Thanks for your interest, guys!

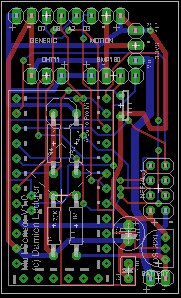

My PCB is getting really close, but I'm not entirely happy with it. I've made up 5 of them and scattered them around my place. For the most part, they're working well. However I have the following issues:

- The battery voltage varies. I don't think my cap is quite doing the job, so I may need to tweak the PCB to get it closer to the voltage divider. I'm running Domoticz and it does a good job of averaging the battery level out, so it's not completely bad, but I'd really like to fix it in the next version of the PCB.

- My moisture sensor (the one from the MySensors store) doesn't work very well. It chews the battery (cos the sensor from the store has 2 leds on it, plus it's always "on". I'll pop those off and see how it goes. However I think I can do the moisture sensor better. I'm thinking of including another voltage divider, and run the sensor off the digital pin for power. That way, I can power the sensor down in between samples.

I think that I can also include my own step up voltage converter. I'm not entirely happy with the chinese step up converter. So far my 2xAA batteries have lasted several weeks, and they're still going strong, but I suspect that I'll only get a few months out of them. I'm aiming for a year.

I'm designing our new house at the moment, which is taking up a lot of time, but I'll get onto rev 2 shortly. Once I'm happy with it, I'll put the design up here so that you guys can get your own made up.