comparing a narrow, curvy, mountain road for a big truck vs a sports car.

The noise is dependent on the drivers, use tmc2100 or later (2108, 2130, etc) and all noise is gone. What control board to use is a whole new story.@executivul

Are you using a thermocouple rather than the thermistor on your hotend? Since the E3D V6 has the capability of reaching thermistor destroying temperatures, I don't understand why a thermocouple isn't the default. I guess because it's not as accurate or something? If so, how is the lower accuracy of the thermocouple managed? -

@executivul

Are you using a thermocouple rather than the thermistor on your hotend? Since the E3D V6 has the capability of reaching thermistor destroying temperatures, I don't understand why a thermocouple isn't the default. I guess because it's not as accurate or something? If so, how is the lower accuracy of the thermocouple managed?@neverdie To be honest I use the cheap thermistors that came with the e3d clones I keep buying on ali.

I don't care about accuracy, I print a temptower and decide the best value for a filament lot that I buy and a nozzle/heatblock I intend to use. A full metal heatbreak is all you need, a teflon lined heatbreak tops at 240-260°C, the thermistor can go up to 300°C, ABS needs 240°C at most, PETG 220°C, PLA 200°C. -

@executivul

Are you using a thermocouple rather than the thermistor on your hotend? Since the E3D V6 has the capability of reaching thermistor destroying temperatures, I don't understand why a thermocouple isn't the default. I guess because it's not as accurate or something? If so, how is the lower accuracy of the thermocouple managed?@neverdie I don't know what the limit is for a thermister, but depending on the material you are printing, be it ABS, PETG or the like, these should not exceed 260°c. I typically print my ABS and PETG at around 240°c and have never had any issues with the thermister. Boards that run skynet or marlin as their firmware should have thermal runaway enabled.

-

https://item.taobao.com/item.htm?spm=a211ha.10565794.0.0.2c2b262eKzSJCq&id=536005864964

This is my corexy workhorse, all metal, linear guides, has a few hundred hours of running without any trouble, only improvement I did was adding a piezo sensor for bed leveling.

-

https://item.taobao.com/item.htm?spm=a211ha.10565794.0.0.2c2b262eKzSJCq&id=536005864964

This is my corexy workhorse, all metal, linear guides, has a few hundred hours of running without any trouble, only improvement I did was adding a piezo sensor for bed leveling.

-

@executivul did you buy a kit?

@gohan It seems the link @executivul provided is the kit. I wouldn't know how to order it, though, as I can't read Chinese.

The price is certainly cheap though. Is it simply called a TaoBao 3D printer? Is there some other source for it?

You know, it already has 2 stepper motors for the z-axis. If you could just add a third, then maybe true auto-leveling (i.e. not just in software) would be a snap, since 3 points determine a plane. Well, you get the idea. In practical terms it might be easier to have one at each corner of the bed (for a total of four). The extra oomph might also help with accelerating the bed, since that's the weak leak in all of this....

-

Guys the printer is a kit. I used the Android taobao app and contacted the seller, he was nice enough to arrange shipping via a Shenzehn shipping company and DHL, paymend via paypal, the guy is reliable.

I've bought the mechanical kit only since I already had all the seppers and electronics from a Prusa i3 clone.

For me this was the best printer I could buy in August 2017 for that kind of money, far better than anything on aliexpress or ebay back then and even now. He was talking about adding it to ebay, but I don't know if he did it by now. -

@gohan It seems the link @executivul provided is the kit. I wouldn't know how to order it, though, as I can't read Chinese.

The price is certainly cheap though. Is it simply called a TaoBao 3D printer? Is there some other source for it?

You know, it already has 2 stepper motors for the z-axis. If you could just add a third, then maybe true auto-leveling (i.e. not just in software) would be a snap, since 3 points determine a plane. Well, you get the idea. In practical terms it might be easier to have one at each corner of the bed (for a total of four). The extra oomph might also help with accelerating the bed, since that's the weak leak in all of this....

@neverdie you can't! since any missalignment will cause binding on the z movement, the linear bearings and ball screws are pretty sensitive to missalignments

-

I just now ordered the Prusa i3 Mk3 kit. It won't actually ship though until after March 26. However, on the plus side I'll be receiving the powder coated spring steel build bed, not the PEI sticker used by the Mk2 that many of those who ordered before me received.

-

I have had an OrdBot Hadron for quite a few years now and it has been serving me well except for one thing - the size 200x200 as well as height are sometimes a limiting factor and especially so since most heated beds are much colder towards the edges.

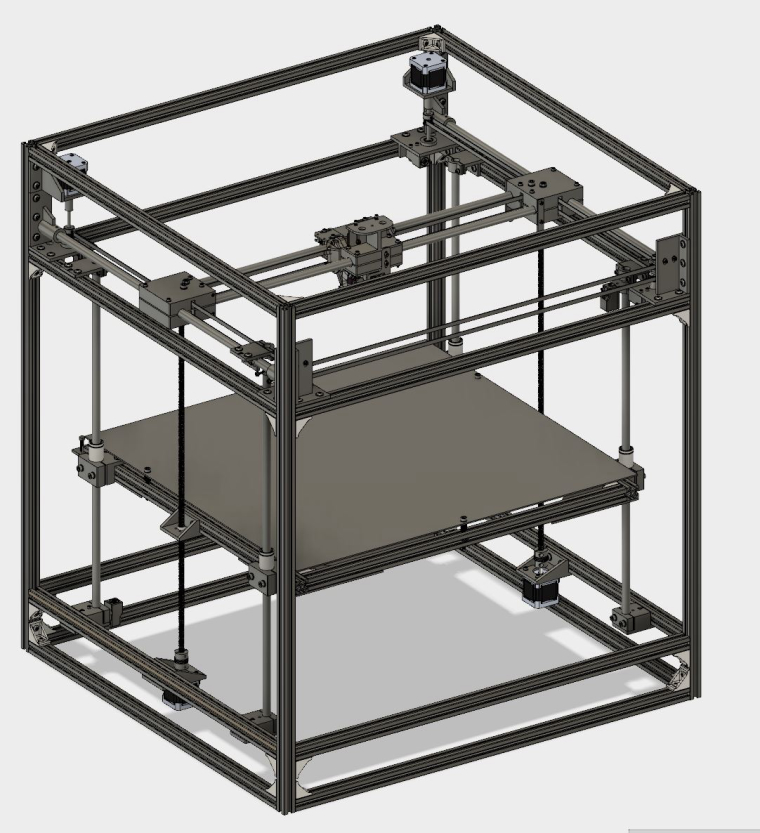

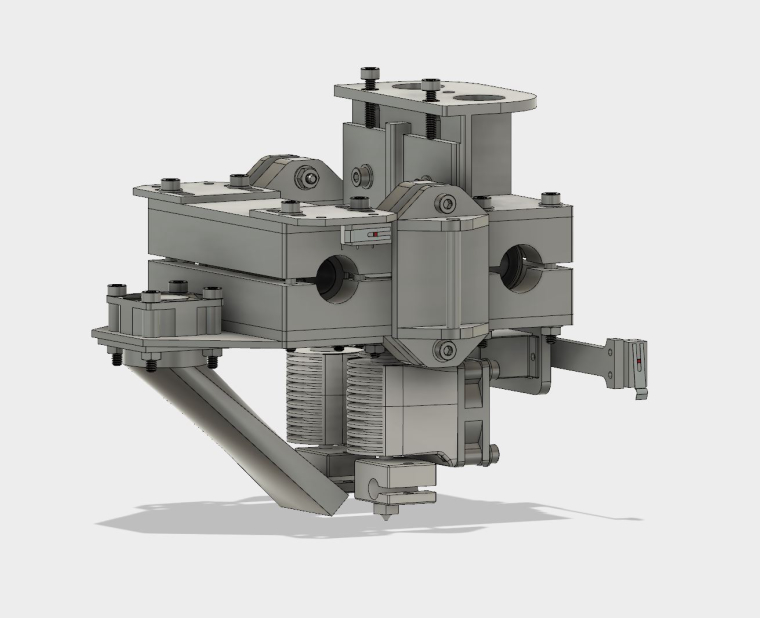

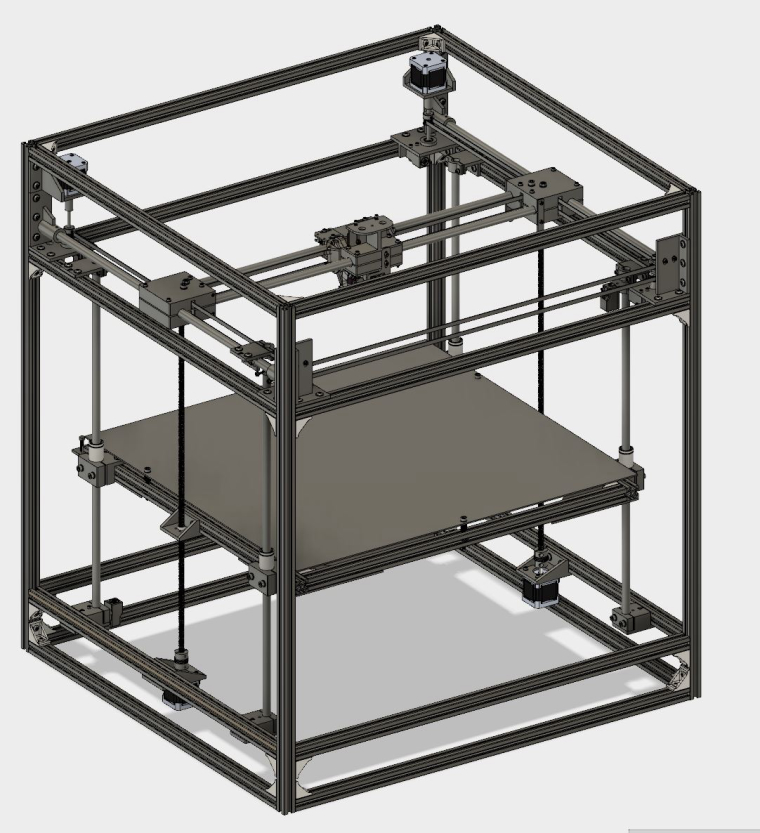

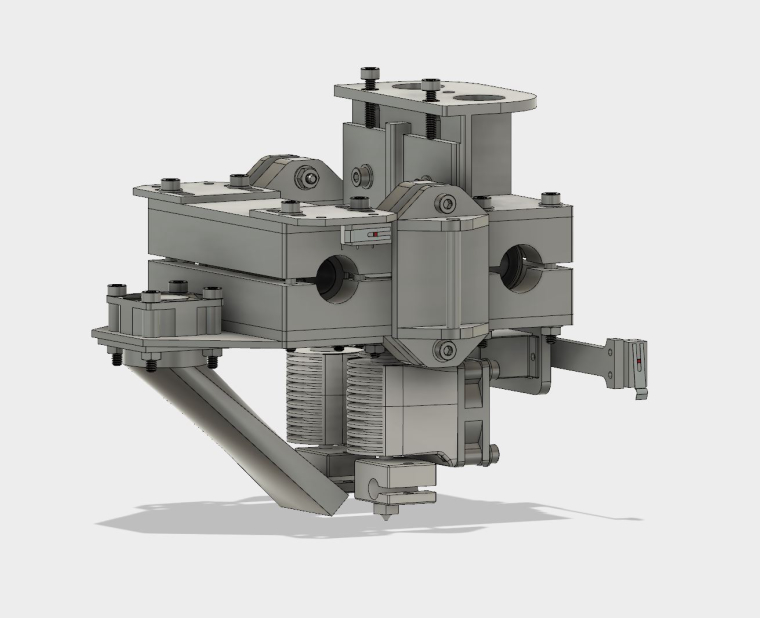

So I decided to design and build a bigger CoreXY which is up and running now with a print size of rougly 450x450x500 mm. It is equipped with double E3D Bowden extruders and a 220V silicon heater for the alu printing bed.

The whole process was of course time (and cost) consuming but it was really fun and a great experience.

One essential aspect of all printing is to be able to keep the print volume warm to minimize warping etc. This means that the print volume should be enclosed and especially so when printing ABS and some others.

-

This post is deleted!

-

I have had an OrdBot Hadron for quite a few years now and it has been serving me well except for one thing - the size 200x200 as well as height are sometimes a limiting factor and especially so since most heated beds are much colder towards the edges.

So I decided to design and build a bigger CoreXY which is up and running now with a print size of rougly 450x450x500 mm. It is equipped with double E3D Bowden extruders and a 220V silicon heater for the alu printing bed.

The whole process was of course time (and cost) consuming but it was really fun and a great experience.

One essential aspect of all printing is to be able to keep the print volume warm to minimize warping etc. This means that the print volume should be enclosed and especially so when printing ABS and some others.

-

@dbemowsk Yes it is a Ramps but in a way it is only "partly" used. The bed heating is, as mentioned, at 220V so Ramps is only used for the signal an external device. Same with the extruder heaters, i e the Ramps is used for a signal to a more robust device. This remedies some of the weaknesses of the Ramps card and enables heating of two extruders simultaneously.

I have bought external drivers for the step motors as well but not yet found any reason to switch to these. So the motors are still driven by the 8225 drivers on the Ramps card.

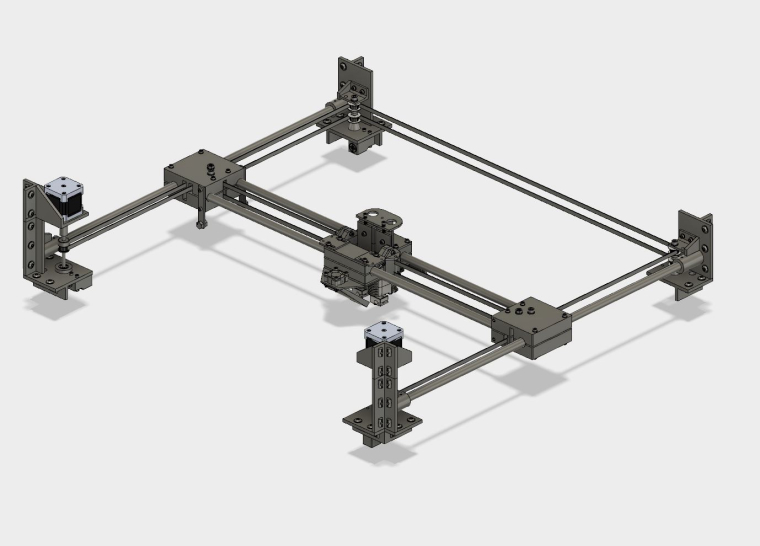

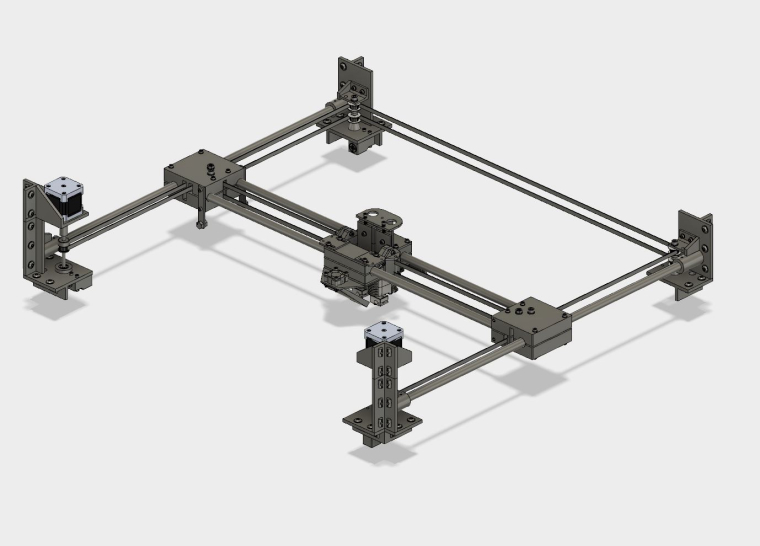

In case anyone is interested, this is what "the Thing" looks like on the drawing board:

Presumably the Mysensors forum is not intended for discussions about 3D printers why I hope I have not violated any rules by jumping into the conversation.

-

@dbemowsk Yes it is a Ramps but in a way it is only "partly" used. The bed heating is, as mentioned, at 220V so Ramps is only used for the signal an external device. Same with the extruder heaters, i e the Ramps is used for a signal to a more robust device. This remedies some of the weaknesses of the Ramps card and enables heating of two extruders simultaneously.

I have bought external drivers for the step motors as well but not yet found any reason to switch to these. So the motors are still driven by the 8225 drivers on the Ramps card.

In case anyone is interested, this is what "the Thing" looks like on the drawing board:

Presumably the Mysensors forum is not intended for discussions about 3D printers why I hope I have not violated any rules by jumping into the conversation.

@mbj said in Anyone tried the Creality CR-10 3D printer?:

Presumably the Mysensors forum is not intended for discussions about 3D printers why I hope I have not violated any rules by jumping into the conversation.

No worries:

General Discussion

A place to talk about whateeeever you want -

@gohan If we are talking about hobby stuff with comparable low cost the belt should be better but there are limitations like how much weight can be handled at high speeds without loosing precision. So it is a question with many answers depending on the circumstances.

-

Of course I am referring to hobby stuff and on a corexy/hypercube setup since I saw also people using lead screws instead of belts. I was trying to understand what is the best option while maintaining the same precision with the option to have a dual extruder setup