💬 Very narrow and minimal switch node

-

@GertSanders How snug is your enclosure? I saw @m26872 used 17x20mm for his slim node, but I was able to find in the UK 16x16mm trunking, which I think maybe a little bit small.

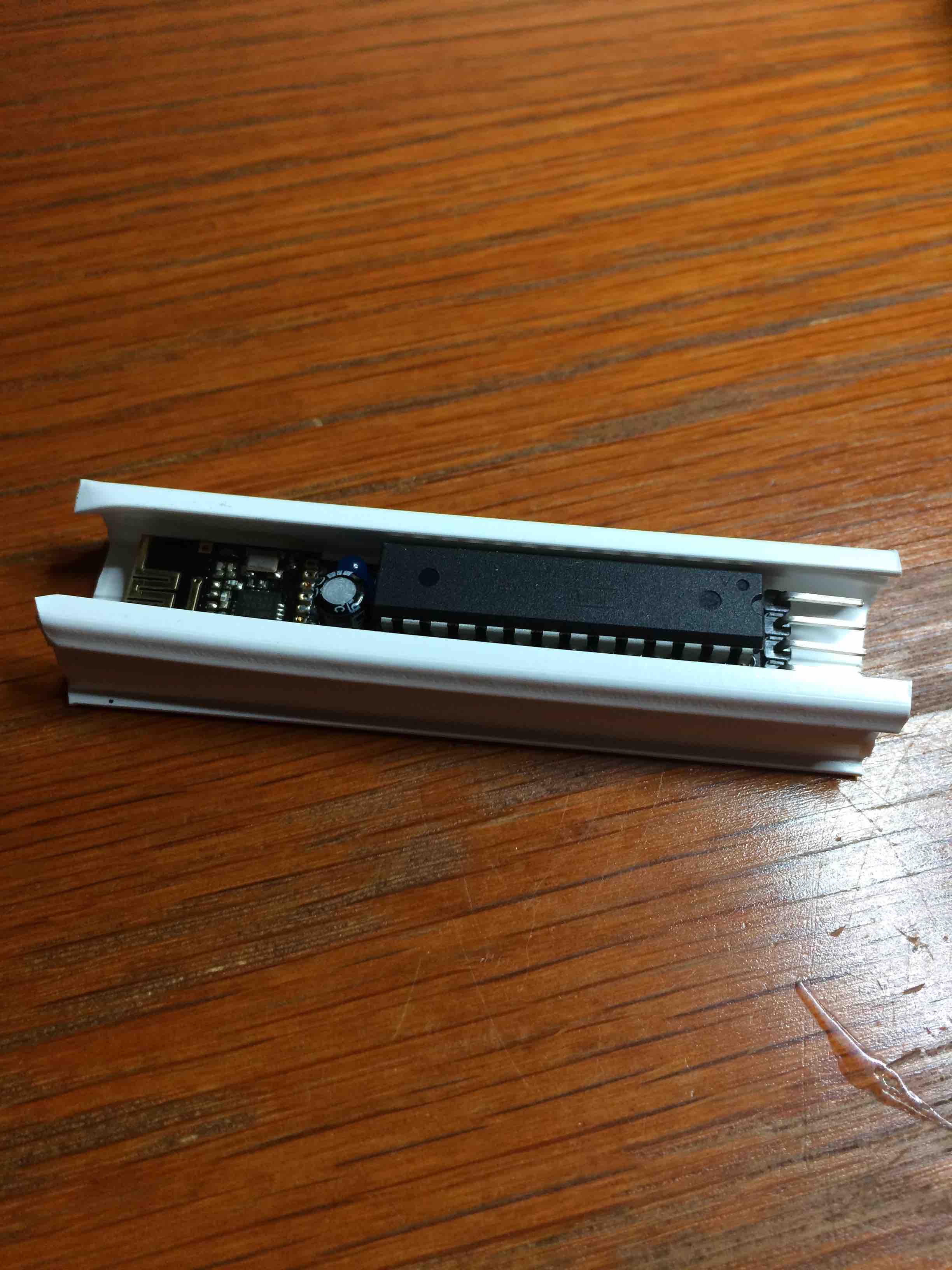

Here are some images of the very narrow node in a 16x16mm cable duct. The batteries are AAA type.

-

@GertSanders - Thanks for photos. I have got 16x16mm trunking and just waiting for some spare parts. Will be posting photos shortly.

-

@alexsh1

I also use a 16x16mm cable guide and it just fits, the batteries are in batteryholders and therefor they stick out by 1mm. Without the batteryholder they fit perfectly.

The board is 13mm wide at the base which allows passing a few wires next to it. So 16x16 is ok for my narrow board.This option with a pir...

or a magnet sensor.

What is the battery live? -

This option with a pir...

or a magnet sensor.

What is the battery live?@Dylano said:

This option with a pir...

or a magnet sensor.This is more a reed sensor. For PIR the size is just not right IMHO.

Given that it sleeps most of the time, the battary life should be excellent.

I do not know, maybe @GertSanders has got more comments? -

@Dylano said:

This option with a pir...

or a magnet sensor.This is more a reed sensor. For PIR the size is just not right IMHO.

Given that it sleeps most of the time, the battary life should be excellent.

I do not know, maybe @GertSanders has got more comments?@alexsh1 with a switch (reed or mechanical) i see a consumption of around 5micro amperes in sleep mode. 2 AAA should last minimum a year. We will see as my node is only started last week.

A small PIR sensor is possible, see the "small AA project" and the mini PIR example.

http://forum.mysensors.org/topic/2715/slim-node-as-a-mini-2aa-battery-pir-motion-sensor

No idea what lifetime to expect there.

-

I've just ordered a batch of these. Really cool, I can't wait to receive them. Thanks for the great work!

-

YES, my first is working. More to make. In my home now: "Big brother is watching you" Placed my first at the door of the refrigerator ;-)

@GertSanders, you write:

powering something with low consumption

You can set both pins D2 and D3 of the processor to OUTPUT, do not mount the pull up resistors, do not activate the internal PullUPs, and by setting one of the pins to HIGH and the other to LOW you can power something. You will need to take care that a maximum of 20mA is consumed, as this is the recommended maximum amperage the pins of the atmega328 can drive or source.Sure not to mount the pull up resistors. But how do de-activate the internal PullUPs, and by setting one of the pins to HIGH and the other to LOW.

Can you explain in "jip en Janneke/suske en wiske" language how to. With the help of this site I made my first one:

https://forum.mysensors.org/topic/3018/tutorial-how-to-burn-1mhz-8mhz-bootloader-using-arduino-ide-1-6-5-r5 -

YES, my first is working. More to make. In my home now: "Big brother is watching you" Placed my first at the door of the refrigerator ;-)

@GertSanders, you write:

powering something with low consumption

You can set both pins D2 and D3 of the processor to OUTPUT, do not mount the pull up resistors, do not activate the internal PullUPs, and by setting one of the pins to HIGH and the other to LOW you can power something. You will need to take care that a maximum of 20mA is consumed, as this is the recommended maximum amperage the pins of the atmega328 can drive or source.Sure not to mount the pull up resistors. But how do de-activate the internal PullUPs, and by setting one of the pins to HIGH and the other to LOW.

Can you explain in "jip en Janneke/suske en wiske" language how to. With the help of this site I made my first one:

https://forum.mysensors.org/topic/3018/tutorial-how-to-burn-1mhz-8mhz-bootloader-using-arduino-ide-1-6-5-r5@Bolliebol

You need to use these instructions:void setup()

{

pinMode(2, OUTPUT);

digitalWrite(2, HIGH);

pinMode(3, OUTPUT);

digitalWrite(2, LOW);// this makes pin 2 the "plus" side and pin 3 the "minus" side.

// Connect your low power consuming thing between these two pins as if they are battery pins.

// If you need to power off the device, just do

digitalWrite(2,LOW);

}

-

To anyone wanting to build this project: take note that it uses machine pin female headers to seat the mcu. Ordinary female headers won't make a good enough connection with the legs of the atmega328.

-

Hi, I have finally receive your narrow board.. I try with a Si7021 sensor (the GY-21 ebay version) and I have no success. But with your other board, because I have your 2 other board version (ac/dc board and the small battery one) it's working with no problem. The difference I think is the first board without external crystal. After reading in forum, I think with Slim board version, i'm not the first with this problem. Did you test your board with si7021 sensor, or can you give my a clue ?? Thanks

-

Hi, I have finally receive your narrow board.. I try with a Si7021 sensor (the GY-21 ebay version) and I have no success. But with your other board, because I have your 2 other board version (ac/dc board and the small battery one) it's working with no problem. The difference I think is the first board without external crystal. After reading in forum, I think with Slim board version, i'm not the first with this problem. Did you test your board with si7021 sensor, or can you give my a clue ?? Thanks

-

@Carl-H did you have an error message? Providing logs would also help. Which address and library did you use for this sensor please?

@alexsh1 I use the this lib: https://github.com/LowPowerLab/SI7021 My board freeze when initialize with begin function.

I can't have the error exactly because this board don't have any FTDI connection. But the same atmega328p chip with other board, it's working !! I think again is it because the board use internal oscillator.

-

@alexsh1 I use the this lib: https://github.com/LowPowerLab/SI7021 My board freeze when initialize with begin function.

I can't have the error exactly because this board don't have any FTDI connection. But the same atmega328p chip with other board, it's working !! I think again is it because the board use internal oscillator.

@Carl-H if your atmega328p programmed to use the internal oscillator, I do not think this would cause a problem with Si7021.

You most likely need to assemble the same on the breadboard and connect the FTDI - I would be a simple error. Once I had a problem with Si7021 using a different address to the one in the library. Took me a while to troubleshoot.

Without logs, this is a pure guess unfortunately -

@alexsh1 I use the this lib: https://github.com/LowPowerLab/SI7021 My board freeze when initialize with begin function.

I can't have the error exactly because this board don't have any FTDI connection. But the same atmega328p chip with other board, it's working !! I think again is it because the board use internal oscillator.

@Carl-H

Did you order the latest version of the slim board ? It has solderjumpers you need to use if you want the SCL/SDA pins connected.

If there is no solderbridge on either solderpad, the D2, SDA and SCL of the atmega are not connected. This board also requires the fuses of the atmega to be set to internal oscillator as there is no external crystal. -

@Carl-H

Did you order the latest version of the slim board ? It has solderjumpers you need to use if you want the SCL/SDA pins connected.

If there is no solderbridge on either solderpad, the D2, SDA and SCL of the atmega are not connected. This board also requires the fuses of the atmega to be set to internal oscillator as there is no external crystal.@GertSanders Yes I used the version 1.1 and yes I connect the jumper pad correctly.

After some hard test, I found the problem, is it my solder or a bad batch of SMD NRF24L01 :( I explain my problem, I make a good solder of the SMD NRF24L01, I put power on the board for testing it and is it working for 2-3 loop because I open the led (d6) on each loop. After 2-3 loop the board is freezing. After I check again the solder and some pin of the SMD NRF24L01+ is shorted (check with my multi-meter). I can explain why, is it my skill of soldering or a bad batch of SMD NRF24lL01+. I test with 5 different and always the same, after power it.. it will shorted some pin. I make my order on this ebay store: http://www.ebay.ca/itm/401054727893?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

-

@GertSanders Yes I used the version 1.1 and yes I connect the jumper pad correctly.

After some hard test, I found the problem, is it my solder or a bad batch of SMD NRF24L01 :( I explain my problem, I make a good solder of the SMD NRF24L01, I put power on the board for testing it and is it working for 2-3 loop because I open the led (d6) on each loop. After 2-3 loop the board is freezing. After I check again the solder and some pin of the SMD NRF24L01+ is shorted (check with my multi-meter). I can explain why, is it my skill of soldering or a bad batch of SMD NRF24lL01+. I test with 5 different and always the same, after power it.. it will shorted some pin. I make my order on this ebay store: http://www.ebay.ca/itm/401054727893?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

@Carl-H

Those modules should be OK. Soldering this radio is indeed very tricky. -

@Carl-H

Those modules should be OK. Soldering this radio is indeed very tricky.@GertSanders Thanks... after practice and practice and practice again... I have now 4 narrow board working with si7021 sensor... I need to put my solder tip very high and use alot of flux.. :)

-

Hi, if external reset is not needed, why you do not short /RESET pin 1 directly to Vcc to avoid resets in noisy environments?

@tlustoch

Good point, will add that to version 1.2 (if I ever find the time :-))