Easy/Newbie PCB for MySensors

-

Hi Sundberg84,

I have some v8 and now enough time for playing.

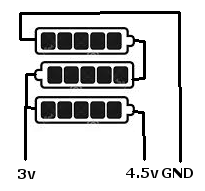

I setup with v3.3 2xAA, booster, NRF24, simple door sensor or DHT.

1-2 week and the batteries are discharged, I hear little buzz from the mini or other components.

This is the 2nd built where I meet this problem.

Do you have any idea what component is the failed ?

thanks

Barna -

@sundberg84 this is not normal buzz, stronger than before.

I have used this source only: https://www.ebay.com/itm/mini-DC-DC-0-8-3-3V-to-DC-3-3V-Step-UP-Boost-Power-Module-For-Breadboard-Arduino-/281556288481?hash=item418e1003e1

which another part could make the buzz ?

yes, I use sleep

sleep(1, CHANGE, SLEEP_TIME); SLEEP_TIME is 900000 , but the node does not wake up and send the battery status, only when door sensor changes.

No, I have not removed the led and regulator, this is the testing period only :) -

Hi Sundberg84,

I have some v8 and now enough time for playing.

I setup with v3.3 2xAA, booster, NRF24, simple door sensor or DHT.

1-2 week and the batteries are discharged, I hear little buzz from the mini or other components.

This is the 2nd built where I meet this problem.

Do you have any idea what component is the failed ?

thanks

Barna -

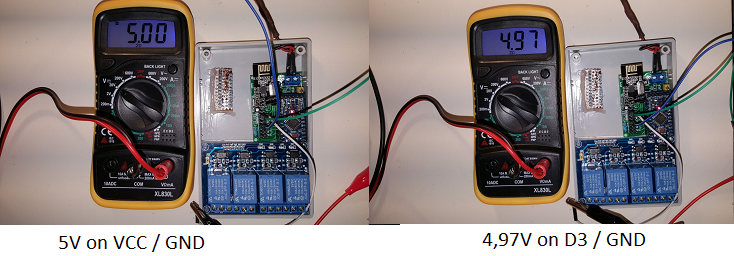

@sincze - and you use the right power source on the PCB? (VCC = 5v and 3.3v = Well... 3.3v) Please send pictures of both setup as mentioned.

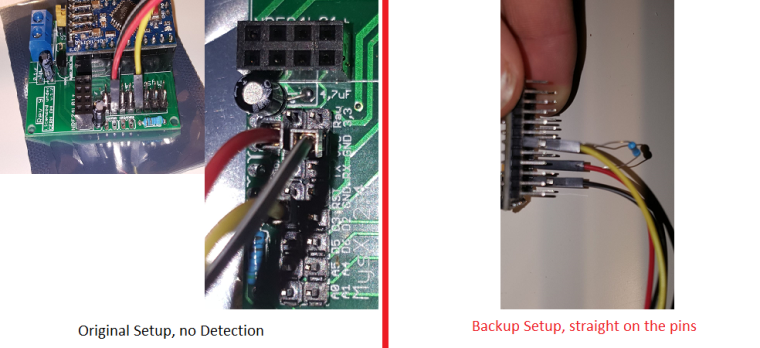

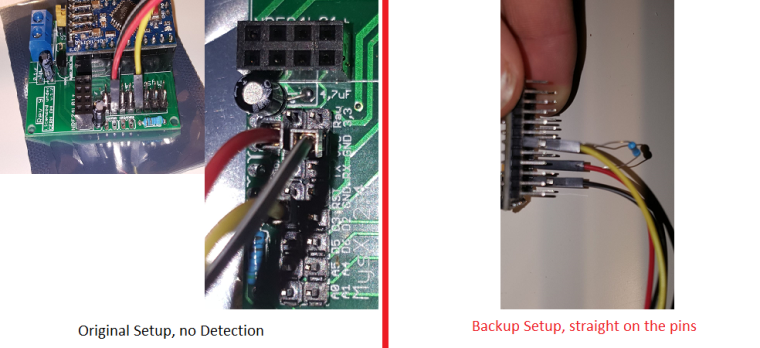

@sundberg84 @dbemowsk Thank you guys for still trying to help me. I almost gave up on using a Dallas Termp sensor o n a pro mini. As said I even tried connecting the temp sensor directly to the pins with same results. If I connect the pins to my nano, it is being detected and transmitting temp values. I even used a different sketch.. Just for the temp sensor. link found_here. Changed it to use Pin 3 ofcourse. I even connected the whole thing to D2 (resistor back in the wires)... without being succesful either.

-

@sundberg84 @dbemowsk Thank you guys for still trying to help me. I almost gave up on using a Dallas Termp sensor o n a pro mini. As said I even tried connecting the temp sensor directly to the pins with same results. If I connect the pins to my nano, it is being detected and transmitting temp values. I even used a different sketch.. Just for the temp sensor. link found_here. Changed it to use Pin 3 ofcourse. I even connected the whole thing to D2 (resistor back in the wires)... without being succesful either.

-

@sincze Are you sure you sure you got correct power on the GND and VCC pins on the MySX connector?

-

Dallas temp sensors needs 3.3v VCC if I remember right. Not 5v.

-

Dallas temp sensors needs 3.3v VCC if I remember right. Not 5v.

@sundberg84 haha yes i was wondering that myself so tried it connecting it to 3,3v as well. However on the 5v nano working just fine. Technical specs tell me: Power supply range is 3.0V to 5.5V

also mysensors link

Pretty strange huh. -

@sundberg84 haha yes i was wondering that myself so tried it connecting it to 3,3v as well. However on the 5v nano working just fine. Technical specs tell me: Power supply range is 3.0V to 5.5V

also mysensors link

Pretty strange huh.@sincze my mistake. Really strange this... Should work just fine. Can you upload a better resolution picture of your hardware and the sketch you are using?

-

@sundberg84 haha yes i was wondering that myself so tried it connecting it to 3,3v as well. However on the 5v nano working just fine. Technical specs tell me: Power supply range is 3.0V to 5.5V

also mysensors link

Pretty strange huh.@sincze I have 10 of these DS18B20s strung over approximately 12m monitoring all rooms on both floors of my house and two side lofts, all running on 3.22v from a Pro-Mini. Never have skipped a beat, reporting every 5 minutes, well, aside from a telephone socket which pins went walkabout (the chips are crimped to RJ11s).

There is something not right with the physical arrangement if you can get the same circuit to report at 5v... -

@sincze my mistake. Really strange this... Should work just fine. Can you upload a better resolution picture of your hardware and the sketch you are using?

@sundberg84 I just soldered a myself a new out of the box pro mini using the same sketch..

10246 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=4,st=OK:21.0

250560 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:21.1

255019 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:22.3

259476 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:23.8

263934 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:25.3

268393 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:26.5

272851 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:27.6

277310 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:28.1

281768 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:28.4

290677 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:28.3

295136 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:28.1

299594 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:27.8

304053 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:27.6

308511 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:27.3

312970 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:27.1

317428 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:26.8

321887 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:26.6

326345 TSF:MSG:SEND,8-8-25-0,s=0,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:26.4Victory... :)

-

@gohan Don't know. Pin3 could be used to drive the led tx without problems. It only did not work with the temp sensors. I moved the temp sensor to d2.... modified the sketch and it did not work as well. and d2 was driveing rx led. So well root cause unknown... solution: solder a new pro mini and keep the other one for different purpose.

-

@gohan Don't know. Pin3 could be used to drive the led tx without problems. It only did not work with the temp sensors. I moved the temp sensor to d2.... modified the sketch and it did not work as well. and d2 was driveing rx led. So well root cause unknown... solution: solder a new pro mini and keep the other one for different purpose.

@sincze Did you use D2+D3 on all the same devices?

-

@sincze Did you use D2+D3 on all the same devices?

@zboblamont @gohan The Sensor with the replaced Pro Mini is in production now ;-). I'll start soldering a new Easy/Newbie PCB, because once you know how to do it... it is Easy and test the individual pins with a door/window sensor.

-

Hi Sundberg84,

What could you advise for battery powering (remove led and regulator too) if I would like to use Mini 5V and measure the battery level too ?

thxBarna

@Barna the 5v pro mini are running a 16mhz crystal as default and this needs higher voltage to be stable compred to 8mhz (3.3v pro mini).

I have never tried this so can't give much advice but I would probably take the effort of reprogramming the fuses and bootloader to a internal 1mhz and run the hardware as that (the hardware is the same on 5v except the regulator and crystal )

-

Hi Sundberg84,

What could you advise for battery powering (remove led and regulator too) if I would like to use Mini 5V and measure the battery level too ?

thxBarna