💬 Relay

-

I was looking for a solution for a low consumption relay and i was adviced in this thread to use a latching relay.

However since i just need to switch on or off a 12V Vcc (from Li ion battery) to trigger a solenoid valve, i'm wondering whether i need a relay for that :

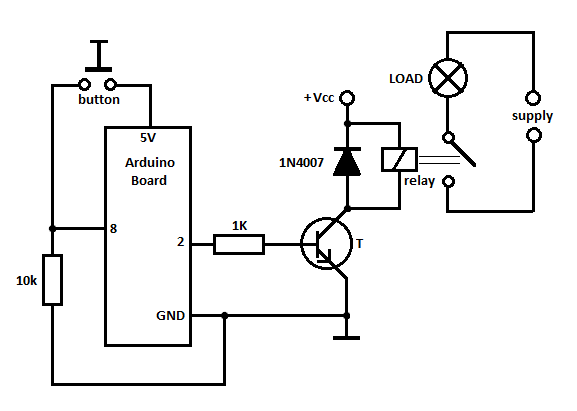

looking at the schematic from post #2 in https://forum.arduino.cc/index.php?topic=436555.0 may be i coud just have my solenoid valve directly in place of the relay in the schematic. In other words , i just need a transistor and not a real relay ... just because my application is a low voltage (12V to apply directly to the Vcc in the schematic) rather than 230V one: can someone confirm ? There is a diode in the schematic : what is it needed for ?

Since an inductor (im many cases a relay coil) cannot change it's current instantly, the flyback diode provides a path for the current when the coil is switched off. Otherwise, a voltage spike will occur causing arcing on switch contacts or possibly destroying switching transistors.

-

treat yor solenoid as it was a relay, the difference is that relay switches flow of current, and solenoid valve switches flow of water. so You have to use the same schematic, but put your valve where the relay is. But if You want power it from a battery, choose a latching solenoid valve instead of regular solenoid valve - and that requeires different schematic.

-

treat yor solenoid as it was a relay, the difference is that relay switches flow of current, and solenoid valve switches flow of water. so You have to use the same schematic, but put your valve where the relay is. But if You want power it from a battery, choose a latching solenoid valve instead of regular solenoid valve - and that requeires different schematic.

@rozpruwacz

thanks, but do you mean that the schematic simply would not work for the regular valve or that it would work but not be low power cinsumption design anymore ?

I have a regular solenoid valve but in my application the valve is normally closed and it will be only exceptionnally opened and for a short time when the 12V is applied, so i guess that i can live with it ...

As for the transistor in the schematic, except it seems to be a NPN , i don't know if i need a particular one for it . probably i can just buy a 2N3904 , or is there a better choice? -

the schematic you posted is not using latching relay/valve. it doesn't matter if it is relay or valve. both works the same and consume power when in ON state. If you plan to use it in a way that the valve will be ON for very short periods than it is not important if it is latching or not.

when choosing a transistor for such use, You have to look at its datasheet into "absolute maximum ratings" section and check if it will handle the voltages you will apply to it. 2N3904 looks like it will handle 12V without a problem.

-

the schematic you posted is not using latching relay/valve. it doesn't matter if it is relay or valve. both works the same and consume power when in ON state. If you plan to use it in a way that the valve will be ON for very short periods than it is not important if it is latching or not.

when choosing a transistor for such use, You have to look at its datasheet into "absolute maximum ratings" section and check if it will handle the voltages you will apply to it. 2N3904 looks like it will handle 12V without a problem.

@rozpruwacz

thanks , i will use 2N2222 because the valve needs between 200 and 400 mA.

I'v read the 2N3904 is OK for < 100 mA -

It works very well with the transistor and schematic posted above. I think the valve is a latching valve because it only discharges the battery when there is a transition. The only remaining problem is that the 5V arduino alone is too much power consuming. So i'm wondering if the transistor could as well work with a 3.3V arduino, that is when the signal level on the transistor Base is 3.3V rather than 5 V ... then i also could remove the arduino led but i'll need to keep the arduino regulator because my 3.7V cell voltage is too much greater than 3.3V

-

It works very well with the transistor and schematic posted above. I think the valve is a latching valve because it only discharges the battery when there is a transition. The only remaining problem is that the 5V arduino alone is too much power consuming. So i'm wondering if the transistor could as well work with a 3.3V arduino, that is when the signal level on the transistor Base is 3.3V rather than 5 V ... then i also could remove the arduino led but i'll need to keep the arduino regulator because my 3.7V cell voltage is too much greater than 3.3V

@fhenryco Actually the internal resistor of the solenoid is 27 Ohm while the resistance between C and E of the transistor in the passing state is 35 Ohm ... so it remains less than Vcc/2 for my solenoid which needs 12V ... so i need to tune my boost module at the max ==> more than 30V ... that does not seem ideal, may be i shoud choose another transistor with less internal resistor, but i have little experience with transistors : studied them a long time ago , so if someone can suggest something smart, ready to buy it ...

-

Can I suggest a change to this page?

As it stands the wiring diagram only applies to sketch 1 (without switch). It could get confusing as the 2 sketches use different pins for the relay and there is no need for this.

I propose that the wiring diagram be changed for the relay to be attached to pin 4.

The first sketch needs the relay pin to change from pin 3 to pin 4.That's it. Then the diagram and sketches will work whichever way the builder wants to do it.

-

Can I suggest a change to this page?

As it stands the wiring diagram only applies to sketch 1 (without switch). It could get confusing as the 2 sketches use different pins for the relay and there is no need for this.

I propose that the wiring diagram be changed for the relay to be attached to pin 4.

The first sketch needs the relay pin to change from pin 3 to pin 4.That's it. Then the diagram and sketches will work whichever way the builder wants to do it.

-

-

@mfalkvidd when updating the example sketch you could maybe consider my version of the relay sketch which offers some nice additions: https://forum.mysensors.org/topic/6638/multiple-relays-motion-sketch-fully-customizable-optional-timer-manual-override

-

@mfalkvidd when updating the example sketch you could maybe consider my version of the relay sketch which offers some nice additions: https://forum.mysensors.org/topic/6638/multiple-relays-motion-sketch-fully-customizable-optional-timer-manual-override

@HenryWhite my mind is divided when it comes to that type of sketch. Yes, it has a lot of functionality. Yes, it is probably what people need anyway. But the examples are meant to be used by someone who is just getting into diy home automation. Someone new should be able to understand as much of the sketch as possible. There should be as little as possible to trubleshoot. If the sketch is complex, most people's initial reaction will be that there is something wrong with the code, when in reality almost all newbie problems are power or wiring-related. Keeping the sketch simple helps, at lest a bit.

-

@HenryWhite my mind is divided when it comes to that type of sketch. Yes, it has a lot of functionality. Yes, it is probably what people need anyway. But the examples are meant to be used by someone who is just getting into diy home automation. Someone new should be able to understand as much of the sketch as possible. There should be as little as possible to trubleshoot. If the sketch is complex, most people's initial reaction will be that there is something wrong with the code, when in reality almost all newbie problems are power or wiring-related. Keeping the sketch simple helps, at lest a bit.

@mfalkvidd You are right but may be should there be for each sensor or actuator first the most basic sketch but also at the end of the page a complete version with all functionalities and granted to work by the mysensors team.

Of course for the complicated sketch version a big warning in red letters that this is not recommended for newbies would help...

-

@mfalkvidd You are right but may be should there be for each sensor or actuator first the most basic sketch but also at the end of the page a complete version with all functionalities and granted to work by the mysensors team.

Of course for the complicated sketch version a big warning in red letters that this is not recommended for newbies would help...

After testing some functionalities of nodemanager, i was wondering if already somebody was working on making a GUI for nodemanager which would allow to build one's sketch completely from a graphical interface (at least the most common and basic functionalities) : i thing the great work that resulted in Nodemanager has so well structured the various functions needed that it has already paved the way for creating such a graphical interface.

-

I would agree that more advanced sketches 'should' be included on the same page. Keep all the info in one resource place. Provided it is clearly marked as an advanced project it might help people looking for similar functionality or just interested in learning more about programming....

-

wow! fantastic! ... the github link readme warns that it's not yet fully ready but the interface is already impressive!

I still have the same question i had for nodemanager though : for measuring another battery than the one that feeds Vcc obviously another pin is needed, however why not propose as well the option of measuring such pin voltage but with Vcc as the reference rather than the internal 1.1V which most of the time makes necessary a voltage divider ? Actually i did the modification in nodemanager.cpp to use DEFAULT (~3.3V) rather than INTERNAL (1.1V) reference for a 3.3 pro mini and i can get the expected battery level without any voltage divider.Another unrelated question i have is : could there be any way to adapt the idea of the readVcc method (which is to measure the internal 1.1V against the Vcc reference to get Vcc) but using any voltage applied to a pin as the reference to again measure the internal 1.1 against it ? This would allow the masurement of any voltage greater than 1.1 without voltage divider while the usual method would be applied for measuring any voltage lower than 1.1 ... what did i miss that makes this impossible ?