IR Blaster (progress)

-

@blacey: very nice design. I think there will be mysensors production for your board as people are interested... And me too, I can't wait to see all sketches and usecases...

In future, it will be great as I feel there is a hardware design movement for Mysensors, very interesting. -

Yes that could be one possible use-case.

Normally (I would imagine) the blaster would pick up your remotes commands and send them to the controller. What you actually do with this information (on the controller side) is up to you. You might wanna send a command to the z-wave controlled curtains to open. Or turn on the lights in certain rooms.

Another usecase could be to create a scene (on the controller) that turns on the tv (or fake-fireplace!) at 7pm every evening.

I'm thinking of pausing the tv when someone calls (as I've got the ip-telephone integrated in my HA soulution)...

-

Yes there are many possibilies and I like the design of the board (looks great). We have create a similar device (only on a breadboard at the moment), which has also include RF433 receive and transmit function and we can controlled it by voice. Each IR code is stored in a txt file on a SD card (raw code). A bit hard for me to explain it here with words, but I can record a video how it works in real if anyone will see it in action.

It has only one disadvantage - you need two Nano or Mini on a PCB board. -

Yes there are many possibilies and I like the design of the board (looks great). We have create a similar device (only on a breadboard at the moment), which has also include RF433 receive and transmit function and we can controlled it by voice. Each IR code is stored in a txt file on a SD card (raw code). A bit hard for me to explain it here with words, but I can record a video how it works in real if anyone will see it in action.

It has only one disadvantage - you need two Nano or Mini on a PCB board.@kalle its not that bad with minis costing few $ each....

-

Ok, here we go a short video demonstration: www.youtube.com/watch?v=y38oIZgV_cU

-

Any one tried using IR transmitter to send IR signal to AC with mini pro ( 328p ) as mysensor node. I know mini pro have limited ram / rom support.

Note: AC remote send long IR signals which may not be completely captured by IR receivers connected to mini pro. may be one try on rasp pi but that's a last resort.

-

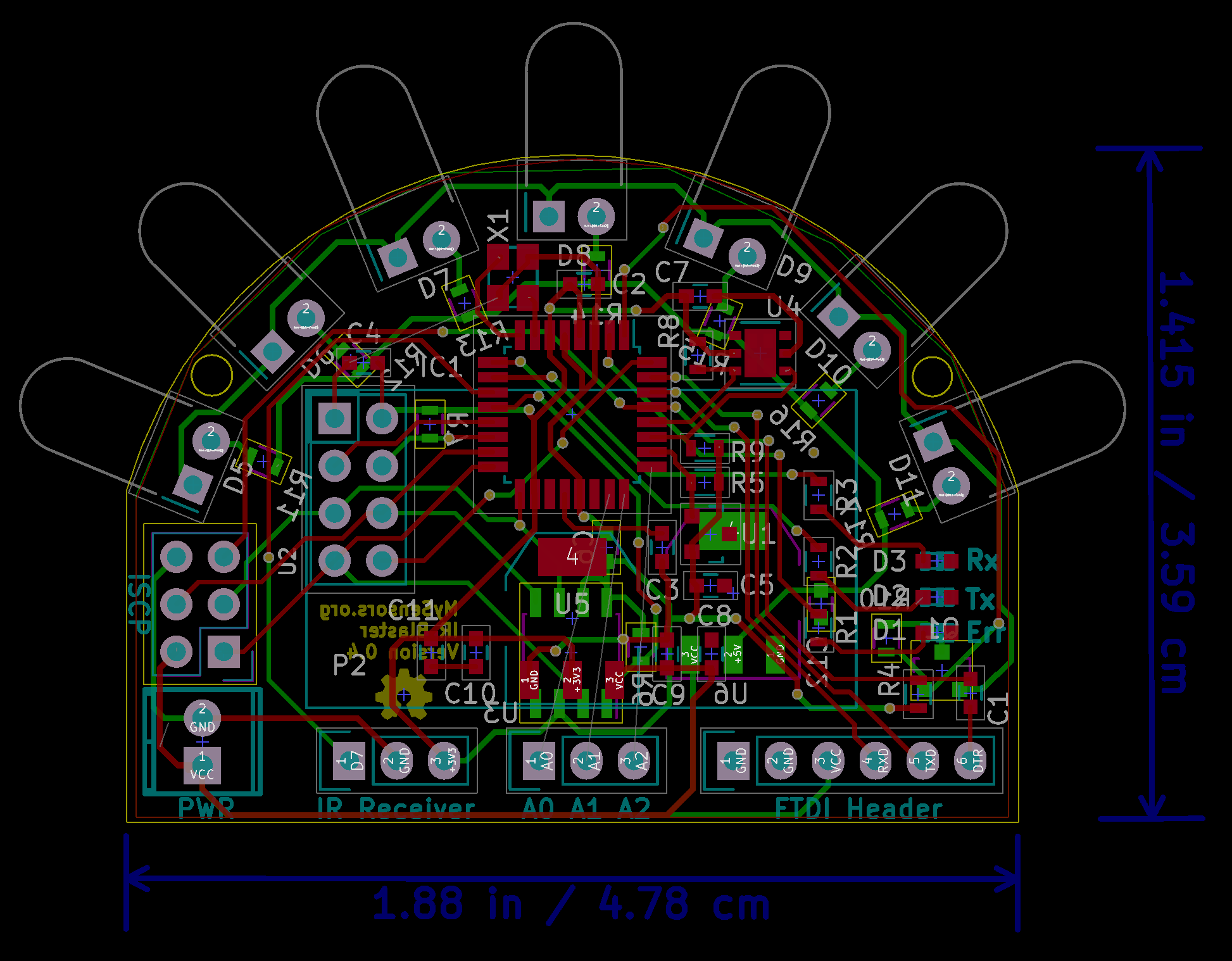

My wife and I were in Italy for the past 3 weeks with friends and family so I didn't have much time to work on the IR Blaster actuator. That said, the long flights back and forth from San Francisco to Italy afforded some concentrated time to finalize the design sufficient for public review before procuring a few prototype boards. To goal of this post is to solicit said feedback so "bring it on" after reading the details below.

@Sparkman - The biggest change is the addition of two more IR LEDs given we are now driving the circuit with a MOSFET (thanks @tbowmo) that can handle higher-current loads; this reduces the risk of IR coverage holes and increases the IR LED component options. However, I have not added a barrel connector for external LEDs to the PCB (yet?) because there are still open issues regarding circuit design to accommodate it (would welcome integration ideas).

I also have not laid the traces for A0, A1, and A2 because these are completely optional inputs, the 3 traces are difficult to place given the physical PCB layout and in fact they may not survive the final board.

Everything is in GitHub in case people want to review the details offline.

The PCB design follows - I had to increase the size of the PCB slightly to accommodate the two additional LEDs.

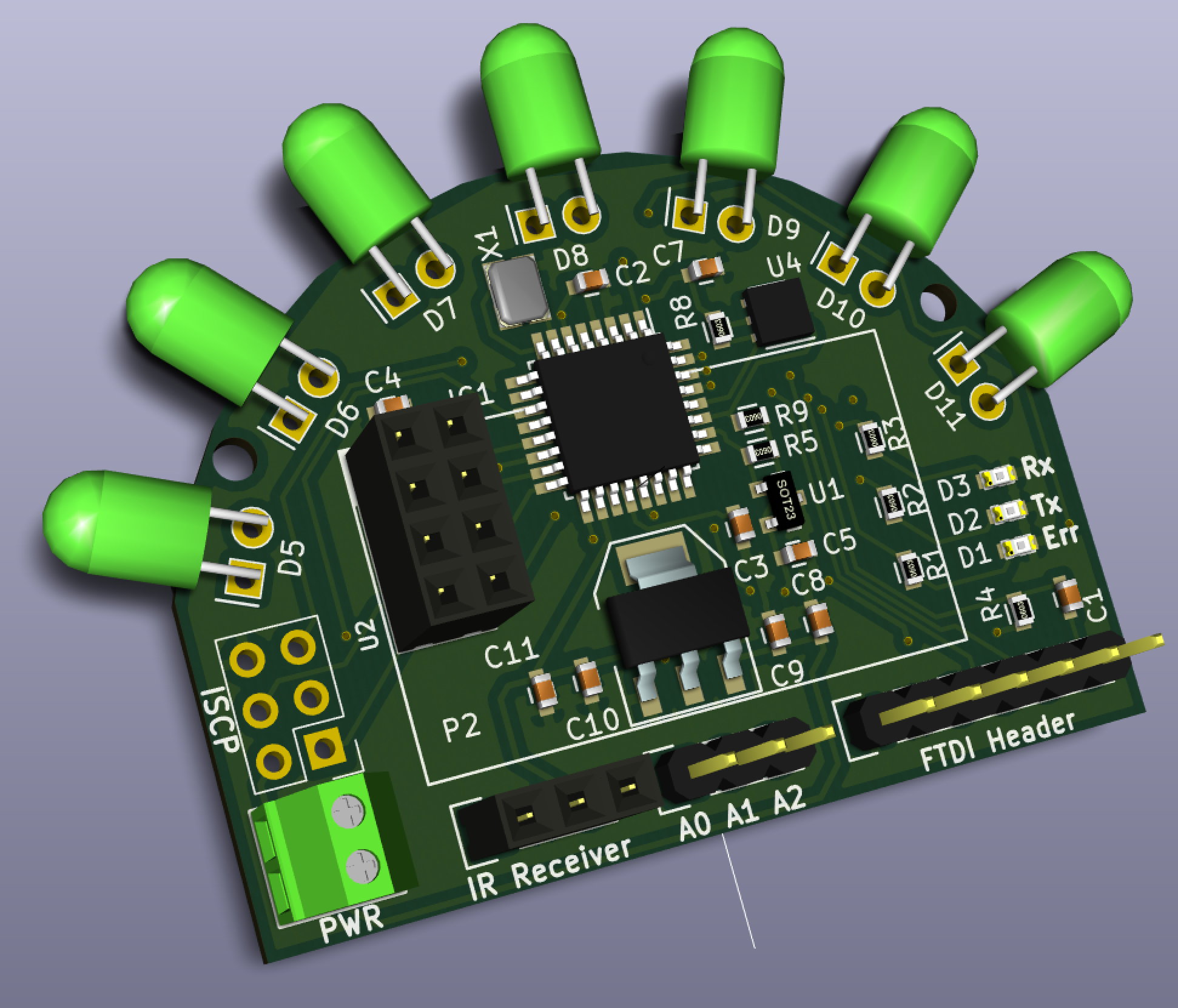

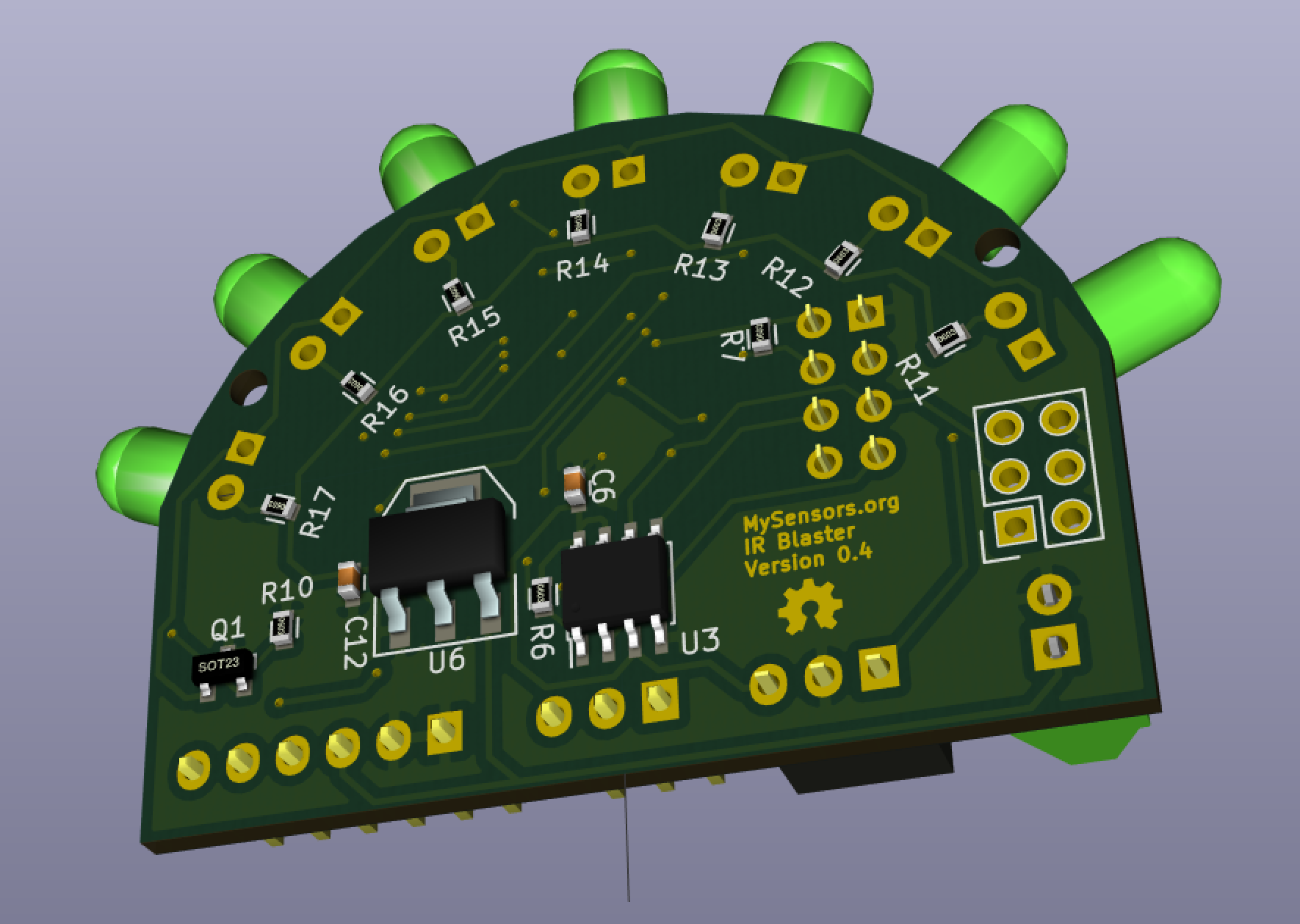

Here are two renders of the board, sans the radio daughterboard:

Finally, here is the version 0.4 schematic.

I have also developed a MySensor's IR Sensor Array that will enable me to measure the IR radiant intensity from different points in a room under varying ambient lighting scenarios. The test scenario is that an IR Sensor Array controller will illuminate the IR Blaster and then broadcast to all the IR Sensor Nodes to collect an IR measurement over a specified interval and report the IR level results back to the Sensor Array Controller at which point it will turn off the IR Blaster IRs and log the sensor node results for analysis. This should allow me to select IR LEDs to ensure maximum radiant luminosity without any IR coverage holes/gaps across the 180 degree radiance field. As an interesting side note, the development of the Sensor Array found a messaging limitation in the current MySensors.org library that @hek is planning to address in the next major release.

Ciao,

Bruce@blacey said:

@Sparkman - The biggest change is the addition of two more IR LEDs given we are now driving the circuit with a MOSFET (thanks @tbowmo) that can handle higher-current loads; this reduces the risk of IR coverage holes and increases the IR LED component options. However, I have not added a barrel connector for external LEDs to the PCB (yet?) because there are still open issues regarding circuit design to accommodate it (would welcome integration ideas).

Sorry for the slow response Bruce, it's been crazy busy at work and a few projects around the house. I have a few days off in a row now so will finish testing. The circuit board design looks great and I'd be interested in a few as well based on current design.

Cheers

Al -

@ServiceXp said:

@blacey Really lovin this.. You plan to sell?

If there is enough community interest and demand, we (@hek et. al.) will offer the IR Blaster in the same fashion as @tbowmo's pioneering and very successful Sensebender Micro and hopefully in-development Gateway Device that I am personally jazzed about. Any proceeds from IR Blaster hardware sales will go directly to supporting the MySensors.org project (monthly hosting fees, etc.). So to answer that question we need to know who else would buy one if we make it available so we can estimate the batch size for an initial run. Anyone interested is encouraged to weigh in here.

-

@blacey said:

@Sparkman - The biggest change is the addition of two more IR LEDs given we are now driving the circuit with a MOSFET (thanks @tbowmo) that can handle higher-current loads; this reduces the risk of IR coverage holes and increases the IR LED component options. However, I have not added a barrel connector for external LEDs to the PCB (yet?) because there are still open issues regarding circuit design to accommodate it (would welcome integration ideas).

Sorry for the slow response Bruce, it's been crazy busy at work and a few projects around the house. I have a few days off in a row now so will finish testing. The circuit board design looks great and I'd be interested in a few as well based on current design.

Cheers

Al@Sparkman said:

Sorry for the slow response Bruce, it's been crazy busy at work and a few projects around the house. I have a few days off in a row now so will finish testing. The circuit board design looks great and I'd be interested in a few as well based on current design.

Al, no worries, I know the crazy busy drill! ;) I hope the work and home projects went well - let me know what you determine based upon your testing.

-

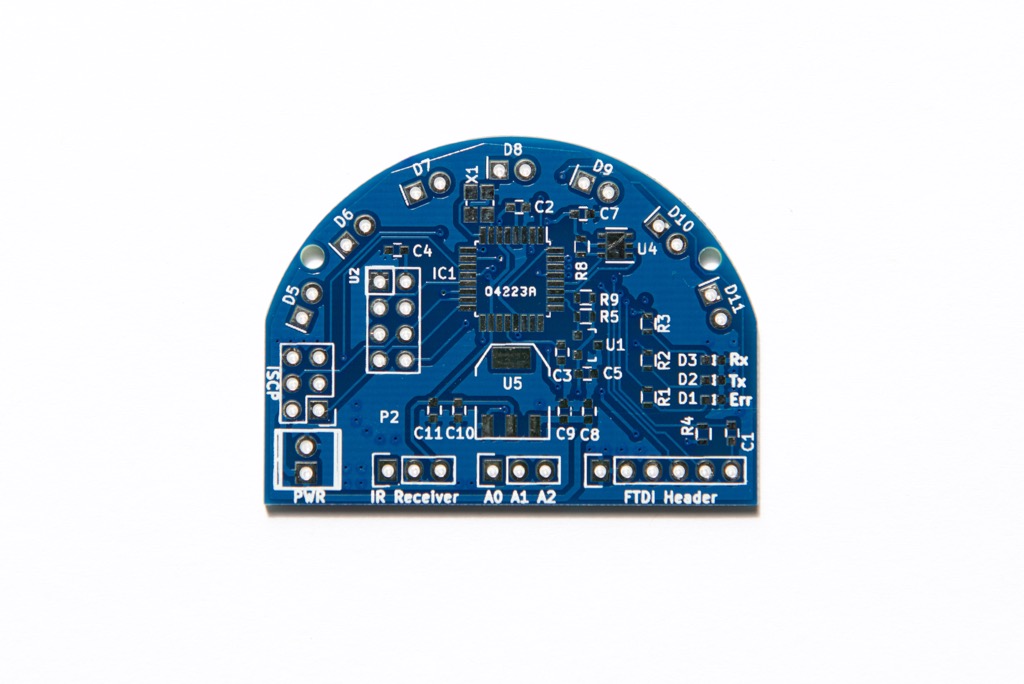

First board revision just arrived from the fab house in China! Boards look good other than the MySensors IR Blaster v0.5 that I placed in the solder paste layer instead of the silk screen layer because the font is too small. Unfortunately the fab house was quicker than I because I haven't even had a chance to finalize the BOM and order the components. Need to get that in gear so I can assemble the first board early next week.

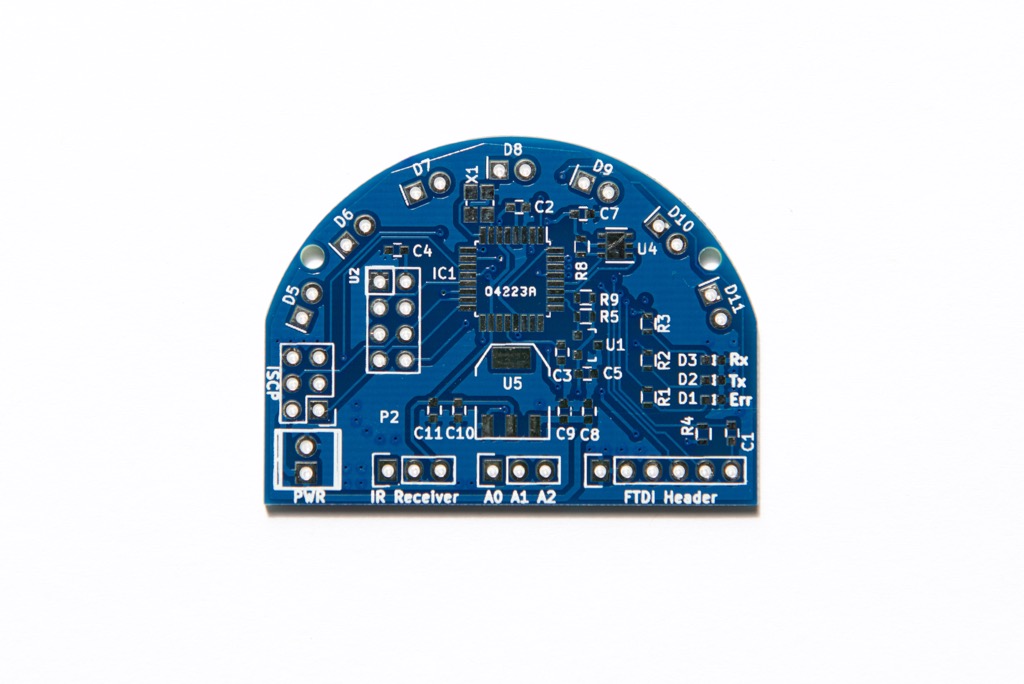

Top of Board

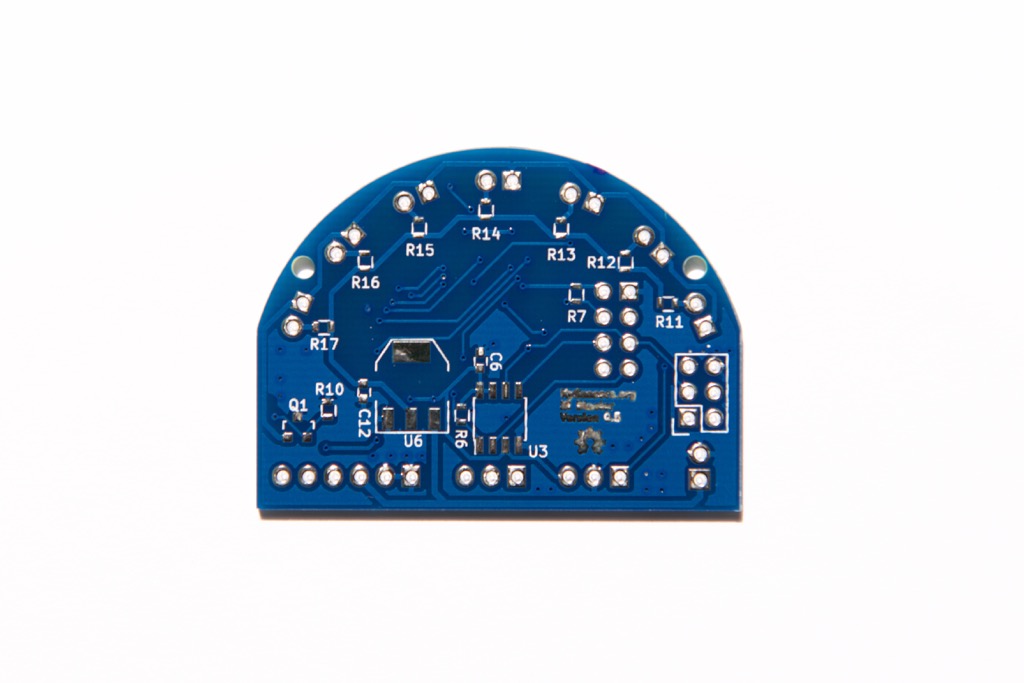

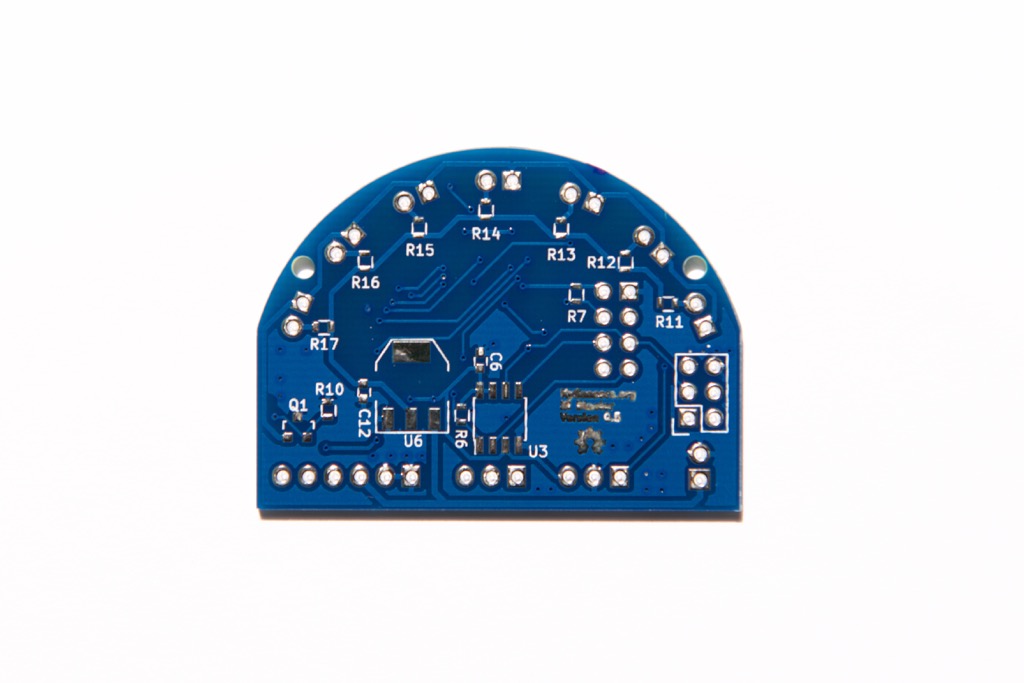

Bottom of Board

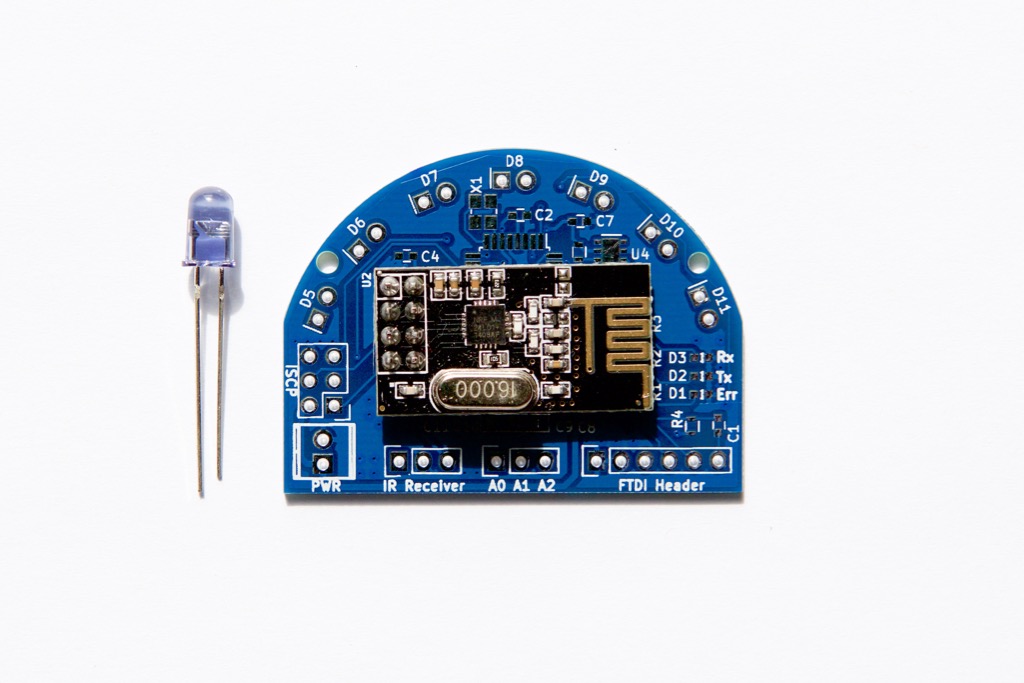

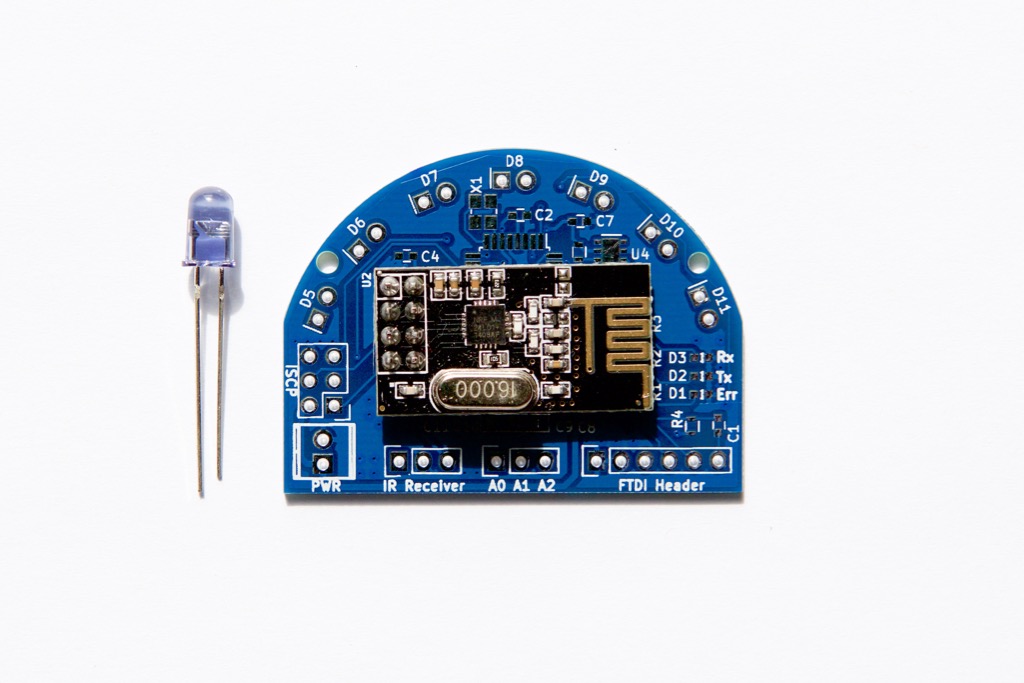

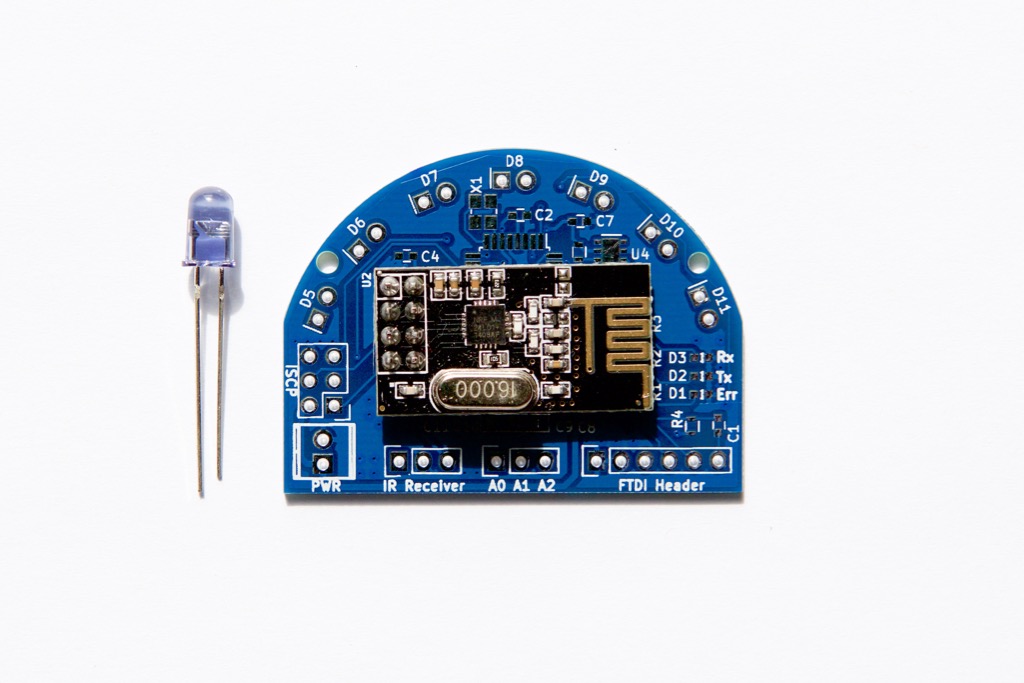

Board with radio set and LED for relative size perspective

-

First board revision just arrived from the fab house in China! Boards look good other than the MySensors IR Blaster v0.5 that I placed in the solder paste layer instead of the silk screen layer because the font is too small. Unfortunately the fab house was quicker than I because I haven't even had a chance to finalize the BOM and order the components. Need to get that in gear so I can assemble the first board early next week.

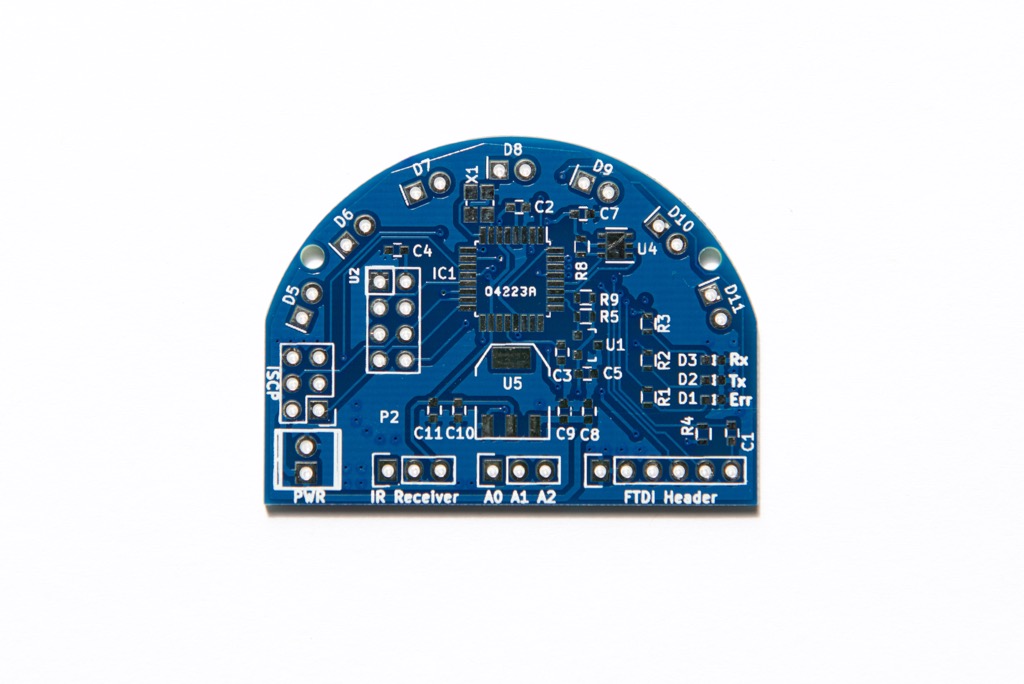

Top of Board

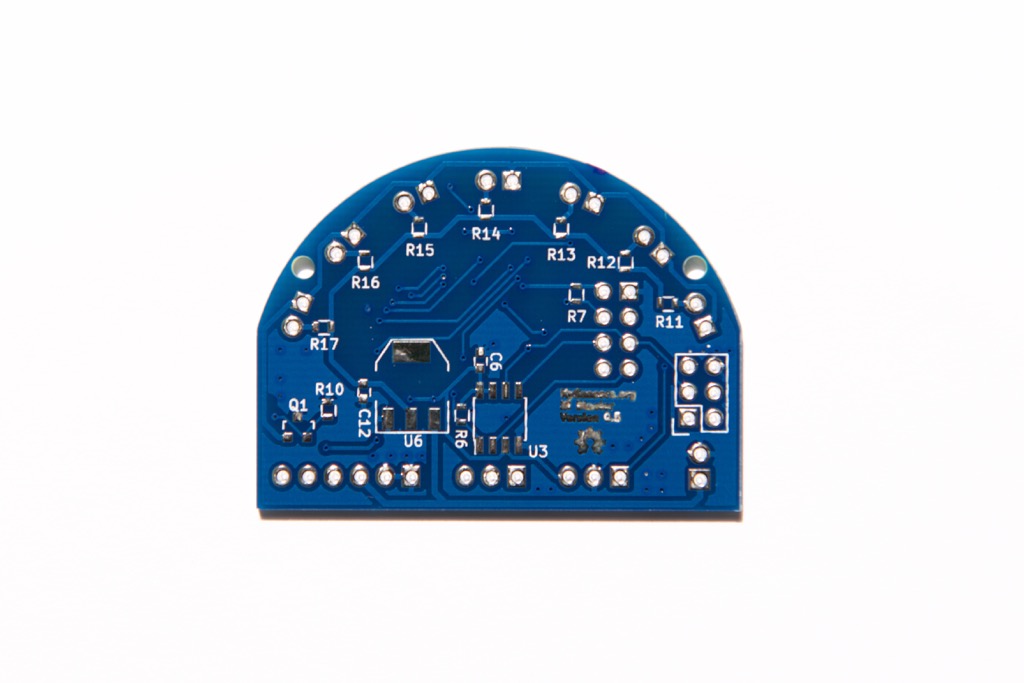

Bottom of Board

Board with radio set and LED for relative size perspective

-

First board revision just arrived from the fab house in China! Boards look good other than the MySensors IR Blaster v0.5 that I placed in the solder paste layer instead of the silk screen layer because the font is too small. Unfortunately the fab house was quicker than I because I haven't even had a chance to finalize the BOM and order the components. Need to get that in gear so I can assemble the first board early next week.

Top of Board

Bottom of Board

Board with radio set and LED for relative size perspective

-

Any one tried using IR transmitter to send IR signal to AC with mini pro ( 328p ) as mysensor node. I know mini pro have limited ram / rom support.

Note: AC remote send long IR signals which may not be completely captured by IR receivers connected to mini pro. may be one try on rasp pi but that's a last resort.

@Dheeraj said:

Any one tried using IR transmitter to send IR signal to AC with mini pro ( 328p ) as mysensor node. I know mini pro have limited ram / rom support.

Note: AC remote send long IR signals which may not be completely captured by IR receivers connected to mini pro. may be one try on rasp pi but that's a last resort.

Not yet but take a look at http://www.analysir.com/blog/2014/03/19/air-conditioners-problems-recording-long-infrared-remote-control-signals-arduino/ for a good explanation of what you are probably experiencing. From a hardware stand-point, the IR Blaster should be able handle the longer IR codes, it will just be a matter of adding the required support to the firmware.

-

-

@Dheeraj said:

Any one tried using IR transmitter to send IR signal to AC with mini pro ( 328p ) as mysensor node. I know mini pro have limited ram / rom support.

Note: AC remote send long IR signals which may not be completely captured by IR receivers connected to mini pro. may be one try on rasp pi but that's a last resort.

Not yet but take a look at http://www.analysir.com/blog/2014/03/19/air-conditioners-problems-recording-long-infrared-remote-control-signals-arduino/ for a good explanation of what you are probably experiencing. From a hardware stand-point, the IR Blaster should be able handle the longer IR codes, it will just be a matter of adding the required support to the firmware.

@blacey Thanks. I have not seen this in my searches. looks promising. I'll give their sketch a try and see if it records the codes properly (as far as I can say). all other libs failed miserably.

-

Hmm.. If a IR recorder is included in the sketch, how would you handle different carrier frequencies of the remotes?

It could be anything between 35Khz and 40Khz (or 400Khz if it's B&O equipment), and IR receivers are made with narrow filters. This could mean that if you use 38Khz carrier frequency on equipment that originally uses 35Khz, then because of the attenuation in the filters, the range is very low.

Ideally we need something to detect the carrier frequency as well.. But don't know if that is possible to obtain easily with an arduino setup