@neverdie Yup, cheap but no (adjustable) temperature profile...

I just found it easier to use a reflow controller, as I had no idea how not using a profile would impact the soldering results.

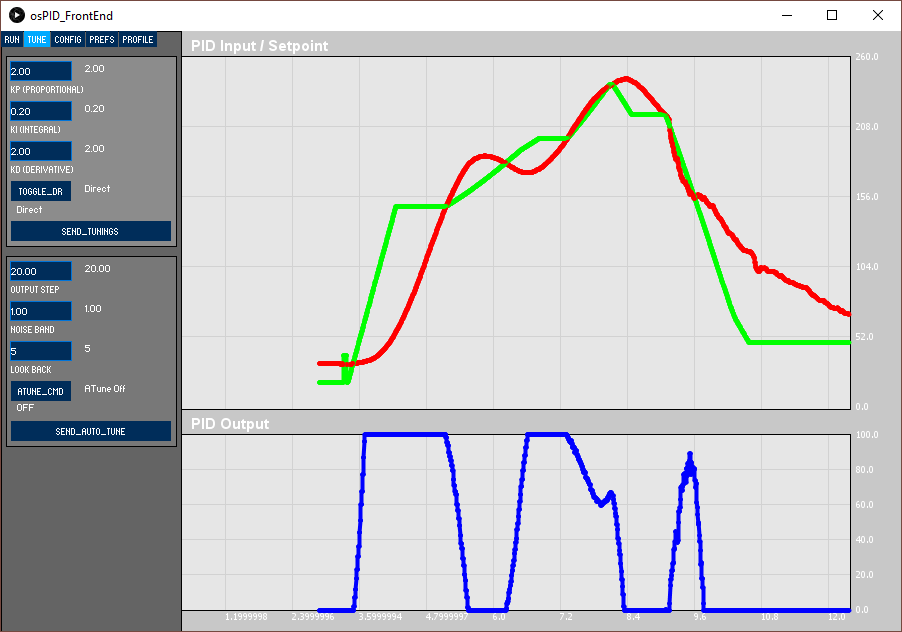

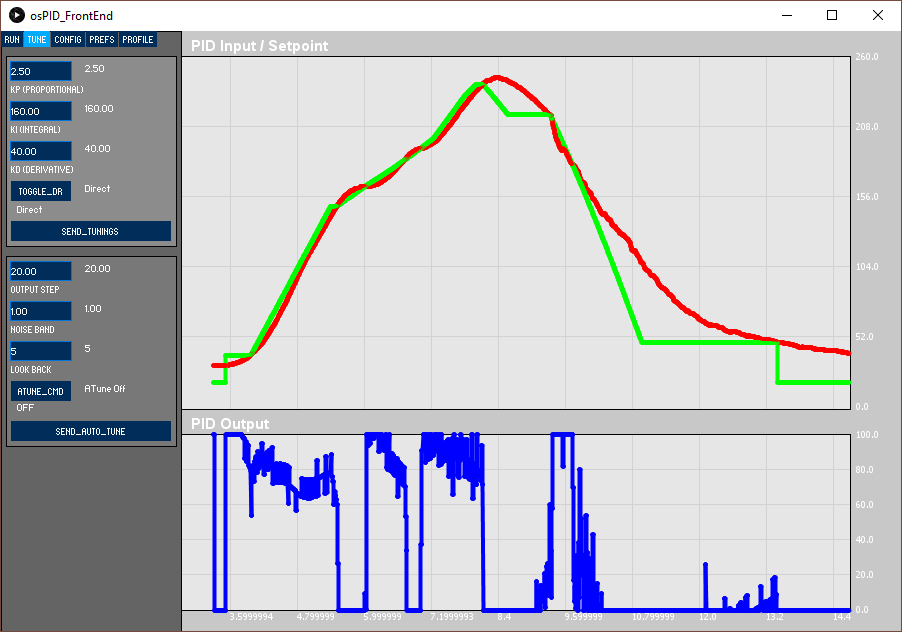

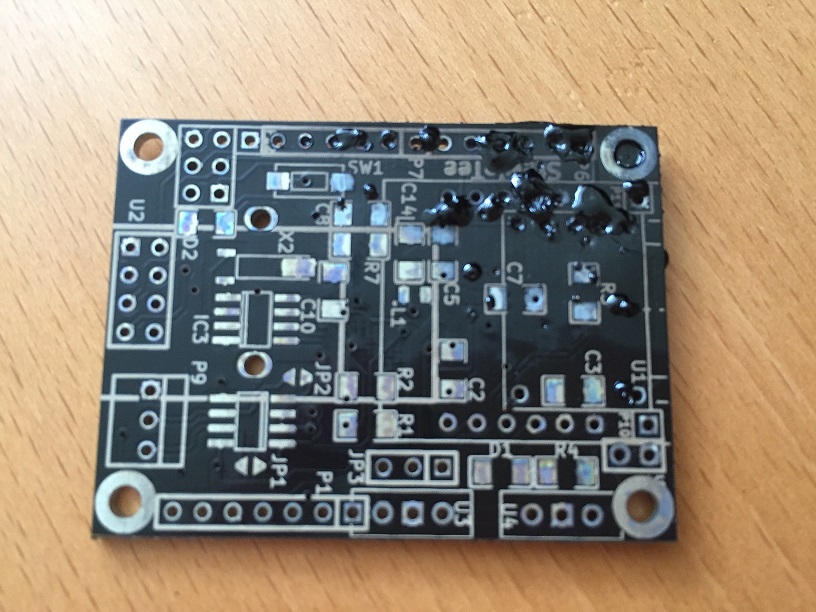

I bought a new, fairly cheap but good €70 oven, and the rest is second hand stuff for around €50; an OMRON SSR (40A), which gets barely warm during a reflow session, an osPID controller and a temperature sensor.

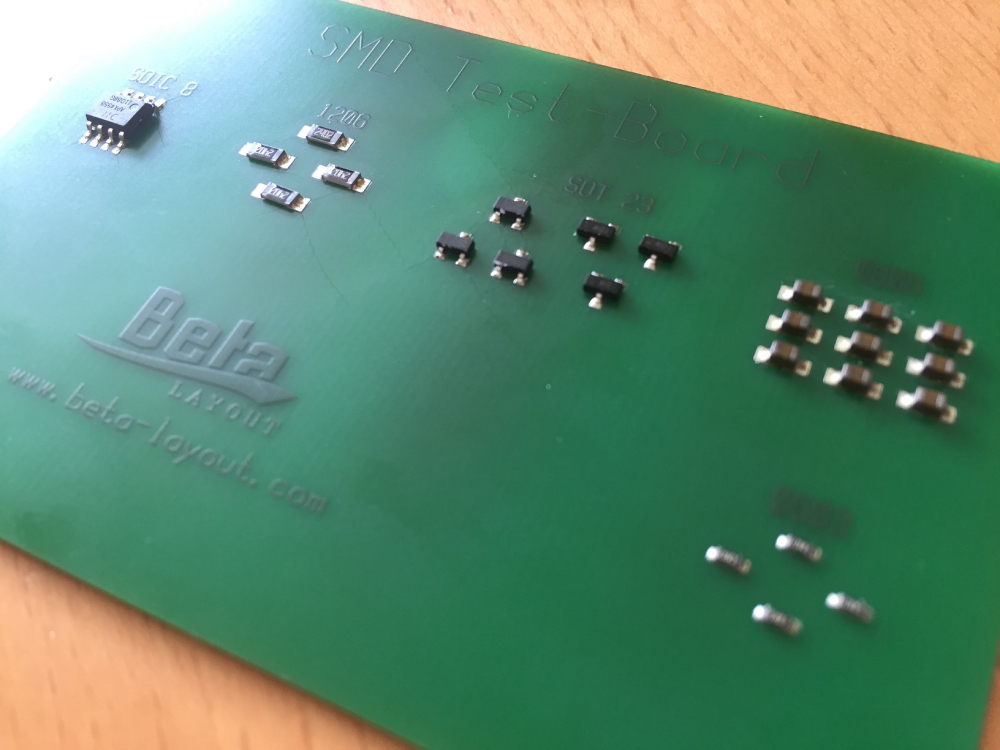

I'm happy with the combination as it gives me reproducible results.

Of course I have no results yet with real boards, but I'm confident that the reflow setup can be adjusted (longer pre-heat and soak times for instance) to meet the PCB, reflow paste and component requirements.

As you can see below, the osPID profile is very easy to setup:

RoHS24X //first row is Profile Name with different crossings

3, 40, 0 //Step Setpoint to 40, wait 0 seconds

2, 0, 0 //Wait for PID Input to cross setpoint

127, 0, 1 //buzz for 1 second as a signal that the oven is starting to heat

1, 150, 100 //PRE-HEAT: ramp setpoint to 150 degrees over the course of 100 seconds

2, 5, 5 //Wait for PID Input to cross setpoint

1, 200, 120 //SOAK: ramp setpoint to 200 degrees over the course of 120 seconds

2, 5, 5 //Wait for PID Input to cross setpoint

1, 240, 45 //REFLOW: ramp setpoint to 240 degrees over the course of 45 seconds

2, 0, 0 //Wait for PID Input to cross setpoint

1, 218, 30 //ramp setpoint to 218 (TAL) over the course of 30 seconds

2, 5, 5 //Wait for PID Input to cross setpoint --> within 5 degrees, 5 seconds

127, 0, 1 //buzz for 2 seconds as a signal to open the oven door

1, 50, 150 //ramp setpoint to 50 over the course of 150 seconds

2, 0, 0 //Wait for PID Input to cross setpoint

127, 0, 2 //buzz for 2 seconds

3, 20, 0 //Step Setpoint to 20, full cooldown!```