Minimal design thoughts

-

Woah, wait.... 2 years of power?? Okay, if I could even get, say 18 months, I would go with battery powered over wall worts in a majority of my sensors.

I was assuming battery power may last 3-6 months or so, given the motion detection.

-

Woah, wait.... 2 years of power?? Okay, if I could even get, say 18 months, I would go with battery powered over wall worts in a majority of my sensors.

I was assuming battery power may last 3-6 months or so, given the motion detection.

@NotYetRated said:

Woah, wait.... 2 years of power?? Okay, if I could even get, say 18 months, I would go with battery powered over wall worts in a majority of my sensors.

I was assuming battery power may last 3-6 months or so, given the motion detection.

With motion detection you probably are further down, also one problem is that the PIR sensors I have seen is only 3.3V, which means you need a step up converter to power it from battery. This also increases the powerdrain on the batteries.

-

Ahh okay. Ill stick with building my stuff out for wall power where possible, and probably test a few of your boards when available. :)

-

@tbowmo Cool staff!

Just one suggestion - to add so called FTDI programming interface like pro mini is using

It allows to use an external USB<->UART converter to work ith the board as usual (using programming through bootloader and Serial debugger)

It is simple, see PROGRAMMER connector for example here http://wiki.devicter.ru/images/f/f7/SNv3sch.png -

@axillent

Hmm have been thinking about it.. Just for the versatility of the unit for other people. I have plans to use good old atmel programmers (I have a bunch of them, both jtagice3, and the older serial/usb programmers), so it's not that big an issue for me to skip serial for programmingAnd at the moment I can't find any room for it the serial (other than rxd/txd in upper right corner) It's almost become an obsession for me, to keep it at the small formfactor :) (Same size as a standard nrf24 module). Just to prove that it is possible to get it that small

btw. squeezed a couple of testpads in for A0, A1 and D3 last night.

-

An update.. I got room for the ftdi header, as well as a 4pin header where I got power, and 3 digital IO (D3, D6 and D7, if I my memory serves me). Just need to find location for the last couple of tracks

Only detail though, is that I have gone with 0402 size smd components..

/ Thomas

-

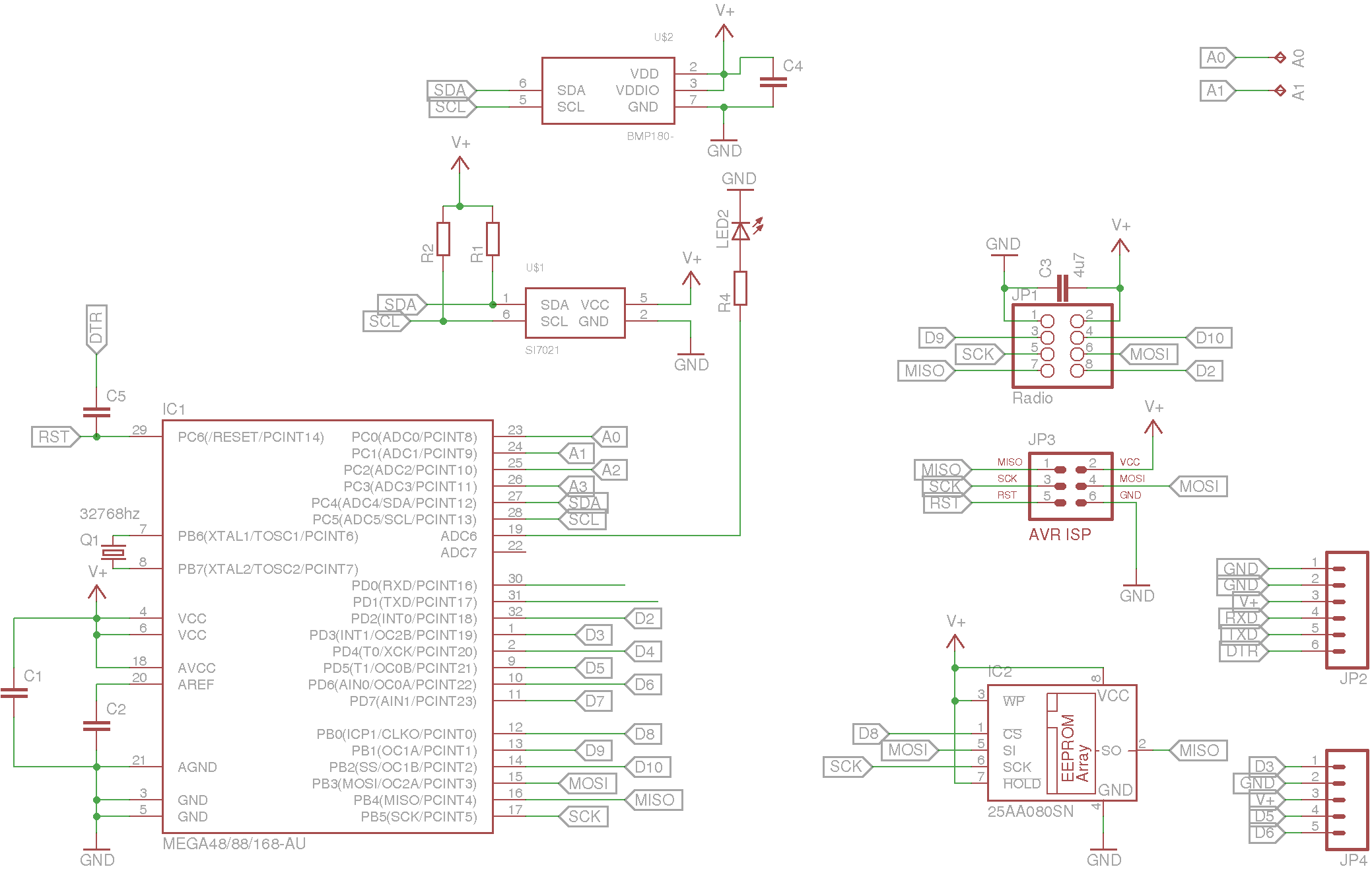

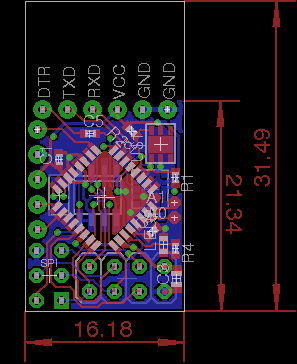

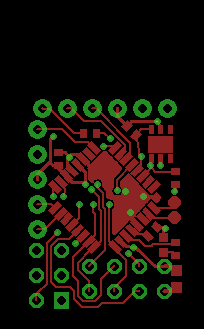

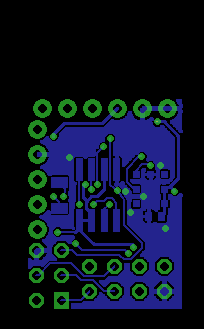

And the latest schematic, and layout (After I scratched the old routing, and started all over, again, for the 5th time I think :))

Actually I enjoy this fiddling with placing components, and routing tracks.. Only problem is that the wife thinks it takes too much time, and I should do other more usefull stuff, than playing with my computer, making noncense drawings :)

Schematics

full layout

top layer

bottom layer

Think I am ready to press the GO button for first spin in china.. This is gonna be exciting :)

-

And off they go to China.. Have ordered the first batch of prototypes.. (10 pcb's, panelized with 2 sensor boards per panel)

Now there is only the waiting time...

@tbowmo Amaons 2-day shipping has killed me. When I started with MySensors projects, and the China waiting time of sometimes 2-3 weeks.... Difficult haha.

-

Here it's more like 3-6 weeks waiting time, for stuff to come back from China.. So maybe it arrives in time for Christmas.. And then I can't get components sourced from mouser at that time (waiting until I have seen the quality of the boards, before I order components)

-

Haha!.. I have the same problem with the wife over here. The modules and half build sensors I spread all over the house is most irritating.

@hek, @tbowmo and rest: ho ho guys, first think WAF, ie Wife Acceptance Factor

This variable has to be VERY high. Like: Darling, this whole fidling of mine would optimize our home and save on energy bills big time, so You can spend more on shopping craze. etc :)

Probably when I finish with testing, I start selling it to friends and we will have problem spending all of the money which suddenly comes our way. (Try here not to laugh :) )

-

The reason why I am building this, is that I always have been currious about collecting data at regular intervals, back in the days (8-9 years ago) I had a setup with 5 DS18B20's on long wires arround the house. One was in my furnace measuring the temperature of the water, one was outside, etc. Everything connected to my old 486 based linux machine with 20Mb ram, collecting data from all the sensors on a regular interval, and presenting it with digitemp (a php package for displaying temperatures).

Just want to make something like that again. And I think my wife can see the ideas in it. Will just use it for environmental measurements throughout the house. Maybe some of them coupled to a SMS gateway, letting the teenagers know when to open up a window for 5 minutes, in order to get fresh air in, and the humidity level down. (And another SMS to remind them to shut the windows again).

And then the fun in collecting data, analyzing it in graphs etc... :)

-

@tbowmo I also have some old programmers including jtagice3 and can well understand you)

and sure, your very small design is best to keepThe only problem I have to use jtagice3 (which I like a lot to do hardware debugging) is that Arduino is not supported by hardware debugging

Just an idea - if you have all pins needed for FTDI programming on the corner later you can have a special connector between your board and FTDI programmer. This case you can keep design without extra space needed

-

@tbowmo I also have some old programmers including jtagice3 and can well understand you)

and sure, your very small design is best to keepThe only problem I have to use jtagice3 (which I like a lot to do hardware debugging) is that Arduino is not supported by hardware debugging

Just an idea - if you have all pins needed for FTDI programming on the corner later you can have a special connector between your board and FTDI programmer. This case you can keep design without extra space needed

@axillent said:

The only problem I have to use jtagice3 (which I like a lot to do hardware debugging) is that Arduino is not supported by hardware debugging

Wouldn't using jtagice3 for debugging also collide with the radio on a mysensor module?

Just an idea - if you have all pins needed for FTDI programming on the corner later you can have a special connector between your board and FTDI programmer. This case you can keep design without extra space needed

There is a full ftdi header on my board now. And I just got information from China that my boards are shipped... so just waiting for them to arrive now :)

-

@tbowmo said:

Wouldn't using jtagice3 for debugging also collide with the radio on a mysensor module?

jtagice3 is using only single pin of atmega328p (RESET pin) to do programming and debugging.There is no reason to have conflict with radio.

The only problem with jtagice3 is that arduino environment is not supporting hardware debugging.

I'm wondering on having ability to compile Mysensors using regular Atmel Astudio to be able to use debugging.There is a full ftdi header on my board now. And I just got information from China that my boards are shipped... so just waiting for them to arrive now :)

Cool! I also like 0603 footprints. But also is fine to use 0402. Sometimes you will probably need it.

If you need support I can prepare a bootloader for you with needed settings for boards.txt -

@tbowmo said:

Wouldn't using jtagice3 for debugging also collide with the radio on a mysensor module?

jtagice3 is using only single pin of atmega328p (RESET pin) to do programming and debugging.There is no reason to have conflict with radio.

The only problem with jtagice3 is that arduino environment is not supporting hardware debugging.

I'm wondering on having ability to compile Mysensors using regular Atmel Astudio to be able to use debugging.There is a full ftdi header on my board now. And I just got information from China that my boards are shipped... so just waiting for them to arrive now :)

Cool! I also like 0603 footprints. But also is fine to use 0402. Sometimes you will probably need it.

If you need support I can prepare a bootloader for you with needed settings for boards.txt@axillent said:

@tbowmo said:

Wouldn't using jtagice3 for debugging also collide with the radio on a mysensor module?

jtagice3 is using only single pin of atmega328p (RESET pin) to do programming and debugging.

Aaahh, yeah, I forgot about their "new" debugWire interface, so thought that a fullblown spi interface was nescessary for the ISP to program the device. Hmm.. With THAT info, I could have used a smaller pinheader, instead of the 6pin ISP header..

Could become handy for next revision of the board (if there'll be anny)

There is no reason to have conflict with radio.

The only problem with jtagice3 is that arduino environment is not supporting hardware debugging.

I'm wondering on having ability to compile Mysensors using regular Atmel Astudio to be able to use debugging.There is a full ftdi header on my board now. And I just got information from China that my boards are shipped... so just waiting for them to arrive now :)

Cool! I also like 0603 footprints. But also is fine to use 0402. Sometimes you will probably need it.

If you need support I can prepare a bootloader for you with needed settings for boards.txtI'm used to the small components.. And for a couple of handbuild sensor boards, I thought that I might as well cope with them, in order to keep the layout small :) If this is becomming a success, and others would like similair boards, the boards should be assembled with an pick & place machine, and then it doesn't matter that the components are 0402.

I'll keep it in mind with the bootloader :)

-

@axillent said:

@tbowmo said:

Wouldn't using jtagice3 for debugging also collide with the radio on a mysensor module?

jtagice3 is using only single pin of atmega328p (RESET pin) to do programming and debugging.

Aaahh, yeah, I forgot about their "new" debugWire interface, so thought that a fullblown spi interface was nescessary for the ISP to program the device. Hmm.. With THAT info, I could have used a smaller pinheader, instead of the 6pin ISP header..

Could become handy for next revision of the board (if there'll be anny)

There is no reason to have conflict with radio.

The only problem with jtagice3 is that arduino environment is not supporting hardware debugging.

I'm wondering on having ability to compile Mysensors using regular Atmel Astudio to be able to use debugging.There is a full ftdi header on my board now. And I just got information from China that my boards are shipped... so just waiting for them to arrive now :)

Cool! I also like 0603 footprints. But also is fine to use 0402. Sometimes you will probably need it.

If you need support I can prepare a bootloader for you with needed settings for boards.txtI'm used to the small components.. And for a couple of handbuild sensor boards, I thought that I might as well cope with them, in order to keep the layout small :) If this is becomming a success, and others would like similair boards, the boards should be assembled with an pick & place machine, and then it doesn't matter that the components are 0402.

I'll keep it in mind with the bootloader :)

@tbowmo said:

With THAT info, I could have used a smaller pinheader, instead of the 6pin ISP header..you cannot remove ISP header because debugWire is activated through ISP )))

@tbowmo said:

I'm used to the small components.. And for a couple of handbuild sensor boards, I thought that I might as well cope with them, in order to keep the layout small :) If this is becomming a success, and others would like similair boards, the boards should be assembled with an pick & place machine, and then it doesn't matter that the components are 0402.

Me and Henrik we have a list of partners for PCB production, If you fine to cooperate more closer with Mysensors we can help you on putting the board unto production. Just let Henrik to know if you have an interest on closer cooperation. I will help with production.

-

@tbowmo said:

With THAT info, I could have used a smaller pinheader, instead of the 6pin ISP header..you cannot remove ISP header because debugWire is activated through ISP )))

@tbowmo said:

I'm used to the small components.. And for a couple of handbuild sensor boards, I thought that I might as well cope with them, in order to keep the layout small :) If this is becomming a success, and others would like similair boards, the boards should be assembled with an pick & place machine, and then it doesn't matter that the components are 0402.

Me and Henrik we have a list of partners for PCB production, If you fine to cooperate more closer with Mysensors we can help you on putting the board unto production. Just let Henrik to know if you have an interest on closer cooperation. I will help with production.

@axillent said:

Me and Henrik we have a list of partners for PCB production, If you fine to cooperate more closer with Mysensors we can help you on putting the board unto production. Just let Henrik to know if you have an interest on closer cooperation. I will help with production.

I know, I have been talking with Henrik about it. Waiting for the first prototypes, so the design can be validated.