Minimal design thoughts

-

Hmm I was tricked by the "crypto-authentication" note on atmel site, so thought it only did auth.

Still, lowest vcc is 2.5v. If they could make a device that could operate down to 1.8v instead instead, it would be more interesting.

-

@ServiceXp

Yes, but I am trying to avoid booster circuits at all costs in this design. Also the main function is to collect temperature and humidity values from around the house. So for my part encryption is not a must have for this device.

btw I'm almost there with rerouting rev 2 to make room for the atsha204 (in sot23 housing)

-

Just reading through the datasheet of ATAES132, and realise that I already have support for it on the board. It uses a standard I2C / SPI eeprom footprint, and that is already on the board. So if anyone would like to use it, they only need to replace the flash.

Anyway, I have finished re-routing things.. and the ATSHA204 is now incorporated in the design, so challenge/response authentication could be implemented.

Just need to do the last couple of reviews, before I press the order button for a new set of pcb's

-

Is it not possible to just encrypt the entire packet with an AES library on both ends?

-

Just reading through the datasheet of ATAES132, and realise that I already have support for it on the board. It uses a standard I2C / SPI eeprom footprint, and that is already on the board. So if anyone would like to use it, they only need to replace the flash.

Anyway, I have finished re-routing things.. and the ATSHA204 is now incorporated in the design, so challenge/response authentication could be implemented.

Just need to do the last couple of reviews, before I press the order button for a new set of pcb's

-

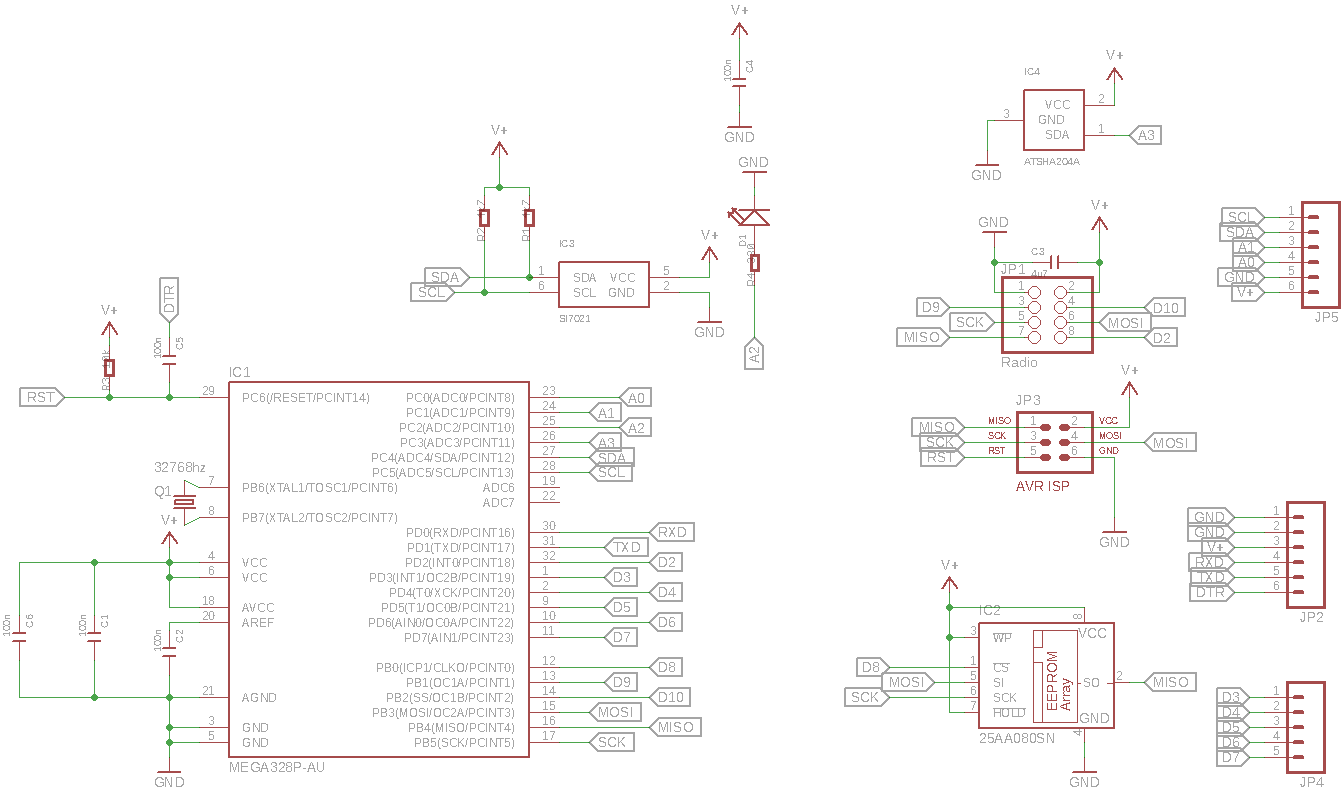

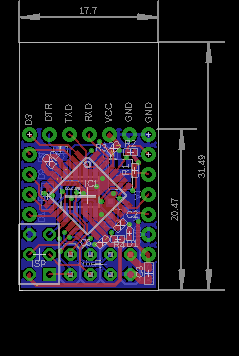

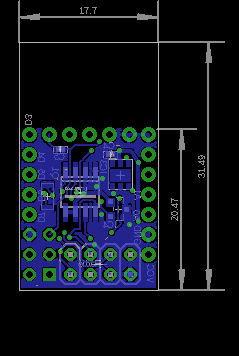

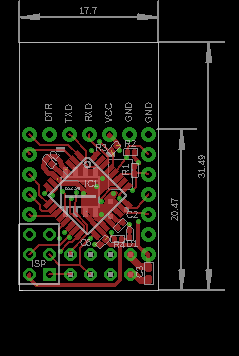

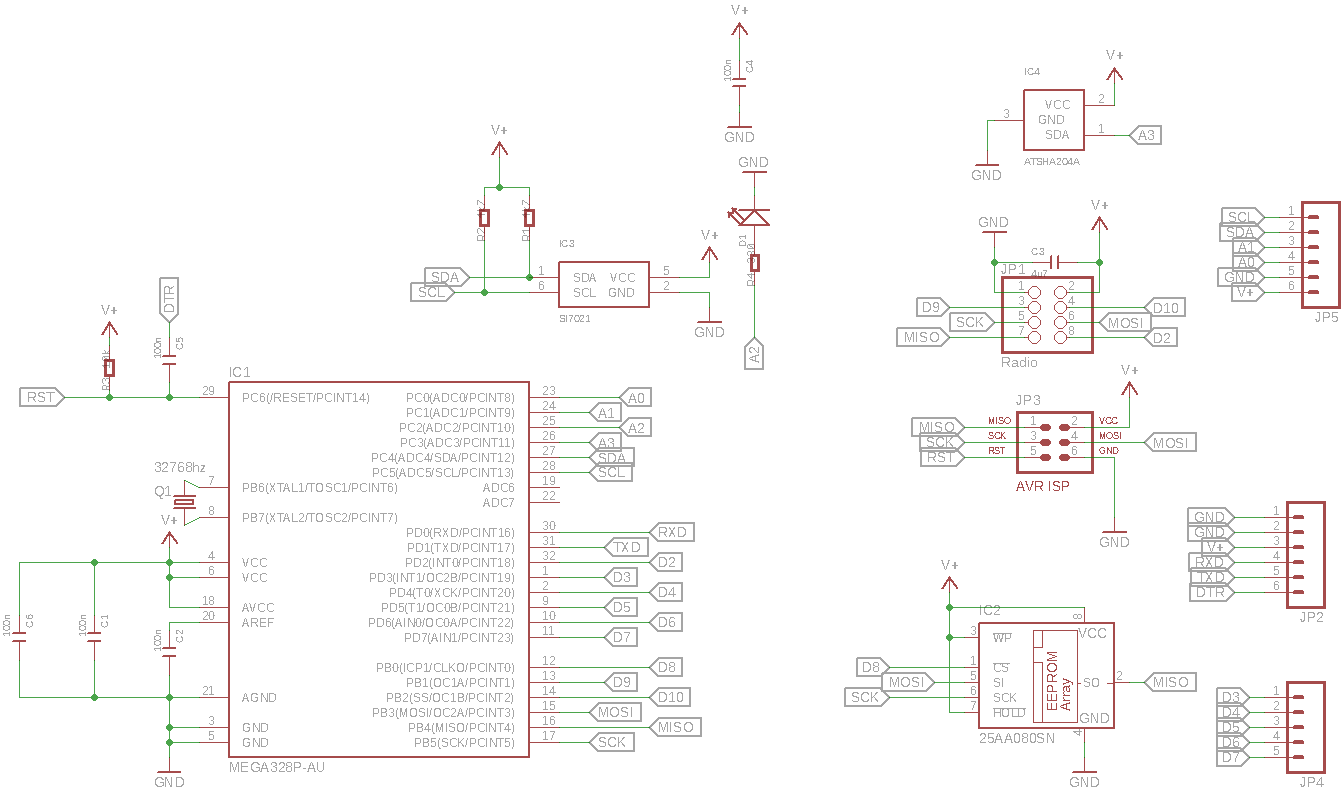

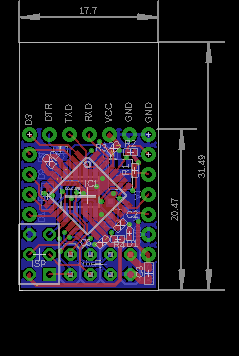

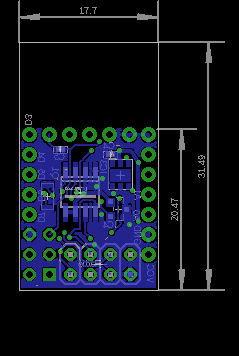

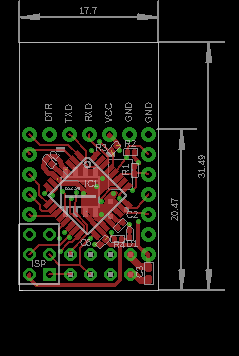

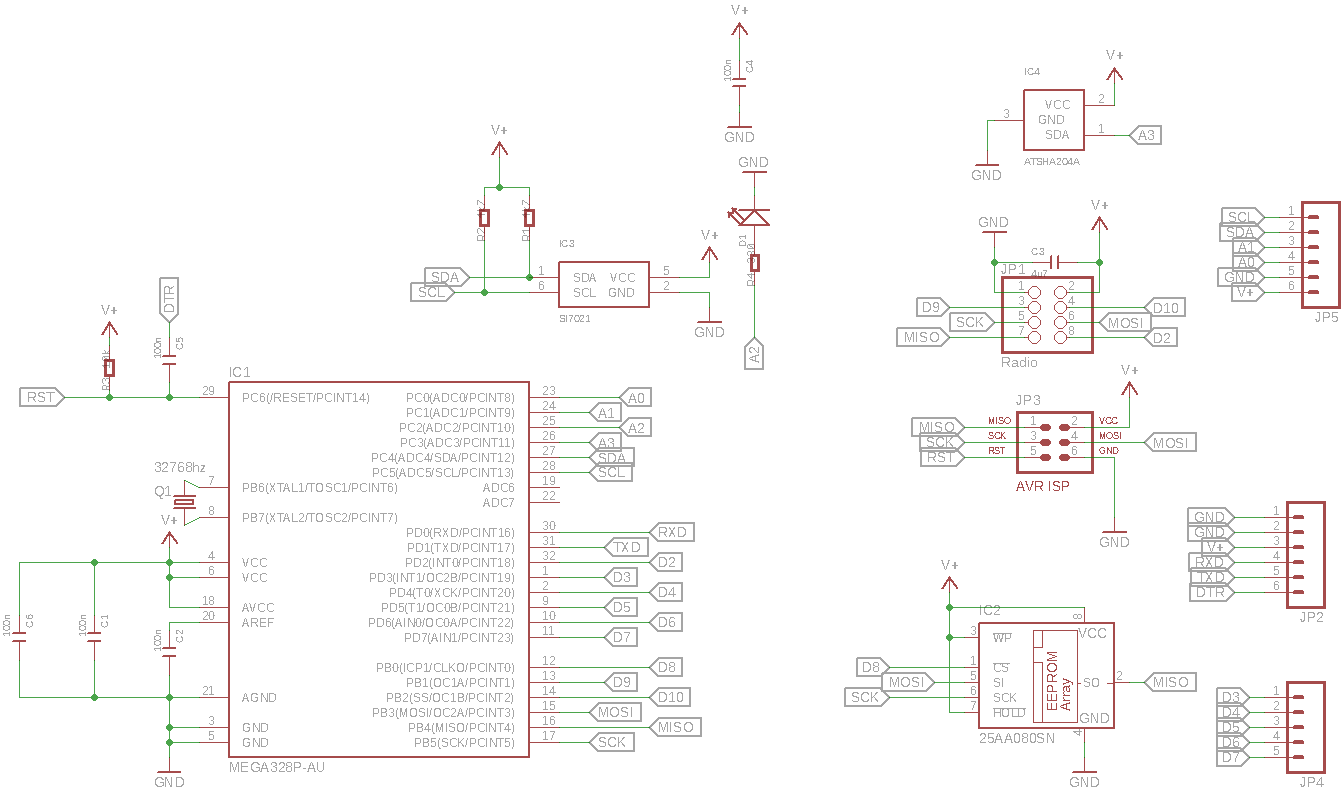

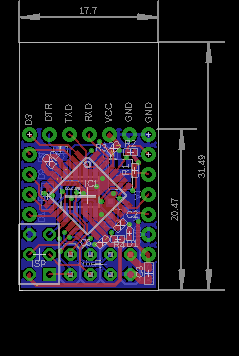

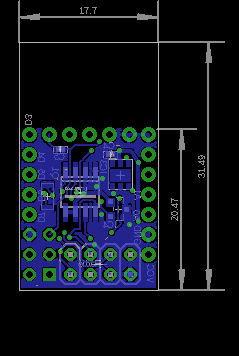

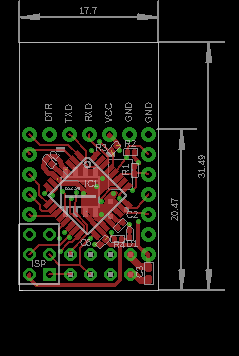

It's single wire atsha204, it's connected to A3. I couldn't fit in the 8 pin variants of the atsha204, so that ruled out the full I2C bus version. It even took me a couple of hours of re-routing to make enough room for the sot23 housing of the ATSHA204.

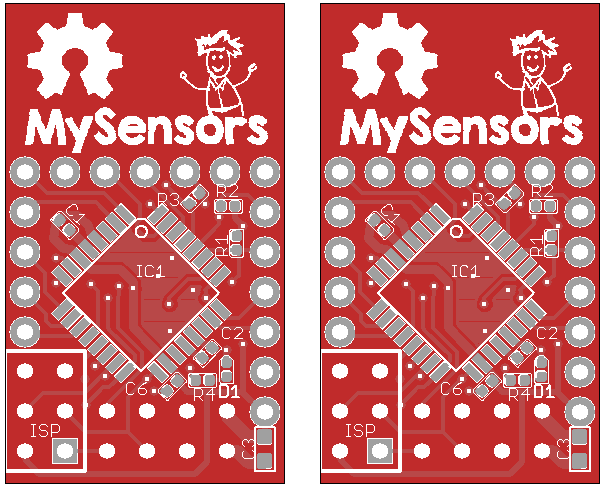

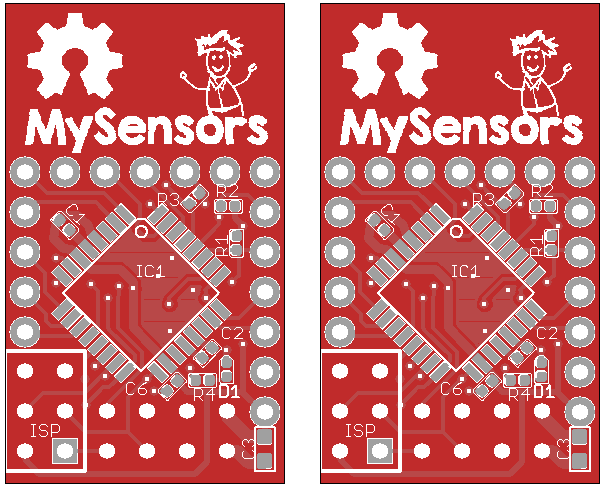

Anyway, schematic / pcb layouts are as follows

-

It's single wire atsha204, it's connected to A3. I couldn't fit in the 8 pin variants of the atsha204, so that ruled out the full I2C bus version. It even took me a couple of hours of re-routing to make enough room for the sot23 housing of the ATSHA204.

Anyway, schematic / pcb layouts are as follows

-

It's single wire atsha204, it's connected to A3. I couldn't fit in the 8 pin variants of the atsha204, so that ruled out the full I2C bus version. It even took me a couple of hours of re-routing to make enough room for the sot23 housing of the ATSHA204.

Anyway, schematic / pcb layouts are as follows

-

I wonder what kind of "hit" on battery life authentication/encryption will have?

-

I do not think it is a big issue. Authentication is normally only needed on nodes that have actuators. And this implies that they always have to listen for incoming data and are therefore inherently non-battery friendly The ATSHA has a very low power consumption, so the added cost for message signing procedures is probably negligible compared to the cost of running the radio continuously.

-

Hmm thinking about it, authentication could be valuable on sensors as well.

If you use the sensor readings to control another actuator, then an attacker could send in his own bogus sensor values in order to trigger system events. He does need to know the specifics about your setup though, so the question is if it's affordable to the mischief to do anything like that :)

-

Yep. This is true, and something I eventually have to add support for.

-

@Dirk_H said:

@tbowmo I don't see a Load Capacitor on the crystal. Especially if you need a precise clock you should use some. Have a look at https://www.adafruit.com/blog/2012/01/24/choosing-the-right-crystal-and-caps-for-your-design/ for example about Load Capacitors.

I know that normally the crystal require load capacitors, but for the low freq. oscilator (32Khz) its not necessary (as far as I have read), that's why I omitted them from the design. I'll try and dig out the datasheets when I'm at home and double check things.

@tbowmo said:

@Dirk_H said:

@tbowmo I don't see a Load Capacitor on the crystal. Especially if you need a precise clock you should use some. Have a look at https://www.adafruit.com/blog/2012/01/24/choosing-the-right-crystal-and-caps-for-your-design/ for example about Load Capacitors.

I know that normally the crystal require load capacitors, but for the low freq. oscilator (32Khz) its not necessary (as far as I have read), that's why I omitted them from the design. I'll try and dig out the datasheets when I'm at home and double check things.

Got around to check up on datasheet for atmel328p, when using lowfrequency oscilator, it has internal load capacitors. If you look at page 33 in the datasheet. So it's not necessary for external capacitors

-

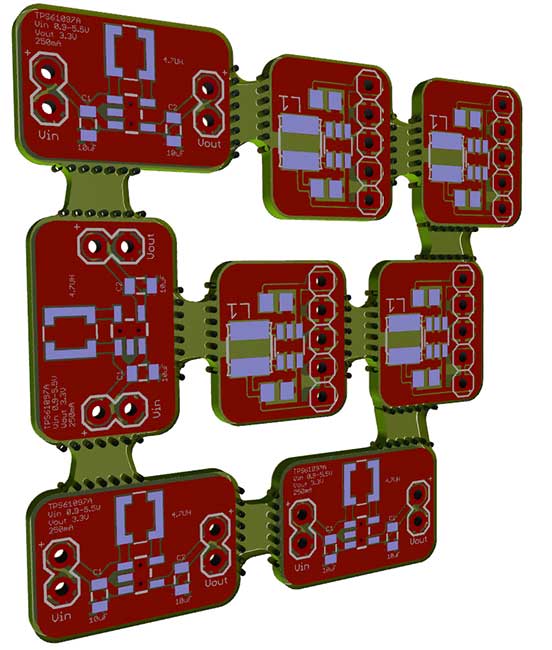

And pcb's are ordered.. Again, using dirtypcbs.com, for the order..

I have used a panelizer tool from http://blog.thisisnotrocketscience.nl/ to panelize the boards this time, so it should be easier to depanelize it when they get here..

-

And pcb's are ordered.. Again, using dirtypcbs.com, for the order..

I have used a panelizer tool from http://blog.thisisnotrocketscience.nl/ to panelize the boards this time, so it should be easier to depanelize it when they get here..

@tbowmo Looks great!

Haven't actually ordered anything produced by the panelizer yet, but the results look really amazing:

I was planning to finally get around to some boost regulators. But I need to design mine from scratch (these are just scavenged from other places) so they follow the same design guide lines and can be plugged in seamlessly to the main pcb.

Would be great if there were some sort of common design to follow for designing shields and such.

-

As you all probably have noticed, there is an mysensor logo on the boards, that I just ordered.. :)

I have been cooperating with @hek for a while, and this is going to be an "official Mysensor pcb" :)

We have been in discussions with a vendor in china, for doing SMT assembly as well.. We are currently waiting for the pcb's to arrive and get them populated, to verify that everything is as it should be, before we start up production in China.

For a batch of 100 units, the price is about 13$ per unit, plus shipping/handling fee, this is without any profits to the project

One question though, I made room for an ATSHA204 chip on the board, that could be used for authentication purposes, we want to know if this should be mounted as default on the board, as it will add arround 1$ to the unit price.

Also how many would be interested in ordering one (or 10, 20, 50?) of them? :) (just so that we get an indication if we should make a batch of 100 units, or 500 units)

-

As you all probably have noticed, there is an mysensor logo on the boards, that I just ordered.. :)

I have been cooperating with @hek for a while, and this is going to be an "official Mysensor pcb" :)

We have been in discussions with a vendor in china, for doing SMT assembly as well.. We are currently waiting for the pcb's to arrive and get them populated, to verify that everything is as it should be, before we start up production in China.

For a batch of 100 units, the price is about 13$ per unit, plus shipping/handling fee, this is without any profits to the project

One question though, I made room for an ATSHA204 chip on the board, that could be used for authentication purposes, we want to know if this should be mounted as default on the board, as it will add arround 1$ to the unit price.

Also how many would be interested in ordering one (or 10, 20, 50?) of them? :) (just so that we get an indication if we should make a batch of 100 units, or 500 units)

That's 2 questions... :-)

- Yes, It's worth it to me (Hopefully there will be MySensors software support down the road)

- I would probably start off with 3 to 5.

Will there be a "kit" price for those who want to populate and reflow themselves?