What did you build today (Pictures) ?

-

New gateway going live and migrating slowly from Domoticz to Homeassistant. At least to try it.

-

@nagelc Thanks! The clip on programmer is one-part Adafruit’s FTDI “Fiddy” from here, and one-part SparkFun’s old (retired?) 3.3 or 5v selectable FTDI programmer with a custom 3D printed enclosure.

I plan to modify the “Fiddy” design a bit as there were some elements of it that I’ve found a bit frustrating. However, YMMV. Gotta love pogo pins for programming though…

Re: Board envy. Really? Well, if you like, I could do what I did on my last project - which was selling the leftovers. At the moment, I always make more than I need, for testing and some much needed practice with the smaller 0402s. Just send me a chat message if you (or anyone else?) are interested.

-

@acb have you written a bootloader yourself, or found already available? Can you tell more about it and a board you using to connect nrf52 to FTDI?

Nice work!@monte Re: FTDI Boards & Bootloaders.

I didn’t write the bootloader myself from scratch, but modified and combined various elements from Nordic’s SDK v11 example, SparkFun’s development version and Adafruit’s Feather version.

It was quite a nice learning experience of hacking in bootloader land and dealing with event-driven architectures without any low level debugging skills (yet!) - that’s why I’m now trying to get into SWD/JTAG debugging to make things like this easier.

I certainly don’t understand everything that’s going on, but “loosely” from what I can figure out, it uses Nordic’s proprietary SoftDevice (S132) combined with some custom bootloader code to boot into a predefined state, where it’ll wait for new “image” either over a serial or bluetooth connection.

The new “image” can be either your regular sketch-type code (referred to as the “application”), a new SoftDevice (S212, S332, etc.) and/or even a new bootloader.

Once the new “image” is received and validated by the (existing) bootloader, it is copied to replace the existing “image” parts where necessary and the chip is reset.

Nordic’s pc-nrfutil command line utility handles interfacing with any standard FTDI board over a COM port (mine is an old SparkFun, but any should work) to perform the upload.

In SDK11, there isn’t much in the way of safeguards, but in SDK15 there are things like cryptographic signing, custom initialization packets and protocol buffers, etc.

I did have to make one tweak to the nrfutil Python code, to make it wait a little longer after opening the COM port before sending the DFU initialization packet. This might be unnecessary with optimized bootloader code, I don’t know, since the nRF52832 boots pretty quickly.

I could go on, but I’m still learning myself, and so if you or anyone else has any other questions, comments, suggestions, etc., perhaps we better move them to a new discussion thread? (Just tag me in so I see it…)

Thanks for your interest though!

-

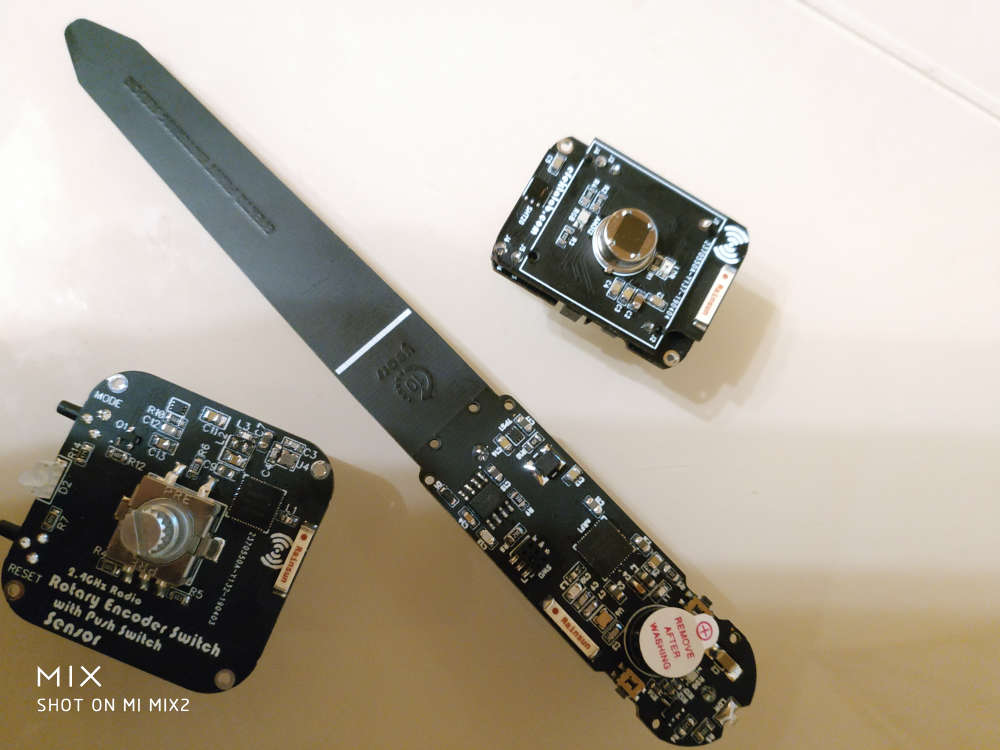

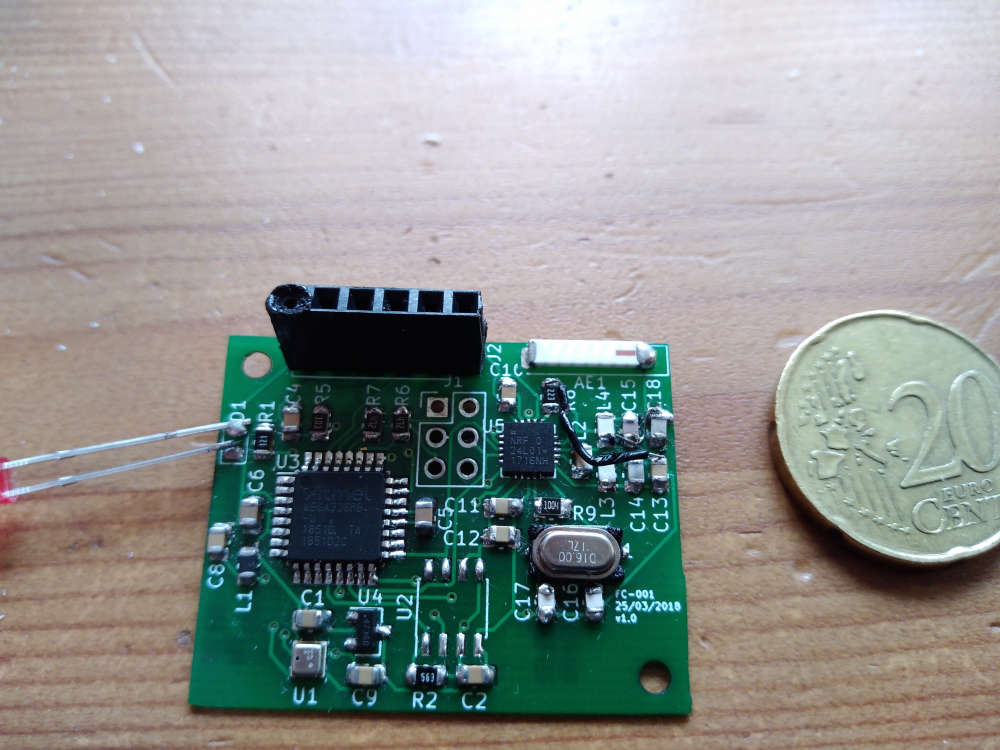

Well,in my case, I mounted and tried to fix bugs in my very first design. This is supposed to be a castelizable Sensebender compatible node, embedding NRF24L01+, LED, Temp/Humi/Press sensor, Memory, crypto, with most of the IO exposed. The updated design is online, but still work in progress.

project on OpenHardware -

Thanks @berkseo!

Have been enjoying your work with nRF52 designs.

Also on my list is trying the built-in capacitive touch capabilities of the chip.

I can @ you if I get anywhere with it - might come in handy for your capacitive touch glass mini switch to save you a few components?

-

Thanks @berkseo!

Have been enjoying your work with nRF52 designs.

Also on my list is trying the built-in capacitive touch capabilities of the chip.

I can @ you if I get anywhere with it - might come in handy for your capacitive touch glass mini switch to save you a few components?

-

@monte Re: FTDI Boards & Bootloaders.

I didn’t write the bootloader myself from scratch, but modified and combined various elements from Nordic’s SDK v11 example, SparkFun’s development version and Adafruit’s Feather version.

It was quite a nice learning experience of hacking in bootloader land and dealing with event-driven architectures without any low level debugging skills (yet!) - that’s why I’m now trying to get into SWD/JTAG debugging to make things like this easier.

I certainly don’t understand everything that’s going on, but “loosely” from what I can figure out, it uses Nordic’s proprietary SoftDevice (S132) combined with some custom bootloader code to boot into a predefined state, where it’ll wait for new “image” either over a serial or bluetooth connection.

The new “image” can be either your regular sketch-type code (referred to as the “application”), a new SoftDevice (S212, S332, etc.) and/or even a new bootloader.

Once the new “image” is received and validated by the (existing) bootloader, it is copied to replace the existing “image” parts where necessary and the chip is reset.

Nordic’s pc-nrfutil command line utility handles interfacing with any standard FTDI board over a COM port (mine is an old SparkFun, but any should work) to perform the upload.

In SDK11, there isn’t much in the way of safeguards, but in SDK15 there are things like cryptographic signing, custom initialization packets and protocol buffers, etc.

I did have to make one tweak to the nrfutil Python code, to make it wait a little longer after opening the COM port before sending the DFU initialization packet. This might be unnecessary with optimized bootloader code, I don’t know, since the nRF52832 boots pretty quickly.

I could go on, but I’m still learning myself, and so if you or anyone else has any other questions, comments, suggestions, etc., perhaps we better move them to a new discussion thread? (Just tag me in so I see it…)

Thanks for your interest though!

@acb we can continue discussion in this thread, If you want: https://forum.mysensors.org/topic/6961/nrf5-action/

So as I understand for now you are using native SDK and not using Arduino and mysensors? As far as I know arduino's core for nrf5 has no support for bootloaders, and mysensors conflicts even with softdevice being present on a chip. And it seems that sandeepmistry (author of the core) isn't going to invest his time into writing bootloader and can't use nordic's one because of license. I would like to have a bootloader solely for bluetooth OTA programming for projects beside mysensors. Maybe you could share your work, and/or write some kind of brief tutorial on where to start working on this subject maybe to avoid problems you have already solved? Anyway, great work from you, hope someday we will have mysensors on nrf52 with working OTA.

-

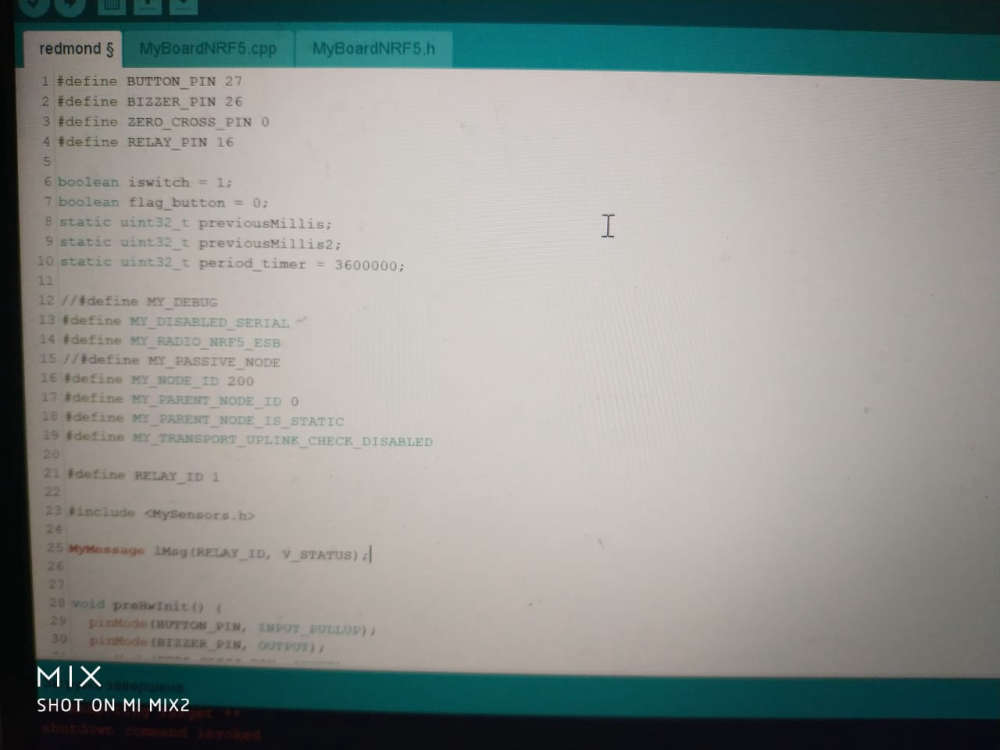

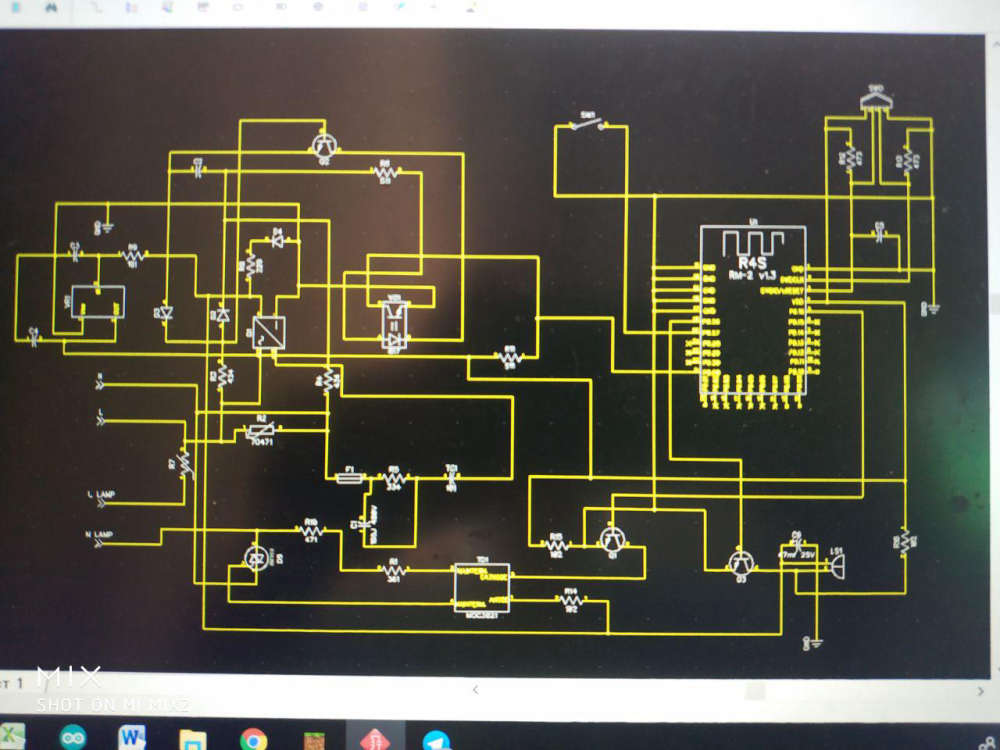

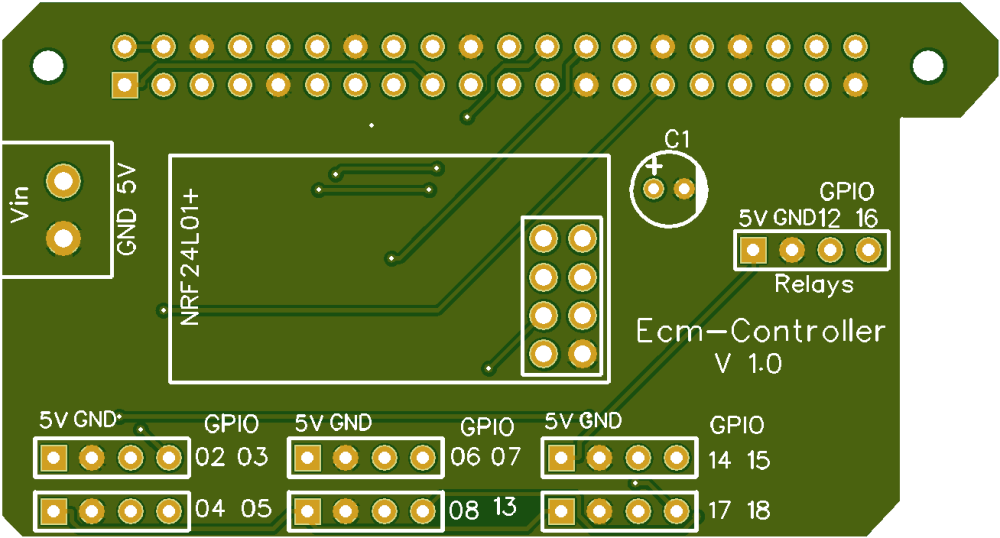

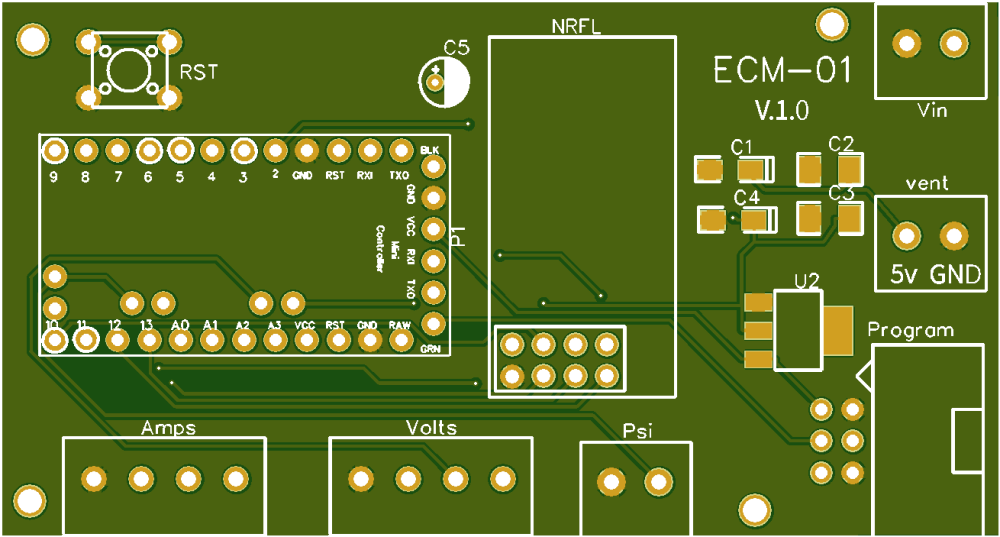

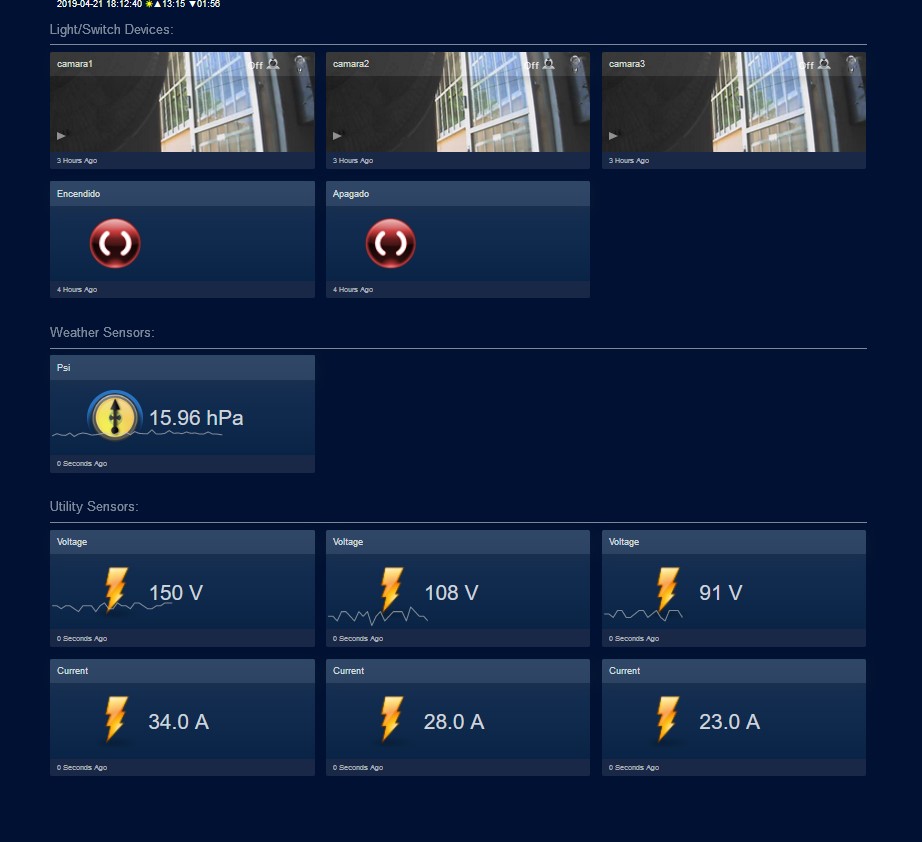

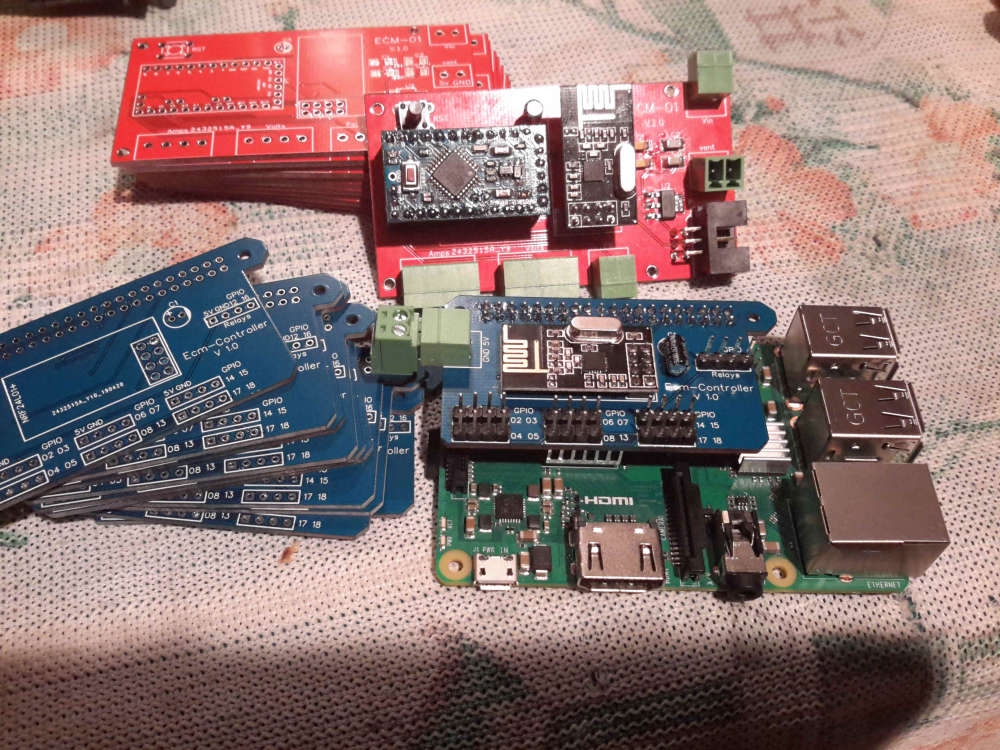

well this is my project , right now im using 2 arduino nano with ethernet shield to read 3 lines Voltage on a delta instalation , 3 current sensors of 300amps for a motor , and 1 water pressure ,

all conected to a raspberry pi with domoticz

but yesterday i decide to change all , instead of 2 uno i will use a pro mini with a nrf24

so i desing two pcb

some code

#define MY_NODE_ID 100 #define MY_DEBUG #define MY_RADIO_NRF24 #include <SPI.h> #include <MySensors.h> #define CHILD_ID_VOLT_1 1 #define CHILD_ID_VOLT_2 2 #define CHILD_ID_VOLT_3 3 #define CHILD_ID_CURRENT_1 4 #define CHILD_ID_CURRENT_2 5 #define CHILD_ID_CURRENT_3 6 #define CHILD_ID_PRESION 7 #define VOLT_SENSOR_ANALOG_PIN_1 0 #define VOLT_SENSOR_ANALOG_PIN_2 1 #define VOLT_SENSOR_ANALOG_PIN_3 2 #define CURRENT_SENSOR_ANALOG_PIN_1 3 #define CURRENT_SENSOR_ANALOG_PIN_2 4 #define CURRENT_SENSOR_ANALOG_PIN_3 5 #define PressPin A6 unsigned long SLEEP_TIME = 20000; // Sleep time between reads (in milliseconds) MyMessage msg(CHILD_ID_VOLT_1, V_VOLTAGE); MyMessage msg2(CHILD_ID_VOLT_2, V_VOLTAGE); MyMessage msg3(CHILD_ID_VOLT_3, V_VOLTAGE); MyMessage msg4(CHILD_ID_CURRENT_1, V_CURRENT); MyMessage msg5(CHILD_ID_CURRENT_2, V_CURRENT); MyMessage msg6(CHILD_ID_CURRENT_3, V_CURRENT); MyMessage pressureMsg(CHILD_ID_PRESION, V_PRESSURE); float lastVolt1; float lastVolt2; float lastVolt3; float lastCurrent1; float lastCurrent2; float lastCurrent3; float lastPresion; int pressure = 0; float PSI = 0; float PSI_CAL = 2.0; // Calibration of sensor int PSImsb = 0; int PSIr = 0; void before() { } void presentation() { sendSketchInfo("Multisensor", "1.7"); // Send the sketch version information to the gateway and Controller present(CHILD_ID_VOLT_1, S_MULTIMETER); // Register this device as power sensor present(CHILD_ID_VOLT_2, S_MULTIMETER); // Register this device as power sensor present(CHILD_ID_VOLT_3, S_MULTIMETER); // Register this device as power sensor present(CHILD_ID_CURRENT_1, S_MULTIMETER); // Register this device as power sensor present(CHILD_ID_CURRENT_2, S_MULTIMETER); // Register this device as power sensor present(CHILD_ID_CURRENT_3, S_MULTIMETER); // Register this device as power sensor present(CHILD_ID_PRESION, S_WATER); // Register this device as power sensor } void setup() { } void loop() { int Voltaje1 = analogRead(A0); int Voltaje2 = analogRead(A1); int Voltaje3 = analogRead(A2); int Corriente1 = analogRead(A3); int Corriente2 = analogRead(A4); int Corriente3 = analogRead(A5); float VoltLevel1 = map(Voltaje1,0,1023,0,500); float VoltLevel2 = map(Voltaje2,0,1023,0,500); float VoltLevel3 = map(Voltaje3,0,1023,0,500); float CorrienteLevel1 = map(Corriente1,0,1023,0,200); float CorrienteLevel2 = map(Corriente2,0,1023,0,200); float CorrienteLevel3 = map(Corriente3,0,1023,0,200); Serial.print("Voltaje L1: "); Serial.println(VoltLevel1); Serial.print("Voltaje L2: "); Serial.println(VoltLevel2); Serial.print("Voltaje L3: "); Serial.println(VoltLevel3); Serial.print("Corriente L1: "); Serial.println(CorrienteLevel1); Serial.print("Corriente L2: "); Serial.println(CorrienteLevel2); Serial.print("Corriente L3: "); Serial.println(CorrienteLevel3); //sensor de voltaje if (VoltLevel1 != lastVolt1) { send(msg.set(VoltLevel1, 1)); lastVolt1 = VoltLevel1; } if (VoltLevel2 != lastVolt2) { send(msg2.set(VoltLevel2, 1)); lastVolt2 = VoltLevel2; } if (VoltLevel3 != lastVolt3) { send(msg3.set(VoltLevel3, 1)); lastVolt3 = VoltLevel3; } //sensor de corriente if (CorrienteLevel1 != lastCurrent1) { send(msg4.set(CorrienteLevel1, 1)); lastCurrent1 = CorrienteLevel1; } if (CorrienteLevel2 != lastCurrent2) { send(msg5.set(CorrienteLevel2, 1)); lastCurrent2 = CorrienteLevel2; } if (CorrienteLevel3 != lastCurrent3) { send(msg6.set(CorrienteLevel3, 1)); lastCurrent3 = CorrienteLevel3; } /* ************************************************ */ pressure = analogRead (PressPin) ; // junk read wait(25); /* • Output: 0.5V – 4.5V linear voltage output. 0 psi outputs 0.5V, 50 psi outputs 2.5V, 100 psi outputs 4.5V 0 psi = .33v after scalling 5.0v to 3.3v 50 psi = 1.65v 100 psi = 2.97v 3.3v/1024 = .0032266 volt per bit */ pressure = analogRead (PressPin) ; if (pressure < 106) pressure = 106; // this is minimum of .5v PSI = (pressure - 106 ) * .1246; // where did we get this?? was .119904 PSI = PSI + PSI_CAL; // adjustment PSImsb = PSI * 100; PSIr = PSImsb % 100; send(pressureMsg.set(PSI, 2)); // Send water pressure to gateway Serial.print("Presion: "); Serial.println(PSI); wait(200); // end of if (SLEEP_MODE || (cu sleep(SLEEP_TIME); }havent tested with sensors yet

but looks good so far

-

@berkseo whoa, time for a Kickstarter! They look great! Where did you have them made, and what do they cost?

@fernando-alvarez-buylla Always nice to see the Aurora theme being used :-)

-

And a few days later my pcb's arrived

Now to test the next version

-

-

How did you 'hack' it? All I see in the video is you changing a power wire?

-

-

@berkseo whoa, time for a Kickstarter! They look great! Where did you have them made, and what do they cost?

@fernando-alvarez-buylla Always nice to see the Aurora theme being used :-)

-

@berkseo very cool! How did you do that? Did you just have to connect the serial holes to an ST_LINK adapter or something similar? Was is difficult to open the device? And, most importantly: is your code available somewhere?

-

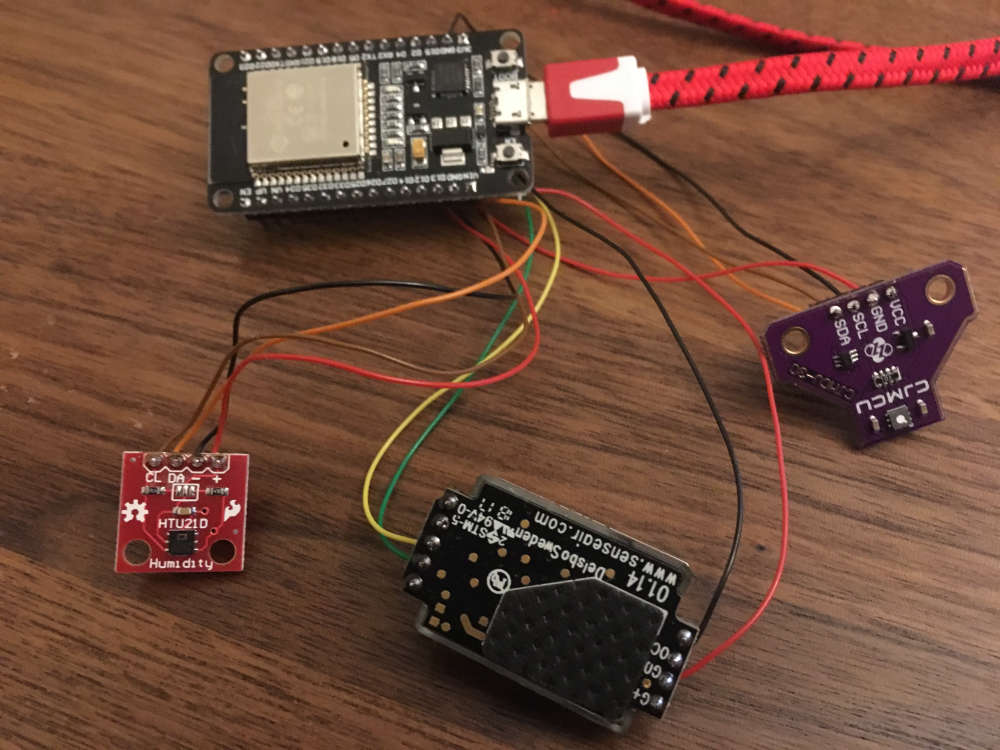

Added two other (e)co2 sensors to my test-setup.

Now 3 NDIR and 2 VOC under observation. :)

-

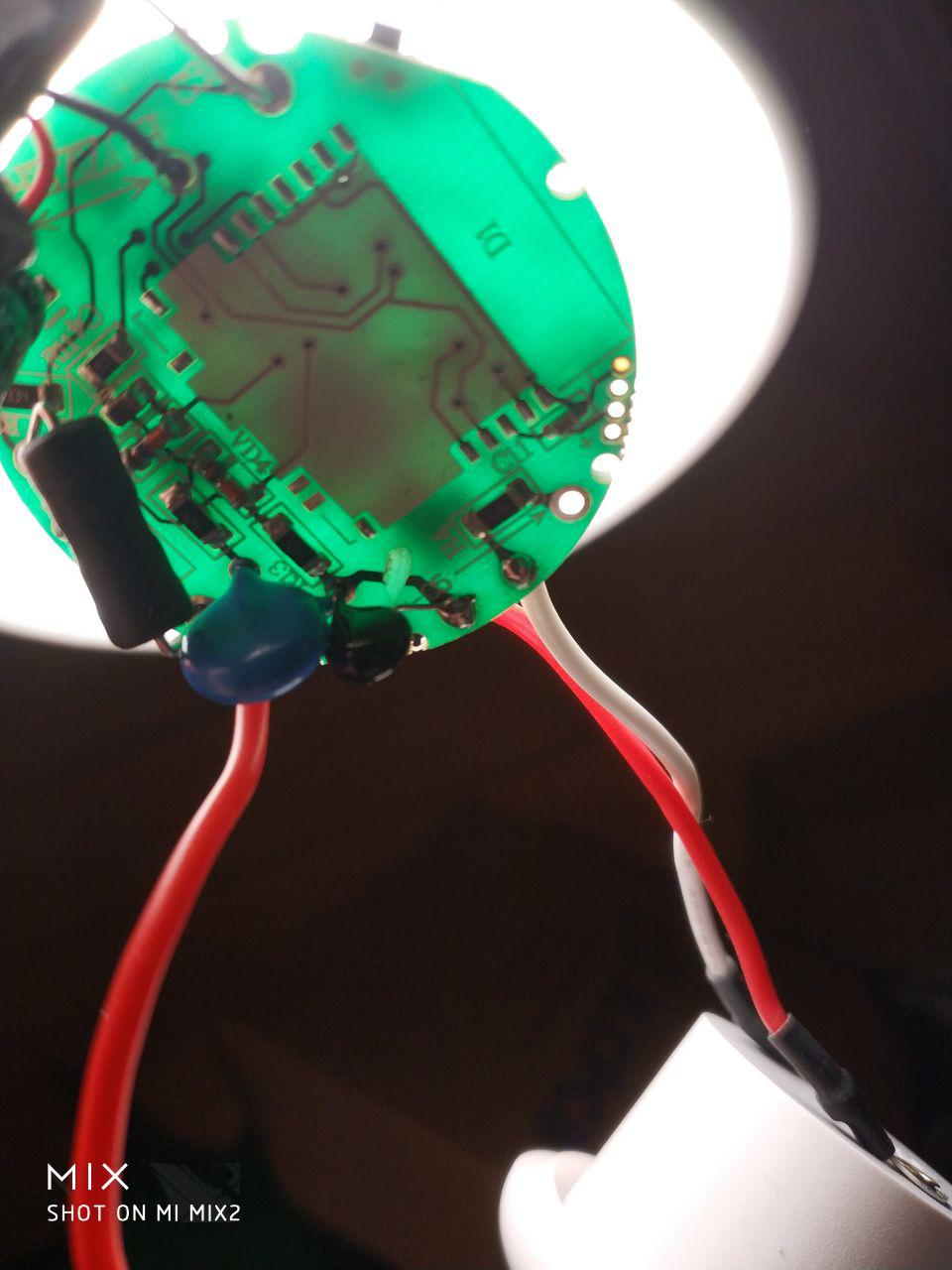

A family member gave me an old lamp with a fancy glass base. Well, I didn't like the lamp, but the base was nice, so I kept it in my basement for a few years. I found it again the other day and decided it needed to become a new type of lamp. I put a 150 LED strip (WS2812B) inside. I have an STM32 Blue Bill and RFM69HCW to run the light patterns and connect to MySensors.

In Domoticz, I have it set up as a dimmer light, but the node just switches patterns depending on what the dimmer level is.

At first, I wrapped the LED strip carefully around a tube that sits in the center of the glass jar, but it didn't look very good. Somehow just spiraling the strip in the bottom of the lamp has a much better effect.

My wife even liked it, so maybe I will put some finishing touches on it and actually use it as a lamp : )