US decora style wall switch

-

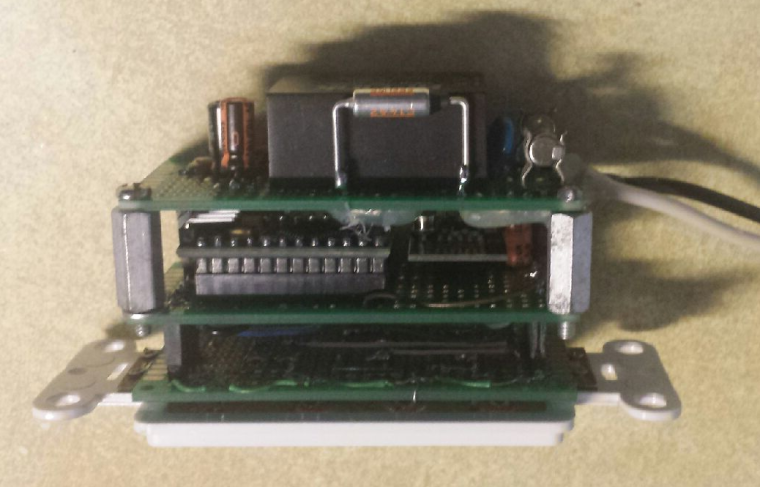

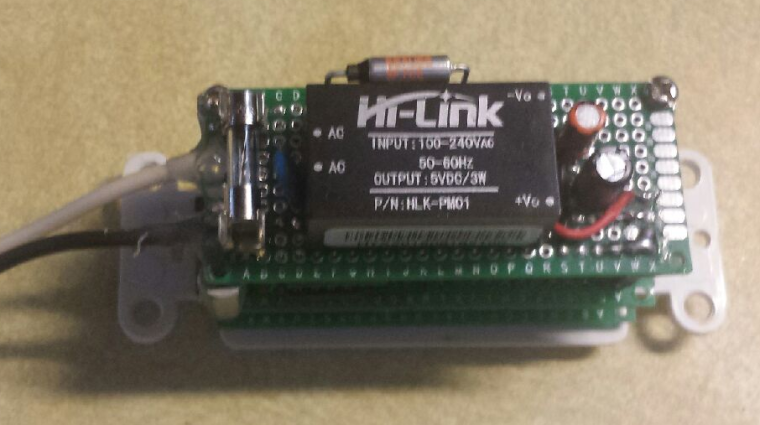

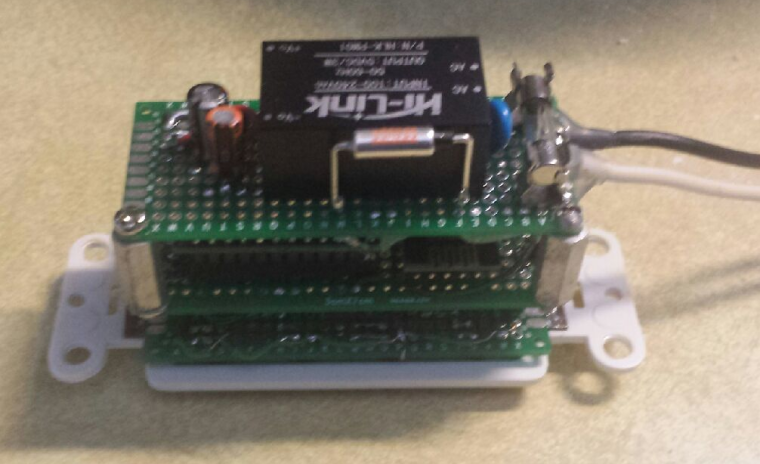

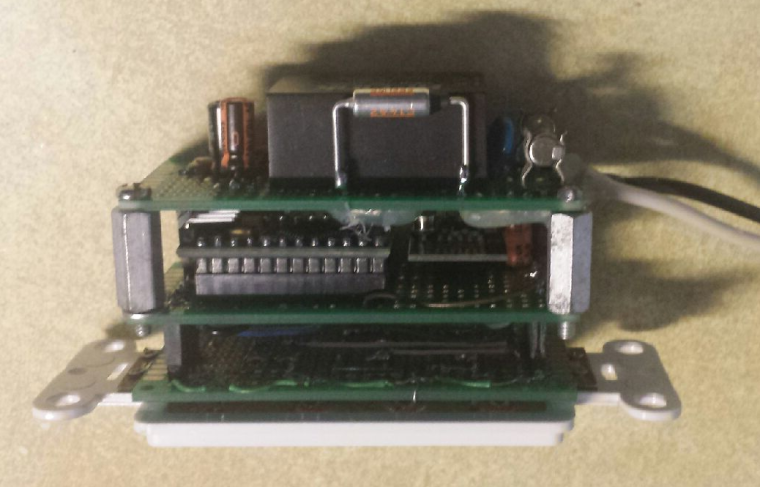

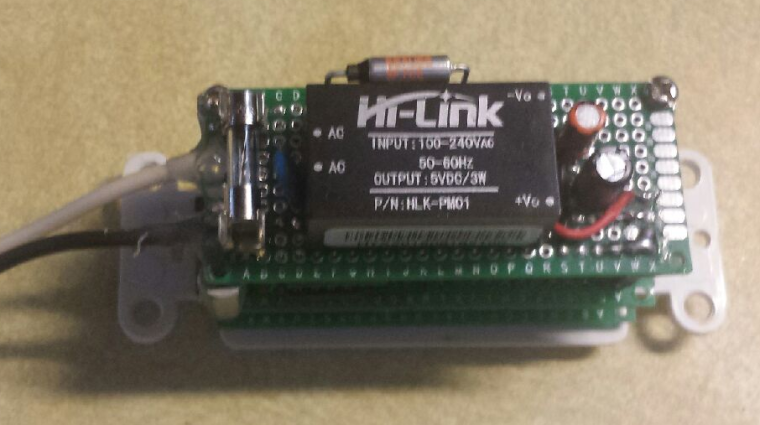

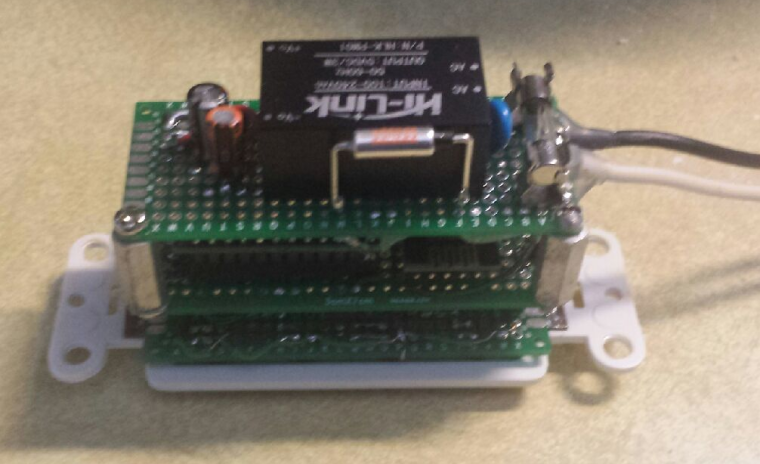

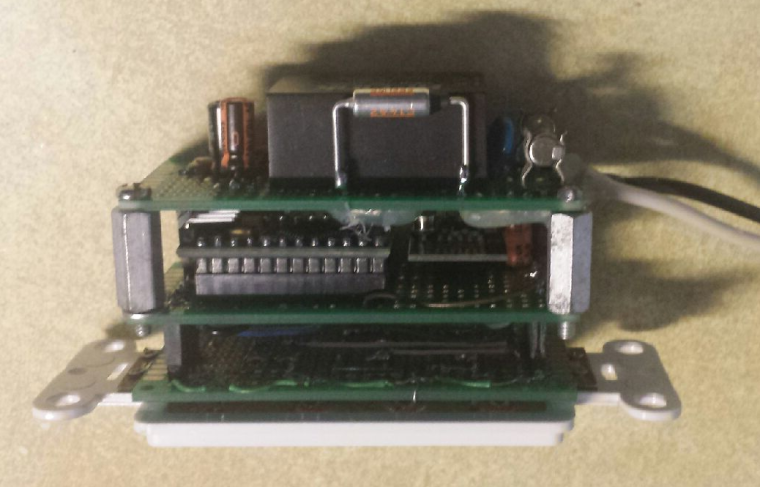

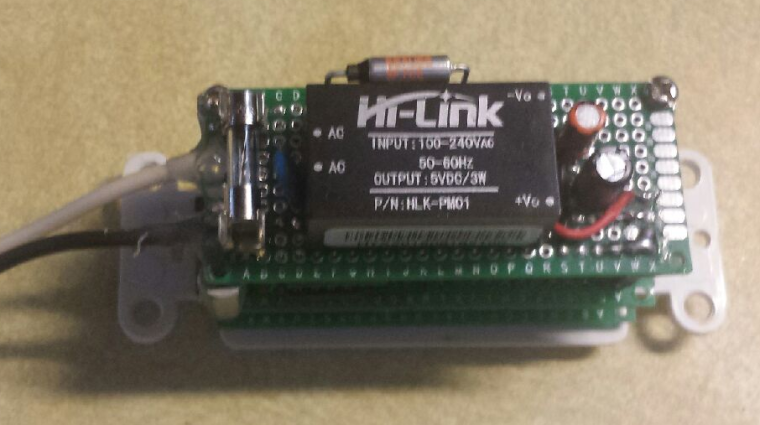

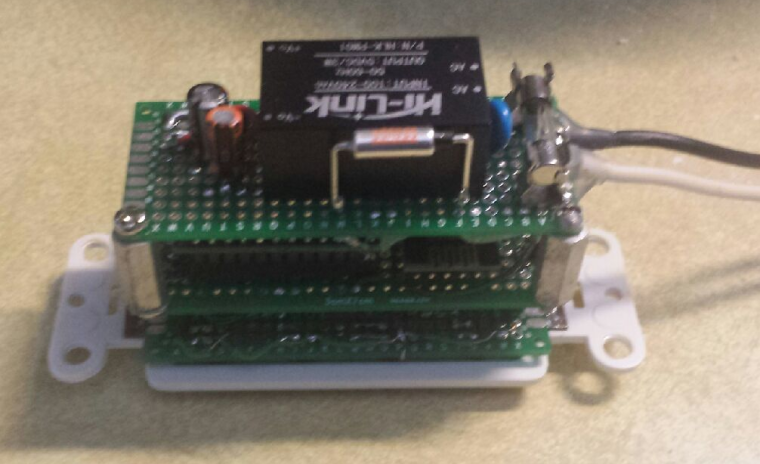

So for my latest update on this, I have finished the power supply board. One thing I learned in making this that I didn't even think of at first was that when I soldered on the thermal relay, the heat from the soldering was enough to blow the relay. Thus, my initial test did not work. I was finally able to get a fuse installed and working. I would have preferred it to be more centered on the side of the Hi-Link module, but I am thinking that it should still be effective.

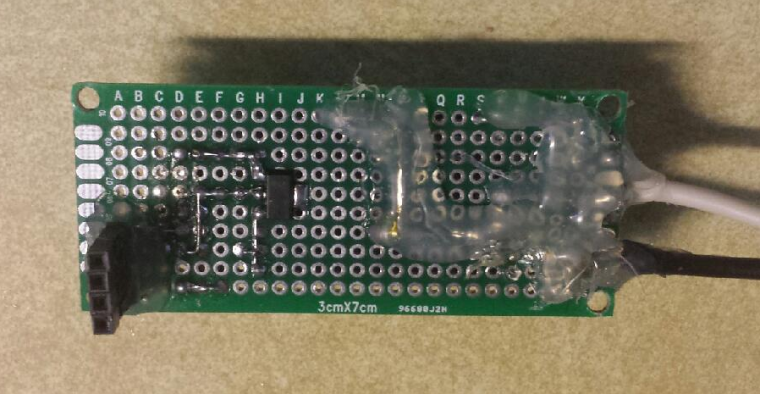

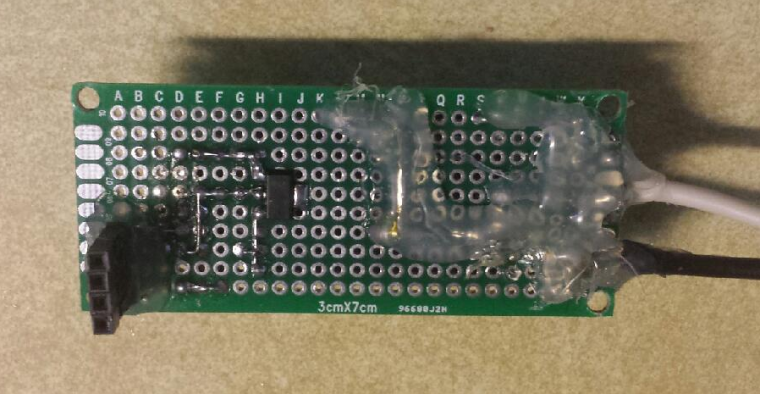

On the bottom side of the board you can see the LM1117 3.3v regulator. For the high voltage side, I have hot glue over all traces for safety in testing.

I used a 22uf cap on the 5 volt output and a 10uf cap on the 3.3 volt output. I have also added hot glue to the incoming hot and neutral leads to provide some strain relief on the wire as it attaches to the board.

The last thing I want to do is fabricate a plastic cover to put over everything that will fit into the wall box. I think I am going to need a deep wall box to house the connections and the module.

I did connect this and have it paired with my Vera. Each row is OFF, ON and status LED to indicate the ON state. I have debated on having the LED on when the switch is off to give better visibility to the switch when it is dark. In Vera, I can tie the switches to devices using scenes.

Overall, this proof of concept design is working well.

-

So for my latest update on this, I have finished the power supply board. One thing I learned in making this that I didn't even think of at first was that when I soldered on the thermal relay, the heat from the soldering was enough to blow the relay. Thus, my initial test did not work. I was finally able to get a fuse installed and working. I would have preferred it to be more centered on the side of the Hi-Link module, but I am thinking that it should still be effective.

On the bottom side of the board you can see the LM1117 3.3v regulator. For the high voltage side, I have hot glue over all traces for safety in testing.

I used a 22uf cap on the 5 volt output and a 10uf cap on the 3.3 volt output. I have also added hot glue to the incoming hot and neutral leads to provide some strain relief on the wire as it attaches to the board.

The last thing I want to do is fabricate a plastic cover to put over everything that will fit into the wall box. I think I am going to need a deep wall box to house the connections and the module.

I did connect this and have it paired with my Vera. Each row is OFF, ON and status LED to indicate the ON state. I have debated on having the LED on when the switch is off to give better visibility to the switch when it is dark. In Vera, I can tie the switches to devices using scenes.

Overall, this proof of concept design is working well.

@dbemowsk

I think that with a little effort the switch and middle PCB can become one in a custom designed PCB. You'll end up with switches and LED's on one side and the Arduino and radio etc on the other side. That's what I did. This will make your design a lot more compact.I used https://easyeda.com/ to design and manufacture my PCB's.

-

So for my latest update on this, I have finished the power supply board. One thing I learned in making this that I didn't even think of at first was that when I soldered on the thermal relay, the heat from the soldering was enough to blow the relay. Thus, my initial test did not work. I was finally able to get a fuse installed and working. I would have preferred it to be more centered on the side of the Hi-Link module, but I am thinking that it should still be effective.

On the bottom side of the board you can see the LM1117 3.3v regulator. For the high voltage side, I have hot glue over all traces for safety in testing.

I used a 22uf cap on the 5 volt output and a 10uf cap on the 3.3 volt output. I have also added hot glue to the incoming hot and neutral leads to provide some strain relief on the wire as it attaches to the board.

The last thing I want to do is fabricate a plastic cover to put over everything that will fit into the wall box. I think I am going to need a deep wall box to house the connections and the module.

I did connect this and have it paired with my Vera. Each row is OFF, ON and status LED to indicate the ON state. I have debated on having the LED on when the switch is off to give better visibility to the switch when it is dark. In Vera, I can tie the switches to devices using scenes.

Overall, this proof of concept design is working well.

@dbemowsk - Nice work!

Here is a discussion and more links about safety in designing a PCB with AC power that might come in handy:

https://forum.mysensors.org/topic/4175/clearance-creepage-and-other-safety-aspects-in-mysensors-pcbs.Also if you dont want to completley redesign a PCB you can take some of my designs and redesign them to your purpose.

-

So I have had my prototype version of this switch installed for a few weeks now and it seems to be performing well with my Vera setup. This week I added a new tool to my arsenal. I purchased an Anet A8 3D printer kit. I just got it put together yesterday. I ordered a roll of ABS which came yesterday. It was supposed to be white, but they sent transparent (Grrrr....). Trying to work with the ebay seller on this.

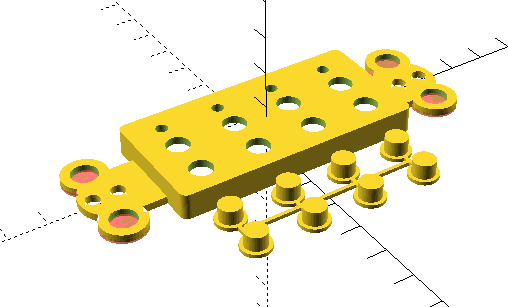

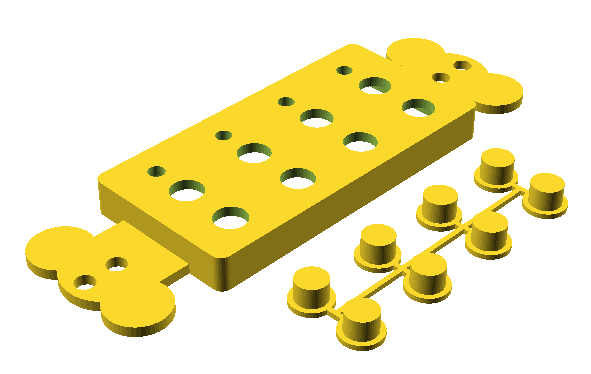

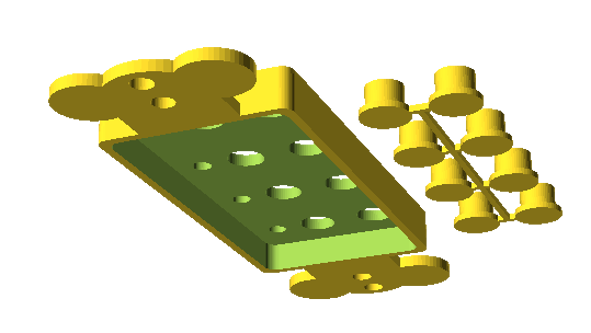

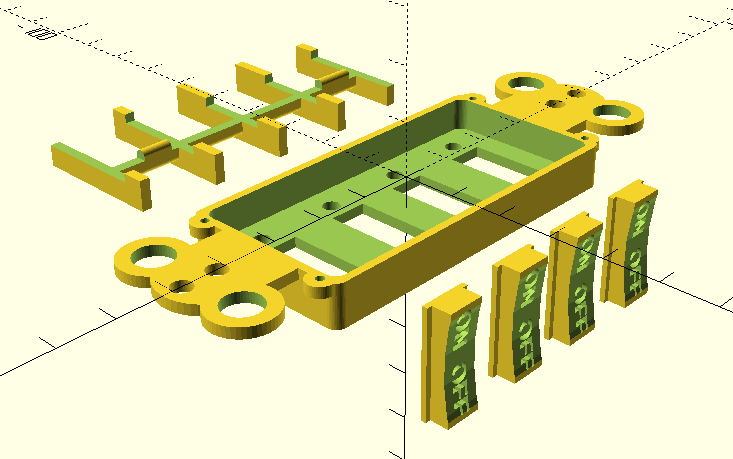

Anyway, I wanted a project to try that would be useful, but not super difficult. I decided to build a better switch plate to improve my prototype of this switch. I knew that one of the big places to go for 3D stuff to print was thingiverse.com. I did a search on the site and someone had a 3d file for a decora blank wall plate. I decided to download the files and see what I could do. I had never done anything in any kind of CAD program, but thought, how bad can it be. I ended up finding OpenSCAD. Drawing objects in the software is done much like a structured programming language. Within a day of teaching myself some things in it, I came up with this:

I have not printed this yet since I am still trying to resolve my filament issue with the ebay seller,. but as soon as I get that figured out, I will give this a test. Before printing I may still look at adding some reliefs in the 4 corner tabs to save at least a little bit of plastic, but overall I think it looks good. I'll post more here as I get it done.

-

Looking forward to pictures :) Keep up the good work!

-

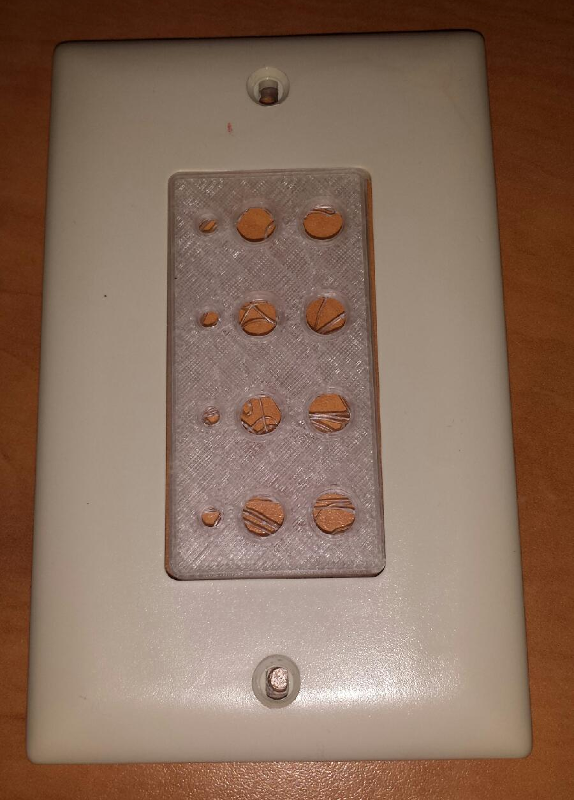

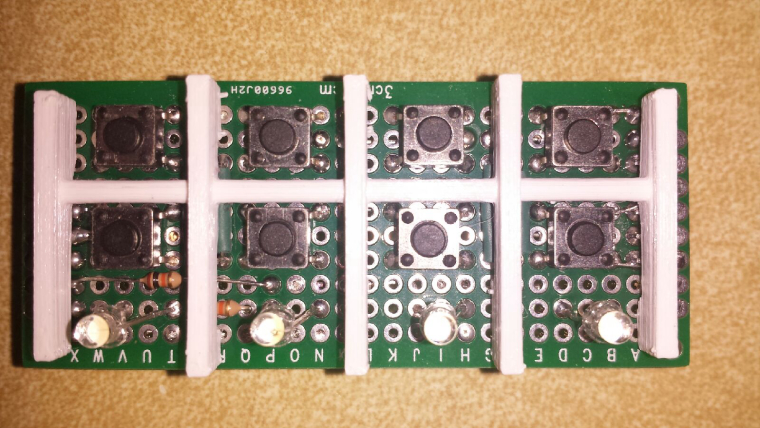

So even though I only have transparent ABS to work with at the moment, I decided to do a test print of this (I actually did 2 test prints). The results were in my eyes only fair. Though the outside didn't look bad, the inside is a bit messy. I think I could clean it up and make it usable, but I think it could be better. I printed it with the ears down and the face up. The print may come out better if I print it with the face down. The ears may be a little stringy, but that is a little less of an issue because the ears are hidden by the faceplate. I had to increase the hole size in the face where the buttons come through for the buttons to fit (this was the reason for the second test print). With the first print, the buttons were a little snug in the holes.

Without further ado, here are the pics:

These two pics show how it fits in the faceplate.

-

If anyone is interested, I posted the 3D design files for this switch plate out on thingiverse.com. Included is the OpenSCAD file and .stl files for making modifications if you'd like.

http://www.thingiverse.com/thing:2136094Enjoy...

-

I think this 3D printer is going to help a lot with my HA hobby. Now I will be able to make custom enclosures and things and not have to search the web to say, "ehh, that will kinda fit". I just have to get used to using OpenSCAD.

@dbemowsk said in US decora style wall switch:

I think this 3D printer is going to help a lot with my HA hobby. Now I will be able to make custom enclosures and things and not have to search the web to say, "ehh, that will kinda fit". I just have to get used to using OpenSCAD.

You should give FreeCAD a shot. Open source and runs on Windows, macOS and Windows and you can download the releases from GitHub

-

@dbemowsk said in US decora style wall switch:

I think this 3D printer is going to help a lot with my HA hobby. Now I will be able to make custom enclosures and things and not have to search the web to say, "ehh, that will kinda fit". I just have to get used to using OpenSCAD.

You should give FreeCAD a shot. Open source and runs on Windows, macOS and Windows and you can download the releases from GitHub

-

@blacey Though I do own a windows laptop, my main desktop is a linux machine. Don't have time now, but I'll see if they have it ported to linux. Thanks for the tip.

@dbemowsk Linux is the primary platform used by the FreeCAD devs so Linux is very well-supported.

There is a PPA for stable and a PPA for daily developer builds.

For example, to install the latest stable:

sudo add-apt-repository ppa:freecad-maintainers/freecad-stable sudo apt-get update sudo apt-get upgrade sudo apt-get install freecad freecad-docMore details here - https://www.freecadweb.org/wiki/Install_on_Unix

-

@dbemowsk Linux is the primary platform used by the FreeCAD devs so Linux is very well-supported.

There is a PPA for stable and a PPA for daily developer builds.

For example, to install the latest stable:

sudo add-apt-repository ppa:freecad-maintainers/freecad-stable sudo apt-get update sudo apt-get upgrade sudo apt-get install freecad freecad-docMore details here - https://www.freecadweb.org/wiki/Install_on_Unix

-

@blacey Thanks for the tip. Just installed it on my Fedora 23 box.

sudo dnf install freecadIt did not find a package called freecad-doc, but that's what the online docs and youtube is for.

@dbemowsk said in US decora style wall switch:

@blacey Thanks for the tip. Just installed it on my Fedora 23 box.

Excellent! Also, there is a pretty vibrant community behind FreeCAD so feel free to introduce yourself and ask questions on the FreeCAD forums - everyone is very helpful.

-

Just an update on this. I gave the wall switch another spin on the design. I made a version of this with nice rocker switches. I think this design looks a bit more professional.

Because of having the rocker switches I have added one more piece to the design which is a rocker support for the switches to prevent both the on and off buttons for a switch to be activated simultaneously.

Here is a view of the prototype with the rocker support in place.

The LEDs that I currently have installed are 3mm white LEDs. I went with 10k resistors on them so as not to make them too bright since at full brightness these can be a bit blinding. I chose those because they are what I had available in my parts bin. Red or green LEDs might be a better fit for this. Choose a resistor value that gives whatever LEDs you choose suitable brightness as this can vary between LEDs.

For anyone interested I posted the 3D design files on thingiverse. Everything you need to make this switch board is posted there.

http://www.thingiverse.com/thing:2202434 -

So, I have added yet one more variation of this to my line of switches. This is a dual rocker switch with customizable text for each on/off switch. You can have just the plain ON / OFF button style or you can choose to add 6 to 7 characters of text above the ON / OFF text. In the images below you can see that I have created one of these for use with a light/ceiling fan combo.

The OpenSCAD and .stl files for this switch variation can be found on thingiverse. http://www.thingiverse.com/thing:2219319

-

@dbemowsk

I think that with a little effort the switch and middle PCB can become one in a custom designed PCB. You'll end up with switches and LED's on one side and the Arduino and radio etc on the other side. That's what I did. This will make your design a lot more compact.I used https://easyeda.com/ to design and manufacture my PCB's.

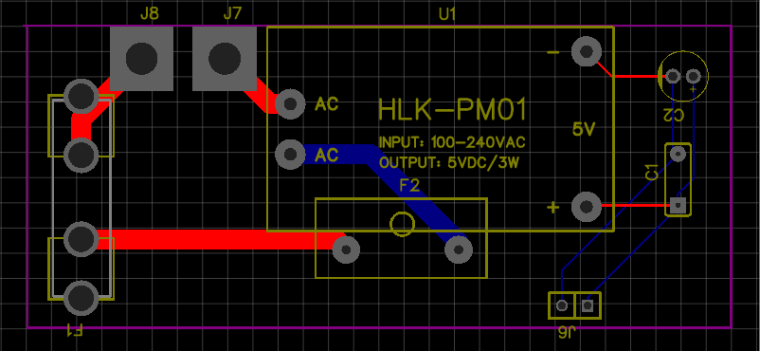

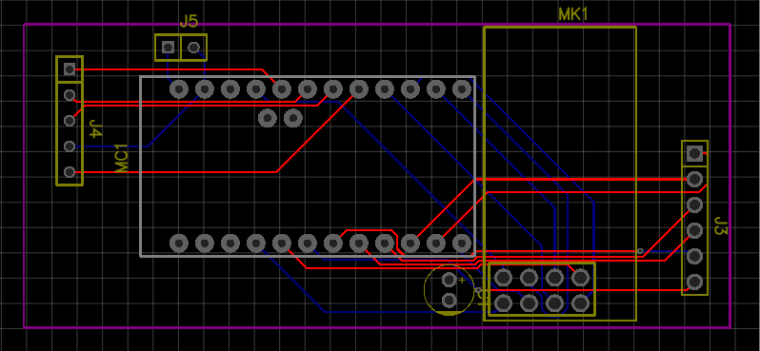

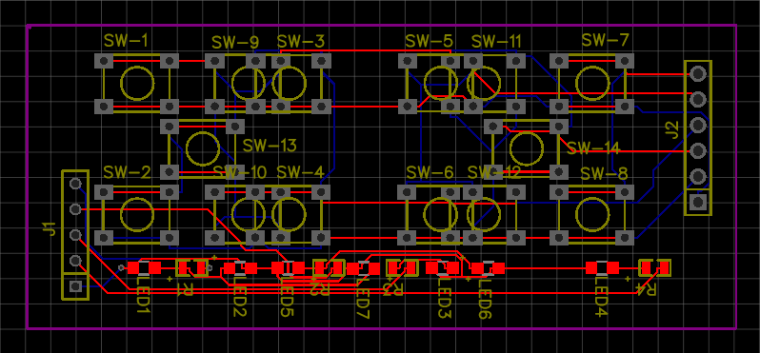

So I was playing a bit with the online schematic and PCB tool that @enterprised mentioned called EasyEDA to create boards for my in-wall switches. For now I stuck with the design that I have a few prototypes of, which consists of 3 boards, a switch board with LED indicators, a main board with arduino and radio and a power supply board. This is what I have so far.

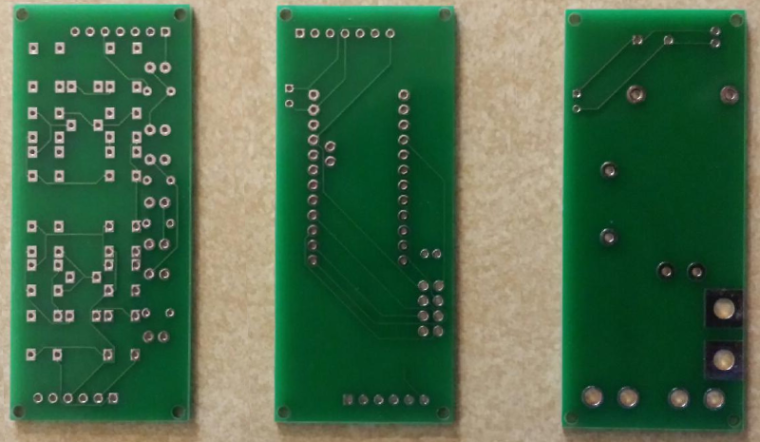

The power supply board is pretty simple and straight forward. Based on an HLK-PM01 with both a standard fuse and a thermal fuse for safety. J7 and J8 are the 110V AC inputs. The output is filtered with 10uf electrolytic and 0.01uf creamic capacitors:

The main board too is pretty simple. It will use a 3.3v pro mini with an nRF24L01+ radio and 2 header connectors for attaching the switch board:

I went a bit complex on the switch board design for flexibility. The design looks a bit busy, but once you understand the idea behind it it makes perfect sense. The board will be able to handle configurations for my original 8 button design (4 on/off switches), my 4 button design (2 on/off switches) and also a standard decora paddle type design. All designs would have LED indicators for each row of buttons. For the 8 button / 4 on/off switch design, you would populate SW-1 through SW-8 and use LED1 through LED4 with R1 through R4. For the 4 button / 2 on/off switch design, SW-9 through SW-12 would be populated and use LED5 and LED6 with R1 and R2. Lastly for the standard paddle design, SW-13 and SW-14 are used with LED7 and R1. This eliminates the need for 3 separate switch board designs. I can have some boards in the parts bin and depending on the type of switch I need, I populate what I need. I went with SMD LEDs and resistors because I thought the through hole ones seemed a bit bulky. I can then print clear lenses for the LEDs to shine through.

One thing that I don't have in the design shown that I will probably add before sending it off for printing is a 3.3V and possibly even 5V positive power connections to one of the header connectors going to the switch board. Having that would allow me to build other sensor boards that could plug on top of the main board for even more flexibility. I currently have a ground, 6 digital IO and 4 analog IO lines being passed to the switch board which would allow for a lot of additional design possibilities.

I am open to comments and suggestions on the design so far.

-

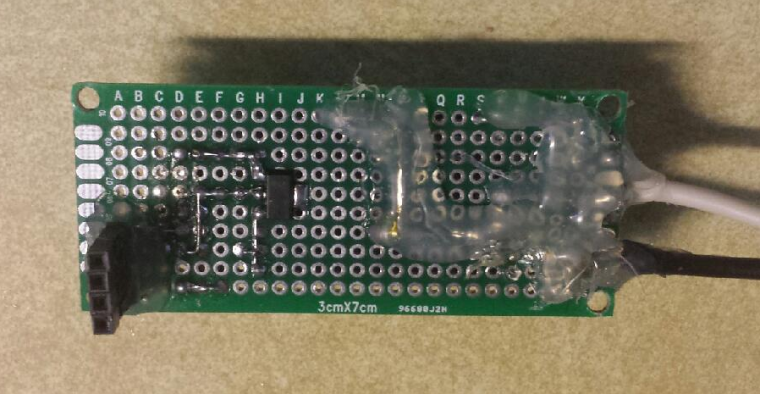

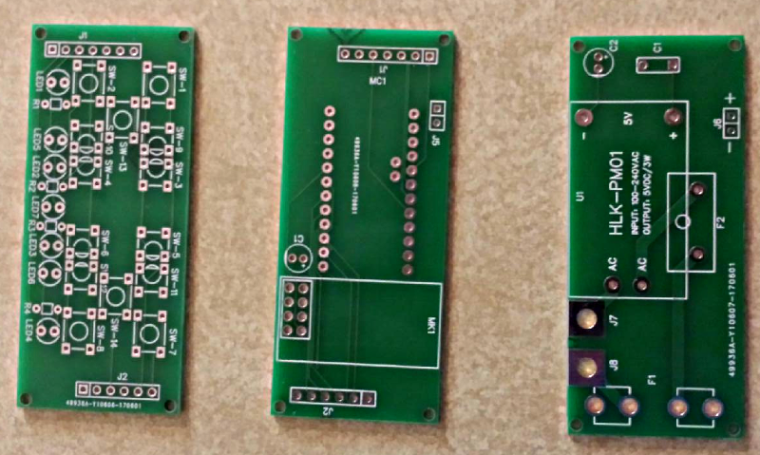

So, one of my big days is here. My first ever fabricated PCBs that I designed are here. A slight change in the switch board from what's shown above, I did a design of one that used through hole components instead of the SMT components shown above. Really the only thing that I did as SMT in the above design were the LEDs and resistors, the switches were still through hole. Anyways, are some pics of the top and bottom sides of the finished product.

I designed them and ordered them through the EasyEDA website. I got 5 each of the boards, so 15 total, for $24.63 plus $18.41 for DHL shipping to the US which comes out to $2.87 per board. For a small test run, I thought that wasn't too bad.Tonight I plan to assemble one of the switches to see about how long it takes. I also received my new batch of thermal fuses needed for the new boards, so I should have everything I need. Once done, I will do another post showing a finished and assembled switch.

-

So, how is the Anet A8 doing? Was thinking of purchasing it, but not sure if it's better or worse than the Anet A6 or Creality Ender 3.

Any thoughts will be highly appreciated.