My Slim 2AA Battery Node

-

Really great idea @m26872 !!

I'm waiting for the V1.2 test and review before ordering some boards on DirtyPcb.

One Tip/question : have you thought on panelizing your slimnode, because we could easily fit 3 board on the 5X5 limitation ? I also think that DirtyPCB would even process the break routing to ease board separation. -

Really great idea @m26872 !!

I'm waiting for the V1.2 test and review before ordering some boards on DirtyPcb.

One Tip/question : have you thought on panelizing your slimnode, because we could easily fit 3 board on the 5X5 limitation ? I also think that DirtyPCB would even process the break routing to ease board separation.@frenchclem

AAMOF I ordered a panelized version just a few days ago. I'm completely new to all this, so I leave no guarantees...

Here's the brd-file.Edit 3/12: Boardhouse link removed (the panelized version of v1.2 contains a faulty via between D13 and SCK.)

-

I guess if you ordered panelized version, you have tested the V1.2 ? Would you mind sharing the schematics also please ?

I'm also very new to this, I've never ordered PCB on Dirtypcb, how long does it takes to arrive in Europe ? -

Delivery times depend mostly on shipping time. DirtyPCB have their boards made usually within a week after uploading the files. But shipping can take 3-4 weeks to get to Europe.

-

I guess if you ordered panelized version, you have tested the V1.2 ? Would you mind sharing the schematics also please ?

I'm also very new to this, I've never ordered PCB on Dirtypcb, how long does it takes to arrive in Europe ?@frenchclem

No I actually ordered before I got the first sample, due to the delivery time. But now (just a day after) I got the first v1.2. Delivery time was 4 weeks (to Sweden). Soon tested...I don't think there are any changes to the already published schematics.

-

@GertSanders @m26872

Thanks guys for the good work I just ordered your boards

Will definitely let you know how things goesGertSanders, did you find a nice box for your board + battery ?

-

@frenchclem Not yet, the height is indeed the limiting factor. I'm now looking for a small box that can hold the sensor on it's side. SO for the moment the sensors are scattered around the house without a box around them (usually in places where the cat does not go or could find them).

-

@GertSanders thats what I was worried about. What is the height of the sensor + battery ?

-

@frenchclem

I can not measure that now (at work), but I guess around 35mm if batteries are mounted on he bottom. By using the extrnal (JST connector) power option, the height of PCB, processor and radio is around 22mm I think.Most boxes have an internal clearance of around 20-25mm.

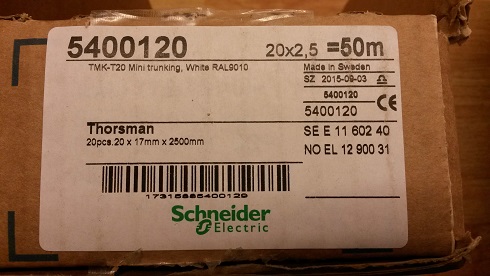

Some boxes have 40mm internal clearance and are good in height, but those are usually also to long and wide for my taste.@m26872 's board certainly is lower, since batteries are not on the bottom but in the axis of the board. The radio is also directed away from the processor on his board, so it can be mounted lower (directly on PCB instead of on a header). I really like that concept, since it will fit the plastic cableducts made by Legrand:

http://www.ecataleg.be/fr/categorie/3020/moulure-et-goulotte-murale-en-pc-abs-sans-halogene -

@frenchclem

Just to confirm: 35mm is the height with the small radio.

Using the larger radio (with PA+LNA) you need 41mm height

Without battery holders, and the small radio, the height is 22 mm

Width is 25mm for AAA battery holders mounted, 33mm for AA battery holder, and length is 53mm (AAA batteries) and 58mm (AA batteries) -

v1.2 tested and working. But the design of crossing R1 and C2 was a horrible choice - it's impossible to fit both nicely under/inside the uC socket. Perhaps possible with a 1/8W R1, but otherwise R1, C2 or both must be placed on bottom side.

Good news is that all versions and orders are OK apart from this little inconvenience.

I'll try to make a better version ASAP.

-

v1.2 tested and working. But the design of crossing R1 and C2 was a horrible choice - it's impossible to fit both nicely under/inside the uC socket. Perhaps possible with a 1/8W R1, but otherwise R1, C2 or both must be placed on bottom side.

Good news is that all versions and orders are OK apart from this little inconvenience.

I'll try to make a better version ASAP.

-

-

I've now ordered yet another prototype version (1.4):

http://dirtypcbs.com/view.php?share=13310&accesskey=58c87fe605eb91958938f70b5efc8629Eagle brd-file.

Photo here.

-

I bought a few enclosures... "mini trunking" seems to be the correct term. This time it was ABS and a little more clear white colour and glossy finish. I think I spent around 2hrs cutting them nicely into >200pcs. 50% 23cm and 50% 19cm lengths.