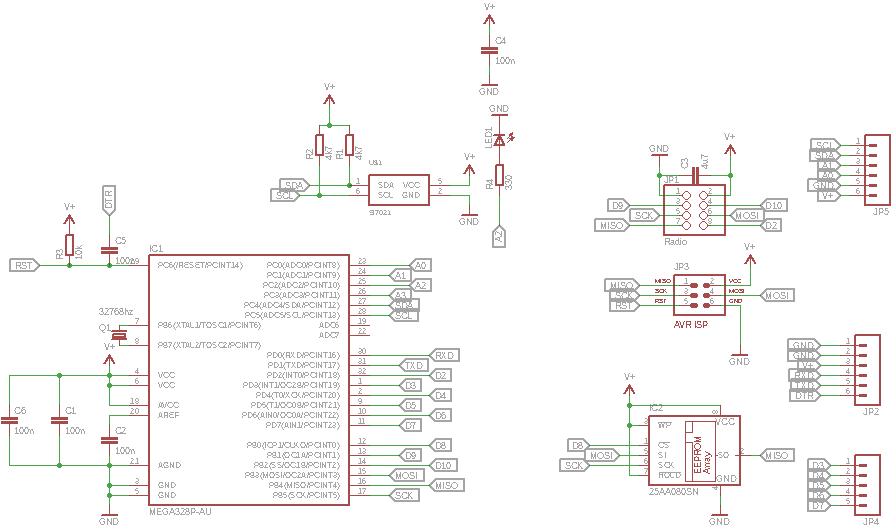

Minimal design thoughts

-

Yeah, they added Danish VAT to the order..

Just double checked, it's actually only 154$ (925dkk).. Remembered wrong with the exchange rate when I converted earlier, and just took some numbers from the top of my head. The VAT is around 31$.

But still it's a lot of money, specially this time of year..

-

If use one-sided mounting and on other side set CR2450 holder. Will get a small deviceю

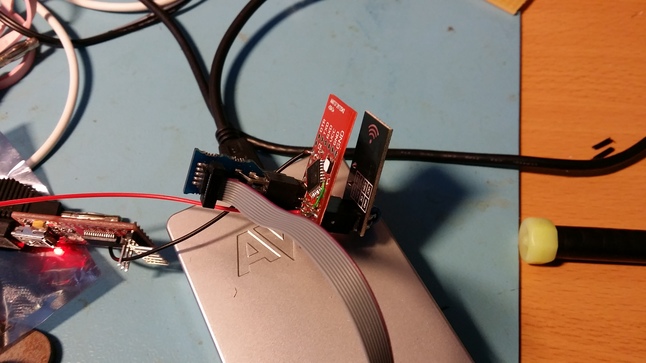

![20141216_175103[1].jpg](/uploads/upload-177cc285-50f8-4b0a-93d4-3232582fe88f.jpg)

-

And now the components arrived :d

Just miss one capacitor, which is out of stock at Mouser. Got a notice that they will get it in stok again in March 2015! So I'll have to see if I can find an alternative (It was decoupling for the radio).

Hopefully I get some time off to do the first board friday evening.

-

So, it's time for board mounting..

One advice, DOUBLE CHECK the component orders, and TRIPLE check them.. After I got the shipment from mouser, I discovered, that I accidentally had ordered some capacitors in 0101 housing, instead of 0204.. that's DAMN small components.. And I can't use it.. Well thats about 10$ down the drain.. (It was all the decoupling capacitors for the board).

Also found out that I forgot to order a ~100R resistor for the status LED's.. What a bummer!

So I'll have to see if I can source the components quickly from some friends in the next couple of days

Anyways, pic's from the build:

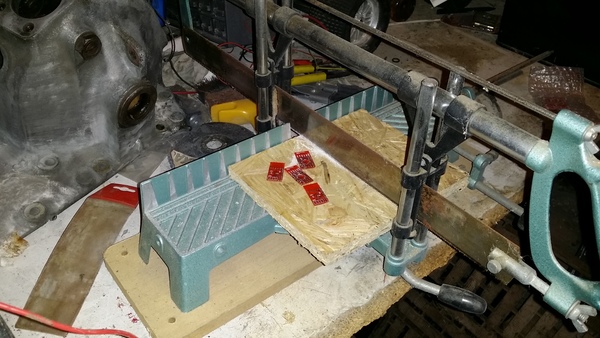

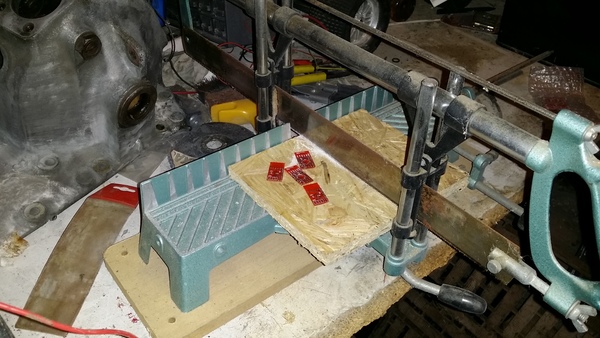

first depanelling in the "garage"

(And just for the fun of it a picture from the garage.. one of my other projects)

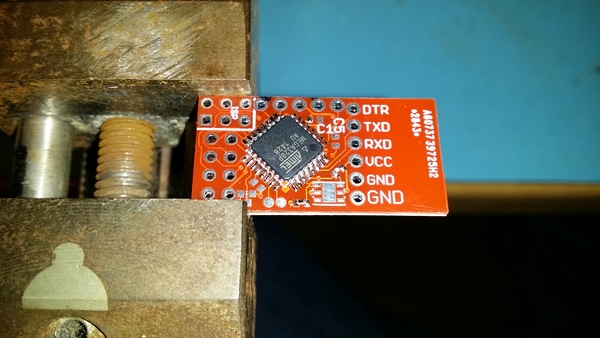

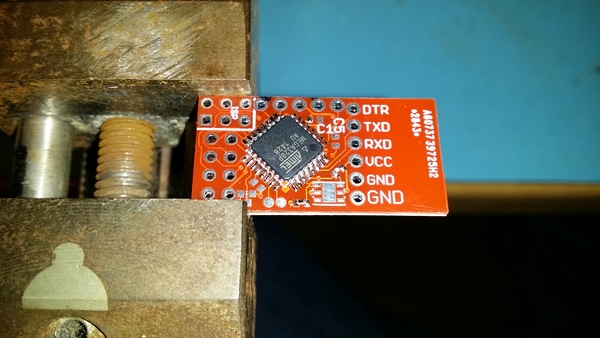

And then to the electronics workshop, mounted the atmega

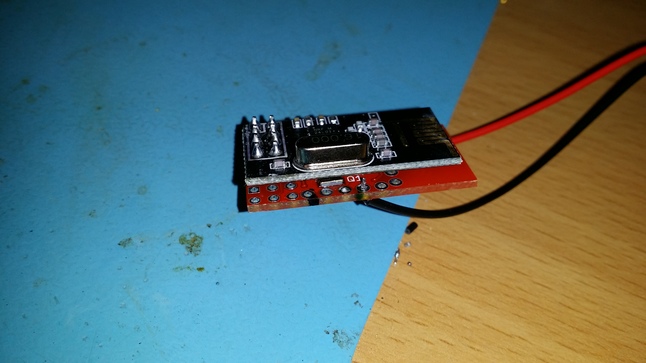

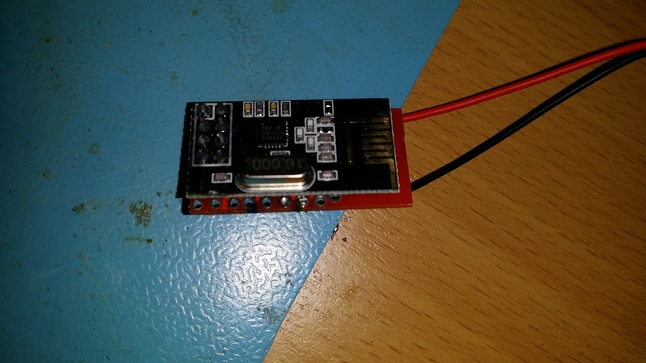

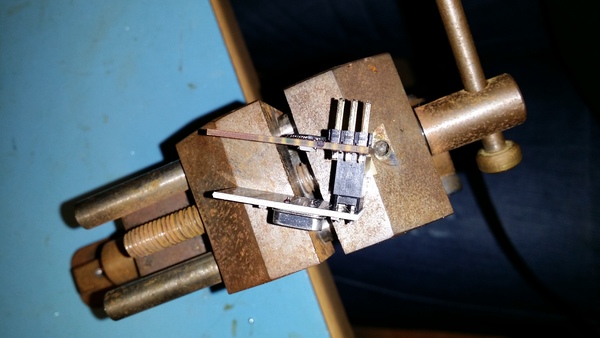

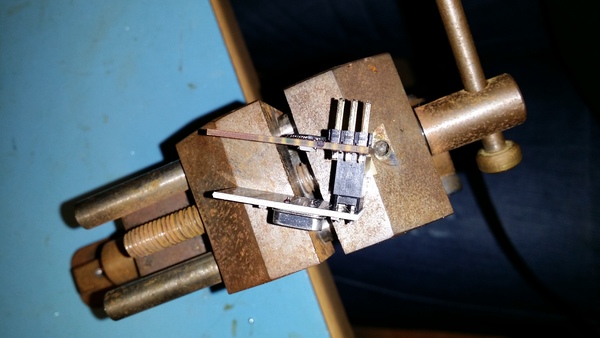

And with NRF module attached...

-

So, it's time for board mounting..

One advice, DOUBLE CHECK the component orders, and TRIPLE check them.. After I got the shipment from mouser, I discovered, that I accidentally had ordered some capacitors in 0101 housing, instead of 0204.. that's DAMN small components.. And I can't use it.. Well thats about 10$ down the drain.. (It was all the decoupling capacitors for the board).

Also found out that I forgot to order a ~100R resistor for the status LED's.. What a bummer!

So I'll have to see if I can source the components quickly from some friends in the next couple of days

Anyways, pic's from the build:

first depanelling in the "garage"

(And just for the fun of it a picture from the garage.. one of my other projects)

And then to the electronics workshop, mounted the atmega

And with NRF module attached...

@tbowmo Sorry to hear about your sourcing troubles. Wish there was an easier and cheaper way to source things.

Smart depaneling, I have a saw like that standing around as well. I have used it to cut some aluminium profiles before but never considered it for cutting pcbs. Still, I will continue to try and look into tabs and "mouse bites" to make depaneling a bit easier.

Is that an old Ferguson that you're renovating? Sorry, but I immediately thought of Frank Erichsen ;-)

So, no problems hand soldering then? Can you complete the circuit for testing or do the missing components get in the way?

-

Sorry to hear about your sourcing troubles. Wish there was an easier and cheaper way to source things.

I am trying to activate my local nerd network, to see if anyone could get the components within the next couple of days (we are 10-18 nerds having regular meetups, some of them are in the electronics business). One of the nerds have some resistors and caps in 0402, but not exactly the values I want (1uF cap, and 760R resistor if I remember correct)

Smart depaneling, I have a saw like that standing around as well. I have used it to cut some aluminium profiles before but never considered it for cutting pcbs. Still, I will continue to try and look into tabs and "mouse bites" to make depaneling a bit easier.

for the next batch of boards, I might go for easier depanelizing options, with tabs and so on (I got the gerber panelizing tool from http://blog.thisisnotrocketscience.nl/projects/pcb-design-tools/)

So, no problems hand soldering then? Can you complete the circuit for testing or do the missing components get in the way?

I managed the soldering so far.. I must admit that I had forgotten how small 0402 components are :) But soldering, and double checking everything with a "monocle" to magnify things, it's doable..

Also I have tried to power up the atmel, it seems to be ok, at least I can get the correct device checksum when I use my jtagice3 on it with avrdude. It would just be more fun to have all the correct components mounted, for testing and verification of the board, before I push the next board revision off to China

Is that an old Ferguson that you're renovating? Sorry, but I immediately thought of Frank Erichsen wink

Yeah it's an old fergie TEA-20 from '54, that I'm trying to renovate :) Not everything should be computers / electronics :) (Btw. is Frank, or "bonderøven" as he's called in Denmark, also known in Sweden?)

-

Sorry to hear about your sourcing troubles. Wish there was an easier and cheaper way to source things.

I am trying to activate my local nerd network, to see if anyone could get the components within the next couple of days (we are 10-18 nerds having regular meetups, some of them are in the electronics business). One of the nerds have some resistors and caps in 0402, but not exactly the values I want (1uF cap, and 760R resistor if I remember correct)

Smart depaneling, I have a saw like that standing around as well. I have used it to cut some aluminium profiles before but never considered it for cutting pcbs. Still, I will continue to try and look into tabs and "mouse bites" to make depaneling a bit easier.

for the next batch of boards, I might go for easier depanelizing options, with tabs and so on (I got the gerber panelizing tool from http://blog.thisisnotrocketscience.nl/projects/pcb-design-tools/)

So, no problems hand soldering then? Can you complete the circuit for testing or do the missing components get in the way?

I managed the soldering so far.. I must admit that I had forgotten how small 0402 components are :) But soldering, and double checking everything with a "monocle" to magnify things, it's doable..

Also I have tried to power up the atmel, it seems to be ok, at least I can get the correct device checksum when I use my jtagice3 on it with avrdude. It would just be more fun to have all the correct components mounted, for testing and verification of the board, before I push the next board revision off to China

Is that an old Ferguson that you're renovating? Sorry, but I immediately thought of Frank Erichsen wink

Yeah it's an old fergie TEA-20 from '54, that I'm trying to renovate :) Not everything should be computers / electronics :) (Btw. is Frank, or "bonderøven" as he's called in Denmark, also known in Sweden?)

@tbowmo said:

Yeah it's an old fergie TEA-20 from '54, that I'm trying to renovate :) Not everything should be computers / electronics :) (Btw. is Frank, or "bonderøven" as he's called in Denmark, also known in Sweden?)

Yep, bonderøven has been on TV over here for a couple of years now. I think I've seen most episodes. I just love that guy's enthusiasm ... and patience.

-

@tbowmo said:

Yeah it's an old fergie TEA-20 from '54, that I'm trying to renovate :) Not everything should be computers / electronics :) (Btw. is Frank, or "bonderøven" as he's called in Denmark, also known in Sweden?)

Yep, bonderøven has been on TV over here for a couple of years now. I think I've seen most episodes. I just love that guy's enthusiasm ... and patience.

I succeeded in getting a couple of components more (Only missing a 2.2uF 0603 capacitor, that was out of stock at mouser.)

I have vacation, so in theory I could go to the "man cave" and mount the last couple of components. Only problem is, that I have 2 "tasmanian devils" aged 3 and 5 years running wild at home today, So no possibility to have time for my self ;)

-

A quick christmas status update, finaly got arround to power the first board up, just with basic code (blink an LED to check that it will work).

Used a couple of hours trying to get my LED to blink. all other pins would toggle, but not my LED, until I finaly digged into the datasheet. I had used A6 for the LED, which turns out to be an input pin only, facepalm. So the board already have the first "green wire" patch :)

Next up is to get serial up and running. before i can start testing temperature / humidity sensor, and radio interface.

-

A quick christmas status update, finaly got arround to power the first board up, just with basic code (blink an LED to check that it will work).

Used a couple of hours trying to get my LED to blink. all other pins would toggle, but not my LED, until I finaly digged into the datasheet. I had used A6 for the LED, which turns out to be an input pin only, facepalm. So the board already have the first "green wire" patch :)

Next up is to get serial up and running. before i can start testing temperature / humidity sensor, and radio interface.

-

And today, radio connection verified, and Si7021 communication is up and running..

Only problem though, is that the Si7021 reports a temperature of 45-50 degrees celcius, where I know it should be closer to 22 degrees..

Also current consumption is rather high at the moment, arround 40mA, It feels like the SI7021 is getting a little bit warmer, than the rest of the components, which (to me) indicates that there is something wrong here.. I accidentially supplied the board with 5V for at test of the internal RC oscilator stability, which is way above the maximum supply voltage of 3.6V. So that might have killed it.

-

And today, radio connection verified, and Si7021 communication is up and running..

Only problem though, is that the Si7021 reports a temperature of 45-50 degrees celcius, where I know it should be closer to 22 degrees..

Also current consumption is rather high at the moment, arround 40mA, It feels like the SI7021 is getting a little bit warmer, than the rest of the components, which (to me) indicates that there is something wrong here.. I accidentially supplied the board with 5V for at test of the internal RC oscilator stability, which is way above the maximum supply voltage of 3.6V. So that might have killed it.

-

@ServiceXp

In the "lab" at the moment, testing the first prototype build.. I got the humidity / temperature "bug" sorted out. Replaced the Si7021 chip on my board, and the new one responded as expected, at least with correct temperature. (humidity is a bit off, I think.. I don't have another humidity sensor at hand here in the lab, so can't compare it..)

I also got the radio up. I haven't done any distance measurements yet, but I can reach the gw in the main building (6-7m away throug a couple of brick walls). Added a 2.2uF cap to the radio. It's still running off the bench power supply. I don't see any problems at the atmel side of things when radio is transmitting.

I just made a test, supplying the setup with 1.9V, and the GW still received the temperature updates :) (somehow my humidity readings don't get through to pidome on the GW, so have to check my setsup again).

I'm waiting for a peer review of the pcb layout, before I push the button for the next batch of proto pcb's. btw. on the next prototype build, I have removed the bmp180, but exposed the SDA/SCL pins on a connector, so it can be attached externally..

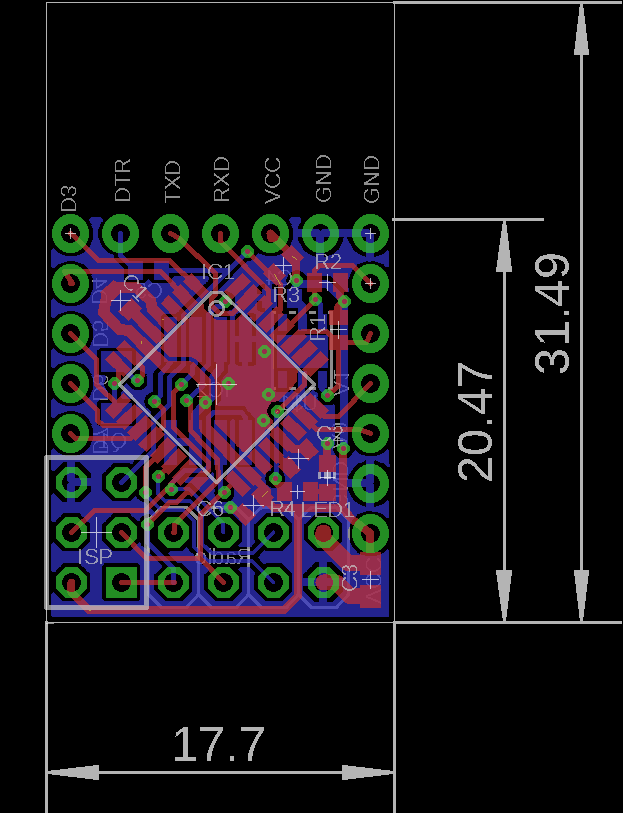

And here is a small preview of the upcomming board prototype.. I had to make the board 1.5mm wider, to make it fit a multiple of 0.1mil between the pinheaders on each side of the pcb. So it will be more versatile to other people as well.. (if any one should want to build them)

-

small update again

Did a small rangetest, and it seems that the range is equal to my other sensor (based on arduino mini and batteries). Also moved the node to the main builidng, besides the weatherstation that I got for christmas (which have hygrometer buildin). It seems that the humidity level on both my sensor node, and the weatherstation is almost comparable.

-

small update again

Did a small rangetest, and it seems that the range is equal to my other sensor (based on arduino mini and batteries). Also moved the node to the main builidng, besides the weatherstation that I got for christmas (which have hygrometer buildin). It seems that the humidity level on both my sensor node, and the weatherstation is almost comparable.

-

@ServiceXp

Haven't tested the eeprom yet, as I don't have any use for it right now. And also need to verify the 32khz crystal oscillator (currently running on the internal rc oscillator). Come to think about it, I need to think up some scenarios where the crystal could come in handy.

Investigations are undergoing, to make something for the "public". Can't say anymore at the moment :)

-

@ServiceXp

Haven't tested the eeprom yet, as I don't have any use for it right now. And also need to verify the 32khz crystal oscillator (currently running on the internal rc oscillator). Come to think about it, I need to think up some scenarios where the crystal could come in handy.

Investigations are undergoing, to make something for the "public". Can't say anymore at the moment :)

-

hmm.. Now I've had the two sensors on the table beside each other (sensor #1 and #2).

Temperature is off by 1.6 degrees celcius, and humidity 2% difference. Could be it's the different temperature, that makes the RH calculation differ a bit..

And for some build data.. It took me a good hour to populate all the parts. This one also have the additional eeprom mounted. but still need something for verifying that it works..

-

hmm.. Now I've had the two sensors on the table beside each other (sensor #1 and #2).

Temperature is off by 1.6 degrees celcius, and humidity 2% difference. Could be it's the different temperature, that makes the RH calculation differ a bit..

And for some build data.. It took me a good hour to populate all the parts. This one also have the additional eeprom mounted. but still need something for verifying that it works..