💬 RFM69 Livolo 2 channels 1 way EU switch(VL-C700X-1_Ver_C2)

-

-

OK...another remake for the classic Livolo 2 channels 1 Way EU switch and THE LAST ONE that I will make(well except for the 1 channel one which I need to work on it after this one) - @shabba I know that you waited for this. This is just the other Livolo hardware project of mine "ported" for the new hw revision that the Chinese manufacturer made. They made the 12V line available on the connector and moved it on the opposite side(the new connector is a 2mm pitch one and SMD - I choose to use the THT variant as it doesn't have any impact from a mechanical point of view and it's easier to solder for all of us the mortals around here).

The good news is that the power board is the same as the old one with some minor modifications(more or less):

- the big MOSFET is in the same place but with a 45 degrees orientation

- the power connector is a 2x7 pins one with the 12V line already supplied on one of the pins - less hacks for the board

- the bistable relays are the same and drived by a ULN2003 IC(current buffer) in a TSSOP package

Thanks to @tonnerre33 for creating the new board outline which I borrowed from his project. The rest of the board is the same as the other one that I made with the dc-dc converter moved on the opposite side and with some rearrangements. Next I need to create the boards AGAIN using some external manufacturer(China of course) and then wait...and patience and... patience again and...wait.

And as always big thanks to the Mysensors community for their great effort and for maintaining this great project.

Oh...and for some reason the boards are not rendered correctly in the browser - I'm referring to the openhardware.io gerber viewer(both 2D and the 3D one) - maybe it has to do with the latest changes from KiCAD regarding the way the gerber are generated or maybe some bug in there? (I'm using the latest nightly version). The Linux gerbview utility displays them correctly.

-

@mtiutiu said in 💬 Livolo 2 channels 1 way EU switch(VL-C700X-1_Ver_C2):

Good work dude !

For information, i think receive in the next 2 weeks, the pcb that i made for training.

If you can wait, i'll can check the mecanical part before your pcb order.

As you want ;) -

Some gerbers just seems to be rendered a bit weirdly using pcb-stackup. I will keep it updated when/if new versions becomes available.

It uses file endings to detect layer type. So it is important to follow the a "standard" naming (which isn't easy as there's a million ways these design pcb programs spit out names).

-

Some gerbers just seems to be rendered a bit weirdly using pcb-stackup. I will keep it updated when/if new versions becomes available.

It uses file endings to detect layer type. So it is important to follow the a "standard" naming (which isn't easy as there's a million ways these design pcb programs spit out names).

Uploaded and public shared this plate design at OSHPark for anyone interested:

https://oshpark.com/shared_projects/wG8bXaBJ

PD: I'm not affiliated in any way to OSHPark and only uploaded and shared the @mtiutiu desing there for facilitation purposes for anyone interested that needed do a quick order of that plate boards in a good board build service at enough good price.

Best regards

-

Hi @mtiutiu, i need your help ;)

The new board outline is perfect and the position of the connector too but my thickness board is too high (just an aesthetic point).

So, the mecanic is good and when i power the pcb with 12v by a battery all is ok.

But, there is a but :( when i power the node by the livolo, that's not working. The 12V goes to 3.15V.

I tried to change the tantalum capacitor localised at the input of the MCP16301 by a ceramic capacitor but i have always the issue.Have you any idea ?

Edit : one thing i didn't place it's the 470pF on the BYP MIC5205-3.3 because i haven't this value. I tried with 100pF and without capactitor but the issue still here

-

Hi @mtiutiu, i need your help ;)

The new board outline is perfect and the position of the connector too but my thickness board is too high (just an aesthetic point).

So, the mecanic is good and when i power the pcb with 12v by a battery all is ok.

But, there is a but :( when i power the node by the livolo, that's not working. The 12V goes to 3.15V.

I tried to change the tantalum capacitor localised at the input of the MCP16301 by a ceramic capacitor but i have always the issue.Have you any idea ?

Edit : one thing i didn't place it's the 470pF on the BYP MIC5205-3.3 because i haven't this value. I tried with 100pF and without capactitor but the issue still here

Missing capacitor will not produce this effect, it will just not allow the low noise operation of the regulator. It might result in poor radio performance but nothing else.

@tonnerre33 do you have a load on the main to allow enough current to pass through ? @mtiutiu uses a capacitor for that. If you don't the board can't draw enough power and that would be a good reason to have voltage droping.

-

Hi @mtiutiu, i need your help ;)

The new board outline is perfect and the position of the connector too but my thickness board is too high (just an aesthetic point).

So, the mecanic is good and when i power the pcb with 12v by a battery all is ok.

But, there is a but :( when i power the node by the livolo, that's not working. The 12V goes to 3.15V.

I tried to change the tantalum capacitor localised at the input of the MCP16301 by a ceramic capacitor but i have always the issue.Have you any idea ?

Edit : one thing i didn't place it's the 470pF on the BYP MIC5205-3.3 because i haven't this value. I tried with 100pF and without capactitor but the issue still here

@tonnerre33 @Nca78 is right. First you need to have a capacitor in parallel with the light bulb (a 0.47uF/275Vac type X2 is enough). This is needed because the power supply from the original Livolo board doesn't provide enough current in standby mode and this is obviously a good reason because otherwise the light bulb will flicker or maybe light up a little bit and this is not wanted. Remember that we talk here about a series circuit and that we need to take power not in the standard way - usually a power supply is made for being wired with both live and neutral and not live wire only as in the current situation.

If the capacitor across the light bulb still doesn't help then you need to follow the other steps I mentioned in the first project that I made for Livolo. One of the steps is to wire a bridge across that resistor marked with 104 - you can spot it easily as seen from those pictures that I made at that time. Then if it still doesn't work you need a second wire for the MOSFET biasing - this may be a little hard to see where it goes exactly as the Livolo manufacturer changed the board layout a little bit - not that much from the original one...but I need to figure out.

-

@mtiutiu I wired a bridge across the resistor marked 104 and my node was powered well.

But after on or two command, the 12v doesn't work when the lamp is off. When the lamp is on (forcing command relay), the 12V appear and all run.

Is the CMOS broken ? Which component produce this 12V when the lamp is off ? -

@mtiutiu I wired a bridge across the resistor marked 104 and my node was powered well.

But after on or two command, the 12v doesn't work when the lamp is off. When the lamp is on (forcing command relay), the 12V appear and all run.

Is the CMOS broken ? Which component produce this 12V when the lamp is off ?Maybe the mosfet bias hack needs to be done also. The truth is that power electronics is not my thing and this power supply is a little bit beyond my understanding...well not that much but some things are not clear for me either. Those hardware modifications were picked from other thread in this forum. Maybe @Nca78 knows better than me this part?

@tonnerre33 did you wired the capacitor across the light bulb as well?

-

Maybe the mosfet bias hack needs to be done also. The truth is that power electronics is not my thing and this power supply is a little bit beyond my understanding...well not that much but some things are not clear for me either. Those hardware modifications were picked from other thread in this forum. Maybe @Nca78 knows better than me this part?

@tonnerre33 did you wired the capacitor across the light bulb as well?

@mtiutiu said in 💬 Livolo 2 channels 1 way EU switch(VL-C700X-1_Ver_C2):

Maybe @Nca78 knows better than me this part?

Haha, no way :D I did my board using NRF24 so I don't have to mess with the power/relay board ;)

-

Maybe the mosfet bias hack needs to be done also. The truth is that power electronics is not my thing and this power supply is a little bit beyond my understanding...well not that much but some things are not clear for me either. Those hardware modifications were picked from other thread in this forum. Maybe @Nca78 knows better than me this part?

@tonnerre33 did you wired the capacitor across the light bulb as well?

@mtiutiu said in 💬 Livolo 2 channels 1 way EU switch(VL-C700X-1_Ver_C2):

did you wired the capacitor across the light bulb as well?

Nope, the light bulb i use contains already a capacitor 1.1µF (thx Nca ;) ) and the bulb is lighted a little even if the button is off.

I duno why but the mofset is HS, i have checked him with my multimetor.

He can operate with 1.5A max, i don't understand why he burnt and why after a command... Before this command all was ok ... Why i pushed the button :laughing:edit : @mtiutiu said

Those hardware modifications were picked from other thread in this forum.

Which thread ?

-

@mtiutiu said in 💬 Livolo 2 channels 1 way EU switch(VL-C700X-1_Ver_C2):

did you wired the capacitor across the light bulb as well?

Nope, the light bulb i use contains already a capacitor 1.1µF (thx Nca ;) ) and the bulb is lighted a little even if the button is off.

I duno why but the mofset is HS, i have checked him with my multimetor.

He can operate with 1.5A max, i don't understand why he burnt and why after a command... Before this command all was ok ... Why i pushed the button :laughing:edit : @mtiutiu said

Those hardware modifications were picked from other thread in this forum.

Which thread ?

Here: https://forum.mysensors.org/topic/2775/livolo-glass-panel-touch-light-wall-switch-arduino-433mhz/62. I think that @Tigroenot and @jirm know better than me actually. Sorry @Nca78 to involve you on this part. But @tonnerre33 if you wait until next week I'll inspect the new Livolo power board in a little bit more detail and see if I can come up with something.

-

@mtiutiu I wired a bridge across the resistor marked 104 and my node was powered well.

But after on or two command, the 12v doesn't work when the lamp is off. When the lamp is on (forcing command relay), the 12V appear and all run.

Is the CMOS broken ? Which component produce this 12V when the lamp is off ?@tonnerre33 well, the reason for that is that livolo switch power circuit board contains two power circuits :)

One is a standby power which feeds the MC while all lamps are off and another one is the circuit that powers the whole system while at least one of the lamps is on (for two lamps switch). -

@tonnerre33 well, the reason for that is that livolo switch power circuit board contains two power circuits :)

One is a standby power which feeds the MC while all lamps are off and another one is the circuit that powers the whole system while at least one of the lamps is on (for two lamps switch).@Tigroenot Thank you for your comment.

I understand there is 2 power circuits, but i don't understand why the mosfet burnt, after wire a bridge across the 100K resistor and after few commands (not immediatly).I did many simulations with LTspice and i didn't find the reason...

I think he has burnt when i have the lamp 1 on and i have pushed on the other button without lamp 2 connected on the livolo.

If someone have any idea, that's will be helpfull for not burn another mofset. ^^

Now i'am waiting the deliveri of the mofset and i am hoping that is the HS component ;)

-

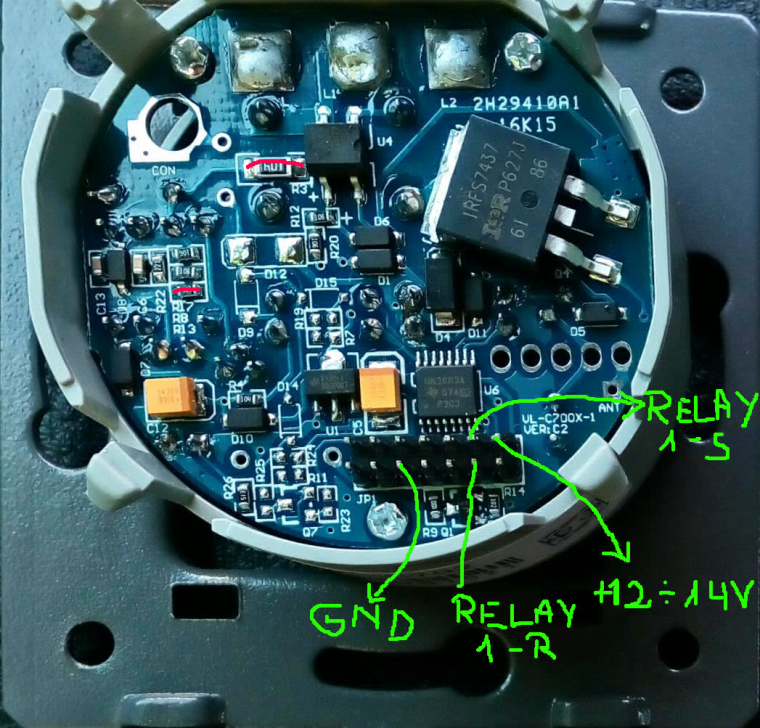

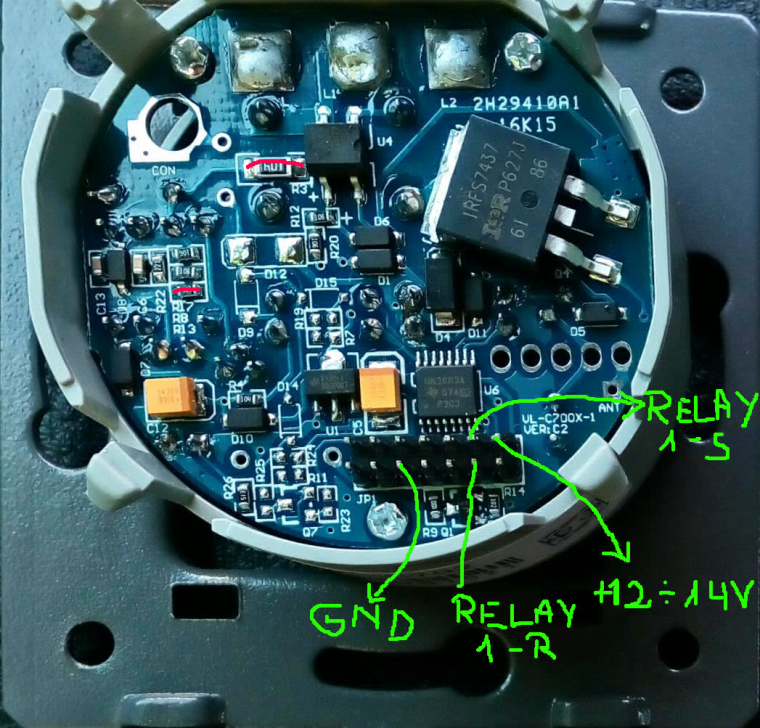

Good news everyone! I managed to set up a test board in order to verify the new Livolo relays/power board and with the required modifications IT WORKS!!! as the previous one did from my old project. This time only 2 modifications are required on the board instead of 3 because the 12-14V supply is already connected now to the 2x7 connector.

I expected this to work as the power/relays board didn't changed - they placed the same set of components but in some different places and I was able to recognize the base layout.

@tonnerre33 Maybe yo wired something wrong..but for me it worked from the start. I will post here images and test results so stay tuned.

There you have it in action(sorry for my phone camera and delays): MySensors Livolo in action

Power/relays board required modifications(red lines represent wires - you could desolder those components too and just put some solder/wire bridges)

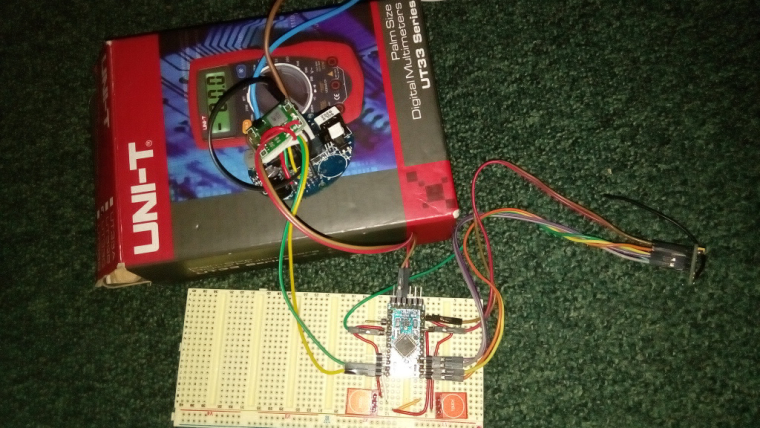

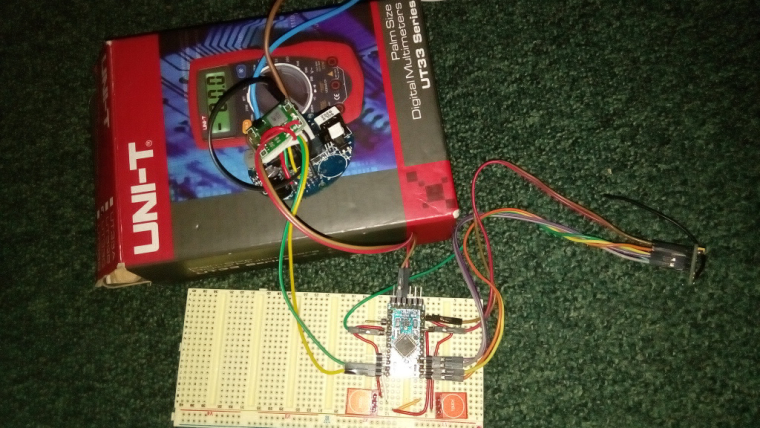

Next as seen in the video I wired a cheap dc-dc step down converter bought from Aliexpress to the 12-14V pin from the connector and ground and used its 3.3V output to power up the arduino pro mini board. The RELAY 1 - S and 1- R pins mean: channel 1(or 2 - it doesn't matter as the channels are identical) Set and Reset(because we have bi-stable relays). Those were wired to some digital outputs on arduino pro mini as seen here:

-

Good news everyone! I managed to set up a test board in order to verify the new Livolo relays/power board and with the required modifications IT WORKS!!! as the previous one did from my old project. This time only 2 modifications are required on the board instead of 3 because the 12-14V supply is already connected now to the 2x7 connector.

I expected this to work as the power/relays board didn't changed - they placed the same set of components but in some different places and I was able to recognize the base layout.

@tonnerre33 Maybe yo wired something wrong..but for me it worked from the start. I will post here images and test results so stay tuned.

There you have it in action(sorry for my phone camera and delays): MySensors Livolo in action

Power/relays board required modifications(red lines represent wires - you could desolder those components too and just put some solder/wire bridges)

Next as seen in the video I wired a cheap dc-dc step down converter bought from Aliexpress to the 12-14V pin from the connector and ground and used its 3.3V output to power up the arduino pro mini board. The RELAY 1 - S and 1- R pins mean: channel 1(or 2 - it doesn't matter as the channels are identical) Set and Reset(because we have bi-stable relays). Those were wired to some digital outputs on arduino pro mini as seen here:

@mtiutiu Did you try with only a brige on the 100K resistor ?

Which type of lamp and power did you use ?