reporting battery to domoticZ

-

thx i got a voltage log only giving me now -44.000 volt and 212 prct at battery level while measuring 3.7 volt battery and voltage on A0 1.3 volts

.// Enable debug prints to serial monitor #define MY_DEBUG // Enable and select radio type attached #define MY_RADIO_NRF24 //#define MY_RADIO_RFM69 #include <SPI.h> #include <MySensors.h> #include <DHT.h> // Enable debug prints #define MY_DEBUG #define CHILD_ID_HUM 0 #define CHILD_ID_TEMP 1 #define HUMIDITY_SENSOR_DIGITAL_PIN 3 #define CHILD_ID_BATTERY 4 unsigned long SLEEP_TIME = 60000; // Sleep time between reads (in milliseconds) #define SKETCH_NAME "Temp_Hum_Batt" // Change to a fancy name you like #define SKETCH_VERSION "2.1" // Your version DHT dht; float lastTemp; float lastHum; boolean metric = true; MyMessage msgHum(CHILD_ID_HUM, V_HUM); MyMessage msgTemp(CHILD_ID_TEMP, V_TEMP); MyMessage msgbatt(CHILD_ID_BATTERY, V_VOLTAGE); //========================= // BATTERY VOLTAGE DIVIDER SETUP // 1M, 470K divider across battery and using internal ADC ref of 1.1V // Sense point is bypassed with 0.1 uF cap to reduce noise at that point // ((1e6+470e3)/470e3)*1.1 = Vmax = 3.44 Volts // 3.44/1023 = Volts per bit = 0.003363075 #define VBAT_PER_BITS 0.0041055718475073313782991202346 // 4.20/1023 volt #define VMIN 3.6 // Vmin = 3.6 lipo empty #define VMAX 4.2 // Vmax = 4.2 volt lipo full int batteryPcnt = 0; // Calc value for battery % int batLoop = 0; // Loop to help calc average int batArray[3]; // Array to store value for average calc. int BATTERY_SENSE_PIN = A0; // select the input pin for the battery sense point //========================= void setup() { analogReference(INTERNAL); // For battery sensing delay(500); // Allow time for radio if power used as reset dht.setup(HUMIDITY_SENSOR_DIGITAL_PIN); metric = getControllerConfig().isMetric; } void presentation() { // Send the Sketch Version Information to the Gateway // Send the Sketch Version Information to the Gateway sendSketchInfo(SKETCH_NAME, SKETCH_VERSION); // Register all sensors to gw (they will be created as child devices) present(CHILD_ID_BATTERY, S_MULTIMETER); present(CHILD_ID_HUM, S_HUM); present(CHILD_ID_TEMP, S_TEMP); } void loop() { delay(500); // Allow time for radio if power used as reset delay(dht.getMinimumSamplingPeriod()); // Fetch temperatures from DHT sensor float temperature = dht.getTemperature(); if (isnan(temperature)) { Serial.println("Failed reading temperature from DHT"); } else if (temperature != lastTemp) { lastTemp = temperature; if (!metric) { temperature = dht.toFahrenheit(temperature); } send(msgTemp.set(temperature, 1)); Serial.print("T: "); Serial.println(temperature); } // Fetch humidity from DHT sensor float humidity = dht.getHumidity(); if (isnan(humidity)) { Serial.println("Failed reading humidity from DHT"); } else if (humidity != lastHum) { lastHum = humidity; send(msgHum.set(humidity, 1)); Serial.print("H: "); Serial.println(humidity); } batM(); sleep(SLEEP_TIME); //sleep a bit } void batM() //The battery calculations { delay(500); // Battery monitoring reading int sensorValue = analogRead(BATTERY_SENSE_PIN); delay(500); // Calculate the battery in % float Vbat = sensorValue * VBAT_PER_BITS; int batteryPcnt = static_cast<int>(((Vbat-VMIN)/(VMAX-VMIN))*100.); Serial.print("Battery percent: "); Serial.print(batteryPcnt); Serial.println(" %"); // Add it to array so we get an average of 3 (3x20min) batArray[batLoop] = batteryPcnt; if (batLoop > 2) { batteryPcnt = (batArray[0] + batArray[1] + batArray[2] + batArray[3]); batteryPcnt = batteryPcnt / 3; if (batteryPcnt > 100) { batteryPcnt=100; } Serial.print("Battery Average (Send): "); Serial.print(batteryPcnt); Serial.println(" %"); sendBatteryLevel(batteryPcnt); send(msgbatt.set(batteryPcnt ,2)); batLoop = 0; } else { batLoop++; } }```@Rene046 what resistors do you use to measure battery. VBAT_PER_BITS is not just 4.2/1023. Personally I am using 1m and 300k it gives me up to 4.77V

-

@Rene046 what resistors do you use to measure battery. VBAT_PER_BITS is not just 4.2/1023. Personally I am using 1m and 300k it gives me up to 4.77V

Hi im using at this moment what i had.

270k-100k giving me 1.07 volt at 4.2 batterySo i stay save , but ok reading is not giving my wanted 4.2 volt but around 3.92 volt

My nano is feeded by an dc -dc boost converter giving me 5 volt from this 4.2 battery.

@AWI

Sorry im still a noob in this, just understood how to make a voltage diver using 3:1 divider

.

Could you please give me a simple example how do this calculation. -

Hi im using at this moment what i had.

270k-100k giving me 1.07 volt at 4.2 batterySo i stay save , but ok reading is not giving my wanted 4.2 volt but around 3.92 volt

My nano is feeded by an dc -dc boost converter giving me 5 volt from this 4.2 battery.

@AWI

Sorry im still a noob in this, just understood how to make a voltage diver using 3:1 divider

.

Could you please give me a simple example how do this calculation.@Rene046

As I understand correct VBAT_PER_BITS is not just 4.2/1032. This depends what resistors do you use. If you use 1m and 470k VBAT_PER_BITS=0.003363075 made from formula and it will never reads more 3.44v.

#define VMIN and #define VMAX 4.2 used only for formula int batteryPcnt = static_cast<int>(((Vbat-VMIN)/(VMAX-VMIN))*100.);

If you use 270k and 100k maximum is 4.07V so will be VBAT_PER_BITS=0.0039784946236559 and not like in your sketch 0.0041055718475073313782991202346 -

Hi im using at this moment what i had.

270k-100k giving me 1.07 volt at 4.2 batterySo i stay save , but ok reading is not giving my wanted 4.2 volt but around 3.92 volt

My nano is feeded by an dc -dc boost converter giving me 5 volt from this 4.2 battery.

@AWI

Sorry im still a noob in this, just understood how to make a voltage diver using 3:1 divider

.

Could you please give me a simple example how do this calculation.@Rene046 You making it complex. The steps)

- Make sure that the input voltage is within the range of the reference. You did that with the voltage divider (max 1.07 V) :+1:

- set

vRefin the sketch to an expected value (4.2 / 1 , where 1 is the calibration value). You did (4.2/1.07) :+1: - Now you need to calibrate in the software:

- Measure the battery voltage (batteryVoltage) (not the voltage divider) with the multimeter. You did (4.2 Volt) :+1:

- Look at the voltage level reported by the sketch (reportedVoltage). You did (3.92 Volt) :+1:

- Calculate the calibration value and adjust vRef. It needs to report 4.2V now it reports 3.92V so you are off by 1.07. => (4.2/1.07) * 1.07 = 4.2 => set vRef to (4.2/ 1.0) and you will be fine.

There are a few reasons why you need to calibrate:

- The internal reference of the Arduino (1.1V) is not calibrated (can roughly vary from 1V to 1.2V)

- Your voltage divider is not always precise.

- Most multimeters are far more accurate...

-

@Rene046

As I understand correct VBAT_PER_BITS is not just 4.2/1032. This depends what resistors do you use. If you use 1m and 470k VBAT_PER_BITS=0.003363075 made from formula and it will never reads more 3.44v.

#define VMIN and #define VMAX 4.2 used only for formula int batteryPcnt = static_cast<int>(((Vbat-VMIN)/(VMAX-VMIN))*100.);

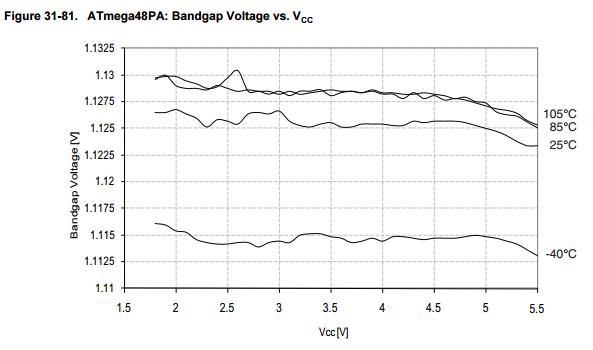

If you use 270k and 100k maximum is 4.07V so will be VBAT_PER_BITS=0.0039784946236559 and not like in your sketch 0.0041055718475073313782991202346@Arnold-Šlepetis Purist physics ;-) : Although you calculation is probably correct for your use case. I associate a

VBAT_PER_BITS=0.0039784946236559with almost atomic precision. As where the internal (band-gap) reference has +- 10% offset and drift with temperature and Vcc (although it is pretty stable for MySensors purposes).

-

What can i do to get a more stable reading now the voltage goes from 3.80 to 4.20 while feeding with an 4.20 volt

-

What can i do to get a more stable reading now the voltage goes from 3.80 to 4.20 while feeding with an 4.20 volt

-

vref: 4.20 V sensorValue: 949 bit 219143 TSF:MSG:SEND,2-2-0-0,s=4,c=1,t=38,pt=7,l=5,sg=0,ft=0,st=OK:3.89 Battery voltage: 3.89 V 219151 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:48 Battery percent: 48 % 219158 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 219164 MCO:SLP:TPD 219166 MCO:SLP:WUP=-1 221699 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:35.2 H: 35.20 vref: 4.20 V sensorValue: 951 bit 222708 TSF:MSG:SEND,2-2-0-0,s=4,c=1,t=38,pt=7,l=5,sg=0,ft=0,st=OK:3.90 Battery voltage: 3.90 V 222717 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:50 Battery percent: 50 % 222724 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 222731 MCO:SLP:TPD 222733 MCO:SLP:WUP=-1 225242 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:20.6 T: 20.60 225251 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:34.5 H: 34.50 vref: 4.20 V sensorValue: 955 bit 226260 TSF:MSG:SEND,2-2-0-0,s=4,c=1,t=38,pt=7,l=5,sg=0,ft=0,st=OK:3.92 Battery voltage: 3.92 V 226269 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:52 Battery percent: 52 % 226276 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 226282 MCO:SLP:TPD -

@Rene046 said in reporting battery to domoticZ:

What can i do to get a more stable reading now the voltage goes from 3.80 to 4.20 while feeding with an 4.20 volt

It seems like when the nano starts reading the voltage drops a bid.

@Rene046 From your earlier postings I can see that you are using a boost converter. Speaking in general these things make a lot of noise on the power line and are certainly not a stable supply.

Just a few considerations:- A nano is not well suited for battery operation. These tend to dissipate at minimum 5mA and will drown a one cell battery fast. Go for a 3.3V pro-mini and remove the led.

- Get rid of the Boost converter and power directly from the battery. The radio and pro-mini will work fine on 3.6V using a regulator (LDO). In this case you can measure battery directly from the Vcc pin without divider.

-

Hi Awi i will build someday if i got it working this project on a pro-mini,.

im not measuring the voltage on the dc-dc booster but on the battery side feeding the converter.

I need this booster because i also feeding my DHT with 5 volt and in future other sensors.BH1750, BMP180, Soil moisture sensor

and im charging my battery in the future with an 6 volt solar panel.

So to see this is working during day time i should be able to read the charging voltage of 4.2 volt and during the night the voltage of battery dropping -

@Rene046 What is the output of the DC=DC converter measuring? Are you powering the nano on the Vcc or Vin pin?

-

Hi Awi i will build someday if i got it working this project on a pro-mini,.

im not measuring the voltage on the dc-dc booster but on the battery side feeding the converter.

I need this booster because i also feeding my DHT with 5 volt and in future other sensors.BH1750, BMP180, Soil moisture sensor

and im charging my battery in the future with an 6 volt solar panel.

So to see this is working during day time i should be able to read the charging voltage of 4.2 volt and during the night the voltage of battery dropping@Rene046 A 3.6-4.2 V battery with 3.3V ldo is perfectly suited to power the sensors you mentioned . I would replace the DHT22 with a (much better) I2C sensor (si7021/ BME280 /... ).

If the measured voltage is not stable then in most cases the power supply or the measured voltage is unstable.