What did you build today (Pictures) ?

-

@sundberg84 said in What did you build today (Pictures) ?:

@scalz - im using volumio (finished image for RPI) and happy with this. Just a tip...

same here with a few additional plugins ;) Agreed, volumio is sexy sw.

your speaker looks nice :+1:

I read and learnt a lot how to make diy speakers. It was very interesting learning curve, lot of parameters I didn't know before (and one of the most important rule is : tune your enclosure regarding speaker drivers specs, not the oppposite (there are software for calculating everything) Now I understand better the curves etc and where commercial stuff cheats. pretty cool

@scalz - this was my first project and I agree with you (because I didnt calculate much before). If you are looking for the best sound its incredible important... for me and this build I wanted a small enclosure in the kitchen but the sound is pretty impressive for such a small thing so Im happy even though I know it could have sounded better.

-

@zboblamont

well actually it's setup as a standalone stereo speaker. I asked my brother (it's a gift for him) if he would prefer separated speakers (better for stereo). But he prefers like this, standalone with no wires, and his room won't be wide so it should be ok.

Yes, i know for the jigs in plywood, but i have a 3d printer, caliper; drawing, print and voilà :)

I like using cad software for checking assemblies in 3d etc, very handy, and it's more precise than my brain :).@fredswed yeah, it sounds very nice. when you hear it, then you know you made the good choice. Better than buying any of these 60 to >200$ smart speakers. I compared them with some others hifi speakers (jbl..) for fun, and still very impressive. Some of my friends are jealous. They want one, or more. Same for my others bro. They sound pretty loud imho, and would like to try a pair like that for fun

I ordered most of the parts at loudspeakerfreaks or audiohobby. if you live in USA, then it's better to give a try to parts express I think.I finished the vinyling yesterday (my bro didn't want I roundish the corner). I now just need to add a rpi inside and connectors etc on back, not bad :)

@scalz Whatever, so long as your brother enjoys what he asked for, job done.

Do I interpret your comment on "roundish the corner" as rounding over the front baffle edges? Sonically it can make a difference for imaging, but with drives this close I doubt it would be noticeable anyway, and would be a pain to vinyl let alone veneer....Almost 50 years I've been building speakers as a hobby....

I'll finish them one day ;) -

Maybe you speaker geniuses can figure out the optimal enclosure for this tiny buzzer? https://www.aliexpress.com/item/2731HZ-3x4-5x1-9mm-Super-small-miniature-AAC-electromagnetic-DET402-G-1-SMD-Passive-buzzer-3/32839766133.html?spm=2114.search0204.3.177.AclxtY&ws_ab_test=searchweb0_0&aff_platform=aaf&cpt=1515527880409&sk=e2Vzr3v&aff_trace_key=7078a47c52334a31ac1f2c6cfa07a508-1515527880409-05187-e2Vzr3v&terminal_id=892660b32ab149c8a0ca840218581bea

I find that if I cup my hand over it, it (somewhat counter-intuitively) gets a lot louder, so I guess the same principles are involved?

It would be neat to have a very tiny buzzer like this available for use in projects, but I guess the enclosure design needs to be considered as well so as to get more volume out of it.

-

Maybe you speaker geniuses can figure out the optimal enclosure for this tiny buzzer? https://www.aliexpress.com/item/2731HZ-3x4-5x1-9mm-Super-small-miniature-AAC-electromagnetic-DET402-G-1-SMD-Passive-buzzer-3/32839766133.html?spm=2114.search0204.3.177.AclxtY&ws_ab_test=searchweb0_0&aff_platform=aaf&cpt=1515527880409&sk=e2Vzr3v&aff_trace_key=7078a47c52334a31ac1f2c6cfa07a508-1515527880409-05187-e2Vzr3v&terminal_id=892660b32ab149c8a0ca840218581bea

I find that if I cup my hand over it, it (somewhat counter-intuitively) gets a lot louder, so I guess the same principles are involved?

It would be neat to have a very tiny buzzer like this available for use in projects, but I guess the enclosure design needs to be considered as well so as to get more volume out of it.

@neverdie said in What did you build today (Pictures) ?:

Maybe you speaker geniuses can figure out the optimal enclosure for this tiny buzzer?

I'll play my "I am not a speaker designer, but..." card! Here is some basic info. :grin:

Jokes aside, a piece of PVC tubing might work. You need something to make the buzzer move the air more efficiently. I'd put a 1/4 wavelength long PVC piping over the buzzer as

a first try. (Any odd multiple of 1/4 wavelength should provide some resonance.)In a more elaborate design, you could try a simple horn. Aim for a size where both the length of the horn and its circumference at the end is ca 1 wavelength.

-

Maybe you speaker geniuses can figure out the optimal enclosure for this tiny buzzer? https://www.aliexpress.com/item/2731HZ-3x4-5x1-9mm-Super-small-miniature-AAC-electromagnetic-DET402-G-1-SMD-Passive-buzzer-3/32839766133.html?spm=2114.search0204.3.177.AclxtY&ws_ab_test=searchweb0_0&aff_platform=aaf&cpt=1515527880409&sk=e2Vzr3v&aff_trace_key=7078a47c52334a31ac1f2c6cfa07a508-1515527880409-05187-e2Vzr3v&terminal_id=892660b32ab149c8a0ca840218581bea

I find that if I cup my hand over it, it (somewhat counter-intuitively) gets a lot louder, so I guess the same principles are involved?

It would be neat to have a very tiny buzzer like this available for use in projects, but I guess the enclosure design needs to be considered as well so as to get more volume out of it.

@neverdie Would this work ?

-

All I know is that there's no point to using a super small buzzer if it requires something big to make it work loud enough.

Maybe this is why the buzzer that I'm currently using instead has such a comparatively large form factor.... i.e. maybe there's just no getting around it.

-

All I know is that there's no point to using a super small buzzer if it requires something big to make it work loud enough.

Maybe this is why the buzzer that I'm currently using instead has such a comparatively large form factor.... i.e. maybe there's just no getting around it.

@neverdie That was kind of the point to that horn picture, the driver at the sharp end is tiny relatively, but this was the early days of speakers..

You can't have a small 1kHz transducer on minimum power and expect a lot really...

-

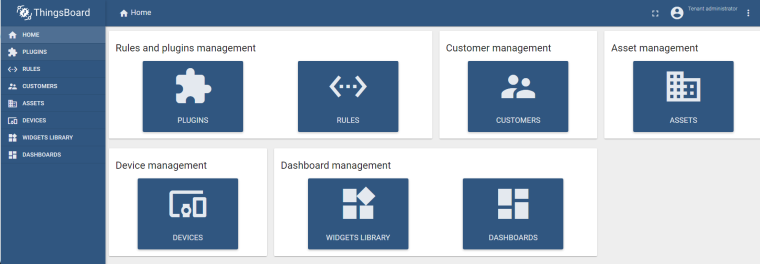

Today I'm trying out Thingsboard, which sort of is a controller, but on steroids.

So far, it seems quite capable, but I have a lot of learning to do. My first step was to integrate it with Sigfox, which seems to work.

-

@mfalkvidd that looks like more an IoT device management, doesn't it?

@gohan could be. What's the difference?

When I think of it, I guess a controller has little need for multi-tenancy.

Btw, some pretty cool dashboard examples can be viewed at https://github.com/thingsboard/thingsboard/blob/master/README.md

-

@gohan could be. What's the difference?

When I think of it, I guess a controller has little need for multi-tenancy.

Btw, some pretty cool dashboard examples can be viewed at https://github.com/thingsboard/thingsboard/blob/master/README.md

@mfalkvidd the difference is that the controller is for your home, the IoT device managment is like for a service provider (look at cayenne mydevices for example) that has different customers and resellers, so it needs to be multi tenant and some other features not needed for home use

-

@mfalkvidd the difference is that the controller is for your home, the IoT device managment is like for a service provider (look at cayenne mydevices for example) that has different customers and resellers, so it needs to be multi tenant and some other features not needed for home use

-

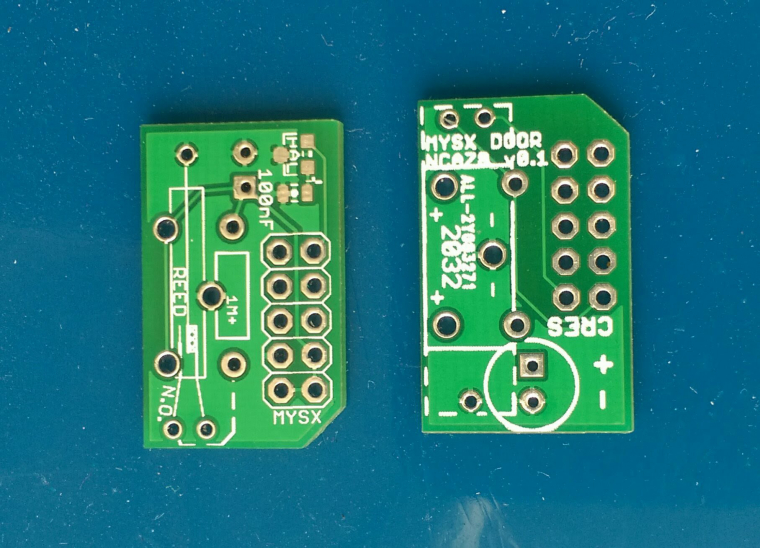

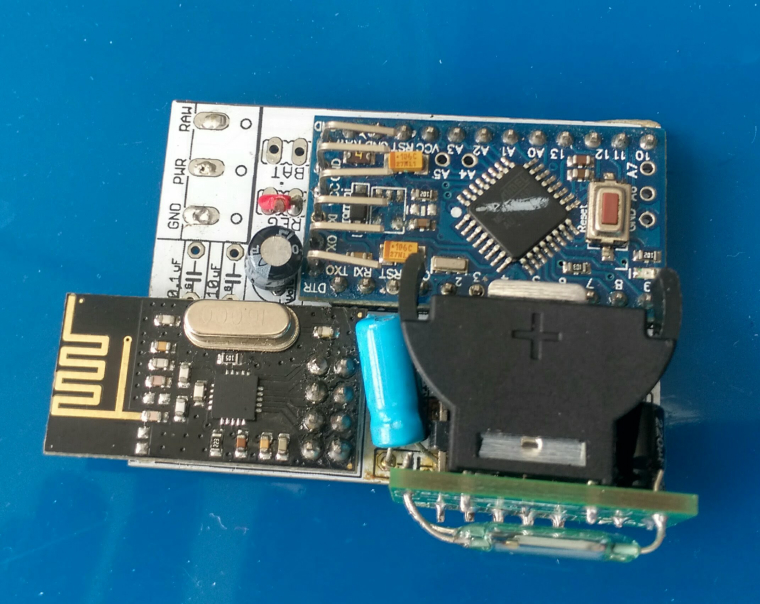

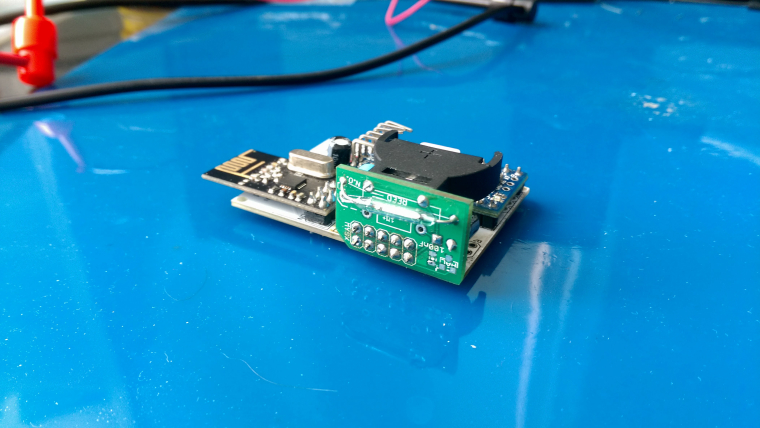

Today I soldered a tiny MYSX board to recycle my EasyPCBs in door sensors as compact as possible. I can also use the "vertical" CR2032 holders I had no use for and make some space in my drawers.

It can use a normal or a NO/NC reed switch (for SMD allergies :D ) or a SMD ultra low power hall sensor and it has a footprint for a reserve capacitor to support the CR2032.

I guess this board will be of interest for @sundberg84 ;)

PS: sorry for the ugly soldering, my old 936 clone soldering station is in "zombie" mode and it's all I have until the new soldering iron arrives.

-

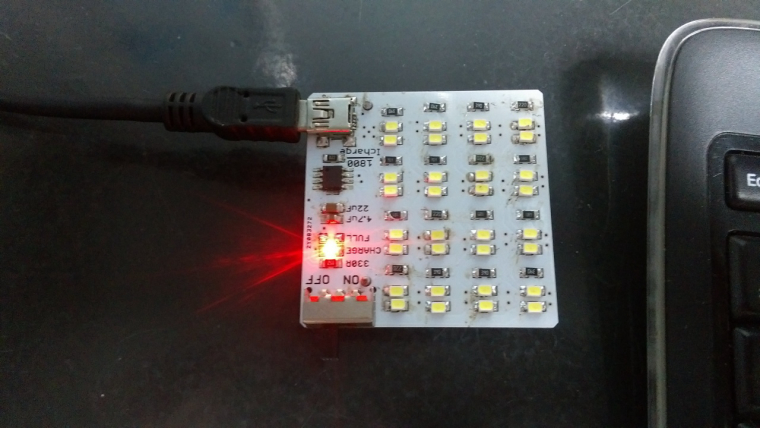

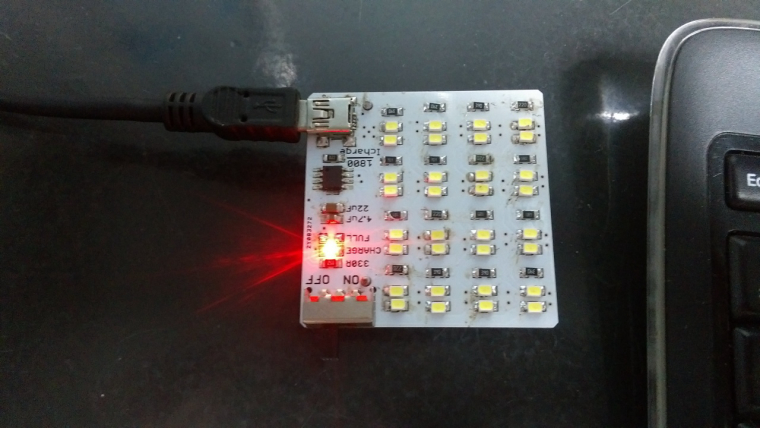

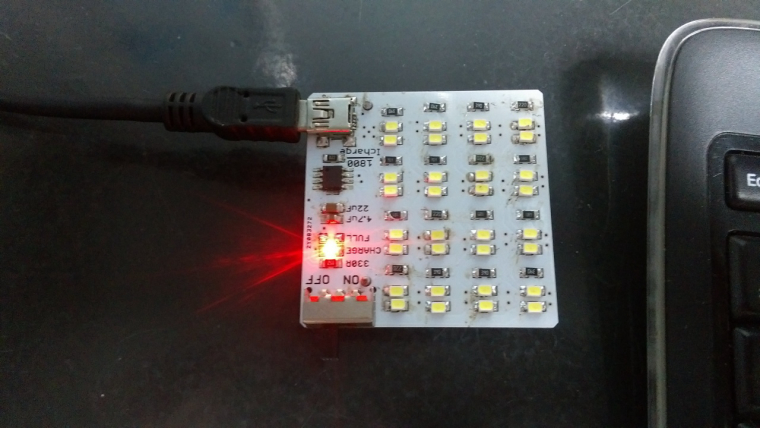

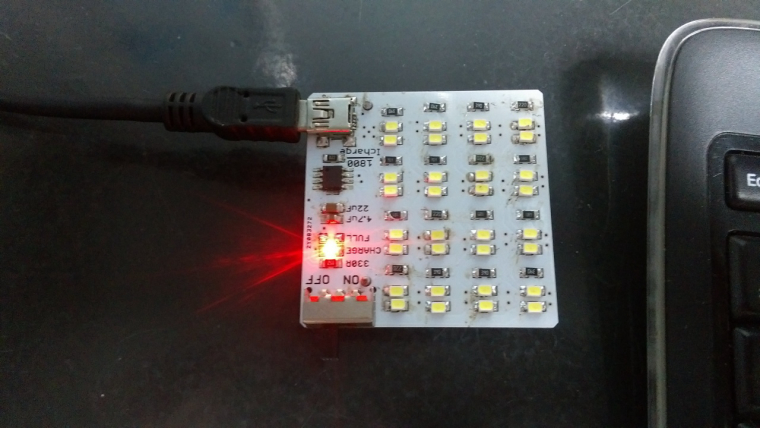

Not related to MySensors but I also assembled a first version of a battery powered led light, it's small and cheap and I will assemble a bunch to put around my home when there are some power cuts in evening/night. I'm using 3020 leds and they emit a lot of light for their small size, even with low current so I expect to get around 2 hours of battery life with the cheap aliexpress 16340 batteries, and way more than needed with the 18650 cells salvaged from my old laptop battery.

My first board with a li-ion charger and it is working well, now I'm waiting for the battery protection ics (cheap DW01 from AliExpress) to arrive as my batteries are not protected.

-

Not related to MySensors but I also assembled a first version of a battery powered led light, it's small and cheap and I will assemble a bunch to put around my home when there are some power cuts in evening/night. I'm using 3020 leds and they emit a lot of light for their small size, even with low current so I expect to get around 2 hours of battery life with the cheap aliexpress 16340 batteries, and way more than needed with the 18650 cells salvaged from my old laptop battery.

My first board with a li-ion charger and it is working well, now I'm waiting for the battery protection ics (cheap DW01 from AliExpress) to arrive as my batteries are not protected.

-

@neverdie said in What did you build today (Pictures) ?:

@nca78 Which 3020's did you get?

Cheap ones from AliExpress, not disappointed especially for the low price. I'll see in the long run how they behave.

https://www.aliexpress.com/item/100pcs-Light-LED-3020-Warm-White-SMD-Diode/32325994533.html -

Not related to MySensors but I also assembled a first version of a battery powered led light, it's small and cheap and I will assemble a bunch to put around my home when there are some power cuts in evening/night. I'm using 3020 leds and they emit a lot of light for their small size, even with low current so I expect to get around 2 hours of battery life with the cheap aliexpress 16340 batteries, and way more than needed with the 18650 cells salvaged from my old laptop battery.

My first board with a li-ion charger and it is working well, now I'm waiting for the battery protection ics (cheap DW01 from AliExpress) to arrive as my batteries are not protected.

-

Not related to MySensors but I also assembled a first version of a battery powered led light, it's small and cheap and I will assemble a bunch to put around my home when there are some power cuts in evening/night. I'm using 3020 leds and they emit a lot of light for their small size, even with low current so I expect to get around 2 hours of battery life with the cheap aliexpress 16340 batteries, and way more than needed with the 18650 cells salvaged from my old laptop battery.

My first board with a li-ion charger and it is working well, now I'm waiting for the battery protection ics (cheap DW01 from AliExpress) to arrive as my batteries are not protected.