@bjornhallberg The sensors are working fine and have been installed in my home for the last couple of years. Some optimisation needs to be done to the code, that i have not done. This is more connected to understanding when the mysensors network is in "range" as i want to fallback on the manual knob if the mysensor network is inactive for some reason or if i sell the house and the controller goes with me.

Denke

Posts

-

Wirsbo/Uponor thermostat replacement -

💬 Wirsbo/uponor thermostat@hepal

Hi The thermostats use mysensors serial gateway to communicate with the openhab that runs on a raspberry Pi 2. I run openhab 2.0 but in the beginning i was running 1.7.x -

💬 2 channel in wall dimmerThe project does not work without neutral wire

-

💬 2 channel in wall dimmerNo i have not tested any minimum loads at the moment, this is one of the next steps

-

💬 Wirsbo/uponor thermostatHI @dexterbot

Here is the code for the openhabItems

/* Thermostats /

/ Hall */

Number Hallway_Temperature "Temperature [%.1f]" <temperature> (Temperature, C_Hallway, gMS) { channel="mysensors:hvacThermostat:gateway:Hallway_Temperature:temp" }

Number Hallway_SetPoint "HVAC/Heater set point " <temperature> (gMS) { channel="mysensors:hvacThermostat:gateway:Hallway_SetPoint:hvac-setPoint-heat" }

String Hallway_FlowState "Mode of heater [%s]" <heating> (gMS) { channel="mysensors:hvacThermostat:gateway:Hallway_FlowState:hvac-flow-state" }

Number Hallway_KnobTempVar1 "Knob temperature [%.1f]" <temperature> (gMS) { channel="mysensors:hvacThermostat:gateway:Hallway_KnobTempVar1:var1" }

String Hallway_FlowMode "Running mode" <heating> (gMS) { channel="mysensors:hvacThermostat:gateway:Hallway_FlowMode:hvac-flow-mode" }

Number Hallway_HystLowVar3 "hyst low [%.1f]" <temperature> (gMS) { channel="mysensors:hvacThermostat:gateway:Hallway_HystLowVar3:var3" }

Number Hallway_HystHighVar4 "hyst high [%.1f]" <temperature> (gMS) { channel="mysensors:hvacThermostat:gateway:Hallway_HystHighVar4:var4" }

Number Hallway_UpdateTimeVar5 "update time (s) [%d s]" <clock> (gMS) { channel="mysensors:hvacThermostat:gateway:Hallway_UpdateTimeVar5:var5" }Things

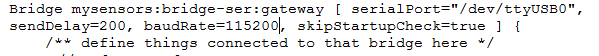

Bridge mysensors:bridge-ser:gateway [ serialPort="/dev/ttyUSB0", sendDelay=200, baudRate=115200, skipStartupCheck=true ] {

/** define things connected to that bridge here */

hvacThermostat Hallway_Temperature [nodeId="59", childId="0"]

hvacThermostat Hallway_SetPoint [nodeId="59", childId="0"]

hvacThermostat Hallway_FlowState [nodeId="59", childId="0"]

hvacThermostat Hallway_KnobTempVar1 [nodeId="59", childId="0"]

hvacThermostat Hallway_FlowMode [nodeId="59", childId="0"]

hvacThermostat Hallway_HystLowVar3 [nodeId="59", childId="0"]

hvacThermostat Hallway_HystHighVar4 [nodeId="59", childId="0"]

hvacThermostat Hallway_UpdateTimeVar5 [nodeId="59", childId="0"]

}

sitemap

Group label="Thermostats" icon="heating"{

Frame label="Hall"{

Text item=Hallway_Temperature

Text item=Hallway_FlowState label="State [%s]"

Setpoint item=Hallway_SetPoint label="Set point [%.1f]" icon="temperature" minValue="0.0" maxValue="32.0" step="0.1"

Text item=Hallway_KnobTempVar1 label="Knob temperature" //Knob temperature

Text item=Hallway_FlowMode //Running mode

Setpoint item=Hallway_HystLowVar3 label="Hysteresis L [%.1f]" minValue="0.0" maxValue="5.0" step="0.1"

Setpoint item=Hallway_HystHighVar4 label="Hysteresis H [%.1f]" minValue="0.0" maxValue="5.0" step="0.1"

Setpoint item=Hallway_UpdateTimeVar5 label="Update time (s) [%d]" minValue="1" maxValue="4096" step="1"

}

} -

💬 Wirsbo/uponor thermostatHi Tomas

I have only replaced the thermostats not anything else in the system.

This thermostat is a replacement of my Cosy thermostat (art no 804661), but i think it should work also for the following article numbers (80466, 80465, 804651 and 80464). This thermostat only works as a on/off for the valve, I did not spend any time on the night temp function. I have connected the thermostat to a transformer unit (art no 80460) which in principle only converts 220 v to 24 V which is then connected to the thermostat. When the thermostat turns on it passes on the ~24 V signal to the valve.I will upload a schematic to the project

-

openHAB 2.0 bindingHi all

I have a problem when my raspberry pi and mysensors/openhab when i do a restart. The problems seems to be ralated to the serial gateway and that the openhab dont find it or has the wrong settings.Openhab starts when i make a reboot

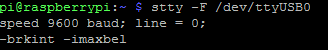

I checked the serial by typing

stty -F /dev/ttyUSB0

response was

Seems here that the baudrate is wrong as my settings in the things file is

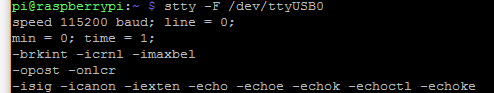

What i did to make it work was just to change this to use baud 9600 and then back to baud = 115200

after this it looked like

And everything started to work nicely

Does anyone now what the cause of this is and also how to fix it?

-

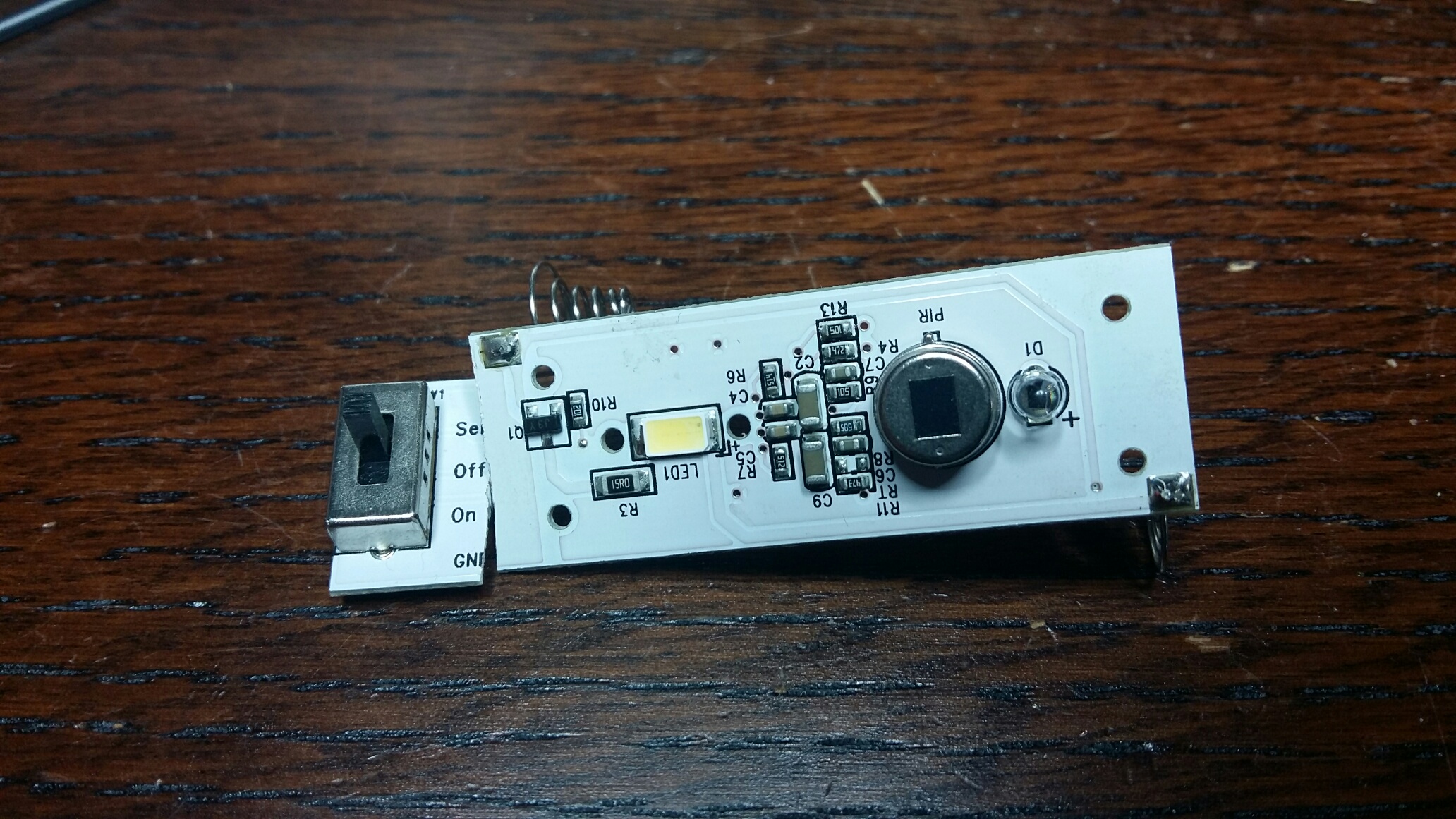

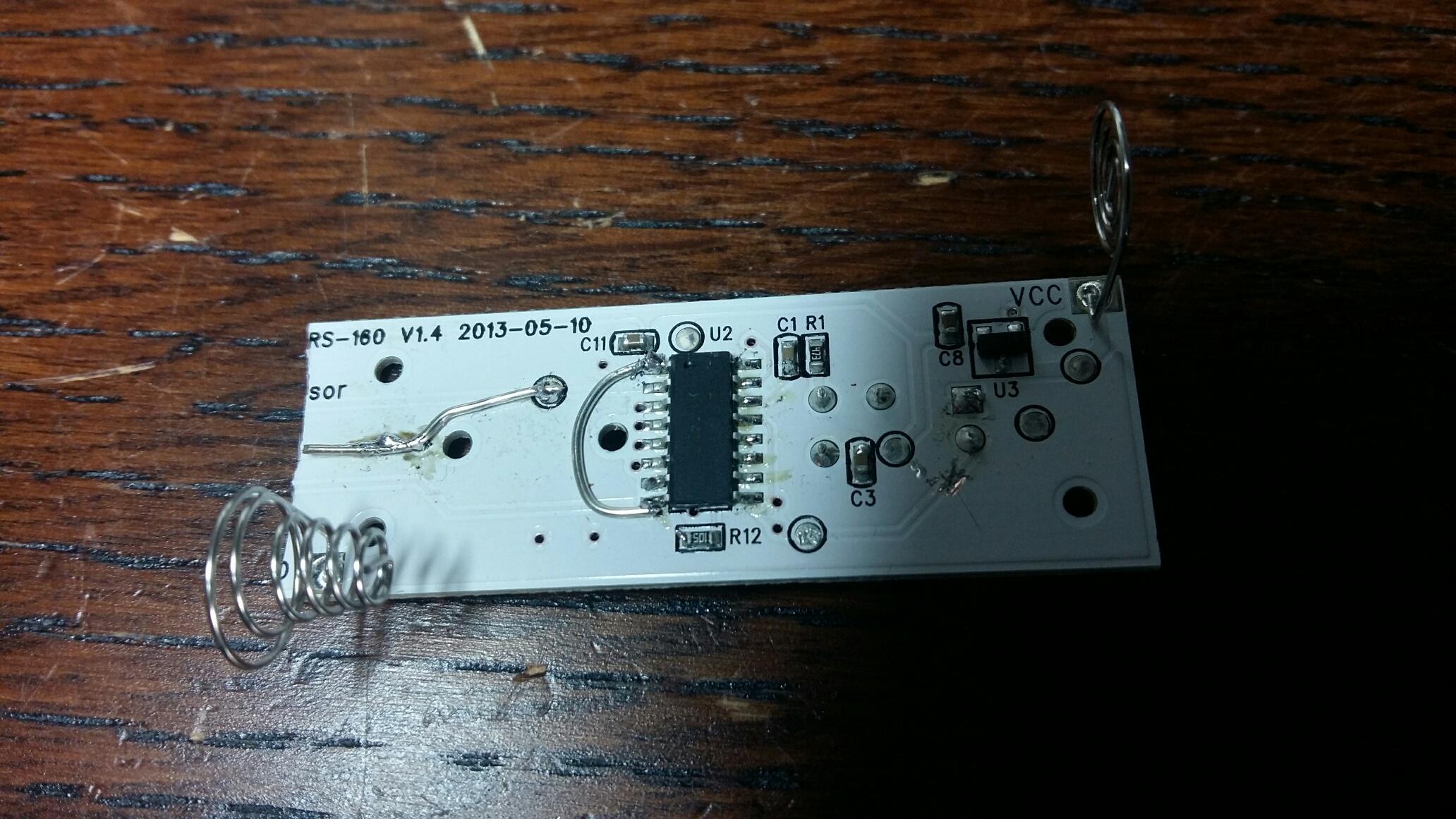

Mini motion detector based on Biltema PIR LEDAnd now everything is connected together.

I had to change some values on the resistors.

R6 = 10k and C4 = 10 nF gives 2.5 seconds ON time. I also changed the sensitivity from 4 s to 0.05 Seconds, I am considering changing this a bit to some greater value to increase the time some.

I also need to do some changes to the Arduino board as the on led is always on and i think i should remove the regulator to save some more power.

-

Mini motion detector based on Biltema PIR LEDJust for the fun off it i bought a Biltema presence controlled LED lamp for 79 SEK ~9$ having in mind that i should be able to use the nice box and interior to build myself a "cheap" motion detector to add to mySensors project.

http://www.biltema.se/sv/Bygg/Belysning-och-lampor/LED/Narvarostyrd-minilampa-2000033627/

I started by opening the lid and remove the board. This was a little troublesome as i had to compress the battery connector to get it out of its position, but i managed.

After that i tested different ways of how to fit in the Arduion mini and the RF in to the box. Unfortunatly i could not get it in without making the PIR sensor board smaller. I just cut down the board at the near the GND connector.

After this i had cut off the VCC and the motion output so i had to fix that by soldering wires for VCC and motion output shown below. connected pin1 and 8 fixin the VCC. and solderded the Via hole to the testpoint to fix the motion output from pin 2. Also i needed to cut the track just right of C3 to disable the fotoresistor so that the sensor work also in daylight.

I assembled back the board. Also you will need to replace the LED with a 10k ohm resistor (to reduce the current when activating) and then connect the Arduino sensor input to the R3 right side. This should give an active low trigger pulse.

And then i placed the component as i see that they should fit.

Now comes the next step to wire the R Fboard to the Arduino and then connect the motion output to the input of the Arduino.

There might be some changes needed for setting up the right length of the pulses on the motion detector. I have to investigate which of the R's and C's just right to the detector that does this.This is as how far i came today.

Hopefully this will be one of those projects i finish.

I will make updates on the progress

-

openHAB 2.0 binding@Denke

I cant find V_PRESSURE connected to CHANNEL_BARO below, can that be the reason? -

openHAB 2.0 bindingHi

Is there anybody that have had a problem with the S_BARO and the V_PRESSURE channel?I try to send a value on this channel as 1.2 I can see that the serial gateway receives it

23:10:51.808 [DEBUG] [g.mysensors.protocol.MySensorsReader] - 0;0;3;0;9;read: 163-163-0 s=10,c=1,t=4,pt=7,l=5,sg=0:1.2

I set up the channel as i have done for alot of other channels through the paper ui. where i link the channel to an item.

The item file looks like this

String Pool_Pressure "Pressure [%s]" <pressure> (gPool)the sitemap file looks like this

Text item=Pool_Pressureresult is this

The field never gets updated.

any suggestions? -

openHAB 2.0 binding@meju25 I saw this from a management perspective.

I have one device, my pool controller, that has multiple sensors and also channels per sensor just as HVAC that has a sum of channels. In my case i implemented a number of sensors in different types of channels "S_HVAC, S_LIGHT,...." what i see that it gets messy when you try to see if the channels are active or the pool control is active it has multiple sensors.So maybe a suggestion is to maybe implement this in the mysensors instead of in the openhab binding.

In that case i would like to add something that allows me to tell what channels are in a "sensor" by combining differnt channels and sensor types.I don't know if i got my message through.

But all this is mainly for management of my devices so that this gets less messy

-

openHAB 2.0 bindingMerging sensor to one

Hi

I have been thinking and i think it would be nice if there is a way to merge sensor data to one in the mysensors binding.Background

I am trying to build a pool control based on mysensors and i have a lot of options that i wan it to handle. For example:- on/off of my pool pumps (S_LIGHT)

- on/off of lights around the pool (S_LIGHT)

- thermostat function for heaters (S_HVAC)

- measuring pressure on pump (S_BARO)

- measuring consumed power on pump (S_POWER)

All this are using the same sensor ID and getting own child IDs. When they now are brought in to openhab they appear as single sensors

Is there a possibility to get an automatic merge for thes combined sensors?

And what do you think about the idea.

Or is there already a solution that exist that I am not aware aboutexample from paper UI

with openhab poolcontrol view

-

openHAB 2.0 bindingHi all

Implemented a barometric sensor "pressure meter" that i sample in the sensor. Then i send the value Through "BARO". I can see in both the sensor output and the openhab debug that i receive a value for example "1.2".

I try to display this in the openhab and i dont get the Text item to update.

Anyone know how this can be as i have other values that i am able to display.

line in .items

String Pool_Pressure "Pressure (bar) [%s]" <pressure> (gPool)line in .sitemap

Text item=Pool_Pressureany help is appriciated as i have tried different options with Number and so on

-

openHAB 2.0 binding@TimO said:

log:set DEBUG org.openhab.binding.mysensors

I tried this. From what i can see after doing some attempts to connect.

First & second attempt

This is what i get after just opening the serial gateway thing and edit and sav, seems as openhab then tries to reconnect with the gateway.

third attempt

It seems like it gets connected, bu some error occurs which closes the connection again

Forth attempt actually seemed to get things going

Now to the next step.

I have a device that was just given a new address from the my sensor binding. I restarted the sensor and waited to see it in the inbox (this is something that i have seen working occasionally( sometimes it gets in there sometimes it don't. I added the device manually and it seems to work. How ever my links dont work -

openHAB 2.0 bindingHi all

Im having major difficulties getting openhab to discover my serial gateway. I have had it working and i have got input from my sensors. But every know and then when i have restarted the computer the serial gateway is offline. The COM port is active and working according to Windows.

I have tried to restart the computer, unplug and plug the usb several times. Doing this i have at some occasions got everything to work again.Any suggestions what it can be that is being the problem.

I also think i have found a bug.

If i for example take the gateway or an sensor that has been added which is marked off line. Then if i press edit on that one and just press the "save" button then it shows that it is on line even though i seriously doubt it is. As i dont get data from my sensors.

Also how do i get the debug window (console view) to show for openhab?

-

openHAB 2.0 binding@Denke

You look and you look, then you ask someone how to do.Then you look again and you find it:)

, true after the set message in send did the trick.

gw.send(msgSetpointHeat.set(setTemp,1),true); -

openHAB 2.0 binding@andreacioni

Hi I have trouble finding out how to get my node to request ack, do you know how. I think i have figured out how to handle incoming message to check that the ack is received ant that is through message.isAck().But how do i get the node to send a request for ack?

-

openHAB 2.0 bindingDoes the ack signaling work in the binding? I have a sensor that will request an ack from the gateway. Does anyone know if this is working?

-

openHAB 2.0 binding@hek SO if i understood it correctly from reading info from this link. My question below is answered by that it is beeing implemented as we sspeak?