My 2AA battery sensor

-

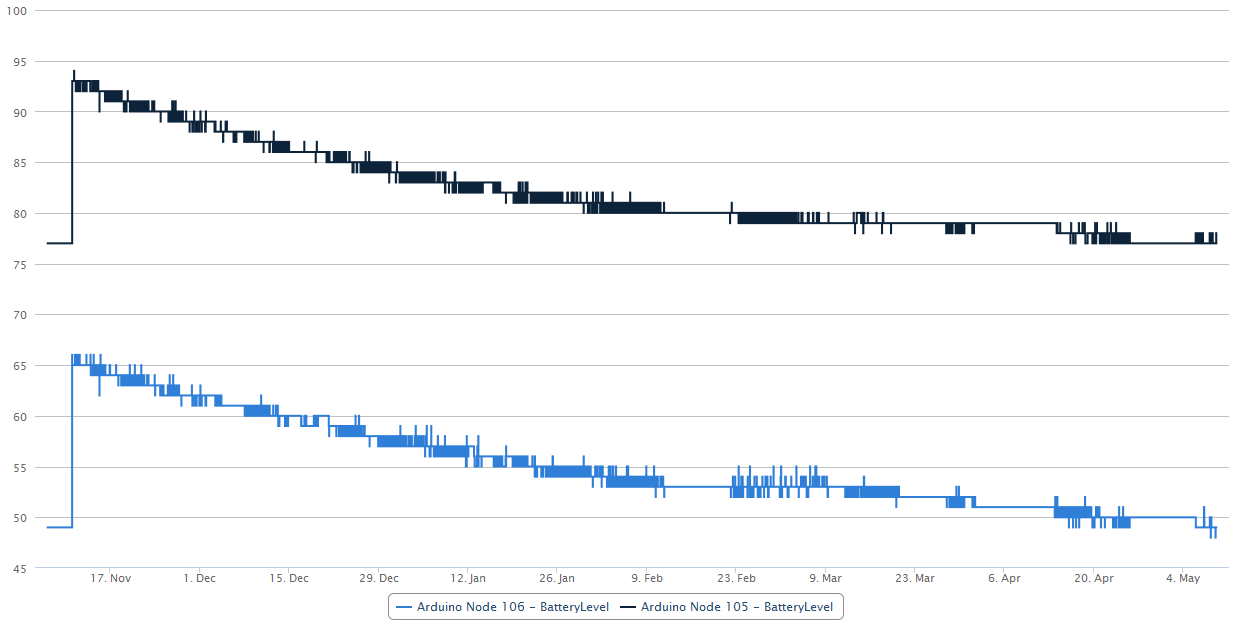

I declare the 6 months criteria easily passed. And the chinese step up regulator to be good value for money. Next target; 12 months.

The 12 months target was done a few days ago. Today's status 105: 63% and 106: 27%

I had a thought to celebrate their birthday by retrieve old Vera data and make nice plot, but that has to wait. Next, 18 months.Just to clarify that these are no "sleeping" nodes; they transmit 100-150 messages each every day.

-

Battery level status report after 18 months:

Node 105: 51%

Node 106 (with used batteries): Died early January.Next 24 months.

-

Hey @m26872 Congrats on the testing and results! Looks great! I was wondering if I could get your feedback on something. I'm trying to build a very low powered ( 2 x AA ) Battery powered 3 in 1 sensor. ( Platform is a Pro Mini 8Mhz, 3.3v, with an PIR HC-SR501, NRF24L01, and a DHT 11 Temp and Hum sensor. The sensor should also report battery power periodically ideally using the vcc library ( not implemented yet ). Because these components use power hungry devices ( PIR, DHT ), I have already moded the PIR to work at 3.3, and have removed the regulator / LED from the pro mini. Would it make sense to use a step up / down regulator, or power directly from the VCC pin? I can't decide what would be more effective in prolonging battery life? Also, in terms of reporting battery state. I'm not sure what would be best also, hence the question around the VCC library?

Below is my sketch. It is really taken from various posts on this forum and stitched together. If you could have a peak at it, and see if it is "optimal", as I don't believe it is today. ie: Perhaps I could only report temp / hum if it changes +/- a degree? Or send everything in a single radio announcement, then "Deep Sleep"? Lots of questions, and of course I am sure there are lots of answers. I'm just trying to build the most optimal battery efficient ( 2 x AA ) powered sensor no problem right! :) Below is my current code:

#define MY_GW_ID 31 // Enable debug prints #define MY_DEBUG // Enable and select radio type attached #define MY_RADIO_NRF24 //#define MY_RADIO_RFM69 #include <SPI.h> #include <MySensor.h> #include <DHT.h> int BATTERY_SENSE_PIN = A0; // select the input pin for the battery sense point //Constants #define SKETCH_NAME "3 in 1 Sensor" #define SKETCH_VERSION "1.0" #define CHILD_ID_HUM 0 // Child id for Humidity #define CHILD_ID_TEMP 1 // Child id for Temperature #define CHILD_ID_MOT 2 // Id of the sensor child #define HUMIDITY_SENSOR_DIGITAL_PIN 7 // Where is my DHT22 data pin connected to #define DIGITAL_INPUT_SENSOR 3 // The digital input you attached your motion sensor. (Only 2 and 3 generates interrupt!) #define INTERRUPT DIGITAL_INPUT_SENSOR-2 // Usually the interrupt = pin -2 (on uno/nano anyway) //Misc. variables uint8_t switchState = 2; unsigned long SLEEP_TIME = 820000; // Sleep time between reads (in milliseconds) (close to 15') unsigned long SLEEP_TIME2 = 275000; // Sleep time after int. (in milliseconds) (close to 5') uint8_t cycleInProgress = 0; uint8_t firstReportDone = 0; uint8_t firstReportWithZeroDone = 0; int oldBatteryPcnt = 0; MySensor gw; DHT dht; float lastTemp = 0 ; float lastHum = 0 ; boolean lastTripped = false ; boolean metric = true; MyMessage msgHum(CHILD_ID_HUM, V_HUM); MyMessage msgTemp(CHILD_ID_TEMP, V_TEMP); MyMessage msgMot(CHILD_ID_MOT, V_TRIPPED); void setup() { // use the 1.1 V internal reference #if defined(__AVR_ATmega2560__) analogReference(INTERNAL1V1); #else analogReference(INTERNAL); #endif gw.begin(); dht.setup(HUMIDITY_SENSOR_DIGITAL_PIN); // Send the Sketch Version Information to the Gateway gw.sendSketchInfo("3 in 1 Sensor", "1.0"); pinMode(DIGITAL_INPUT_SENSOR, INPUT); // sets the motion sensor digital pin as input // Register all sensors to gw (they will be created as child devices) gw.present(CHILD_ID_HUM, S_HUM); gw.present(CHILD_ID_TEMP, S_TEMP); gw.present(CHILD_ID_MOT, S_MOTION); metric = gw.getConfig().isMetric; } void loop() { delay(dht.getMinimumSamplingPeriod()); float temperature = dht.getTemperature(); float humidity = dht.getHumidity(); if (isnan(temperature)) { Serial.println("Failed reading temperature from DHT"); } else if (temperature != lastTemp) { lastTemp = temperature; if (!metric) { temperature = dht.toFahrenheit(temperature); } gw.send(msgTemp.set(temperature, 1)); Serial.print("T: "); Serial.println(temperature); } if (isnan(humidity)) { Serial.println("Failed reading humidity from DHT"); } else if (humidity != lastHum) { lastHum = humidity; gw.send(msgHum.set(humidity, 1)); Serial.print("H: "); Serial.println(humidity); } // get the battery Voltage int sensorValue = analogRead(BATTERY_SENSE_PIN); #ifdef DEBUG Serial.println(sensorValue); #endif // 1M, 470K divider across battery and using internal ADC ref of 1.1V // Sense point is bypassed with 0.1 uF cap to reduce noise at that point // ((1e6+470e3)/470e3)*1.1 = Vmax = 3.44 Volts // 3.44/1023 = Volts per bit = 0.003363075 float batteryV = sensorValue * 0.003363075; int batteryPcnt = sensorValue / 10; #ifdef DEBUG Serial.print("Battery Voltage: "); Serial.print(batteryV); Serial.println(" V"); Serial.print("Battery percent: "); Serial.print(batteryPcnt); Serial.println(" %"); #endif // Read digital motion value boolean tripped = digitalRead(DIGITAL_INPUT_SENSOR) == HIGH; if (tripped != lastTripped ) { Serial.println(tripped); gw.send(msgMot.set(tripped?"1":"0")); // Send tripped value to gw } if (oldBatteryPcnt != batteryPcnt) { // Power up radio after sleep gw.sendBatteryLevel(batteryPcnt); oldBatteryPcnt = batteryPcnt; } // Sleep until interrupt comes in on motion sensor. Send update every two minute. gw.sleep(INTERRUPT, CHANGE, 0 ); }thanks very much!

-

Hey @m26872 Congrats on the testing and results! Looks great! I was wondering if I could get your feedback on something. I'm trying to build a very low powered ( 2 x AA ) Battery powered 3 in 1 sensor. ( Platform is a Pro Mini 8Mhz, 3.3v, with an PIR HC-SR501, NRF24L01, and a DHT 11 Temp and Hum sensor. The sensor should also report battery power periodically ideally using the vcc library ( not implemented yet ). Because these components use power hungry devices ( PIR, DHT ), I have already moded the PIR to work at 3.3, and have removed the regulator / LED from the pro mini. Would it make sense to use a step up / down regulator, or power directly from the VCC pin? I can't decide what would be more effective in prolonging battery life? Also, in terms of reporting battery state. I'm not sure what would be best also, hence the question around the VCC library?

Below is my sketch. It is really taken from various posts on this forum and stitched together. If you could have a peak at it, and see if it is "optimal", as I don't believe it is today. ie: Perhaps I could only report temp / hum if it changes +/- a degree? Or send everything in a single radio announcement, then "Deep Sleep"? Lots of questions, and of course I am sure there are lots of answers. I'm just trying to build the most optimal battery efficient ( 2 x AA ) powered sensor no problem right! :) Below is my current code:

#define MY_GW_ID 31 // Enable debug prints #define MY_DEBUG // Enable and select radio type attached #define MY_RADIO_NRF24 //#define MY_RADIO_RFM69 #include <SPI.h> #include <MySensor.h> #include <DHT.h> int BATTERY_SENSE_PIN = A0; // select the input pin for the battery sense point //Constants #define SKETCH_NAME "3 in 1 Sensor" #define SKETCH_VERSION "1.0" #define CHILD_ID_HUM 0 // Child id for Humidity #define CHILD_ID_TEMP 1 // Child id for Temperature #define CHILD_ID_MOT 2 // Id of the sensor child #define HUMIDITY_SENSOR_DIGITAL_PIN 7 // Where is my DHT22 data pin connected to #define DIGITAL_INPUT_SENSOR 3 // The digital input you attached your motion sensor. (Only 2 and 3 generates interrupt!) #define INTERRUPT DIGITAL_INPUT_SENSOR-2 // Usually the interrupt = pin -2 (on uno/nano anyway) //Misc. variables uint8_t switchState = 2; unsigned long SLEEP_TIME = 820000; // Sleep time between reads (in milliseconds) (close to 15') unsigned long SLEEP_TIME2 = 275000; // Sleep time after int. (in milliseconds) (close to 5') uint8_t cycleInProgress = 0; uint8_t firstReportDone = 0; uint8_t firstReportWithZeroDone = 0; int oldBatteryPcnt = 0; MySensor gw; DHT dht; float lastTemp = 0 ; float lastHum = 0 ; boolean lastTripped = false ; boolean metric = true; MyMessage msgHum(CHILD_ID_HUM, V_HUM); MyMessage msgTemp(CHILD_ID_TEMP, V_TEMP); MyMessage msgMot(CHILD_ID_MOT, V_TRIPPED); void setup() { // use the 1.1 V internal reference #if defined(__AVR_ATmega2560__) analogReference(INTERNAL1V1); #else analogReference(INTERNAL); #endif gw.begin(); dht.setup(HUMIDITY_SENSOR_DIGITAL_PIN); // Send the Sketch Version Information to the Gateway gw.sendSketchInfo("3 in 1 Sensor", "1.0"); pinMode(DIGITAL_INPUT_SENSOR, INPUT); // sets the motion sensor digital pin as input // Register all sensors to gw (they will be created as child devices) gw.present(CHILD_ID_HUM, S_HUM); gw.present(CHILD_ID_TEMP, S_TEMP); gw.present(CHILD_ID_MOT, S_MOTION); metric = gw.getConfig().isMetric; } void loop() { delay(dht.getMinimumSamplingPeriod()); float temperature = dht.getTemperature(); float humidity = dht.getHumidity(); if (isnan(temperature)) { Serial.println("Failed reading temperature from DHT"); } else if (temperature != lastTemp) { lastTemp = temperature; if (!metric) { temperature = dht.toFahrenheit(temperature); } gw.send(msgTemp.set(temperature, 1)); Serial.print("T: "); Serial.println(temperature); } if (isnan(humidity)) { Serial.println("Failed reading humidity from DHT"); } else if (humidity != lastHum) { lastHum = humidity; gw.send(msgHum.set(humidity, 1)); Serial.print("H: "); Serial.println(humidity); } // get the battery Voltage int sensorValue = analogRead(BATTERY_SENSE_PIN); #ifdef DEBUG Serial.println(sensorValue); #endif // 1M, 470K divider across battery and using internal ADC ref of 1.1V // Sense point is bypassed with 0.1 uF cap to reduce noise at that point // ((1e6+470e3)/470e3)*1.1 = Vmax = 3.44 Volts // 3.44/1023 = Volts per bit = 0.003363075 float batteryV = sensorValue * 0.003363075; int batteryPcnt = sensorValue / 10; #ifdef DEBUG Serial.print("Battery Voltage: "); Serial.print(batteryV); Serial.println(" V"); Serial.print("Battery percent: "); Serial.print(batteryPcnt); Serial.println(" %"); #endif // Read digital motion value boolean tripped = digitalRead(DIGITAL_INPUT_SENSOR) == HIGH; if (tripped != lastTripped ) { Serial.println(tripped); gw.send(msgMot.set(tripped?"1":"0")); // Send tripped value to gw } if (oldBatteryPcnt != batteryPcnt) { // Power up radio after sleep gw.sendBatteryLevel(batteryPcnt); oldBatteryPcnt = batteryPcnt; } // Sleep until interrupt comes in on motion sensor. Send update every two minute. gw.sleep(INTERRUPT, CHANGE, 0 ); }thanks very much!

@rhuehn It looks like you are repeating the conversation in this thread. Its better to continue the discussion there.

-

I agree with AWI, but would like to add one thing: By using the DHT11 you are really fighting an uphill battle. There are several sensors that are more suitable for battery-powered sensors. See the study referenced by @AWI in https://forum.mysensors.org/topic/3801/witch-temp-hum-sensor-is-best-to-use-for-battery-powered-sensors/2

-

Thanks @mfalkvidd Starting to realize that..... I might swap to the HTU21D, but keep in mind I'm also using a PIR..... Is there a reliable, low voltage PIR sensor that works well? I haven't seen one yet ( 2 x AA BATT's, under 2.8 V )?

Thanks

-

@Nicklas-Starkel I've been busy for few months moving to a new house and have had my sensor network offline until now because of this. Node 105 was kept on and handled with care, but I was pretty sure it would be dead when I started my gateway yesterday. BUT, it was ALIVE ?! at 14% battery level. Amazing! 24 months with such poor and simple hardware and software. :exclamation: :two_hearts: :star: :musical_note: :dancers: :clap: :muscle: Same batteries and only one restart (due to my controller change last year).

One little remark though, it doesn't seem to send temperature och pressure, only humidity and battery level. Maybe an issue of voltage recovery time between transmissions. -

This post is deleted!

-

Sorry for the noob question...

I would re-create your setup. At which point of it you insert the multimeter to measure the current?Is it ok to "interrupt" the ground (proximity to the step up) and measure the current there?

Thank you

-

Sorry for the noob question...

I would re-create your setup. At which point of it you insert the multimeter to measure the current?Is it ok to "interrupt" the ground (proximity to the step up) and measure the current there?

Thank you

@sineverba Just cut one of the battery wires of the finished assembly. Solder together again when your done measuring.

-

Has anyone got a V2 version working for this?

-

Has anyone got a V2 version working for this?

@palmerfarmer said in My 2AA battery sensor:

Has anyone got a V2 version working for this?

Do you mean running with MySensors 2.3?

-

Any Ver 2.xx,

So I have cobbled together/hacked this and it seem to work, battery has stayed at 97% for 2 weeks now. Feel free to Hack about and improve i have this mounted on an easyPCB board, x2AA batteries, NRF radio, BME280 with a 3.3v convertor ./* * use mysensors library 2.2.0 * ALL WORKING AND TESTED ON EASY PCB BOARD WITH BATTERY SAVING CODE 29/11/18 * * Time SET to 15 mins * also added BME280.writeMode (smSleep); to reduce quisecent to current to 40uA * BME280 sensor connections: 3.3v, 0V, SCL to A5, SDA to A4, BAT to A0 **/ //Enable debug prints to serial monitor #define MY_DEBUG // Enable and select radio type attached #define MY_RADIO_NRF24 #define MY_RF24_PA_LEVEL RF24_PA_MIN //settings are MIN, LOW, HIGH, MAX #define MY_NODE_ID 18 //#define MY_RADIO_RFM69 #include <SPI.h> #include <MySensors.h> #include <Wire.h> #include <BME280_MOD-1022.h> // BME280 libraries and variables // Bosch BME280 Embedded Adventures MOD-1022 weather multi-sensor Arduino code // Written originally by Embedded Adventures // https://github.com/embeddedadventures/BME280 #define BARO_CHILD 0 #define TEMP_CHILD 1 #define HUM_CHILD 2 int BATTERY_SENSE_PIN = A0; // select the input pin for the battery sense point unsigned long SLEEP_TIME = 15*60000; // sleep time between reads (seconds x*1000 milliseconds) //unsigned long SLEEP_TIME = 20000; // Debug test time 20 seconds int oldBatteryPcnt = 0; long interval = 1000; // 1 min interval at which to send (milliseconds) long previousMillis = interval; // will store last time data was sent const float ALTITUDE = 0; // <-- adapt this value to your location's altitude (in m). Use your smartphone GPS to get an accurate value! const char *weather[] = { "stable", "sunny", "cloudy", "unstable", "thunderstorm", "unknown" }; enum FORECAST { STABLE = 0, // "Stable Weather Pattern" SUNNY = 1, // "Slowly rising Good Weather", "Clear/Sunny " CLOUDY = 2, // "Slowly falling L-Pressure ", "Cloudy/Rain " UNSTABLE = 3, // "Quickly rising H-Press", "Not Stable" THUNDERSTORM = 4, // "Quickly falling L-Press", "Thunderstorm" UNKNOWN = 5 // "Unknown (More Time needed) }; const int LAST_SAMPLES_COUNT = 5; float lastPressureSamples[LAST_SAMPLES_COUNT]; // this CONVERSION_FACTOR is used to convert from Pa to kPa in the forecast algorithm // get kPa/h by dividing hPa by 10 #define CONVERSION_FACTOR (1.0/10.0) int minuteCount = 0; bool firstRound = true; // average value is used in forecast algorithm. float pressureAvg; // average after 2 hours is used as reference value for the next iteration. float pressureAvg2; float dP_dt; boolean metric; MyMessage tempMsg(TEMP_CHILD, V_TEMP); MyMessage humMsg(HUM_CHILD, V_HUM); MyMessage pressureMsg(BARO_CHILD, V_PRESSURE); float getLastPressureSamplesAverage() { float lastPressureSamplesAverage = 0; for (int i = 0; i < LAST_SAMPLES_COUNT; i++) { lastPressureSamplesAverage += lastPressureSamples[i]; } lastPressureSamplesAverage /= LAST_SAMPLES_COUNT; return lastPressureSamplesAverage; } // Algorithm found here // http://www.freescale.com/files/sensors/doc/app_note/AN3914.pdf // Pressure in hPa --> forecast done by calculating kPa/h int sample(float pressure) { // Calculate the average of the last n minutes. int index = minuteCount % LAST_SAMPLES_COUNT; lastPressureSamples[index] = pressure; minuteCount++; if (minuteCount > 185) { minuteCount = 6; } if (minuteCount == 5) { pressureAvg = getLastPressureSamplesAverage(); } else if (minuteCount == 35) { float lastPressureAvg = getLastPressureSamplesAverage(); float change = (lastPressureAvg - pressureAvg) * CONVERSION_FACTOR; if (firstRound) // first time initial 3 hour { dP_dt = change * 2; // note this is for t = 0.5hour } else { dP_dt = change / 1.5; // divide by 1.5 as this is the difference in time from 0 value. } } else if (minuteCount == 65) { float lastPressureAvg = getLastPressureSamplesAverage(); float change = (lastPressureAvg - pressureAvg) * CONVERSION_FACTOR; if (firstRound) //first time initial 3 hour { dP_dt = change; //note this is for t = 1 hour } else { dP_dt = change / 2; //divide by 2 as this is the difference in time from 0 value } } else if (minuteCount == 95) { float lastPressureAvg = getLastPressureSamplesAverage(); float change = (lastPressureAvg - pressureAvg) * CONVERSION_FACTOR; if (firstRound) // first time initial 3 hour { dP_dt = change / 1.5; // note this is for t = 1.5 hour } else { dP_dt = change / 2.5; // divide by 2.5 as this is the difference in time from 0 value } } else if (minuteCount == 125) { float lastPressureAvg = getLastPressureSamplesAverage(); pressureAvg2 = lastPressureAvg; // store for later use. float change = (lastPressureAvg - pressureAvg) * CONVERSION_FACTOR; if (firstRound) // first time initial 3 hour { dP_dt = change / 2; // note this is for t = 2 hour } else { dP_dt = change / 3; // divide by 3 as this is the difference in time from 0 value } } else if (minuteCount == 155) { float lastPressureAvg = getLastPressureSamplesAverage(); float change = (lastPressureAvg - pressureAvg) * CONVERSION_FACTOR; if (firstRound) // first time initial 3 hour { dP_dt = change / 2.5; // note this is for t = 2.5 hour } else { dP_dt = change / 3.5; // divide by 3.5 as this is the difference in time from 0 value } } else if (minuteCount == 185) { float lastPressureAvg = getLastPressureSamplesAverage(); float change = (lastPressureAvg - pressureAvg) * CONVERSION_FACTOR; if (firstRound) // first time initial 3 hour { dP_dt = change / 3; // note this is for t = 3 hour } else { dP_dt = change / 4; // divide by 4 as this is the difference in time from 0 value } pressureAvg = pressureAvg2; // Equating the pressure at 0 to the pressure at 2 hour after 3 hours have past. firstRound = false; // flag to let you know that this is on the past 3 hour mark. Initialized to 0 outside main loop. } int forecast = UNKNOWN; if (minuteCount < 35 && firstRound) //if time is less than 35 min on the first 3 hour interval. { forecast = UNKNOWN; } else if (dP_dt < (-0.25)) { forecast = THUNDERSTORM; } else if (dP_dt > 0.25) { forecast = UNSTABLE; } else if ((dP_dt > (-0.25)) && (dP_dt < (-0.05))) { forecast = CLOUDY; } else if ((dP_dt > 0.05) && (dP_dt < 0.25)) { forecast = SUNNY; } else if ((dP_dt >(-0.05)) && (dP_dt < 0.05)) { forecast = STABLE; } else { forecast = UNKNOWN; } return forecast; } void setup() { // use the 1.1 V internal reference #if defined(__AVR_ATmega2560__) analogReference(INTERNAL1V1); #else analogReference(INTERNAL); #endif metric = getControllerConfig().isMetric; // was getConfig().isMetric; before MySensors v2.1.1 Wire.begin(); // Wire.begin(sda, scl) // use the 1.1 V internal reference #if defined(__AVR_ATmega2560__) analogReference(INTERNAL1V1); #else analogReference(INTERNAL); #endif } void presentation() { // Send the sketch version information to the gateway and Controller sendSketchInfo("BME280_BAT_V2", "V2e."); // Register sensors to gw (they will be created as child devices) present(BARO_CHILD, S_BARO); present(TEMP_CHILD, S_TEMP); present(HUM_CHILD, S_HUM); } // Loop void loop() { { // get the battery Voltage int sensorValue = analogRead(BATTERY_SENSE_PIN); #ifdef MY_DEBUG Serial.println(sensorValue); #endif // 1M, 470K divider across battery and using internal ADC ref of 1.1V // Sense point is bypassed with 0.1 uF cap to reduce noise at that point // ((1e6+470e3)/470e3)*1.1 = Vmax = 3.44 Volts // 3.44/1023 = Volts per bit = 0.003363075 int batteryPcnt = sensorValue / 10; #ifdef MY_DEBUG float batteryV = sensorValue * 0.003363075; Serial.print("Battery Voltage: "); Serial.print(batteryV); Serial.println(" V"); Serial.print("Battery percent: "); Serial.print(batteryPcnt); Serial.println(" %"); #endif if (oldBatteryPcnt != batteryPcnt) { // Power up radio after sleep sendBatteryLevel(batteryPcnt); oldBatteryPcnt = batteryPcnt; } // sleep(SLEEP_TIME); } unsigned long currentMillis = millis(); if(currentMillis - previousMillis > interval) { // save the last time sent the data previousMillis = currentMillis; analogReference(INTERNAL); wait(500); // need to read the NVM compensation parameters BME280.readCompensationParams(); // Normal mode for regular automatic samples BME280.writeStandbyTime(tsb_0p5ms); // tsb = 0.5ms BME280.writeFilterCoefficient(fc_16); // IIR Filter coefficient 16 BME280.writeOversamplingPressure(os16x); // pressure x16 BME280.writeOversamplingTemperature(os8x); // temperature x8 BME280.writeOversamplingHumidity(os8x); // humidity x8 BME280.writeMode(smNormal); // Just to be sure, wait until sensor is done mesuring while (BME280.isMeasuring()) { } // Read out the data - must do this before calling the getxxxxx routines BME280.readMeasurements(); float temperature = BME280.getTemperatureMostAccurate(); // must get temp first float humidity = BME280.getHumidityMostAccurate(); float pressure_local = BME280.getPressureMostAccurate(); // Get pressure at current location float pressure = pressure_local/pow((1.0 - ( ALTITUDE / 44330.0 )), 5.255); // Adjust to sea level pressure using user altitude int forecast = sample(pressure); if (!metric) { // Convert to fahrenheit temperature = temperature * 9.0 / 5.0 + 32.0; } //**/ Serial.println(); Serial.print("Temperature = "); Serial.print(temperature); Serial.println(metric ? " °C" : " °F"); Serial.print("Humidity = "); Serial.print(humidity); Serial.println(" %"); Serial.print("Pressure = "); Serial.print(pressure); Serial.println(" hPa"); Serial.print("Forecast = "); Serial.println(weather[forecast]); Serial.println(); //*/ send(tempMsg.set(temperature, 1)); wait(50); send(humMsg.set(humidity, 1)); wait(50); send(pressureMsg.set(pressure, 2)); wait(50); BME280.writeMode (smSleep); sleep(SLEEP_TIME); } } -

11months on battery at 87%... still working!

-

This post is deleted!

-

11months on battery at 87%... still working!

That project box is perfect! Where did you find it (it doesn't look printed)?

-

I got it from CPC in the UK which are owned by Farnell

https://cpc.farnell.com/hammond/1593qgy/case-with-bat-compart-110x66x28mm/dp/EN82140

You may have to make a slight mod to the board or enclosure to make it fit.

good luck