💬 Battery Powered Sensors

-

@sineverba thanks, I got it working and it's up and running. Still have to desolder the led and remove the regulator, will do that later.

Regarding the BOD, what happens if I disable it? Will it run for longer as it does not shutdown? Or is any voltage below 1.8v bad for the arduino?A bit off topic maybe, but I was wondering how the 'pros' around here make the sensor small and sturdy for Arduino's with Si7021+ 2xAA battery pack. My DuPont wires seem a bit loose, so I'm wondering whether I should solder them. And perhaps someone 3d printed a case for an Arduino+Batterypack or some sorts.

@Sebex said in 💬 Battery Powered Sensors:

A bit off topic maybe, but I was wondering how the 'pros' around here make the sensor small and sturdy for Arduino's with Si7021+ 2xAA battery pack. My DuPont wires seem a bit loose, so I'm wondering whether I should solder them. And perhaps someone 3d printed a case for an Arduino+Batterypack or some sorts.

You may want to try wire wrapping. It’s faster than soldering, sturdier than DuPont and you can connect multiple wires on same pin. Works wonders for gnd and vcc. Of course if the project is yanked harder, the wire wraps come out.

I made this small video for my home automation group in India. - hence prices for the wire wraps and tool are mentioned in local currency. I leant about this amazing technique from Andreas Spiess

my video

guy with Swiss accent -

@Sebex said in 💬 Battery Powered Sensors:

A bit off topic maybe, but I was wondering how the 'pros' around here make the sensor small and sturdy for Arduino's with Si7021+ 2xAA battery pack. My DuPont wires seem a bit loose, so I'm wondering whether I should solder them. And perhaps someone 3d printed a case for an Arduino+Batterypack or some sorts.

You may want to try wire wrapping. It’s faster than soldering, sturdier than DuPont and you can connect multiple wires on same pin. Works wonders for gnd and vcc. Of course if the project is yanked harder, the wire wraps come out.

I made this small video for my home automation group in India. - hence prices for the wire wraps and tool are mentioned in local currency. I leant about this amazing technique from Andreas Spiess

my video

guy with Swiss accent@Puneit-Thukral Both DuPont and wirewrap are generally considered as prototyping methods. For final device build and production more secure connections should be implemented.

-

@Puneit-Thukral Both DuPont and wirewrap are generally considered as prototyping methods. For final device build and production more secure connections should be implemented.

@skywatch Agree with every word of yours. Not justifying myself here but wirewraps are deployed all over my house. I pour some hot glue to ensure that they don’t come loose. And then a 3D printed enclosure takes care of the elements.

Also, it helps me to quickly repurpose the hardware.

It’s just another approach.

In an ideal world - where PCB shipments never arrive from China and locally they are a but expensive , this is my poor man’s alternative.

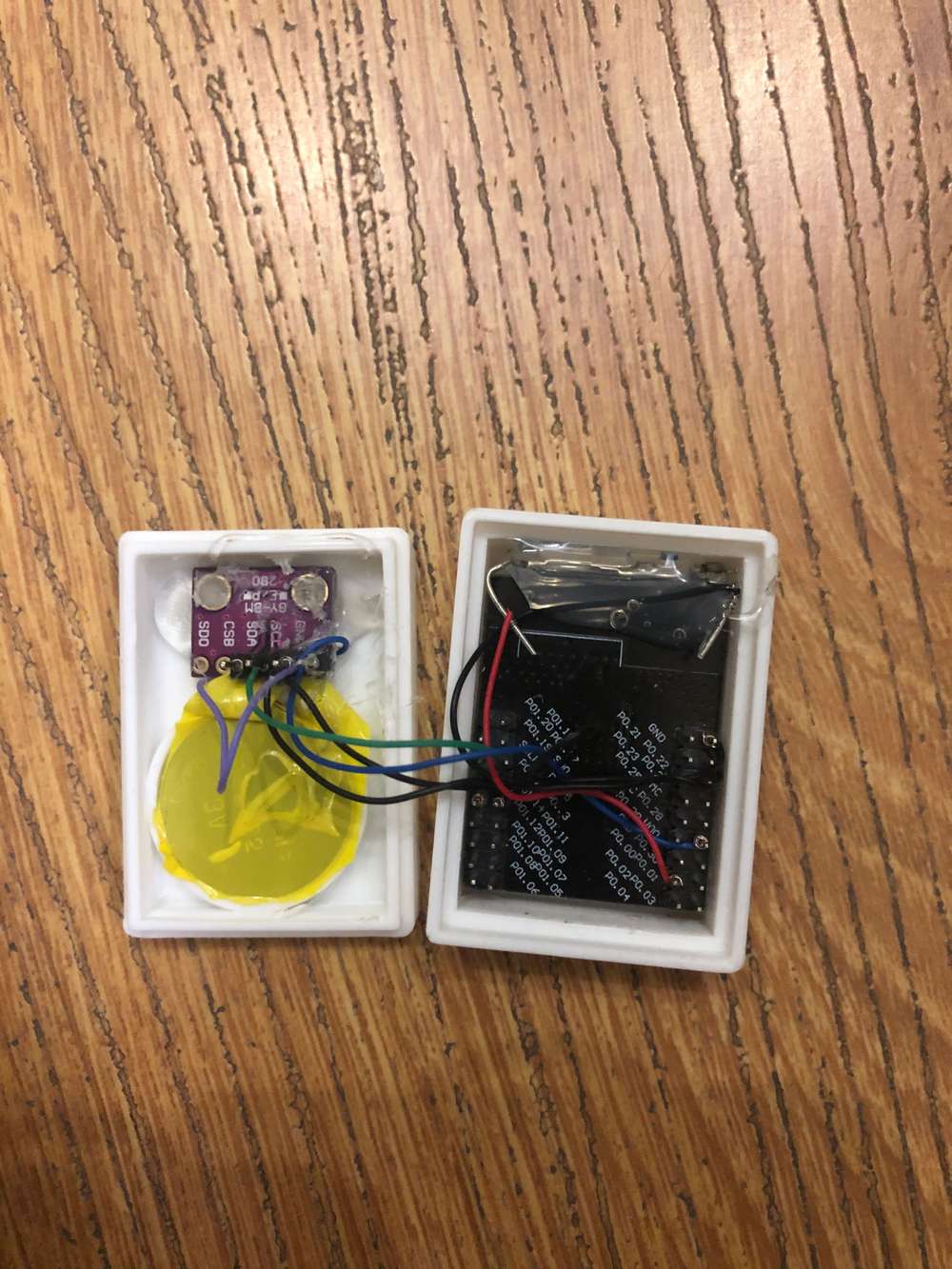

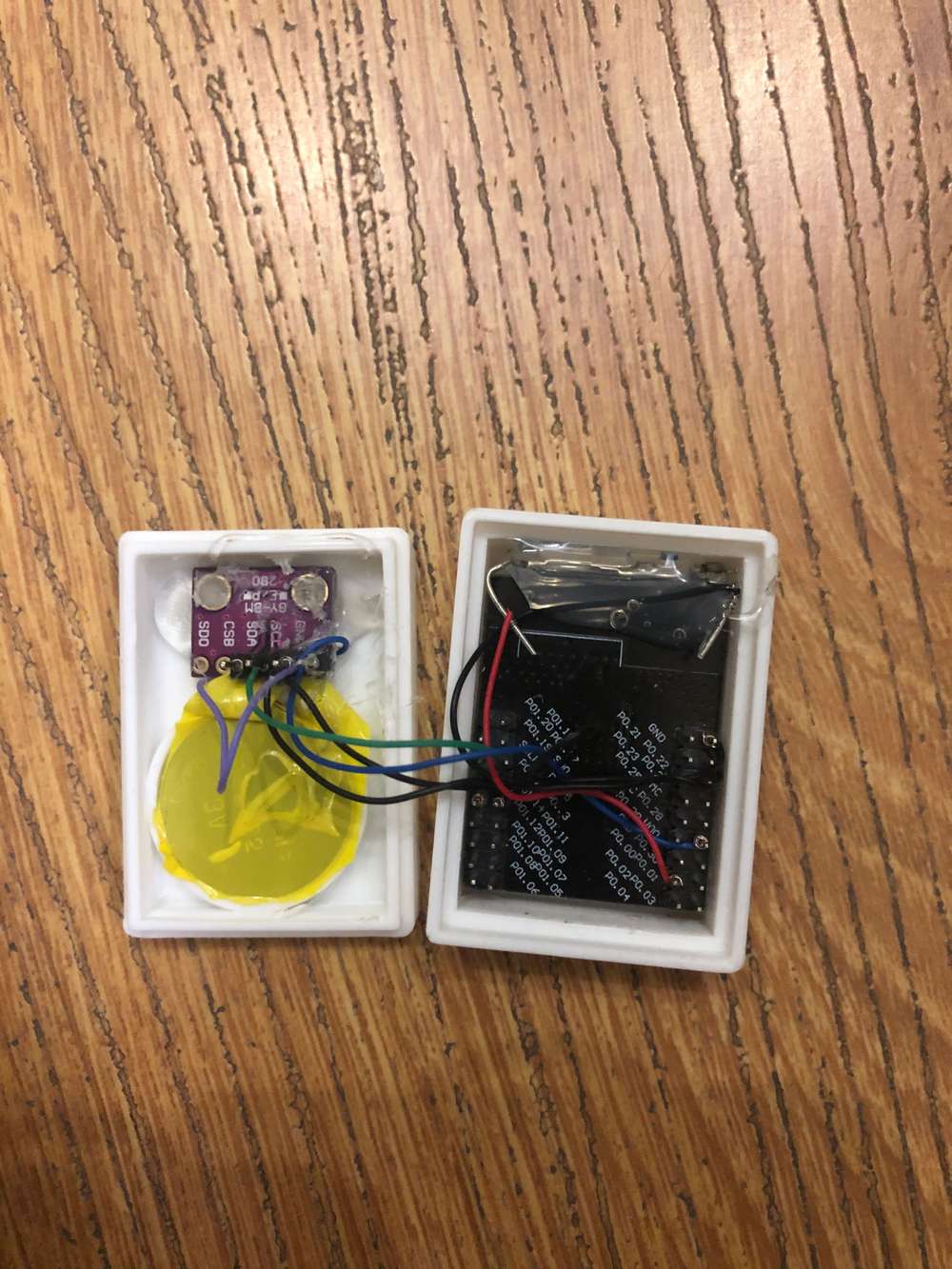

Example photos. The coin cell holder is diy. Used shaving blades and wrapped wires and taped to create a circuit.

Example photos. The coin cell holder is diy. Used shaving blades and wrapped wires and taped to create a circuit. -

@skywatch Agree with every word of yours. Not justifying myself here but wirewraps are deployed all over my house. I pour some hot glue to ensure that they don’t come loose. And then a 3D printed enclosure takes care of the elements.

Also, it helps me to quickly repurpose the hardware.

It’s just another approach.

In an ideal world - where PCB shipments never arrive from China and locally they are a but expensive , this is my poor man’s alternative.

Example photos. The coin cell holder is diy. Used shaving blades and wrapped wires and taped to create a circuit.

Example photos. The coin cell holder is diy. Used shaving blades and wrapped wires and taped to create a circuit.@Puneit-Thukral I understand 'poor mans alternative' soooo well! ;)

Glue on the wirewraps will help keep them in place and mitigate thermal stress to some degree and also stop dust and moisture. But over time the glue will change and shrink/crack and things will start to become strange with that arrangement.

It's hard to beat a good soldered joint in the end, that's why all the commercial kit is done that way.

Nice case BTW. I also am working on 3D printed cases for some nodes. Another 6 weeks of lockdown and I should have started on them! ;)

-

@Sebex said in 💬 Battery Powered Sensors:

A bit off topic maybe, but I was wondering how the 'pros' around here make the sensor small and sturdy for Arduino's with Si7021+ 2xAA battery pack. My DuPont wires seem a bit loose, so I'm wondering whether I should solder them. And perhaps someone 3d printed a case for an Arduino+Batterypack or some sorts.

You may want to try wire wrapping. It’s faster than soldering, sturdier than DuPont and you can connect multiple wires on same pin. Works wonders for gnd and vcc. Of course if the project is yanked harder, the wire wraps come out.

I made this small video for my home automation group in India. - hence prices for the wire wraps and tool are mentioned in local currency. I leant about this amazing technique from Andreas Spiess

my video

guy with Swiss accent@Puneit-Thukral interesting! Seems as a better option than Dupont, I'm gonna look into it.

You mention hot glueing the wires yourself as extra protection. But I imagine you can also put a layer of solder on it right? -

@Puneit-Thukral interesting! Seems as a better option than Dupont, I'm gonna look into it.

You mention hot glueing the wires yourself as extra protection. But I imagine you can also put a layer of solder on it right?@Sebex yes, of course. I have done that as well. In case I need to repurpose something , removing solder completely away is a tougher job for me than peeling away a layer of glue. Guess, I am just lazy. 😃

-

@Sebex yes, of course. I have done that as well. In case I need to repurpose something , removing solder completely away is a tougher job for me than peeling away a layer of glue. Guess, I am just lazy. 😃

@Puneit-Thukral haha okay I see.

Another question, your case that you use in the video snaps onto the pins perfectly it seems. Did you 3d print that yourself? I'm looking to 3D print a case for my pro mini and some other sensors that snaps in a similar way so that nothing moves around. However I'd rather copy a proven design than figuring out the tolerances myself.

-

@Puneit-Thukral haha okay I see.

Another question, your case that you use in the video snaps onto the pins perfectly it seems. Did you 3d print that yourself? I'm looking to 3D print a case for my pro mini and some other sensors that snaps in a similar way so that nothing moves around. However I'd rather copy a proven design than figuring out the tolerances myself.

@Sebex Yes, I 3D printed on my ender 3 and I am using this on nodemcu running ESPhome. But I did not design it. Here is the Thingiverse link to it.

Nodemcu caseI would love to do similar case and a larger case like this to fit other boards. Its rock solid. I do not have skills to make a linear pattern like this. I think I should figure out how to do it.

-

@Sebex Yes, I 3D printed on my ender 3 and I am using this on nodemcu running ESPhome. But I did not design it. Here is the Thingiverse link to it.

Nodemcu caseI would love to do similar case and a larger case like this to fit other boards. Its rock solid. I do not have skills to make a linear pattern like this. I think I should figure out how to do it.

@Puneit-Thukral cool, from what I read the pins are the same size as on Arduino's. I'll use this design to create one for myself.

-

@Puneit-Thukral cool, from what I read the pins are the same size as on Arduino's. I'll use this design to create one for myself.

@Sebex Do share the STL - it will be great and if you use Fusion360, then may I request for the F3D file.. I am semi-skilled when it comes to designing

-

@Sebex Do share the STL - it will be great and if you use Fusion360, then may I request for the F3D file.. I am semi-skilled when it comes to designing

@Puneit-Thukral Will do!

After closer inspection the pins of the NodeMCU seem to be a lot bigger in size. However I am struggling to find the correct sizing of Arduino Pro Mini pins (width/thickness). The spacing between pins and length of them are easy to find but I cannot find the thickness at all. Do you have an idea? -

@Puneit-Thukral Will do!

After closer inspection the pins of the NodeMCU seem to be a lot bigger in size. However I am struggling to find the correct sizing of Arduino Pro Mini pins (width/thickness). The spacing between pins and length of them are easy to find but I cannot find the thickness at all. Do you have an idea?@Sebex Will this help

https://grabcad.com/library/arduino-pro-mini-1

and should we move this conversation to another topic /PM as this is not relevant to this thread. -

@mfalkvidd, on the image I see the following marking in red

VCC ==> N/C

Do you know what the meaning is?

This VCC pin and the other VCC pin at the bottom of the image are connected. I verified with the multimeter.

So, what's the purpose of this remark?These pins at the right are used to program the pro mini. I had no problems to program after removing the led and the power regulator. The programmer used the VCC to power the pro mini without any problem...

-

@mfalkvidd, on the image I see the following marking in red

VCC ==> N/C

Do you know what the meaning is?

This VCC pin and the other VCC pin at the bottom of the image are connected. I verified with the multimeter.

So, what's the purpose of this remark?These pins at the right are used to program the pro mini. I had no problems to program after removing the led and the power regulator. The programmer used the VCC to power the pro mini without any problem...

@evb I believe that the reason is to physically (and electrically) isolate the voltage regulator from the circuit. Then only VCC will work and not RAW.

Essentially the same as removing the led or it's series resistor (only one or the other will do) and the regulator from the board.

-

@evb I believe that the reason is to physically (and electrically) isolate the voltage regulator from the circuit. Then only VCC will work and not RAW.

Essentially the same as removing the led or it's series resistor (only one or the other will do) and the regulator from the board.

@skywatch, you mean that in normal conditions with the power regulator, we connect the power supply (max 16VDC) to the raw pin and can take 3.3V or 5V, depending on which version, at the pin VCC?

And that now it isn't possible anymore with the regulator removed?I would propose to change the picture :

- there are 2 VCC pins, so the current picture is confusing

- adapt the drawing and mention to connect the battery (2xAA) 3V directly to VCC pin at the bottom (not the VCC pin in the programming row of contacts!)

@skywatch and @mfalkvidd, what do you think?

-

@skywatch, you mean that in normal conditions with the power regulator, we connect the power supply (max 16VDC) to the raw pin and can take 3.3V or 5V, depending on which version, at the pin VCC?

And that now it isn't possible anymore with the regulator removed?I would propose to change the picture :

- there are 2 VCC pins, so the current picture is confusing

- adapt the drawing and mention to connect the battery (2xAA) 3V directly to VCC pin at the bottom (not the VCC pin in the programming row of contacts!)

@skywatch and @mfalkvidd, what do you think?

@evb said in 💬 Battery Powered Sensors:

@skywatch, you mean that in normal conditions with the power regulator, we connect the power supply (max 16VDC) to the raw pin and can take 3.3V or 5V, depending on which version, at the pin VCC?

And that now it isn't possible anymore with the regulator removed?Yes, because the regulator will drain batteries faster using raw than connecting an appropriate voltage to VCC....

I would propose to change the picture :

- there are 2 VCC pins, so the current picture is confusing

- adapt the drawing and mention to connect the battery (2xAA) 3V directly to VCC pin at the bottom (not the VCC pin in the programming row of contacts!)

@skywatch and @mfalkvidd, what do you think?

I think it is up to the user to decide what pins they want to connect to and why.

-

@skywatch, you mean that in normal conditions with the power regulator, we connect the power supply (max 16VDC) to the raw pin and can take 3.3V or 5V, depending on which version, at the pin VCC?

And that now it isn't possible anymore with the regulator removed?I would propose to change the picture :

- there are 2 VCC pins, so the current picture is confusing

- adapt the drawing and mention to connect the battery (2xAA) 3V directly to VCC pin at the bottom (not the VCC pin in the programming row of contacts!)

@skywatch and @mfalkvidd, what do you think?

@evb I don't know what the N/C text means. Presumably N/C stands for Not Connected, but I don't understand what isn't (or shouldn't?) be connected, so I can't say anything about that part unfortunately.

The device can be powered through any of the two Vcc pins. Use the one that is most convenient.

I am not aware of any Arduinos that can handle 16V input on the raw pin. Most clones don't even handle 12V.

If the regulator is removed, the Arduino can no longer be powered through the raw pin.

-

@evb I don't know what the N/C text means. Presumably N/C stands for Not Connected, but I don't understand what isn't (or shouldn't?) be connected, so I can't say anything about that part unfortunately.

The device can be powered through any of the two Vcc pins. Use the one that is most convenient.

I am not aware of any Arduinos that can handle 16V input on the raw pin. Most clones don't even handle 12V.

If the regulator is removed, the Arduino can no longer be powered through the raw pin.

@mfalkvidd That's why I propose to adapt the article and image :-)

If even experienced people like you don't know what it means, what should beginners think?

I was confused and did some extra research on schematics, etc on the internet and measurements on my pro mini, afraid to blow up my only TTL to USB programmer after the modification of the pro mini for saving power consumption :sweat:The 16V was found on a schematics from the arduino.cc (https://www.arduino.cc/en/uploads/Main/Arduino-Pro-Mini-schematic.pdf). I use typically a 9V power adapter to be safe.

@skywatch You are right that the user finally decides what VCC pins he or she will connect, but we can help him and give a hint : if he uses the right VCC pin to solder his battery wire, he will have a hard time to connect his TTL to USB programmer...

-

@mfalkvidd That's why I propose to adapt the article and image :-)

If even experienced people like you don't know what it means, what should beginners think?

I was confused and did some extra research on schematics, etc on the internet and measurements on my pro mini, afraid to blow up my only TTL to USB programmer after the modification of the pro mini for saving power consumption :sweat:The 16V was found on a schematics from the arduino.cc (https://www.arduino.cc/en/uploads/Main/Arduino-Pro-Mini-schematic.pdf). I use typically a 9V power adapter to be safe.

@skywatch You are right that the user finally decides what VCC pins he or she will connect, but we can help him and give a hint : if he uses the right VCC pin to solder his battery wire, he will have a hard time to connect his TTL to USB programmer...

@evb yes I see your point. But changing things without understanding the background is troublesome, in my experience. Whoever created the original image probably had a good reason to write the N/C part. Therefore, I would prefer if any of the "Ancients" (i.e. people who joined the project before me) could chip in.

-

@mfalkvidd That's why I propose to adapt the article and image :-)

If even experienced people like you don't know what it means, what should beginners think?

I was confused and did some extra research on schematics, etc on the internet and measurements on my pro mini, afraid to blow up my only TTL to USB programmer after the modification of the pro mini for saving power consumption :sweat:The 16V was found on a schematics from the arduino.cc (https://www.arduino.cc/en/uploads/Main/Arduino-Pro-Mini-schematic.pdf). I use typically a 9V power adapter to be safe.

@skywatch You are right that the user finally decides what VCC pins he or she will connect, but we can help him and give a hint : if he uses the right VCC pin to solder his battery wire, he will have a hard time to connect his TTL to USB programmer...

@evb MySensors is a a technical project that involves both hardware, software and firmare. It is not that easy for everyone to follow a single example and then get all that they want.

Think of it as a leanring curve. You already found something that is not the way you want it to be for your use. Many others will agree with that. Some want it a different way.

The main objective is to learn all you can (or need) to get your projects to where you want them. Some out there won't have a single battery node at all, some will be more advanced in battery power conservation than the case in this thread.

I flagged a faulty 'build' example more than 2 years ago, but it is still there and still wrong. But mine works as it should because I studied the data sheets and did it the right way. Change does not come quickly it seems.

You have to put time and a lot of effort into this unless you already work in such an area or have a degree in associated methodolgy.