ds18b20 on 2xAAA battery

-

@pihome No expert, but recall these one-wire devices have a digital communications protocol. As such they rely on accurate timing, hence your clock speed disrupts it?

@zboblamont might be on the right track. See https://github.com/arduino/Arduino/issues/7181 for a discussion on timing problems, especially at 1MHz

-

It appears that you during runtime can change prescale, so you should be able to change clock frequency to 8MHz when reading DS18B20 and after reading change clock back to 1MHz

-

@bjacobse

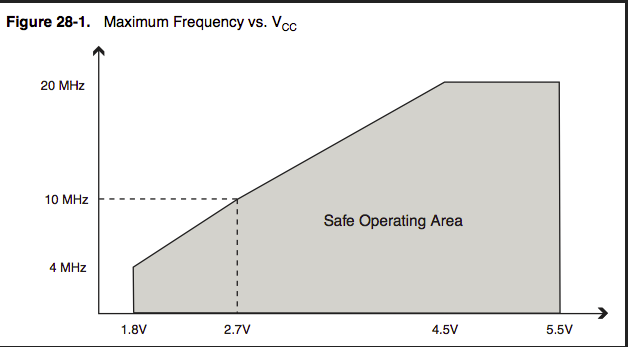

reason behind 1mhz mcu is to run it on lower voltage but switching between speed still need higher voltage. if i m not wrong!!! -

@bjacobse

reason behind 1mhz mcu is to run it on lower voltage but switching between speed still need higher voltage. if i m not wrong!!! -

Well then another approach is not to use DS18B20 :-)

Have you checked TMP117 price seems to be 2USD in higher qty, and supply range: 1.8 V to 5.5 Vhttp://www.ti.com/product/TMP117

And someone have made a lib to Arduino: https://github.com/NilsMinor/TMP117-Arduino

-

Hi, I'm on a somehow "comparable" (but very different scenario) project in terms of using same DS18B20 and arduino 3.3V, a mkr SAMD21 in my case, and trying to get the longer autonomy I can.

The best option I've seen so far seems to be to use the (best option) TPS61291 or (alternate option) TPS61221, as the first seems to be designed for this use cases, and the second has enable option to switch it off. All those seemed to me (newbie here) better than the TPS you indicate.

For my use case, the "low tech" option indicated by @mfalkvidd could fit very nicely, so I'll dig into that option.

-

just for reference, 4 out of 5 sensebender micros is still running strong, after 4 years on the same set of AA batteries, that they where deployed with.

The 5th sensebender is my outdoor sensor, that one eats a set of batteries within 48 hours.. But i suspect that it's the air humidity that has destroyed it.

I opted to use a Si7021 instead (there might be others that are better suited now), as it was better suited for low power operation, and runs down to 1.2V supply (if I remember right).