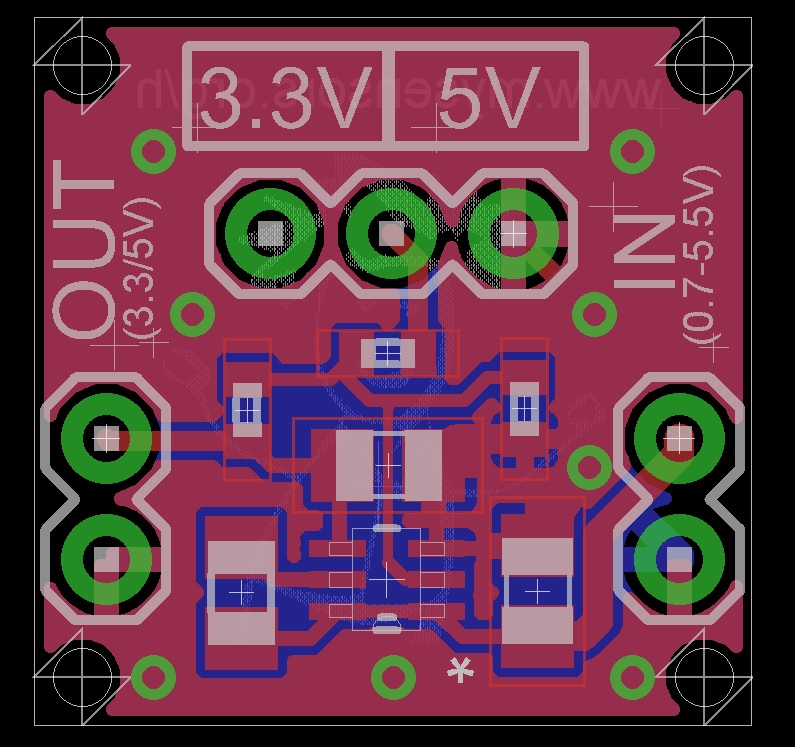

MySensors micro step-up module revision 1.0

-

Through a discussion on the forum we found a potential interest to the step-up module with excellent battery saving capabilities

We decided to present to you such a module

It is actually same technology as will be used for MySensors Battery board, but it allows to choose any other board for your battery operated project.

Module is using one of the best in class chip with hight efficiency and low quiescent current, this allows to run your device for longer time

Module is designed with standard 2.54 pitch connector, can be easily connected using dupon wires

Output voltage can be selected by switch 3.3V or 5V

As power source you can use:- for 3.3V output - 1-2 alkaline, 1-3 NiMh/NiCd or solar up to 3.3V

- for 5V - 1-3 alkaline, 1-4 NiMh/NiCd or solar up to 5V

100mA output for 3.3V or 70mA for 5V are at minimum guaranteed

Size is just 15x15mm

Estimated retail price before shipping cost is $5

Anyone interested?Prototype is on photo fully tested

@axillent Looks like a much-needed part for our battery sensors. Is there any chance of moving the pins together to emulate the current step converter in the store? Ie, having three pins in a row: Vout GND Vin. This makes it a drop-in replacement for the existing part.

-

@Bandra said:

moving the pins together to emulate the current step converter in the store? Ie, having three pins in a row: Vout GND Vin. This makes it a drop-in replacement for the existing part.

Wow..Nice! Nice fingernails too...i could never photo mine...all chewed up!!! ;-)

With respect to the capacitior for the radio - i saw @axillent you are soldering a tantalum cap directly to the radio - i really like that method!

http://forum.mysensors.org/topic/185/battery-sensor-v-1-0-pcb/29Alex - i guess this chip cannot output both 3.3 and 5V at the same time, so would it be possible to have a module with two of these chips each one at 3.3 and the other at 5v ??

-Then it can be used for 5v sensors/devices.Greg

-

What is the chip used?

-

@axillent Looks like a much-needed part for our battery sensors. Is there any chance of moving the pins together to emulate the current step converter in the store? Ie, having three pins in a row: Vout GND Vin. This makes it a drop-in replacement for the existing part.

@Bandra said:

@axillent Looks like a much-needed part for our battery sensors. Is there any chance of moving the pins together to emulate the current step converter in the store? Ie, having three pins in a row: Vout GND Vin. This makes it a drop-in replacement for the existing part.

unfortunately there is no standard convention of this type. It is hard to match all different needs

input and output connectors are a generic tradeoff -

@Bandra said:

moving the pins together to emulate the current step converter in the store? Ie, having three pins in a row: Vout GND Vin. This makes it a drop-in replacement for the existing part.

Wow..Nice! Nice fingernails too...i could never photo mine...all chewed up!!! ;-)

With respect to the capacitior for the radio - i saw @axillent you are soldering a tantalum cap directly to the radio - i really like that method!

http://forum.mysensors.org/topic/185/battery-sensor-v-1-0-pcb/29Alex - i guess this chip cannot output both 3.3 and 5V at the same time, so would it be possible to have a module with two of these chips each one at 3.3 and the other at 5v ??

-Then it can be used for 5v sensors/devices.Greg

@gregl said:

Alex - i guess this chip cannot output both 3.3 and 5V at the same time, so would it be possible to have a module with two of these chips each one at 3.3 and the other at 5v ??

-Then it can be used for 5v sensors/devices.current draw from the battery is a multiplication from the stepup ratio

this means that current draw from the buttery with 5V output is 1.5 times higher comparing to 3.3V with the same current on the output

also current on the output much less depends on the voltage etc. MCU will draw 1-5mA regardless (with some extend) the VCC voltage

this leads into conclusion that as lower VCC used as better will be battery lifeIn my opinion 2.4V will be even more optimal for Battery board, but it is much more convenient to have 3.3V

While you need 5V you need to choose:

- best choice is to find all needed components able to work from 3.3V. For example PIR sensor is usually run from 4.5-20V. But there is no problem to purchase PIR running from 0.7-6V

- least optimal choice is to select 5V as a basic operation. This way you can use cheap LDO (like XC6206P332MR) to source radio

having two channels in stepup as you requested will double cost because you will need double number of components

and you always can use two universal modules simultaneously, one configured to 3.3V and other to 5V

-

Interested.. any ETA?

-

I'm finally back from a long trip

Sorry to be silentSeeed stepup boards are awaiting me at home.

Just need to run final performance tests

@axillent Fantastic! But they will come pre-soldered I hope :P

-

@axillent Fantastic! But they will come pre-soldered I hope :P