Anyone tried the Creality CR-10 3D printer?

-

@dbemowsk Yes it is a Ramps but in a way it is only "partly" used. The bed heating is, as mentioned, at 220V so Ramps is only used for the signal an external device. Same with the extruder heaters, i e the Ramps is used for a signal to a more robust device. This remedies some of the weaknesses of the Ramps card and enables heating of two extruders simultaneously.

I have bought external drivers for the step motors as well but not yet found any reason to switch to these. So the motors are still driven by the 8225 drivers on the Ramps card.

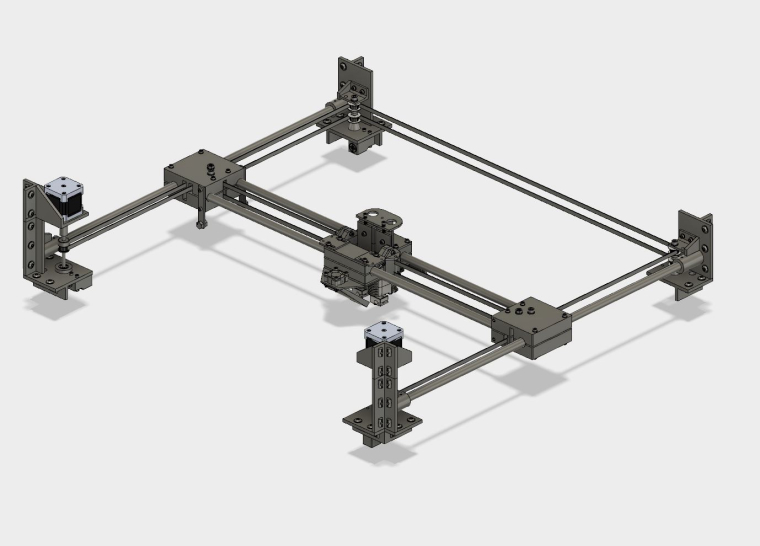

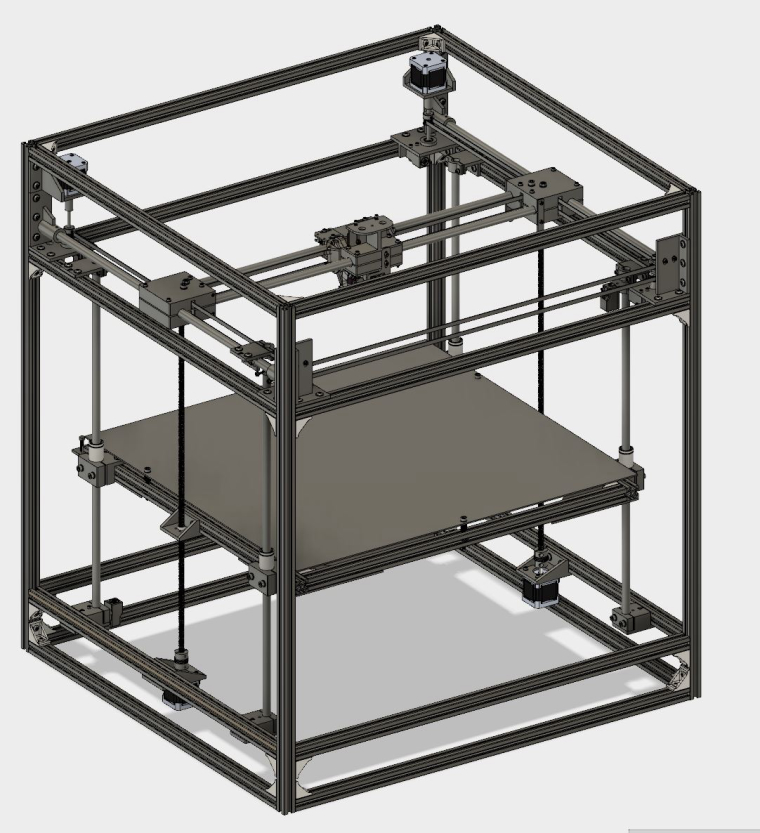

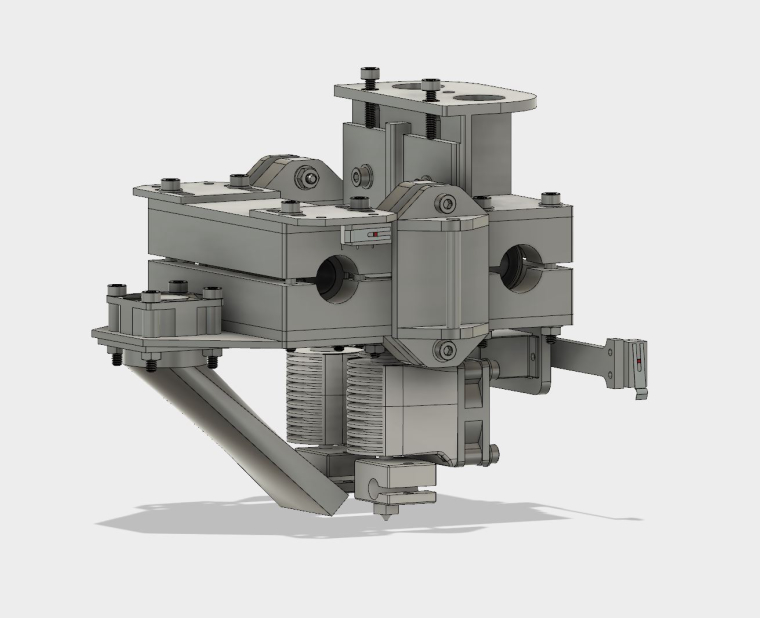

In case anyone is interested, this is what "the Thing" looks like on the drawing board:

Presumably the Mysensors forum is not intended for discussions about 3D printers why I hope I have not violated any rules by jumping into the conversation.

@mbj said in Anyone tried the Creality CR-10 3D printer?:

Presumably the Mysensors forum is not intended for discussions about 3D printers why I hope I have not violated any rules by jumping into the conversation.

No worries:

General Discussion

A place to talk about whateeeever you want -

@gohan If we are talking about hobby stuff with comparable low cost the belt should be better but there are limitations like how much weight can be handled at high speeds without loosing precision. So it is a question with many answers depending on the circumstances.

-

Of course I am referring to hobby stuff and on a corexy/hypercube setup since I saw also people using lead screws instead of belts. I was trying to understand what is the best option while maintaining the same precision with the option to have a dual extruder setup

-

Of course I am referring to hobby stuff and on a corexy/hypercube setup since I saw also people using lead screws instead of belts. I was trying to understand what is the best option while maintaining the same precision with the option to have a dual extruder setup

@gohan The beauty with a CoreXY is that both X and Y movements are handled by stationary motors which do not add any moving weight. Changing to lead screws means that most likely 2 motors are needed for Y (for a large design) and then another screw and motor for X and these will add to the moving weight. Of course a belt could also be used for X but the motor arrangement needed for this will still be a moving part.

Even if my CoreXY is really big it can print with same or even better resolution than my old OrdBot Hadron which is so much smaller. The OrdBot has a direct drive extruder and also the X motor arrangement attached as a moving parts and this affects what printing speeds can be achieved at a given resolution. The CoreXY has a Bowden arrangement which further lowers the moving weight.

-

@gohan The beauty with a CoreXY is that both X and Y movements are handled by stationary motors which do not add any moving weight. Changing to lead screws means that most likely 2 motors are needed for Y (for a large design) and then another screw and motor for X and these will add to the moving weight. Of course a belt could also be used for X but the motor arrangement needed for this will still be a moving part.

Even if my CoreXY is really big it can print with same or even better resolution than my old OrdBot Hadron which is so much smaller. The OrdBot has a direct drive extruder and also the X motor arrangement attached as a moving parts and this affects what printing speeds can be achieved at a given resolution. The CoreXY has a Bowden arrangement which further lowers the moving weight.

@mbj said in Anyone tried the Creality CR-10 3D printer?:

Changing to lead screws means that most likely 2 motors are needed for Y

This was a question that came up in one of the groups I am a member of for my Anet A8 as it has 2 motors for the Z axis that lifts the gantry. Wouldn't it be possible to use one higher torque motor for the Y axis and then use a notched belt between them? With two motors, you have the risk of one missing a step and then having to re-position your Y axis from time to time because of that.

-

@mbj said in Anyone tried the Creality CR-10 3D printer?:

Changing to lead screws means that most likely 2 motors are needed for Y

This was a question that came up in one of the groups I am a member of for my Anet A8 as it has 2 motors for the Z axis that lifts the gantry. Wouldn't it be possible to use one higher torque motor for the Y axis and then use a notched belt between them? With two motors, you have the risk of one missing a step and then having to re-position your Y axis from time to time because of that.

@dbemowsk For Z I have seen solutions with motors and belts so this is possible. It is just another piece to design and the motor need to be sized for both which might be a bigger problem with Y than with Z. I have never thought about it so it is just a guess.

-

@dbemowsk There is one example: Anet A2 dual Z single motor

-

@pjr I guess the trick is to find a closed loop belt of suitable length and also make a screw design which can move enough sideways to tighten the belt.

-

@mbj It would have to tighten and also not cause any binding of the Z axis during travel. I have see belt tensioner springs that snap on to the belt, but with this needing to be continual rotation, that wouldn't work.

-

Tevo Black Widow uses a single z stepper with 2 screws.

-

I'm in the middle of putting the Prusa IS3 MK3 together, and it is a lot of assembly. If it's true that the CR-10 can be put together in half an hour, then that's really quite impressive.

-

I'm in the middle of putting the Prusa IS3 MK3 together, and it is a lot of assembly. If it's true that the CR-10 can be put together in half an hour, then that's really quite impressive.

@neverdie If it is anything like my Anet A8, mine took quite a few hours to put together. It looks like the MK3 has an all or at least mostly metal frame which is nice. The frame on min is laser cut acrylic and one of the big things with that is that the acrylic comes with a protective paper coating which needed to be peeled off prior to assembly. That part took over an hour in itself and was a pain.

-

I'm in the middle of putting the Prusa IS3 MK3 together, and it is a lot of assembly. If it's true that the CR-10 can be put together in half an hour, then that's really quite impressive.

-

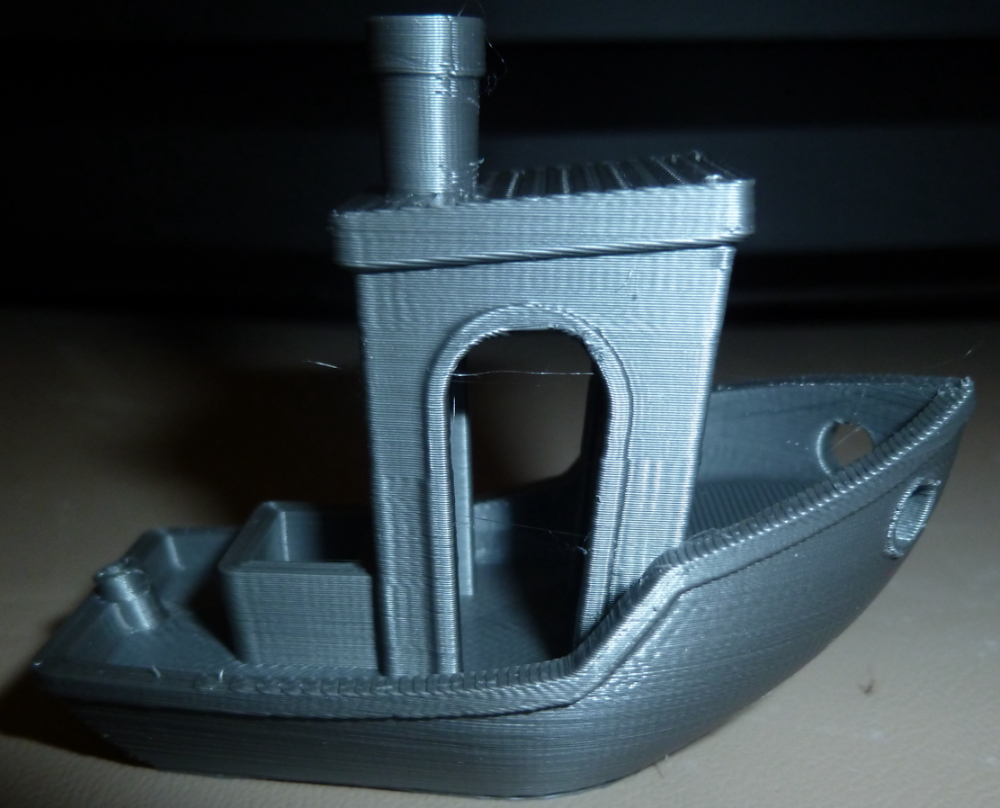

Attached is a photo of the benchy that was printed in PLA from a file that came

on the Prusa I3 MK3 SD Card. Not perfect, but I guess about par for a hobbyist 3D printer. -

Nice, a little stringing that you can solve with minor tweaks. What happened to the chimney?

@gohan said in Anyone tried the Creality CR-10 3D printer?:

What happened to the chimney?

Heck if I know. This is only the second object I've ever printed. However, if I had to guess, I'd guess that it's an artifact of the way it was sliced.

Presently I'm printing the Andreas Spiess power meter case: https://www.thingiverse.com/thing:2789890/#files

Just for the box itself, not even including the lid, the estimated print time is over 5 hours! So maybe when the megavolcano hot end comes out, I'll look into getting one.