Pellet burner Monitoring

-

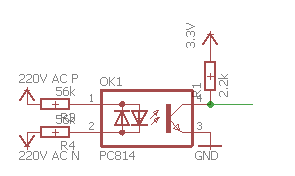

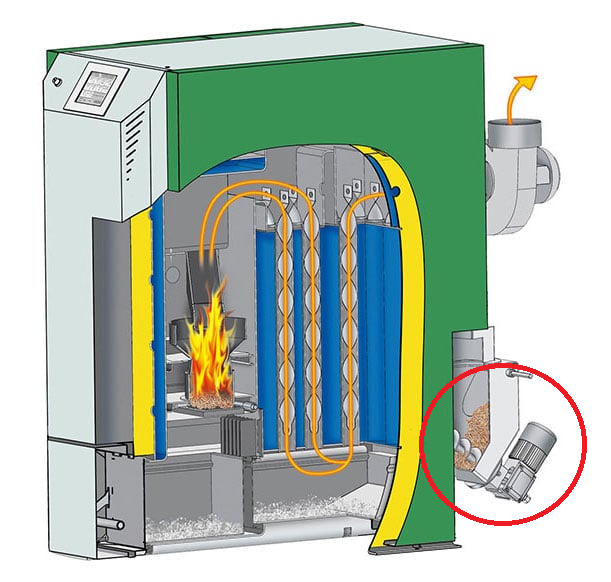

With please. Here is a global schema of the pellet burner:

I have circled the part displaying the beginning of the pellet conveyor and the motor.

-

Maybe I'm missing something, but why not using a clamp current sensor so you don't have to mess with mains ?

I think the vibration sensor was not a bad idea, but should be done with an accelerometer. Then you could set a minimum vibration threshold based on the "action" of your pellet burner that is of interest for you ?

-

With please. Here is a global schema of the pellet burner:

I have circled the part displaying the beginning of the pellet conveyor and the motor.

@qqlapraline I don't quite see the logic here, you are looking at checking a mechanical output but from electrical behaviour, or am I completely missing the objective?

Most pellet feed archimidean screw drives I've seen have the drive shaft extend beyond the gearbox, even if only a short stub to which you could attach a rotational sensor or a magnet... Short of shearing the shaft, detecting shaft rotation at that end should be 100%, no?.

Failing that, there is usually a flat plate at the start of the shaft where the feed comes in to prevent clogging or choking, perhaps the passing of the paddle could be detected, giving you turns per whatever? -

something else, can't you measure the pellet storage tank with an ultrasonic range?, as times go by you can measure the hight is increasing (If the sensor is on the top lid)

and then I would measure the smoke temperature with a KTY sensor, as those can withstand around 1.000degree C.

Depending of your specific pellet boiler it might always have a little fire, some can self ignite the fire with a ceramic heatcoildoes your pellet tank looks like this?

http://midtfyns-montage.dk/wp-content/uploads/2016/12/Snegl-SCOTTE.jpg -

@Nca78, actually, I did not want to touch the existing cables to avoid any claim from the maintenance guy ;) And as I could not access one single wire, I had to find another way. Interesting enough, using the existing connecting screws was easier.

@zboblamont: the picture is quite not clear but the motor is very well protected to avoid any mechanical injury. And, probably as a consequence, there is not detectable magnetic field coming out of it.

@bjacobse: I have considered this as well (as well as some kind of a gauge based on pressure or anything else in the tank). But, unfortunatly, as this is a 7 tons / 11 m3 pellet tank, it is filled by a truck blowing pellets into it....making the life of the ultrasonic sensor really not long :)

Furthermore, ultrasonic sensor would be good to measure a level with a very large error margin. With my sensor, I will be close to a 1-gram quantum...measuring the current consumption very accurately.

For the story of it, I already have a way to measure pellet consumption in a rough approximation: but weighting the ashes :) :)QQ.

-

@Nca78, actually, I did not want to touch the existing cables to avoid any claim from the maintenance guy ;) And as I could not access one single wire, I had to find another way. Interesting enough, using the existing connecting screws was easier.

@zboblamont: the picture is quite not clear but the motor is very well protected to avoid any mechanical injury. And, probably as a consequence, there is not detectable magnetic field coming out of it.

@bjacobse: I have considered this as well (as well as some kind of a gauge based on pressure or anything else in the tank). But, unfortunatly, as this is a 7 tons / 11 m3 pellet tank, it is filled by a truck blowing pellets into it....making the life of the ultrasonic sensor really not long :)

Furthermore, ultrasonic sensor would be good to measure a level with a very large error margin. With my sensor, I will be close to a 1-gram quantum...measuring the current consumption very accurately.

For the story of it, I already have a way to measure pellet consumption in a rough approximation: but weighting the ashes :) :)QQ.

@qqlapraline I think you were replying to @gohan suggestion.

Is neither end of the shaft exposed or are they both shrouded?

Interesting solution though.... -

@Nca78, actually, I did not want to touch the existing cables to avoid any claim from the maintenance guy ;) And as I could not access one single wire, I had to find another way. Interesting enough, using the existing connecting screws was easier.

@zboblamont: the picture is quite not clear but the motor is very well protected to avoid any mechanical injury. And, probably as a consequence, there is not detectable magnetic field coming out of it.

@bjacobse: I have considered this as well (as well as some kind of a gauge based on pressure or anything else in the tank). But, unfortunatly, as this is a 7 tons / 11 m3 pellet tank, it is filled by a truck blowing pellets into it....making the life of the ultrasonic sensor really not long :)

Furthermore, ultrasonic sensor would be good to measure a level with a very large error margin. With my sensor, I will be close to a 1-gram quantum...measuring the current consumption very accurately.

For the story of it, I already have a way to measure pellet consumption in a rough approximation: but weighting the ashes :) :)QQ.

-

@zboblamont : it's not exposed under the tank and totally shrouded on the boiler side

@gohan: right, by I really don't want to touch the wires. And neutral and phase are inside a single cable with not enough space to put a clamp..;)

-

Yep ! And that's why it's fun ! :)

But my zc detector will work too. My first tests are OK :)QQ.

-

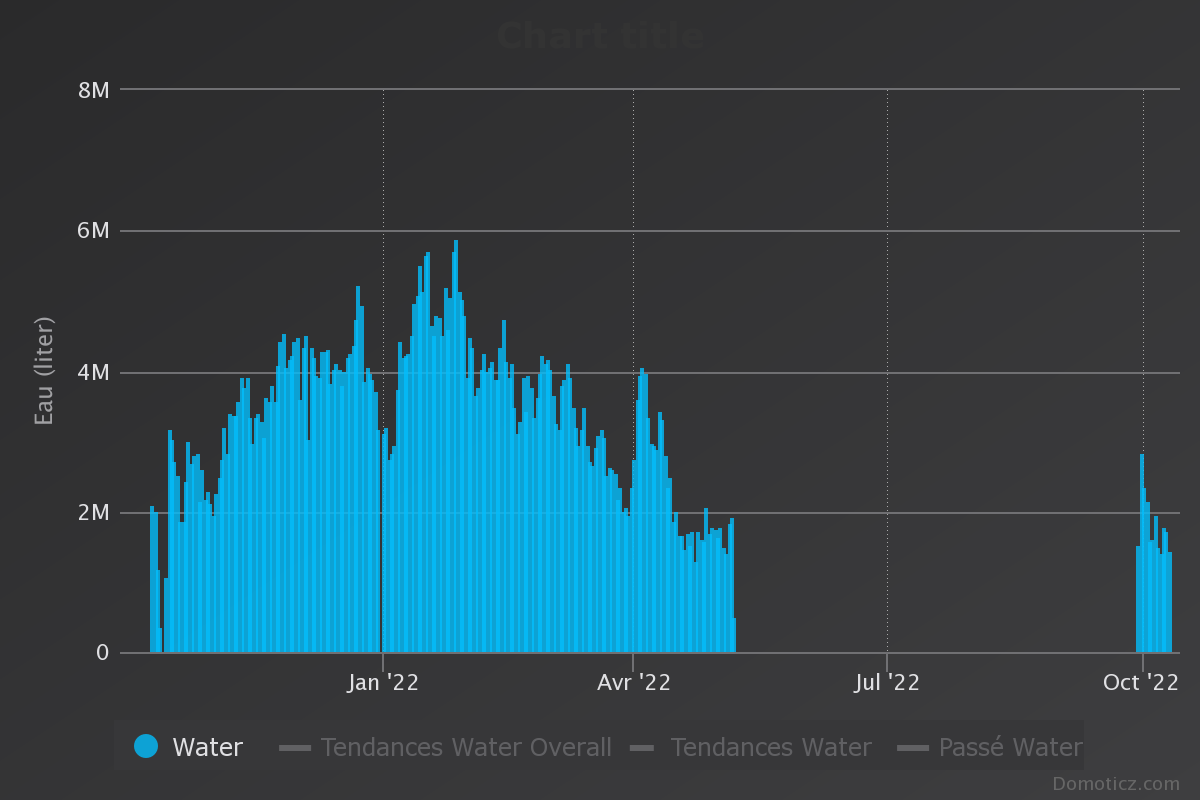

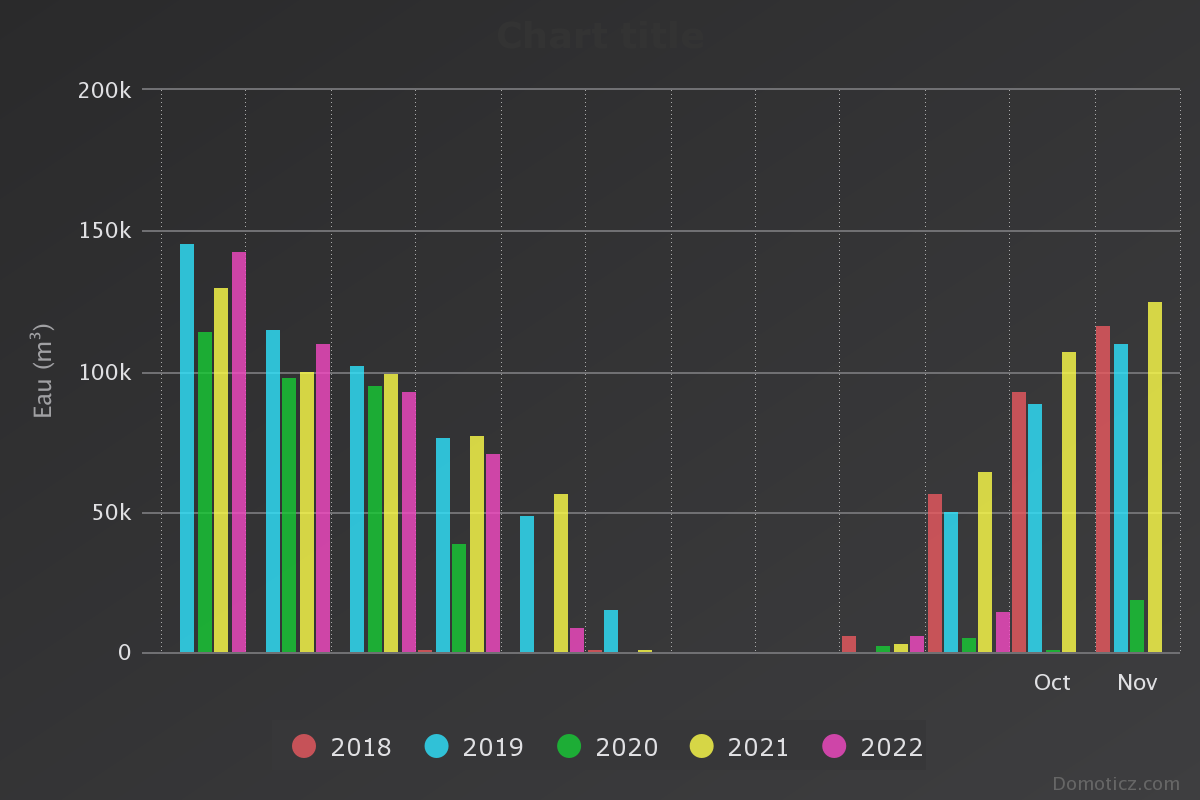

After a 4 years work, here are some samples of my pellet consumption.

Now, guess when I usually stop the boiler ..:)

Cheers,

QQ.