💬 Easy/Newbie PCB for MySensors

-

@Lior-Rubin - the PCB or the hardware has nothing to do with 2.0

It will work fine - 2.0 is only software (what you program it with).

I have been running 2.0 beta (dev) for a long time now without any problems.@sundberg84 I'm aware of it. I just ask to be sure.

Can you upload here an example sketch (v2.0) with battery reporting ? -

@sundberg84 I'm aware of it. I just ask to be sure.

Can you upload here an example sketch (v2.0) with battery reporting ?@Lior-Rubin said:

@sundberg84 I'm aware of it. I just ask to be sure.

Can you upload here an example sketch (v2.0) with battery reporting ?You can just check the examples included in the library, I've been using the beta version of MySensors 2 for a long time and started from supplied examples, never had a problem.

This is some code I use to report battery level, it's harder to make it more simple, juste keep your existing code to read the battery level and replace the line sending the value with the sendBatteryLevel() :

int currentBatteryPercent = SystemStatus().getVCCPercent(VccMin, VccMax); if (currentBatteryPercent != LastBatteryPercent) { LastBatteryPercent = currentBatteryPercent; sendBatteryLevel(currentBatteryPercent); }``` -

@sundberg84 I'm aware of it. I just ask to be sure.

Can you upload here an example sketch (v2.0) with battery reporting ?@Lior-Rubin - If you use a voltage divider and 2xAA use this:

Defines:

//========================= // BATTERY VOLTAGE DIVIDER SETUP // 1M, 470K divider across battery and using internal ADC ref of 1.1V // Sense point is bypassed with 0.1 uF cap to reduce noise at that point // ((1e6+470e3)/470e3)*1.1 = Vmax = 3.44 Volts // 3.44/1023 = Volts per bit = 0.003363075 #define VBAT_PER_BITS 0.003363075 #define VMIN 1.9 // Vmin (radio Min Volt)=1.9V (564v) #define VMAX 3.0 // Vmax = (2xAA bat)=3.0V (892v) int batteryPcnt = 0; // Calc value for battery % int batLoop = 0; // Loop to help calc average int batArray[3]; // Array to store value for average calc. int BATTERY_SENSE_PIN = A0; // select the input pin for the battery sense point //=========================void batM() //The battery calculations { delay(500); // Battery monitoring reading int sensorValue = analogRead(BATTERY_SENSE_PIN); delay(500); // Calculate the battery in % float Vbat = sensorValue * VBAT_PER_BITS; int batteryPcnt = static_cast<int>(((Vbat-VMIN)/(VMAX-VMIN))*100.); Serial.print("Battery percent: "); Serial.print(batteryPcnt); Serial.println(" %"); // Add it to array so we get an average of 3 (3x20min) batArray[batLoop] = batteryPcnt; if (batLoop > 2) { batteryPcnt = (batArray[0] + batArray[1] + batArray[2] + batArray[3]); batteryPcnt = batteryPcnt / 3; if (batteryPcnt > 100) { batteryPcnt=100; } Serial.print("Battery Average (Send): "); Serial.print(batteryPcnt); Serial.println(" %"); sendBatteryLevel(batteryPcnt); batLoop = 0; } else { batLoop++; } }Add batM(); in the loop where you want to measure.

This calculates an avarage and sends it every 3rd time. So i sleep my sensors for 20 min, and battery is reported every 1hour.If you want to measure incoming VCC agains ref use @Nca78 but this does not work if you are using a booster (since it will always be 3.3v on incoming).

-

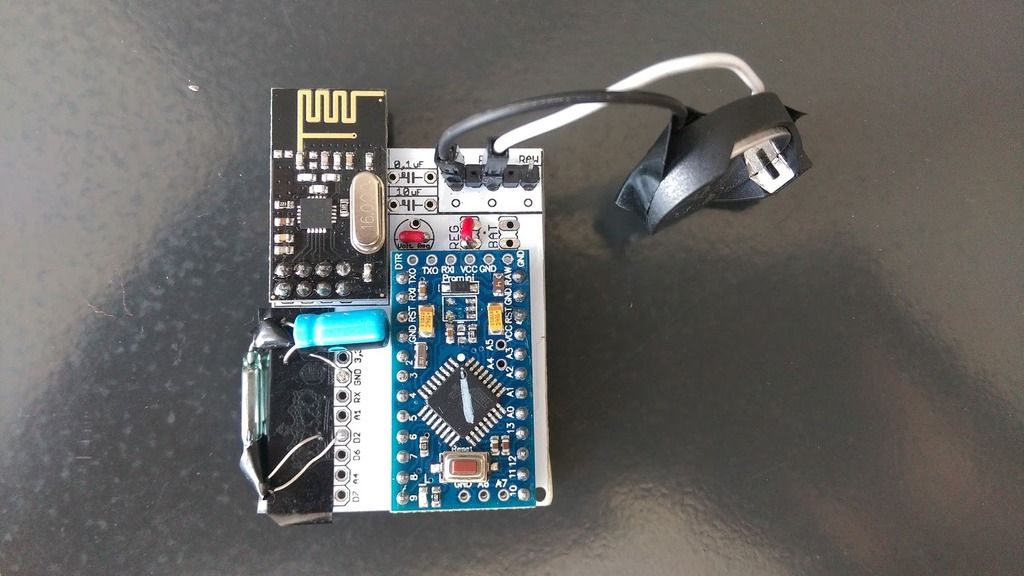

Thank you for the tip @sundberg84, it just needed the bypassing of the regulator, and then I can connect my cell battery to the GND and PWR and it runs fine.

@Samuel235 yes you are right I did it and it didn't have Vcc power that's why I asked that question to sundberg84, next time I'll precise it as it could have ended in wasted time...

@chuckconnors this is how you have to connect the jumpers to use directly on battery power (on GND and PWR pins). But as sundberg84 says you will not have a long battery life with AA batteries and without a booster. Even if you update the fuses and bootloader to run at 1MHz and have the BOD at 1.8V there will still be power left (I guess not far from 25% of capacity with 2 batteries) that is wasted. If you keep the defaults settings of the arduino at 8MHz it will run down to 2.4V and around half of the energy in your batteries will be wasted.

Hello @sundberg84 I have a request for update for your board :)

Can you remove the trace from the INT pin of the NRF24 to the D2 pin of the pro mini ? As interrupt is not used in MySensors for the NRF24, it's not useful while it creates some side effects.I explain you my problem:

I made a door sensor using a reed switch with both normally open and normally closed pins, and connected them to D2 and D3 (+ ground on the other side connected, as on my last picture above).

In the code I switch the status of the pins in the loop between HIGH/LOW values and set the interrupt on the unconnected pin so the pin is connected to ground only during a very short time (just the time to get out of the sleep mode). I'm supposed to have a very low consumption during deep sleep mode (few microamps). But I have that only when D2 is not connected to ground. If it's connected then it seems I have some current leaking from the INT pin of the NRF24 to the ground through the reed switch, as the board is using 6.5mA.

Without any other change, I made a barbaric cut of the trace near the NRF24 and now the current consumption is around 1.5 µA for both states of the reed switch. For the next boards I will just remove the INT pin of the NRF24, but it would be more simple to have nothing to do :PJust in case this is my sketch (not final, please be tolerant) but I don't think it's really relevant

// Enable debug prints #define MY_DEBUG // Enable and select radio type attached #define MY_RADIO_NRF24 #include <SPI.h> #include <MyConfig.h> #include <MySensors.h> #include <SystemStatus.h> #define SKETCH_NAME "NCA Door Sensor" #define SKETCH_MAJOR_VER "0" #define SKETCH_MINOR_VER "7" #define PRIMARY_CHILD_ID 30 #define SECONDARY_CHILD_ID 4 #define PRIMARY_BUTTON_PIN 2 // Arduino Digital I/O pin for button/reed switch #define SECONDARY_BUTTON_PIN 3 // Arduino Digital I/O pin for button/reed switch #if (PRIMARY_BUTTON_PIN < 2 || PRIMARY_BUTTON_PIN > 3) #error PRIMARY_BUTTON_PIN must be either 2 or 3 for interrupts to work #endif #if (SECONDARY_BUTTON_PIN < 2 || SECONDARY_BUTTON_PIN > 3) #error SECONDARY_BUTTON_PIN must be either 2 or 3 for interrupts to work #endif #if (PRIMARY_BUTTON_PIN == SECONDARY_BUTTON_PIN) #error PRIMARY_BUTTON_PIN and BUTTON_PIN2 cannot be the same #endif #if (PRIMARY_CHILD_ID == SECONDARY_CHILD_ID) #error PRIMARY_CHILD_ID and SECONDARY_CHILD_ID cannot be the same #endif #define MY_NODE_ID 2 #define MY_PARENT_NODE_ID 0 // Change to V_LIGHT if you use S_LIGHT in presentation below MyMessage msg(PRIMARY_CHILD_ID, V_TRIPPED); //MyMessage msg2(SECONDARY_CHILD_ID, V_TRIPPED); // Parameters for VCC measurement const int VccMin = 2400; // Minimum expected Vcc level, in Volts. If you have updated bootloader&BOD you can change to 1.8V here const int VccMax = 3000; // Maximum expected Vcc level, in Volts. SystemStatus vcc(); int LastBatteryPercent = 200; // so we are sure to send the battery level at first check bool isEven = false; // to check+send battery level only for each open+close cycles // This is the activated pin, on which the interrupt is set byte connectedPin = PRIMARY_BUTTON_PIN; byte connectedPinAtLastSending = 0; // Initialized at 0 so we will always send the first time void setup() { // First thing to do: change clock prescaling to 8 to change from 8MHz to 1MHz // of course not necessary if you already have updated fuses and bootloader... #ifndef MY_DEBUG // only if we are not in debug mode, so we can keep the fast baudrate in debug clock_prescale_set (clock_div_8); #endif } void presentation() { // Send the sketch version information to the gateway and Controller sendSketchInfo(SKETCH_NAME, SKETCH_MAJOR_VER "." SKETCH_MINOR_VER); // Register binary input sensor to sensor_node (they will be created as child devices) present(PRIMARY_CHILD_ID, S_DOOR); } // Loop will iterate on changes on the BUTTON_PINs void loop() { // Short delay to allow buttons to properly settle sleep(5); deActivatePin(PRIMARY_BUTTON_PIN); deActivatePin(SECONDARY_BUTTON_PIN); // Check if the previously connected pin is now connected. We do that because it's the most likely to be unconnected now // so it's the best way not to lose any current byte newConnectedPin = GetNonConnectedPin(); if (checkPinIsConnected(connectedPin)) { // If pin is still connected we set back the value to connected pin newConnectedPin = connectedPin; #ifdef MY_DEBUG Serial.println("Connected pin is connected !"); #endif } connectedPin = newConnectedPin; // If connected pin is different that the one during the last sending of status, we send again #ifdef MY_DEBUG Serial.print("Connected pin = "); Serial.println(connectedPin); Serial.print("New Connected pin = "); Serial.println(newConnectedPin); #endif if (connectedPin != connectedPinAtLastSending) { // Value has changed from last transmission, send the updated value send(msg.set(connectedPin==PRIMARY_BUTTON_PIN ? 1 : 0)); connectedPinAtLastSending = connectedPin; isEven = !isEven; } if (isEven) { // send only every two changes for a full open + close cycle int currentBatteryPercent = SystemStatus().getVCCPercent(VccMin, VccMax); if (currentBatteryPercent != LastBatteryPercent) { LastBatteryPercent = currentBatteryPercent; sendBatteryLevel(currentBatteryPercent); } } #ifdef MY_DEBUG Serial.print("Preparing to sleep, pin "); Serial.println(GetNonConnectedPin()); wait(50); #endif // Activate the non connected pin before setting up interrupt activatePin(GetNonConnectedPin()); // Sleep until something happens with the door sensor sleep(GetNonConnectedPin()-2, CHANGE); } void activatePin(byte pin) { // Set pin as input pinMode(pin, INPUT); // Activate internal pull up digitalWrite(pin, HIGH); } void deActivatePin(byte pin) { // Set back pin as output, low pinMode(pin, OUTPUT); digitalWrite(pin, LOW); } // Will check if pin is grounded (returns true) or not boolean checkPinIsConnected(byte pin) { activatePin(pin); // Read value byte valPin = digitalRead(pin); deActivatePin(pin); #ifdef MY_DEBUG Serial.print("checkPinIsConnected pin = "); Serial.print(pin); Serial.print(", value = "); Serial.println(valPin); #endif return valPin != HIGH; } // Returns the pin that is not connected byte GetNonConnectedPin() { return (connectedPin == PRIMARY_BUTTON_PIN) ? SECONDARY_BUTTON_PIN : PRIMARY_BUTTON_PIN; } -

Hello @sundberg84 I have a request for update for your board :)

Can you remove the trace from the INT pin of the NRF24 to the D2 pin of the pro mini ? As interrupt is not used in MySensors for the NRF24, it's not useful while it creates some side effects.I explain you my problem:

I made a door sensor using a reed switch with both normally open and normally closed pins, and connected them to D2 and D3 (+ ground on the other side connected, as on my last picture above).

In the code I switch the status of the pins in the loop between HIGH/LOW values and set the interrupt on the unconnected pin so the pin is connected to ground only during a very short time (just the time to get out of the sleep mode). I'm supposed to have a very low consumption during deep sleep mode (few microamps). But I have that only when D2 is not connected to ground. If it's connected then it seems I have some current leaking from the INT pin of the NRF24 to the ground through the reed switch, as the board is using 6.5mA.

Without any other change, I made a barbaric cut of the trace near the NRF24 and now the current consumption is around 1.5 µA for both states of the reed switch. For the next boards I will just remove the INT pin of the NRF24, but it would be more simple to have nothing to do :PJust in case this is my sketch (not final, please be tolerant) but I don't think it's really relevant

// Enable debug prints #define MY_DEBUG // Enable and select radio type attached #define MY_RADIO_NRF24 #include <SPI.h> #include <MyConfig.h> #include <MySensors.h> #include <SystemStatus.h> #define SKETCH_NAME "NCA Door Sensor" #define SKETCH_MAJOR_VER "0" #define SKETCH_MINOR_VER "7" #define PRIMARY_CHILD_ID 30 #define SECONDARY_CHILD_ID 4 #define PRIMARY_BUTTON_PIN 2 // Arduino Digital I/O pin for button/reed switch #define SECONDARY_BUTTON_PIN 3 // Arduino Digital I/O pin for button/reed switch #if (PRIMARY_BUTTON_PIN < 2 || PRIMARY_BUTTON_PIN > 3) #error PRIMARY_BUTTON_PIN must be either 2 or 3 for interrupts to work #endif #if (SECONDARY_BUTTON_PIN < 2 || SECONDARY_BUTTON_PIN > 3) #error SECONDARY_BUTTON_PIN must be either 2 or 3 for interrupts to work #endif #if (PRIMARY_BUTTON_PIN == SECONDARY_BUTTON_PIN) #error PRIMARY_BUTTON_PIN and BUTTON_PIN2 cannot be the same #endif #if (PRIMARY_CHILD_ID == SECONDARY_CHILD_ID) #error PRIMARY_CHILD_ID and SECONDARY_CHILD_ID cannot be the same #endif #define MY_NODE_ID 2 #define MY_PARENT_NODE_ID 0 // Change to V_LIGHT if you use S_LIGHT in presentation below MyMessage msg(PRIMARY_CHILD_ID, V_TRIPPED); //MyMessage msg2(SECONDARY_CHILD_ID, V_TRIPPED); // Parameters for VCC measurement const int VccMin = 2400; // Minimum expected Vcc level, in Volts. If you have updated bootloader&BOD you can change to 1.8V here const int VccMax = 3000; // Maximum expected Vcc level, in Volts. SystemStatus vcc(); int LastBatteryPercent = 200; // so we are sure to send the battery level at first check bool isEven = false; // to check+send battery level only for each open+close cycles // This is the activated pin, on which the interrupt is set byte connectedPin = PRIMARY_BUTTON_PIN; byte connectedPinAtLastSending = 0; // Initialized at 0 so we will always send the first time void setup() { // First thing to do: change clock prescaling to 8 to change from 8MHz to 1MHz // of course not necessary if you already have updated fuses and bootloader... #ifndef MY_DEBUG // only if we are not in debug mode, so we can keep the fast baudrate in debug clock_prescale_set (clock_div_8); #endif } void presentation() { // Send the sketch version information to the gateway and Controller sendSketchInfo(SKETCH_NAME, SKETCH_MAJOR_VER "." SKETCH_MINOR_VER); // Register binary input sensor to sensor_node (they will be created as child devices) present(PRIMARY_CHILD_ID, S_DOOR); } // Loop will iterate on changes on the BUTTON_PINs void loop() { // Short delay to allow buttons to properly settle sleep(5); deActivatePin(PRIMARY_BUTTON_PIN); deActivatePin(SECONDARY_BUTTON_PIN); // Check if the previously connected pin is now connected. We do that because it's the most likely to be unconnected now // so it's the best way not to lose any current byte newConnectedPin = GetNonConnectedPin(); if (checkPinIsConnected(connectedPin)) { // If pin is still connected we set back the value to connected pin newConnectedPin = connectedPin; #ifdef MY_DEBUG Serial.println("Connected pin is connected !"); #endif } connectedPin = newConnectedPin; // If connected pin is different that the one during the last sending of status, we send again #ifdef MY_DEBUG Serial.print("Connected pin = "); Serial.println(connectedPin); Serial.print("New Connected pin = "); Serial.println(newConnectedPin); #endif if (connectedPin != connectedPinAtLastSending) { // Value has changed from last transmission, send the updated value send(msg.set(connectedPin==PRIMARY_BUTTON_PIN ? 1 : 0)); connectedPinAtLastSending = connectedPin; isEven = !isEven; } if (isEven) { // send only every two changes for a full open + close cycle int currentBatteryPercent = SystemStatus().getVCCPercent(VccMin, VccMax); if (currentBatteryPercent != LastBatteryPercent) { LastBatteryPercent = currentBatteryPercent; sendBatteryLevel(currentBatteryPercent); } } #ifdef MY_DEBUG Serial.print("Preparing to sleep, pin "); Serial.println(GetNonConnectedPin()); wait(50); #endif // Activate the non connected pin before setting up interrupt activatePin(GetNonConnectedPin()); // Sleep until something happens with the door sensor sleep(GetNonConnectedPin()-2, CHANGE); } void activatePin(byte pin) { // Set pin as input pinMode(pin, INPUT); // Activate internal pull up digitalWrite(pin, HIGH); } void deActivatePin(byte pin) { // Set back pin as output, low pinMode(pin, OUTPUT); digitalWrite(pin, LOW); } // Will check if pin is grounded (returns true) or not boolean checkPinIsConnected(byte pin) { activatePin(pin); // Read value byte valPin = digitalRead(pin); deActivatePin(pin); #ifdef MY_DEBUG Serial.print("checkPinIsConnected pin = "); Serial.print(pin); Serial.print(", value = "); Serial.println(valPin); #endif return valPin != HIGH; } // Returns the pin that is not connected byte GetNonConnectedPin() { return (connectedPin == PRIMARY_BUTTON_PIN) ? SECONDARY_BUTTON_PIN : PRIMARY_BUTTON_PIN; }@Nca78 Thanks. Someone else posted this as well. I will update this Inow rev 9 with some jumper or something.

-

Another real quick question. I have a simple sensor using a DHT11. I have this connected to D3 for signal and power and ground from the right holes. I'm getting an error saying it can't read temp/hum from the DHT. That set up should be right though? I also have a 4.7k ohm resistor in the board for D3 (that's the pin, right?).

-

@chuckconnors - that right, see my post at 110 (https://forum.mysensors.org/topic/2740/easy-newbie-pcb-for-mysensors/110)

I have the dht22 in the prototyping area but have made alot of dht22 attached directly to power/gnd and d3 pin on the mysx connector. Works great. -

@chuckconnors - that right, see my post at 110 (https://forum.mysensors.org/topic/2740/easy-newbie-pcb-for-mysensors/110)

I have the dht22 in the prototyping area but have made alot of dht22 attached directly to power/gnd and d3 pin on the mysx connector. Works great.@sundberg84 Thanks. Another dumb question: What is the difference between the RAW ad the PWR pads and when should I use one rather than the other?

-

If you have unregulated power (RAW) within pro minis on board voltage regulater you can instead of using 5v regulated power use this and the arduino will convert it to 5v. I think the specs are 6-12v (with a varning on that clones can not handle 12v!). So for example if you have a 9v battery you can power everything with connecting this to RAW and GND instead of PWR and GND and the voltage regulater on the pro mini will output 5v for the rest of the PCB. @chuckconnors

-

Just wanted to say great work on this board. I have the first one wired up w/ batteries, 3.3v APM w/led and regulations removed, voltage regulator, dht11 and motion w 3v mod and works wonderfully. Once I get my caliper in, I'll get the right mounting screws, finish my enclosure and post the pics.

-

what is the size of the mounting holes? i don't have a caliper yet to measure this small of a size (ordering on amazon)

@rchamp said:

what is the size of the mounting holes? i don't have a caliper yet to measure this small of a size (ordering on amazon)

I dont have eagles at this computer, so I have to answer you tonight (8 hours) or so...

Thanks for the nice feedback! -

what is the size of the mounting holes? i don't have a caliper yet to measure this small of a size (ordering on amazon)

@rchamp - sorry for later reply, the mounting holes are 2mm or 78.7mil.

-

@rchamp - sorry for later reply, the mounting holes are 2mm or 78.7mil.

@sundberg84

awesome thanks! -

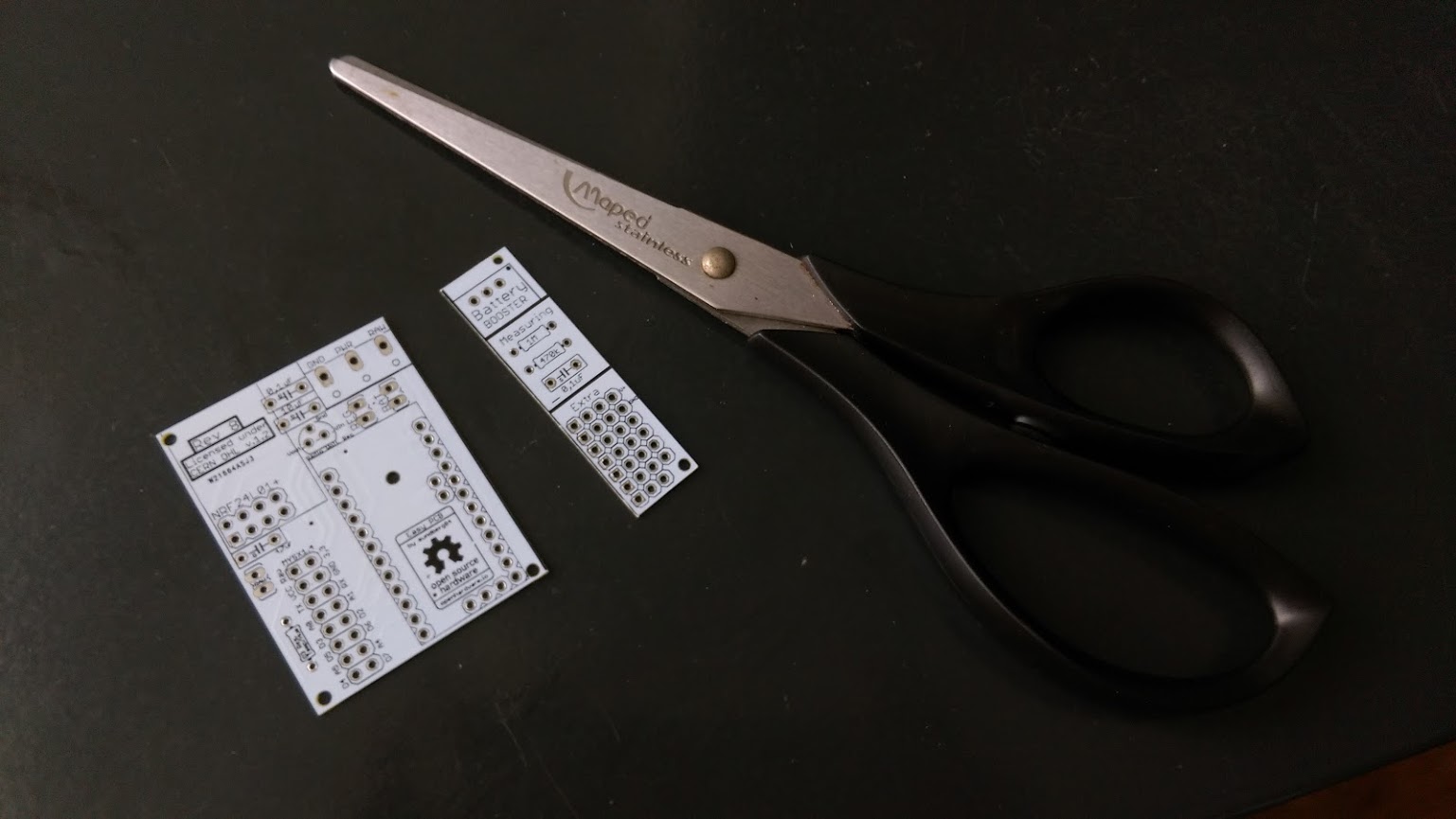

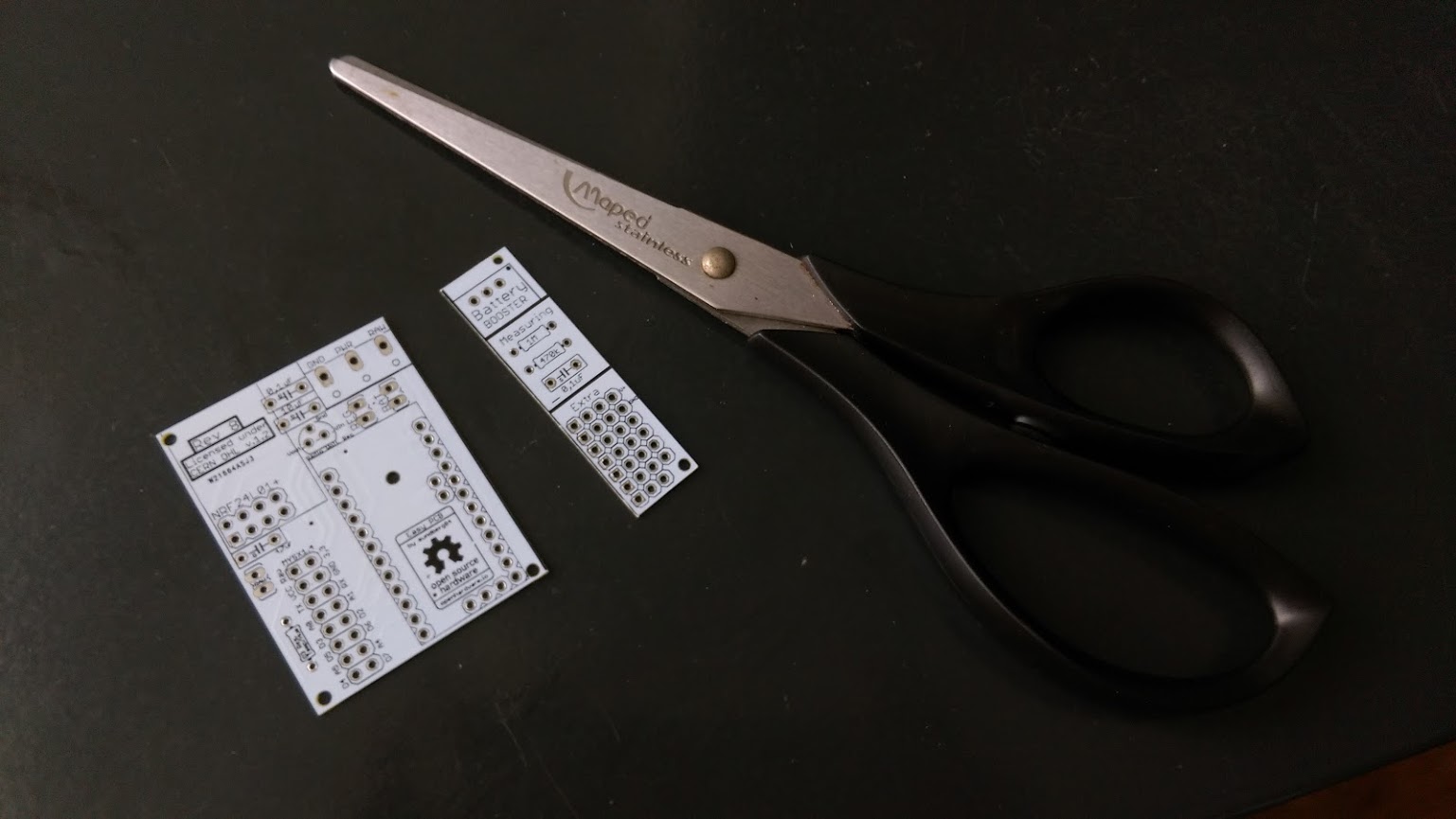

Hello, I ordered a second batch from PCBWay, it's ok except some components have a frame on the silkscreen, not very beautiful.

Just wanted to say that it was a pain to cut the 1.6mm PCB so this time I ordered in 0.8mm and it is sooooo easy to cut with regular cissors: no efforts and very clean cut ! So if you plan to cut the right part, order at 1mm or below, you will enjoy the cutting phase :D

-

Hello, I ordered a second batch from PCBWay, it's ok except some components have a frame on the silkscreen, not very beautiful.

Just wanted to say that it was a pain to cut the 1.6mm PCB so this time I ordered in 0.8mm and it is sooooo easy to cut with regular cissors: no efforts and very clean cut ! So if you plan to cut the right part, order at 1mm or below, you will enjoy the cutting phase :D

@Nca78 said:

it's ok except some components have a frame on the silkscreen, not very beautiful.

Sorry, I dont understand what you mean - can you give me a closeup photo? It should be functional AND beautiful :) If the silkscreen overlaps the copper parts this could interfer as well...

you will enjoy the cutting phase

I also learned it the hard way - and since there isnt any high power ciciut it should be ok to order very thin pcbs.

I used a metallic saw for one :persevere: and for some i cut a trace with a knife and bended it until it cracked. -

Just ordered 10 white bords, they look so great :)

-

@Nca78 said:

it's ok except some components have a frame on the silkscreen, not very beautiful.

Sorry, I dont understand what you mean - can you give me a closeup photo? It should be functional AND beautiful :) If the silkscreen overlaps the copper parts this could interfer as well...

you will enjoy the cutting phase

I also learned it the hard way - and since there isnt any high power ciciut it should be ok to order very thin pcbs.

I used a metallic saw for one :persevere: and for some i cut a trace with a knife and bended it until it cracked.@sundberg84 said:

Sorry, I dont understand what you mean - can you give me a closeup photo? It should be functional AND beautiful :) If the silkscreen overlaps the copper parts this could interfer as well...

I fact it's the case only for the "Rev B" and licence text at the top left. No big deal but it was looking better without the frame from DirtyPCB

I also learned it the hard way - and since there isnt any high power ciciut it should be ok to order very thin pcbs.

I used a metallic saw for one :persevere: and for some i cut a trace with a knife and bended it until it cracked.I used the knife too (don't have a metal saw) with the 1.6mm PCBs and it was long and messy. Now it's just like a strong cardboard.

-

I ordered some via DirtyPCB - Ordering via OpenHardware it seems to suggest you are buying Rev4. Says Rev4 under the order button at least.

@Qu3Uk - Yes, and its missleading. Its rev 9 you are ordering but the fourth update on openhardware.io Its no problem ordering from there, I always update those gerber files first.