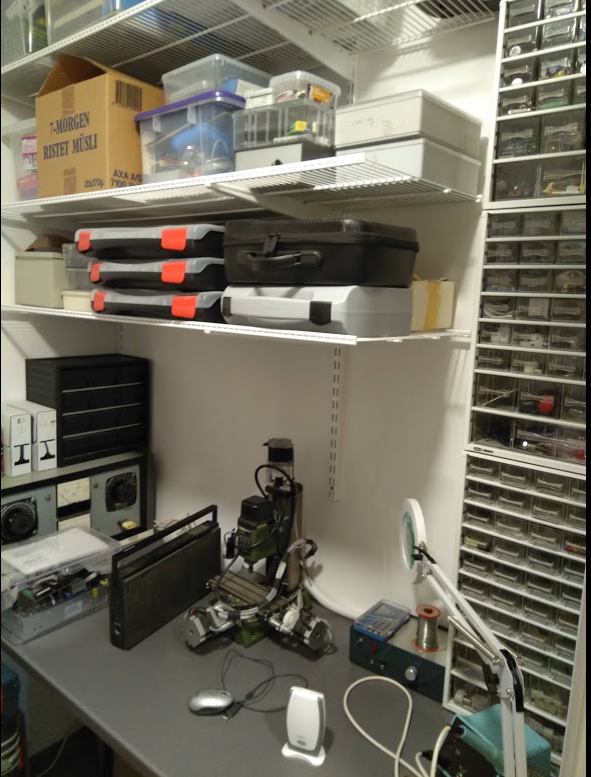

Your workshop :)

-

So I had to replace a micro USB connector on a tablet the other day. So to get the old connector off, I used my heat gun which is similar to the one pictured below. It worked okay and I was able to get the connector off.

I have been wanting to get a hot air re-work station for a while now. I was looking at the picture of @sundberg84 's workshop and I saw that he had an 858D, so I searched that on ebay. I noticed that there are a variety of 858D stations out there ranging from $30 to $121 US. They all look very similar as far as front panel controls and functionality. My question is, is there a big difference between the lower and higher priced units? I guess, if I get one of the $30 units, is it going to fall apart sooner than one of the others?@dbemowsk i bought mine used from England. It was in the cheaper price range. Works great so far and this is ok for me.

-

@dbemowsk i bought mine used from England. It was in the cheaper price range. Works great so far and this is ok for me.

@sundberg84 Thanks, hard to tell from your picture, but does yours have the cord for the wand going directly into the base, or is it on a connector that plugs into the front? I noticed that most of the more expensive ones have a removable/replaceable wand, but everything else looks to be about the same. I will probably just order the $30 one and see how it goes.

-

So I had to replace a micro USB connector on a tablet the other day. So to get the old connector off, I used my heat gun which is similar to the one pictured below. It worked okay and I was able to get the connector off.

I have been wanting to get a hot air re-work station for a while now. I was looking at the picture of @sundberg84 's workshop and I saw that he had an 858D, so I searched that on ebay. I noticed that there are a variety of 858D stations out there ranging from $30 to $121 US. They all look very similar as far as front panel controls and functionality. My question is, is there a big difference between the lower and higher priced units? I guess, if I get one of the $30 units, is it going to fall apart sooner than one of the others?@dbemowsk I bought from AliExpress in the cheapest price range too (but not so cheap with shipping) and it's been working very well until now.

I bought this model, it's not available any more but there are plenty of seller with the exact same brand and model (Youyue 858D+), with extra nozzles (I had 3 only, now it seems 6 is standard) and accessories (I had none):

https://www.aliexpress.com/item/Hot-Air-Gun-700W-UYUE-858D-ESD-Soldering-Station-LED-Digital-Heat-Gun-Desoldering-Station-Upgrade/32657929118.htmlI opened it after reception to check for the common safety problems that were reported with first versions of the 858D/D+ models and it was safely wired and earthed.

It's also show the right temperature when overheating (it was not the case in the first models) so you know when to wait to avoid burning your board (don't worry this is only happening at start-up when it's heating fast from ambient temperature). -

@dbemowsk I bought from AliExpress in the cheapest price range too (but not so cheap with shipping) and it's been working very well until now.

I bought this model, it's not available any more but there are plenty of seller with the exact same brand and model (Youyue 858D+), with extra nozzles (I had 3 only, now it seems 6 is standard) and accessories (I had none):

https://www.aliexpress.com/item/Hot-Air-Gun-700W-UYUE-858D-ESD-Soldering-Station-LED-Digital-Heat-Gun-Desoldering-Station-Upgrade/32657929118.htmlI opened it after reception to check for the common safety problems that were reported with first versions of the 858D/D+ models and it was safely wired and earthed.

It's also show the right temperature when overheating (it was not the case in the first models) so you know when to wait to avoid burning your board (don't worry this is only happening at start-up when it's heating fast from ambient temperature). -

Found an old post at eeevblog, where they hacked the Youyue heat gun. It was using atmega328p, so I am considering that one (even though they might have changed hardware since then. You'll never know what the sneaky people are doing ;))

-

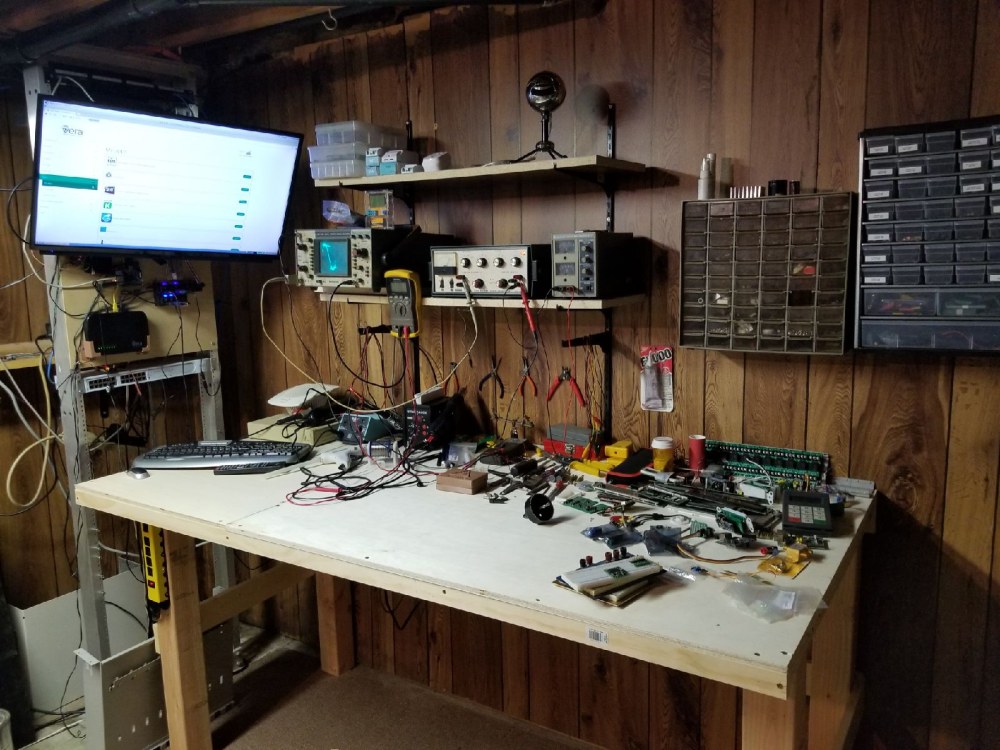

Still need to do some setup and sorting of things, but here are some pics of my newly remodeled workshop area.

I really need to get rid of that old Leader analog scope and get myself a DSO. It is a conversation piece though. I have it connected to my old heathkit square/sine wave audio function generator. Does anyone have a recommendation on a cheaper DSO that would be good for microcontroller work? -

I moved my desk to a new spot in the house and reoriented the desk. Still a mess, but that is how my mind seems to work these days: lots of stuff in parallel ...

-

I moved my desk to a new spot in the house and reoriented the desk. Still a mess, but that is how my mind seems to work these days: lots of stuff in parallel ...

-

@gertsanders so that's what kept you busy last 7 months! :rolling_on_the_floor_laughing:

@yveaux indeed. It seems there is always some other thing to do first. Moving my desk was part of a greater reorganisation of desks and rooms. I set myself deadlines to be able to advance a little (next one is 16 May: lasercutting boxes at the FabLab), but still progress is slow.

The fact that my switch to version 2.2.0 on sensors and on ethernetgateway on Raspberry is not going well, also slows down progress. Step by step ...

-

@yveaux indeed. It seems there is always some other thing to do first. Moving my desk was part of a greater reorganisation of desks and rooms. I set myself deadlines to be able to advance a little (next one is 16 May: lasercutting boxes at the FabLab), but still progress is slow.

The fact that my switch to version 2.2.0 on sensors and on ethernetgateway on Raspberry is not going well, also slows down progress. Step by step ...

@gertsanders said in Your workshop :):

The fact that my switch to version 2.2.0 on sensors and on ethernetgateway on Raspberry is not going well, also slows down progress. Step by step ...

Well, if you need any help or have suggestions how to make the transition more smooth, you know where to find us!

Good to have you back on the forum though :+1:

-

@gertsanders said in Your workshop :):

The fact that my switch to version 2.2.0 on sensors and on ethernetgateway on Raspberry is not going well, also slows down progress. Step by step ...

Well, if you need any help or have suggestions how to make the transition more smooth, you know where to find us!

Good to have you back on the forum though :+1:

@yveaux I'm not sure the issues is with the MySensors part. The gateway listens, but presenting a new node crashes Domoticz. After reboot I do see the new sensor and can receive and show updates, but the "new node" part is what bugs me now (I made a new node with atmega1284p which I want to add to my network)

I am using the beta version of the gateway & Domoticz -

@yveaux I'm not sure the issues is with the MySensors part. The gateway listens, but presenting a new node crashes Domoticz. After reboot I do see the new sensor and can receive and show updates, but the "new node" part is what bugs me now (I made a new node with atmega1284p which I want to add to my network)

I am using the beta version of the gateway & Domoticz@gertsanders said in Your workshop :):

I am using the beta version of the gateway

Why are you using a beta version? I thought 2.2.0 was in stable release?

-

@gertsanders said in Your workshop :):

I am using the beta version of the gateway

Why are you using a beta version? I thought 2.2.0 was in stable release?

@dbemowsk like to push my luck I guess ;-)

It seems the latest Domoticz beta (9379 build date 28.04.18-09:18:07) has a problem with presentation of new sensors. So I will have to sweat it until they fix that.

I compiled the gateway on Raspberry also with the beta version (after trying the stable version first), as it was mentioned that this could fix communication errors. No luck so far.

Bu this discussion of my problem should be on another forum branch. -

@gohan

Indeed, it is a Domoticz beta issue