Anyone tried the Creality CR-10 3D printer?

-

@executivul

Are you using a thermocouple rather than the thermistor on your hotend? Since the E3D V6 has the capability of reaching thermistor destroying temperatures, I don't understand why a thermocouple isn't the default. I guess because it's not as accurate or something? If so, how is the lower accuracy of the thermocouple managed?@neverdie To be honest I use the cheap thermistors that came with the e3d clones I keep buying on ali.

I don't care about accuracy, I print a temptower and decide the best value for a filament lot that I buy and a nozzle/heatblock I intend to use. A full metal heatbreak is all you need, a teflon lined heatbreak tops at 240-260°C, the thermistor can go up to 300°C, ABS needs 240°C at most, PETG 220°C, PLA 200°C. -

@executivul

Are you using a thermocouple rather than the thermistor on your hotend? Since the E3D V6 has the capability of reaching thermistor destroying temperatures, I don't understand why a thermocouple isn't the default. I guess because it's not as accurate or something? If so, how is the lower accuracy of the thermocouple managed?@neverdie I don't know what the limit is for a thermister, but depending on the material you are printing, be it ABS, PETG or the like, these should not exceed 260°c. I typically print my ABS and PETG at around 240°c and have never had any issues with the thermister. Boards that run skynet or marlin as their firmware should have thermal runaway enabled.

-

https://item.taobao.com/item.htm?spm=a211ha.10565794.0.0.2c2b262eKzSJCq&id=536005864964

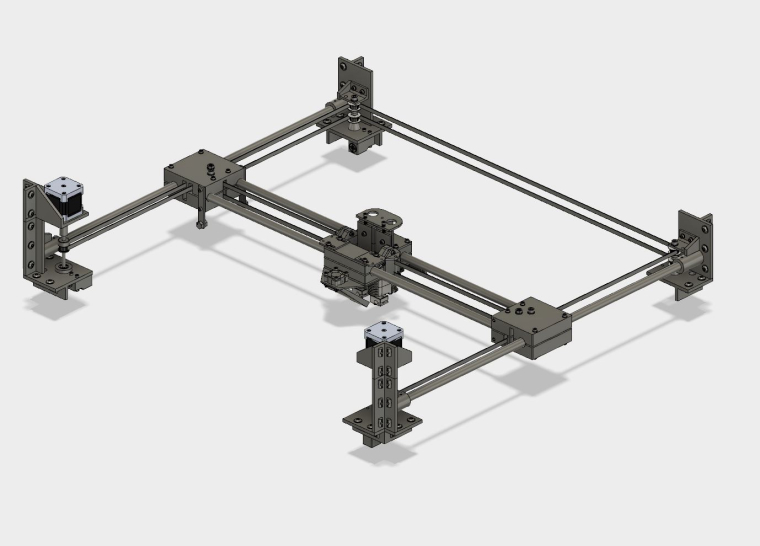

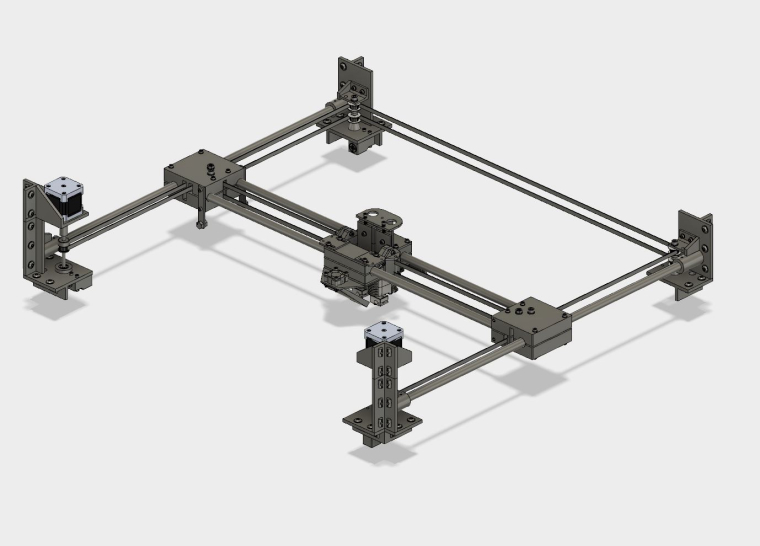

This is my corexy workhorse, all metal, linear guides, has a few hundred hours of running without any trouble, only improvement I did was adding a piezo sensor for bed leveling.

-

https://item.taobao.com/item.htm?spm=a211ha.10565794.0.0.2c2b262eKzSJCq&id=536005864964

This is my corexy workhorse, all metal, linear guides, has a few hundred hours of running without any trouble, only improvement I did was adding a piezo sensor for bed leveling.

-

@executivul did you buy a kit?

@gohan It seems the link @executivul provided is the kit. I wouldn't know how to order it, though, as I can't read Chinese.

The price is certainly cheap though. Is it simply called a TaoBao 3D printer? Is there some other source for it?

You know, it already has 2 stepper motors for the z-axis. If you could just add a third, then maybe true auto-leveling (i.e. not just in software) would be a snap, since 3 points determine a plane. Well, you get the idea. In practical terms it might be easier to have one at each corner of the bed (for a total of four). The extra oomph might also help with accelerating the bed, since that's the weak leak in all of this....

-

Guys the printer is a kit. I used the Android taobao app and contacted the seller, he was nice enough to arrange shipping via a Shenzehn shipping company and DHL, paymend via paypal, the guy is reliable.

I've bought the mechanical kit only since I already had all the seppers and electronics from a Prusa i3 clone.

For me this was the best printer I could buy in August 2017 for that kind of money, far better than anything on aliexpress or ebay back then and even now. He was talking about adding it to ebay, but I don't know if he did it by now. -

@gohan It seems the link @executivul provided is the kit. I wouldn't know how to order it, though, as I can't read Chinese.

The price is certainly cheap though. Is it simply called a TaoBao 3D printer? Is there some other source for it?

You know, it already has 2 stepper motors for the z-axis. If you could just add a third, then maybe true auto-leveling (i.e. not just in software) would be a snap, since 3 points determine a plane. Well, you get the idea. In practical terms it might be easier to have one at each corner of the bed (for a total of four). The extra oomph might also help with accelerating the bed, since that's the weak leak in all of this....

@neverdie you can't! since any missalignment will cause binding on the z movement, the linear bearings and ball screws are pretty sensitive to missalignments

-

I just now ordered the Prusa i3 Mk3 kit. It won't actually ship though until after March 26. However, on the plus side I'll be receiving the powder coated spring steel build bed, not the PEI sticker used by the Mk2 that many of those who ordered before me received.

-

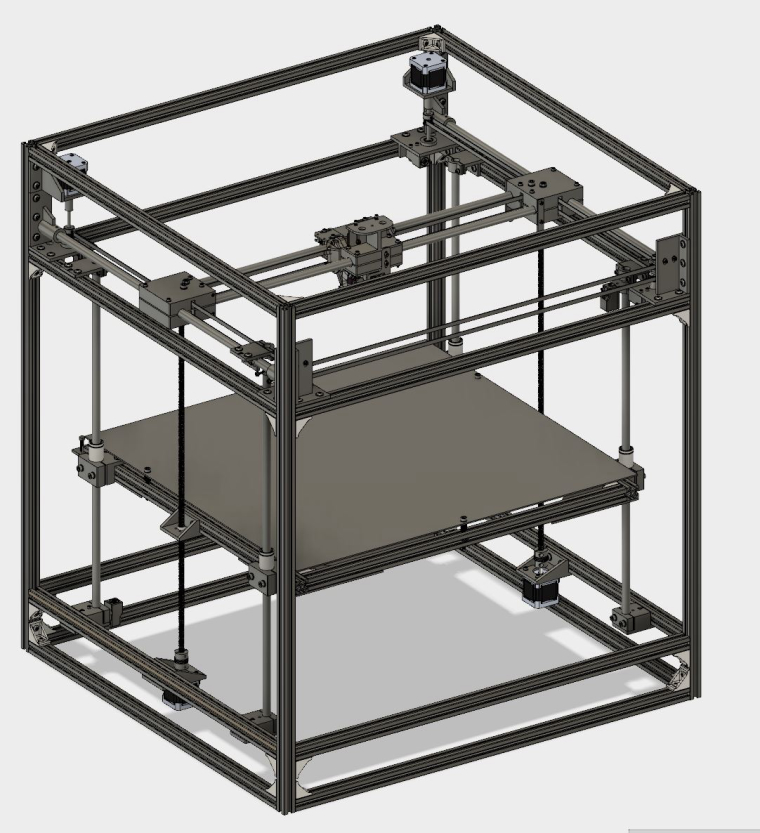

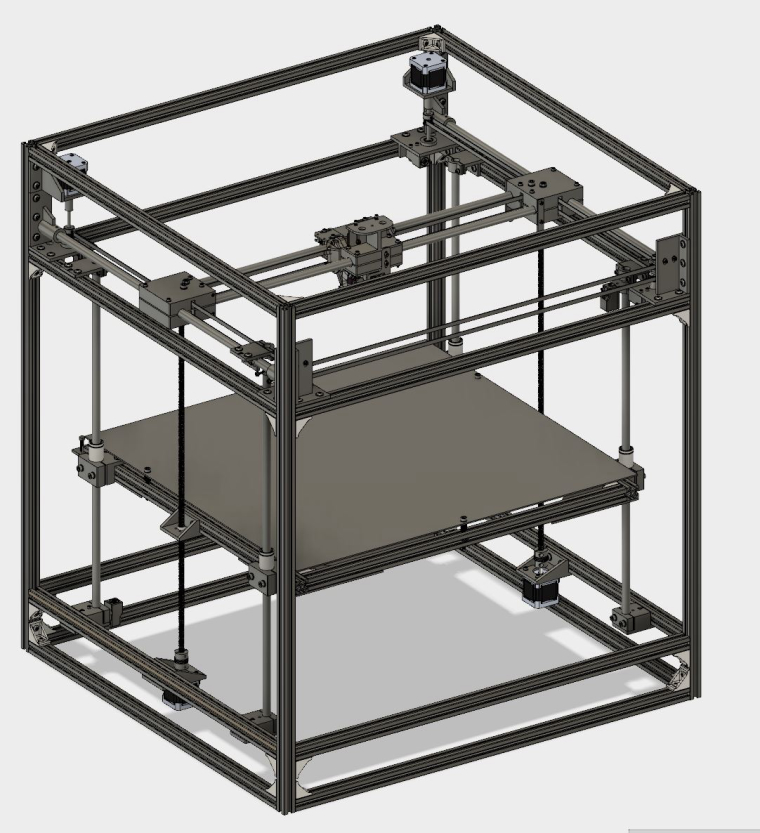

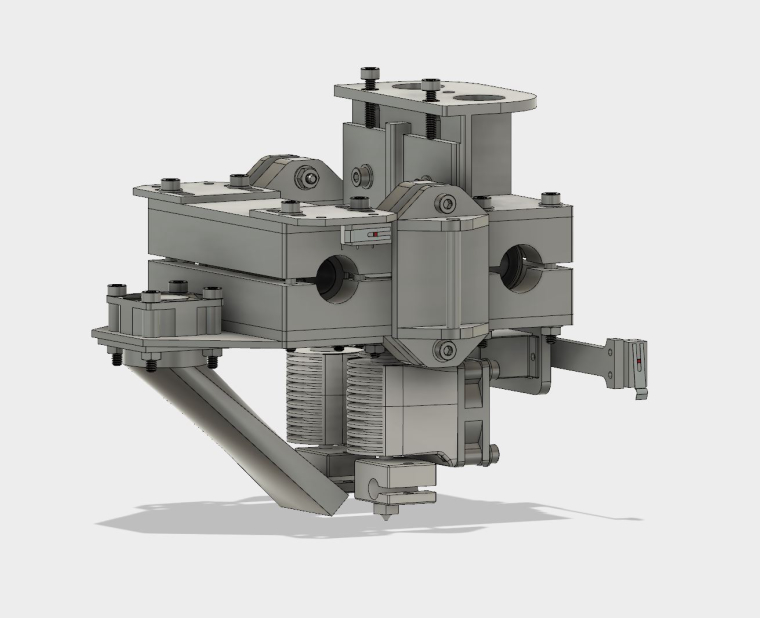

I have had an OrdBot Hadron for quite a few years now and it has been serving me well except for one thing - the size 200x200 as well as height are sometimes a limiting factor and especially so since most heated beds are much colder towards the edges.

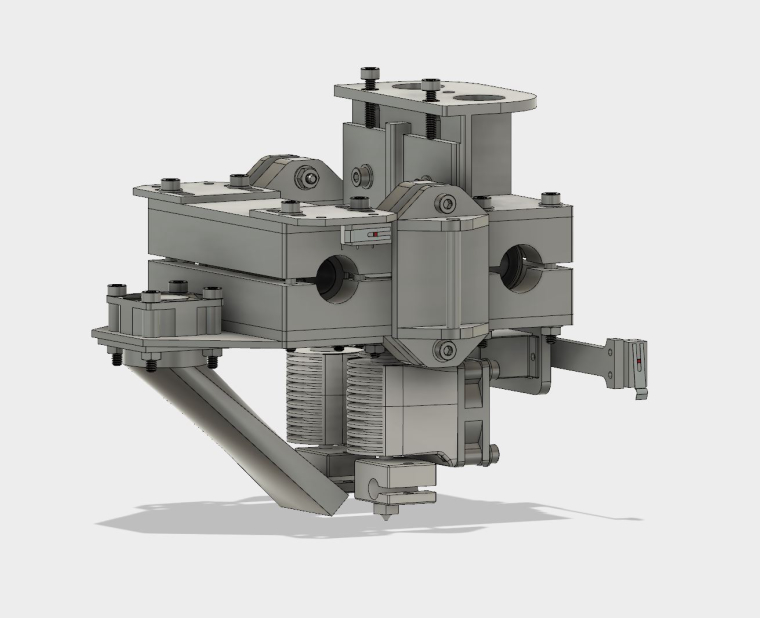

So I decided to design and build a bigger CoreXY which is up and running now with a print size of rougly 450x450x500 mm. It is equipped with double E3D Bowden extruders and a 220V silicon heater for the alu printing bed.

The whole process was of course time (and cost) consuming but it was really fun and a great experience.

One essential aspect of all printing is to be able to keep the print volume warm to minimize warping etc. This means that the print volume should be enclosed and especially so when printing ABS and some others.

-

This post is deleted!

-

I have had an OrdBot Hadron for quite a few years now and it has been serving me well except for one thing - the size 200x200 as well as height are sometimes a limiting factor and especially so since most heated beds are much colder towards the edges.

So I decided to design and build a bigger CoreXY which is up and running now with a print size of rougly 450x450x500 mm. It is equipped with double E3D Bowden extruders and a 220V silicon heater for the alu printing bed.

The whole process was of course time (and cost) consuming but it was really fun and a great experience.

One essential aspect of all printing is to be able to keep the print volume warm to minimize warping etc. This means that the print volume should be enclosed and especially so when printing ABS and some others.

-

@dbemowsk Yes it is a Ramps but in a way it is only "partly" used. The bed heating is, as mentioned, at 220V so Ramps is only used for the signal an external device. Same with the extruder heaters, i e the Ramps is used for a signal to a more robust device. This remedies some of the weaknesses of the Ramps card and enables heating of two extruders simultaneously.

I have bought external drivers for the step motors as well but not yet found any reason to switch to these. So the motors are still driven by the 8225 drivers on the Ramps card.

In case anyone is interested, this is what "the Thing" looks like on the drawing board:

Presumably the Mysensors forum is not intended for discussions about 3D printers why I hope I have not violated any rules by jumping into the conversation.

-

@dbemowsk Yes it is a Ramps but in a way it is only "partly" used. The bed heating is, as mentioned, at 220V so Ramps is only used for the signal an external device. Same with the extruder heaters, i e the Ramps is used for a signal to a more robust device. This remedies some of the weaknesses of the Ramps card and enables heating of two extruders simultaneously.

I have bought external drivers for the step motors as well but not yet found any reason to switch to these. So the motors are still driven by the 8225 drivers on the Ramps card.

In case anyone is interested, this is what "the Thing" looks like on the drawing board:

Presumably the Mysensors forum is not intended for discussions about 3D printers why I hope I have not violated any rules by jumping into the conversation.

@mbj said in Anyone tried the Creality CR-10 3D printer?:

Presumably the Mysensors forum is not intended for discussions about 3D printers why I hope I have not violated any rules by jumping into the conversation.

No worries:

General Discussion

A place to talk about whateeeever you want -

@gohan If we are talking about hobby stuff with comparable low cost the belt should be better but there are limitations like how much weight can be handled at high speeds without loosing precision. So it is a question with many answers depending on the circumstances.

-

Of course I am referring to hobby stuff and on a corexy/hypercube setup since I saw also people using lead screws instead of belts. I was trying to understand what is the best option while maintaining the same precision with the option to have a dual extruder setup

-

Of course I am referring to hobby stuff and on a corexy/hypercube setup since I saw also people using lead screws instead of belts. I was trying to understand what is the best option while maintaining the same precision with the option to have a dual extruder setup

@gohan The beauty with a CoreXY is that both X and Y movements are handled by stationary motors which do not add any moving weight. Changing to lead screws means that most likely 2 motors are needed for Y (for a large design) and then another screw and motor for X and these will add to the moving weight. Of course a belt could also be used for X but the motor arrangement needed for this will still be a moving part.

Even if my CoreXY is really big it can print with same or even better resolution than my old OrdBot Hadron which is so much smaller. The OrdBot has a direct drive extruder and also the X motor arrangement attached as a moving parts and this affects what printing speeds can be achieved at a given resolution. The CoreXY has a Bowden arrangement which further lowers the moving weight.

-

@gohan The beauty with a CoreXY is that both X and Y movements are handled by stationary motors which do not add any moving weight. Changing to lead screws means that most likely 2 motors are needed for Y (for a large design) and then another screw and motor for X and these will add to the moving weight. Of course a belt could also be used for X but the motor arrangement needed for this will still be a moving part.

Even if my CoreXY is really big it can print with same or even better resolution than my old OrdBot Hadron which is so much smaller. The OrdBot has a direct drive extruder and also the X motor arrangement attached as a moving parts and this affects what printing speeds can be achieved at a given resolution. The CoreXY has a Bowden arrangement which further lowers the moving weight.

@mbj said in Anyone tried the Creality CR-10 3D printer?:

Changing to lead screws means that most likely 2 motors are needed for Y

This was a question that came up in one of the groups I am a member of for my Anet A8 as it has 2 motors for the Z axis that lifts the gantry. Wouldn't it be possible to use one higher torque motor for the Y axis and then use a notched belt between them? With two motors, you have the risk of one missing a step and then having to re-position your Y axis from time to time because of that.

-

@mbj said in Anyone tried the Creality CR-10 3D printer?:

Changing to lead screws means that most likely 2 motors are needed for Y

This was a question that came up in one of the groups I am a member of for my Anet A8 as it has 2 motors for the Z axis that lifts the gantry. Wouldn't it be possible to use one higher torque motor for the Y axis and then use a notched belt between them? With two motors, you have the risk of one missing a step and then having to re-position your Y axis from time to time because of that.

@dbemowsk For Z I have seen solutions with motors and belts so this is possible. It is just another piece to design and the motor need to be sized for both which might be a bigger problem with Y than with Z. I have never thought about it so it is just a guess.