SMD Reflow Oven / PID

-

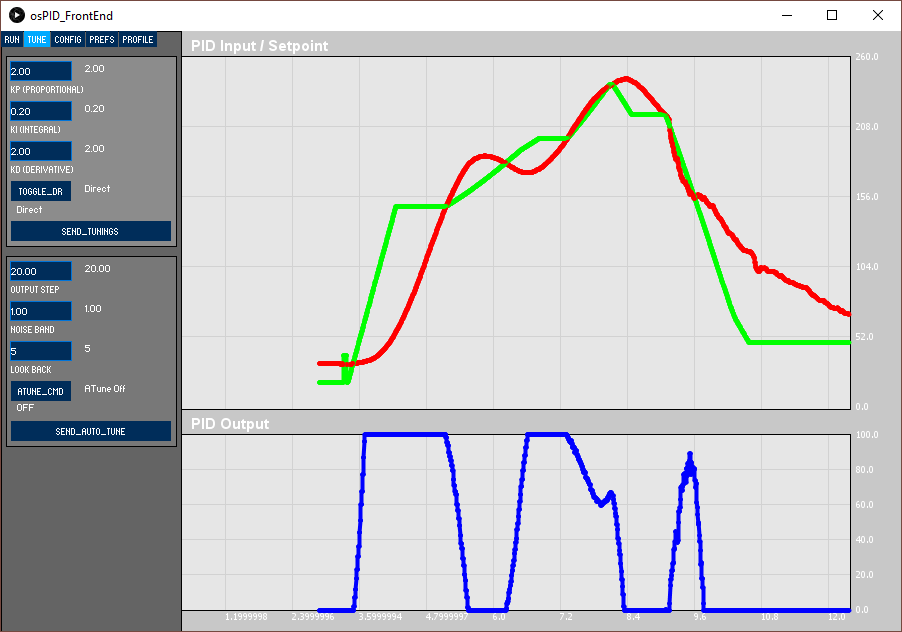

A bit off-topic, but as per the suggestions earlier in this topic I managed to get a toaster oven working with an OSPId reflow controller, and got some test boards with 0603, 0805, 1206 and SOT23 stuff reflowed with 4 year old AIM solder paste (no flux, lead free of course).

Learned a lot. Now should get my hands dirty with some nRF52832 (ebyte E73) modules / PCB's to produce something useful ;-)

I see so much nice designs here with that module!

-

A bit off-topic, but as per the suggestions earlier in this topic I managed to get a toaster oven working with an OSPId reflow controller, and got some test boards with 0603, 0805, 1206 and SOT23 stuff reflowed with 4 year old AIM solder paste (no flux, lead free of course).

Learned a lot. Now should get my hands dirty with some nRF52832 (ebyte E73) modules / PCB's to produce something useful ;-)

I see so much nice designs here with that module!

@mars-warrior That's cool that you got lead free paste to work. How difficult was it?

-

@mars-warrior That's cool that you got lead free paste to work. How difficult was it?

@neverdie No idea if this was difficult as I never worked with leaded solder paste :laughing:

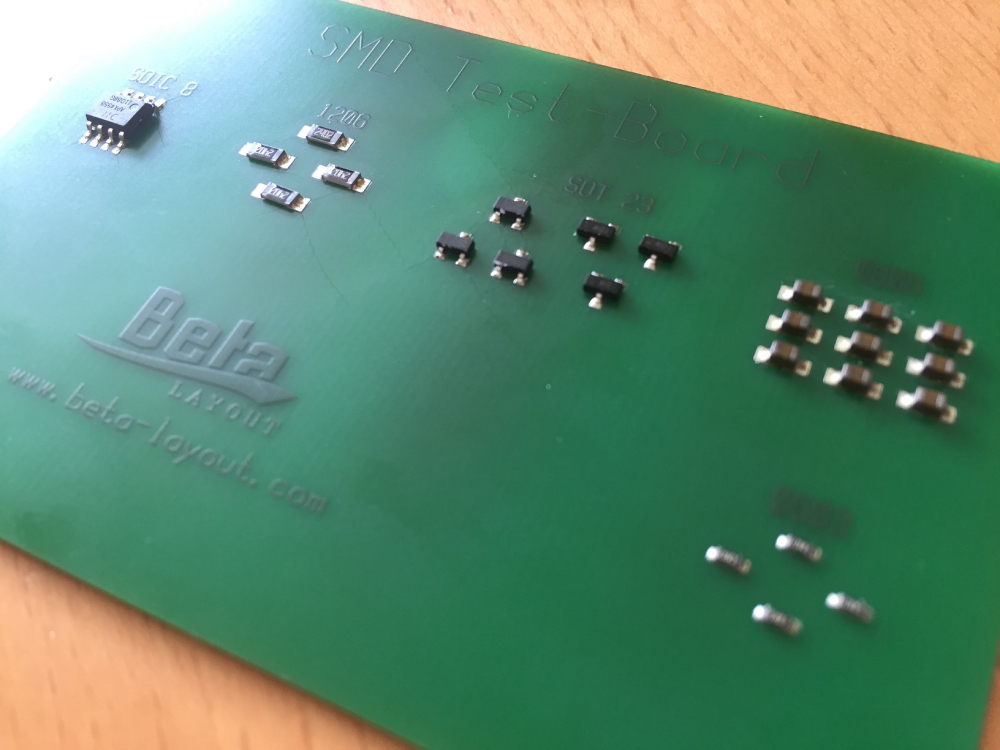

I used OSPID's RoHS reflow profile to reflow a test board

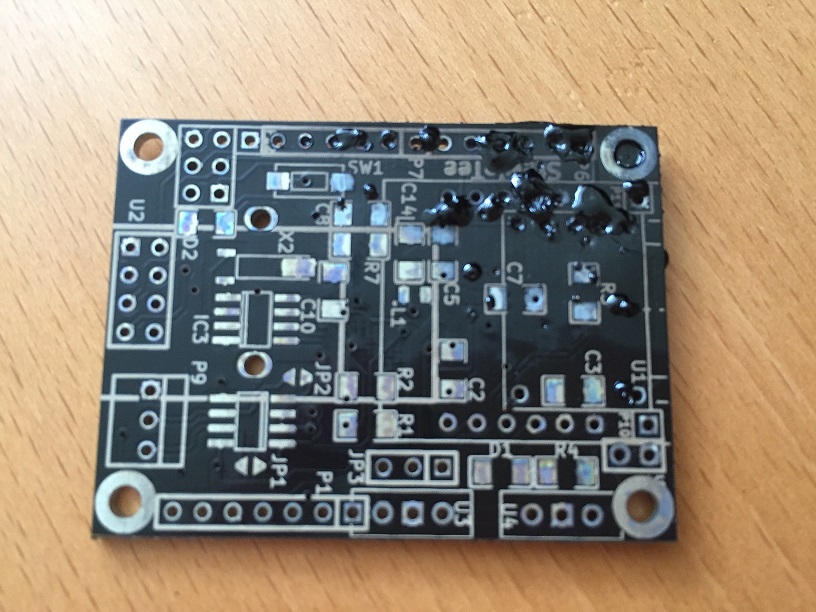

The test board looks like this. I was surprised that I managed to place the 0603 (imperial) with a pincet on the board (and magnifying glasses).

No idea how good the connections really are with 4 year old solderpaste. I guess I should not use that for real boards :sunglasses:

-

A bit off-topic, but as per the suggestions earlier in this topic I managed to get a toaster oven working with an OSPId reflow controller, and got some test boards with 0603, 0805, 1206 and SOT23 stuff reflowed with 4 year old AIM solder paste (no flux, lead free of course).

Learned a lot. Now should get my hands dirty with some nRF52832 (ebyte E73) modules / PCB's to produce something useful ;-)

I see so much nice designs here with that module!

-

There's starting to be some interesting solder paste dispensors on thingiverse, such as:

https://www.thingiverse.com/thing:384680

or

https://www.thingiverse.com/thing:2123259I'd probably need a tool like one of those. I didn't have good enough technique dispensing manually directly from a solder paste syringe, and I never really warmed up to the idea of using stencils. Well, not yet anyway. Using non-leaded solder paste would make the whole thing more appealing. Since nobody seemed to be doing it, I just assumed it was too hard to get it to work...until you came along!

-

@toyman said in nRF5 action!:

@mars-warrior said in nRF5 action!:

OSPId reflow controller

where did you get it?

I bought it from someone else, but he bought it from Rocketstream

..

In the mean time I learned how a PID controller works (approx) as described here with this nice GIF from Wikipedia:

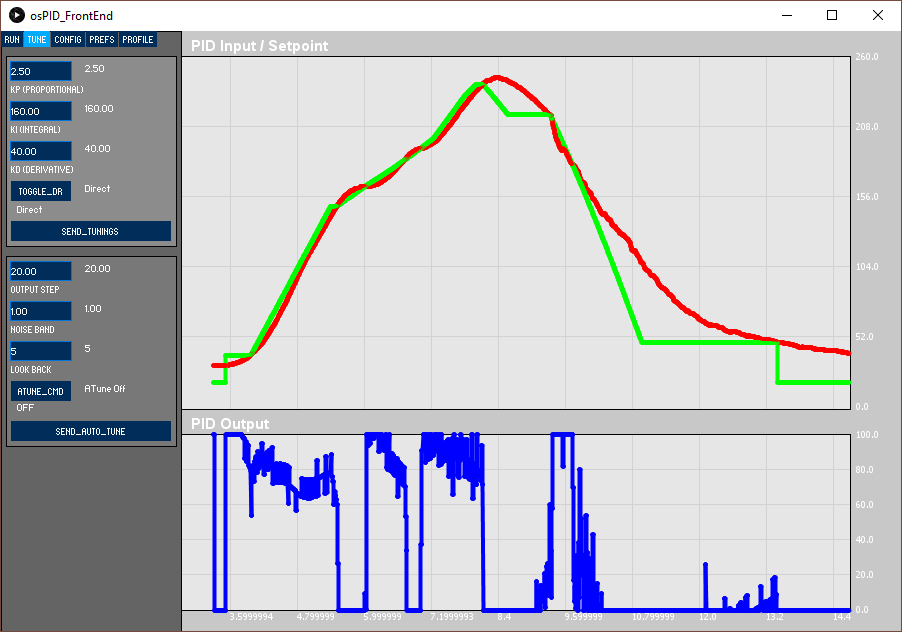

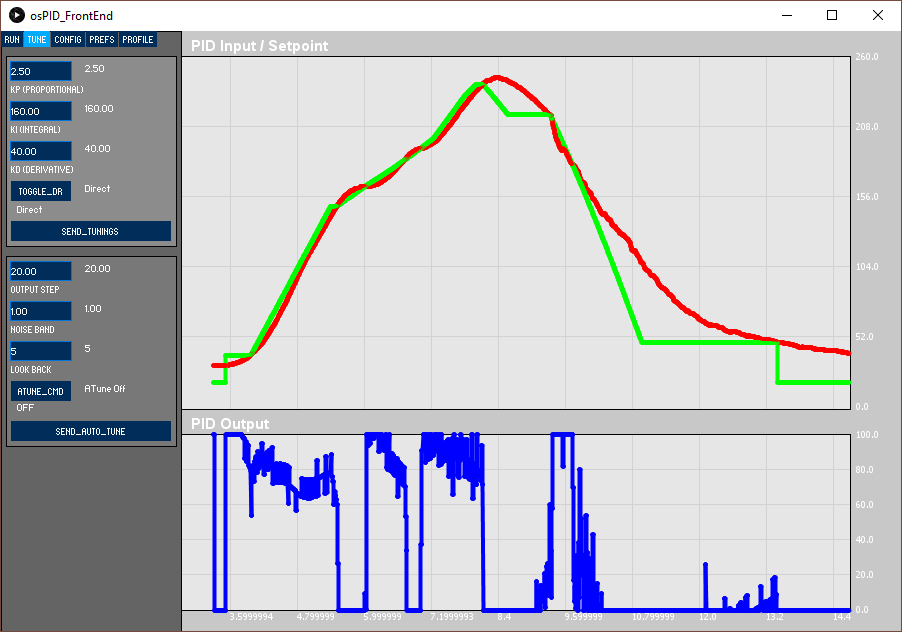

And managed to get a very good implementation by OSPid of my (slightly modified) reflow profile for lead free solderpaste (max of 245 degrees):

As you can see much better than my previous posted picture. Note that green = profile, and red is the actual temperature measurements.

The original OOTB PID settings where 2/0.5/2 and I'm now using 2.5/160/40 which gives a very nice result!

I increased the P value a bit. Made I much higher to make it follow the profile much, much, much better and used 40 for the D value to smoothen the temperature and prevent to much overshoot at 240 degrees.The only weird thing is that the oven is spec'd at max 230 degrees, but I already got it to 280 degrees (that was before I understood PID settings, I entered completely wrong ones) and burning the test PCB with the attached temperature sensor inside it:

So now I have to make a real PCB and see if all this learning (using a stencil, applying solder paste, placing components, reflowing) can produce a working product :grinning:

Since nobody seemed to be doing it, I just assumed it was too hard to get it to work...until you came along!

:innocent:

-

Maybe this, or one like it? There are a ton of them on ebay.

https://www.ebay.com/itm/AC-110-240-Digital-PID-Temperature-controller-40A-SSR-K-thermocouple-Sensor/371134791350?epid=918051785&hash=item56695b7eb6:g:yRAAAOSwVFlUBBap

Ah, but of course, I don't suppose they would follow a temperature profile.... -

Maybe this, or one like it? There are a ton of them on ebay.

https://www.ebay.com/itm/AC-110-240-Digital-PID-Temperature-controller-40A-SSR-K-thermocouple-Sensor/371134791350?epid=918051785&hash=item56695b7eb6:g:yRAAAOSwVFlUBBap

Ah, but of course, I don't suppose they would follow a temperature profile....@neverdie Yup, cheap but no (adjustable) temperature profile...

I just found it easier to use a reflow controller, as I had no idea how not using a profile would impact the soldering results.

I bought a new, fairly cheap but good €70 oven, and the rest is second hand stuff for around €50; an OMRON SSR (40A), which gets barely warm during a reflow session, an osPID controller and a temperature sensor.

I'm happy with the combination as it gives me reproducible results.

Of course I have no results yet with real boards, but I'm confident that the reflow setup can be adjusted (longer pre-heat and soak times for instance) to meet the PCB, reflow paste and component requirements.

As you can see below, the osPID profile is very easy to setup:

RoHS24X //first row is Profile Name with different crossings 3, 40, 0 //Step Setpoint to 40, wait 0 seconds 2, 0, 0 //Wait for PID Input to cross setpoint 127, 0, 1 //buzz for 1 second as a signal that the oven is starting to heat 1, 150, 100 //PRE-HEAT: ramp setpoint to 150 degrees over the course of 100 seconds 2, 5, 5 //Wait for PID Input to cross setpoint 1, 200, 120 //SOAK: ramp setpoint to 200 degrees over the course of 120 seconds 2, 5, 5 //Wait for PID Input to cross setpoint 1, 240, 45 //REFLOW: ramp setpoint to 240 degrees over the course of 45 seconds 2, 0, 0 //Wait for PID Input to cross setpoint 1, 218, 30 //ramp setpoint to 218 (TAL) over the course of 30 seconds 2, 5, 5 //Wait for PID Input to cross setpoint --> within 5 degrees, 5 seconds 127, 0, 1 //buzz for 2 seconds as a signal to open the oven door 1, 50, 150 //ramp setpoint to 50 over the course of 150 seconds 2, 0, 0 //Wait for PID Input to cross setpoint 127, 0, 2 //buzz for 2 seconds 3, 20, 0 //Step Setpoint to 20, full cooldown!``` -

Have look here: http://www.whizoo.com/

and source code: https://github.com/engineertype/ControLeo/tree/master/ControLeo/examples/ReflowWizard -

@toyman said in nRF5 action!:

@mars-warrior said in nRF5 action!:

OSPId reflow controller

where did you get it?

I bought it from someone else, but he bought it from Rocketstream

..

In the mean time I learned how a PID controller works (approx) as described here with this nice GIF from Wikipedia:

And managed to get a very good implementation by OSPid of my (slightly modified) reflow profile for lead free solderpaste (max of 245 degrees):

As you can see much better than my previous posted picture. Note that green = profile, and red is the actual temperature measurements.

The original OOTB PID settings where 2/0.5/2 and I'm now using 2.5/160/40 which gives a very nice result!

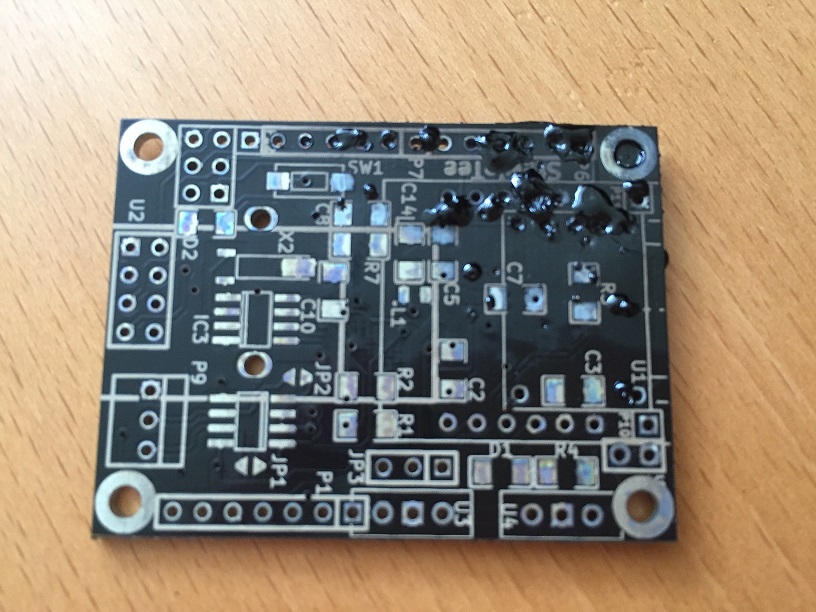

I increased the P value a bit. Made I much higher to make it follow the profile much, much, much better and used 40 for the D value to smoothen the temperature and prevent to much overshoot at 240 degrees.The only weird thing is that the oven is spec'd at max 230 degrees, but I already got it to 280 degrees (that was before I understood PID settings, I entered completely wrong ones) and burning the test PCB with the attached temperature sensor inside it:

So now I have to make a real PCB and see if all this learning (using a stencil, applying solder paste, placing components, reflowing) can produce a working product :grinning:

Since nobody seemed to be doing it, I just assumed it was too hard to get it to work...until you came along!

:innocent:

@mars-warrior said in nRF5 action!:

In the mean time I learned how a PID controller

Thanks!

I have to admit I've acquired pretty decent understanding of PID while working on my sous-vide machine :-) -

There's starting to be some interesting solder paste dispensors on thingiverse, such as:

https://www.thingiverse.com/thing:384680

or

https://www.thingiverse.com/thing:2123259I'd probably need a tool like one of those. I didn't have good enough technique dispensing manually directly from a solder paste syringe, and I never really warmed up to the idea of using stencils. Well, not yet anyway. Using non-leaded solder paste would make the whole thing more appealing. Since nobody seemed to be doing it, I just assumed it was too hard to get it to work...until you came along!

-

@neverdie said in nRF5 action!:

I didn't have good enough technique dispensing manually directly from a solder paste syringe,

what did you have issues with?

@toyman said in nRF5 action!:

@neverdie said in nRF5 action!:

I didn't have good enough technique dispensing manually directly from a solder paste syringe,

what did you have issues with?

It was very hard to extrude it, so I always seemed to either underextrude or overstrude. I found it very hard to get the right amount exactly where it should go by just manually pressing the plunger on the solder paste syringe that the material came in.

-

@toyman said in nRF5 action!:

@neverdie said in nRF5 action!:

I didn't have good enough technique dispensing manually directly from a solder paste syringe,

what did you have issues with?

It was very hard to extrude it, so I always seemed to either underextrude or overstrude. I found it very hard to get the right amount exactly where it should go by just manually pressing the plunger on the solder paste syringe that the material came in.

-

@neverdie

two hypothesis:

a) old paste

b) wrong needle gaugeI use Mechanic XG paste, works perfect

-

@neverdie yes, although I use the one in small cans and reload small amount into 1 ml syringe (with proper gauge needle!)

This bottle contains all the needles conviniently cut

-

@neverdie yes, although I use the one in small cans and reload small amount into 1 ml syringe (with proper gauge needle!)

This bottle contains all the needles conviniently cut

@toyman What about the syringes? Do you have a link for those as well?

I suppose a syringe gun might be handy, if no stepper motor operated one is available:

https://www.aliexpress.com/item/New-Arrival-Manual-Syringe-Gun-Dispenser-10cc-Glue-Dispensing-Gun/32555533165.html?spm=2114.search0604.8.44.58b37fcbKvXPej&priceBeautifyAB=0 -

@toyman What about the syringes? Do you have a link for those as well?

I suppose a syringe gun might be handy, if no stepper motor operated one is available:

https://www.aliexpress.com/item/New-Arrival-Manual-Syringe-Gun-Dispenser-10cc-Glue-Dispensing-Gun/32555533165.html?spm=2114.search0604.8.44.58b37fcbKvXPej&priceBeautifyAB=0@neverdie c'mon, you don't need any special syringe. Ordinary BD will do

Regarding the motor operated one, I actually printed out a full set of 3d parts for the motor oerated syringe but never assembled as there is no need.

If I ever decide to automate the process, I'll make an air driven station with 2 valves. Mechanic solder syringes are supposed to be used with this type of dispensers. -

So I gave it a try today with a solder paste syringe from AliExpress (not perempted like the paste I got from my local shop before). I used a normal syringe pusher (after removing the rubber end) and it went relatively smoothly with a green colored needle (don't know the diameter). I guess I'll try the small syringe technique as it must be easier to have regular flow, but it was good enough.

Without much training I managed to solder my ESP32 module (and 2 buttons) to the adapter board. I used my small 10*10cm hotplate, remotely following the reflow profile for this solder type and all connections are good. -

So I gave it a try today with a solder paste syringe from AliExpress (not perempted like the paste I got from my local shop before). I used a normal syringe pusher (after removing the rubber end) and it went relatively smoothly with a green colored needle (don't know the diameter). I guess I'll try the small syringe technique as it must be easier to have regular flow, but it was good enough.

Without much training I managed to solder my ESP32 module (and 2 buttons) to the adapter board. I used my small 10*10cm hotplate, remotely following the reflow profile for this solder type and all connections are good.