CNC PCB milling

-

@andrew

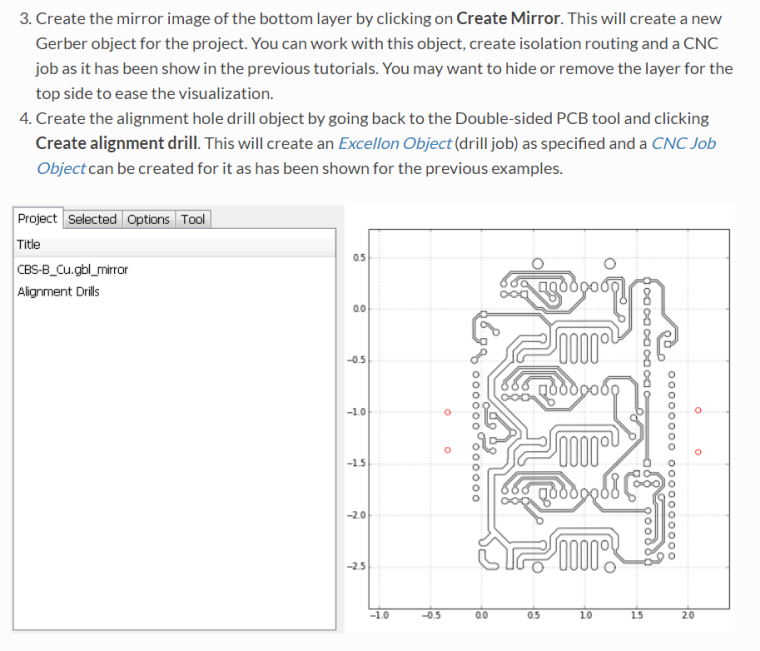

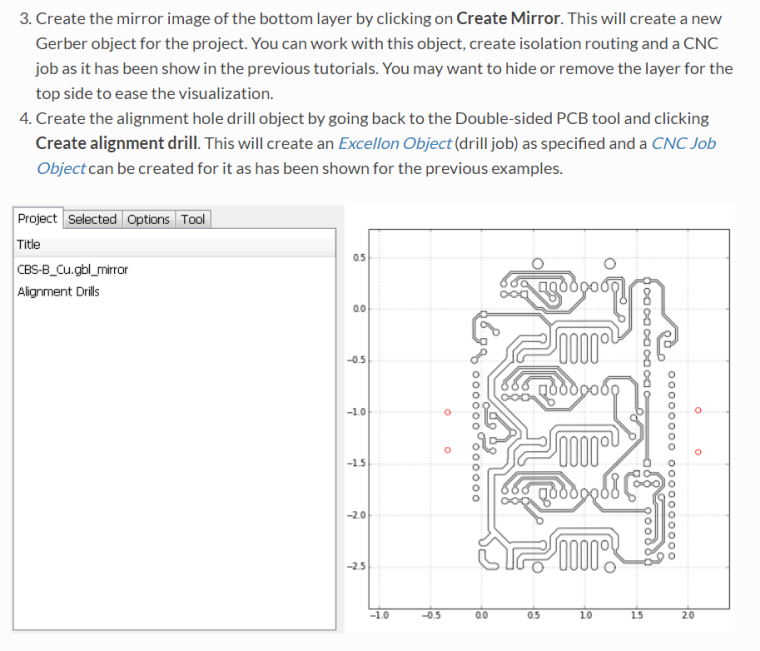

Trying to create a double sided PCB, but I am currently stuck on step 3:

I can see that it has created a mirror image which it displays, but I do not see a mirror image gerber object displayed in the project area. That's in contrast to step 4, where when I click "create alignment drill" it does create a drill file that I can see in the project area.Without access to a mirror image gerber object, there's nothing I can select to produce the gcode for the mirror image. So, I'm stuck on this step. How do I gain access to the mirror image gerber object? I've followed the given directions, but so far no joy.

-

@andrew

Trying to create a double sided PCB, but I am currently stuck on step 3:

I can see that it has created a mirror image which it displays, but I do not see a mirror image gerber object displayed in the project area. That's in contrast to step 4, where when I click "create alignment drill" it does create a drill file that I can see in the project area.Without access to a mirror image gerber object, there's nothing I can select to produce the gcode for the mirror image. So, I'm stuck on this step. How do I gain access to the mirror image gerber object? I've followed the given directions, but so far no joy.

Apparently it doesn't produce a newly named gerber object. Instead, you just work with whatever it has in memory.

-

@andrew

Trying to create a double sided PCB, but I am currently stuck on step 3:

I can see that it has created a mirror image which it displays, but I do not see a mirror image gerber object displayed in the project area. That's in contrast to step 4, where when I click "create alignment drill" it does create a drill file that I can see in the project area.Without access to a mirror image gerber object, there's nothing I can select to produce the gcode for the mirror image. So, I'm stuck on this step. How do I gain access to the mirror image gerber object? I've followed the given directions, but so far no joy.

- I ise Scotch 665 double sided tape and lately I use a heavy item connected to the ground pin when probing. Put it on the pcb and you get the pcb face grounded. The probe pin clips to the bit. I tend to probe using the same bit used for engraving.

- You select the bottom layer in flatcam. I create a bounding box around it first. Then select the box, the x axis. A few alignment drill locations on one side of the flip line. Hit create aligment drills and hit mirror object which mirrors the already loaded bottom layer (GBL) object. If you watch closely you should see the tracks are mirrored. Then select the object and go on with creating iso geometry and cnc paths.

-

- I ise Scotch 665 double sided tape and lately I use a heavy item connected to the ground pin when probing. Put it on the pcb and you get the pcb face grounded. The probe pin clips to the bit. I tend to probe using the same bit used for engraving.

- You select the bottom layer in flatcam. I create a bounding box around it first. Then select the box, the x axis. A few alignment drill locations on one side of the flip line. Hit create aligment drills and hit mirror object which mirrors the already loaded bottom layer (GBL) object. If you watch closely you should see the tracks are mirrored. Then select the object and go on with creating iso geometry and cnc paths.

@executivul said in CNC PCB milling:

You select the bottom layer in flatcam. I create a bounding box around it first. Then select the box, the x axis. A few alignment drill locations on one side of the flip line. Hit create aligment drills and hit mirror object which mirrors the already loaded bottom layer (GBL) object. If you watch closely you should see the tracks are mirrored. Then select the object and go on with creating iso geometry and cnc paths.

Yes, I think the flatcam's original instructions were faulty. It said to load both the top and bottom layer. Maybe that's fine for selecting pin alignment locations, but there should be only one layer displayed before the mirroring, or else it creates a mess.

Also, I had thought it would create a new file for the mirrored gerber, but it doesn't. Instead, I just work with the mirrored gerber that's in memory to produce the gcode for the mirrored image. I guess that's good enough.

-

I drilled the alignment holes with 0.8mm diameter. I'm using regular male header pins for the alignment, and having tried it, I think 0.8mm is really too tight. Not sure how @andrew is using 0.7mm. Different pins I guess? Anyhow, next time I'll try 0.9mm hole diameter.

-

How do I mill a slot? Do I treat it the same as a regular hole, except use a routing bit rather than a drill bit when it comes time to cut the slot?

-

How do I mill a slot? Do I treat it the same as a regular hole, except use a routing bit rather than a drill bit when it comes time to cut the slot?

@neverdie said in CNC PCB milling:

How do I mill a slot? Do I treat it the same as a regular hole, except use a routing bit rather than a drill bit when it comes time to cut the slot?

Couldn't find a good answer to this, so I'm going to approximate it by simply drilling a series of overlapping holes.

It's needed for the micro-usb connector.

-

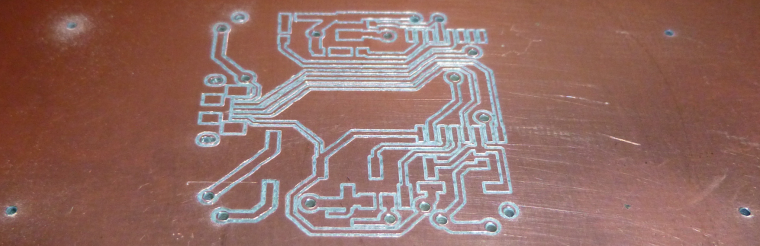

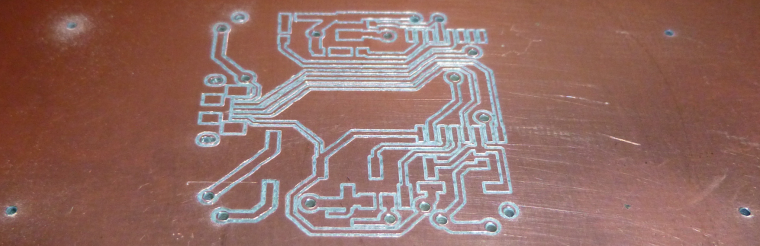

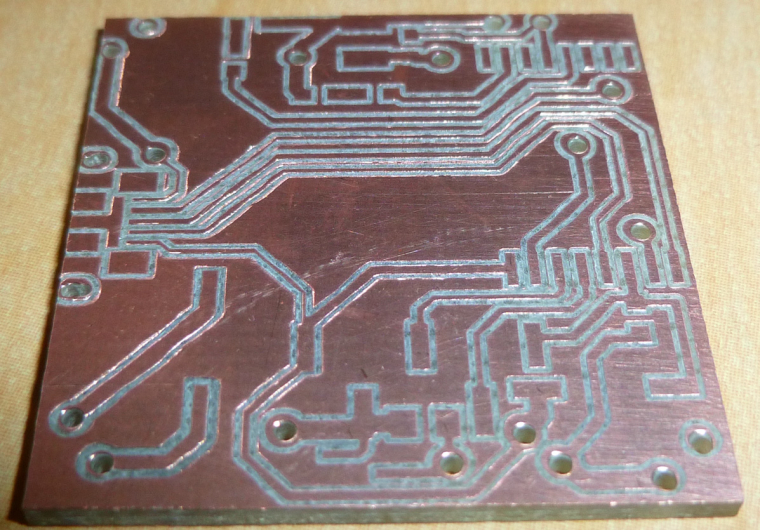

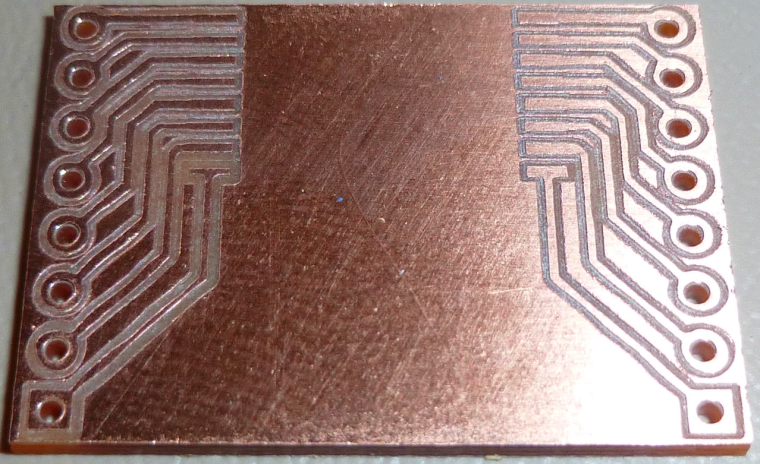

I did the top layer, together with alignment holes, for a real FR4 PCB:

As an experiment, I thought I would standardize on 0.9mm holes for the through-holes, via-holes, and alignment holes, so that there would be fewer tool changes. Looks like it will work, but, meh, I think I'll use smaller via holes in the future.Out of time for today, so I plan to etch the flip side tomorrow.

-

I did the top layer, together with alignment holes, for a real FR4 PCB:

As an experiment, I thought I would standardize on 0.9mm holes for the through-holes, via-holes, and alignment holes, so that there would be fewer tool changes. Looks like it will work, but, meh, I think I'll use smaller via holes in the future.Out of time for today, so I plan to etch the flip side tomorrow.

@neverdie 0.4-0.5mm for vias using 0.3mm silver plated "wrapping wire". 0.9 for TH and alignment holes.

Tomorrow redo the alignment holes on the sacrificial layer so you get perfect alignment (if you don't have homing endstops, as I don't) and put the pins in and sick the pcb after that, be careful how you flip the board, I tend to use asymmetric alignment holes so I can only flip it one way (; -

Argh, it just occurred to me that I was premature in drilling the TH and via holes, because they may seriously interfere with the autoleveling when I etch the reverse side. This must be why @andrew etches the mirrored bottom side first, so that when it's flipped the top side can be etched and then drilled.

-

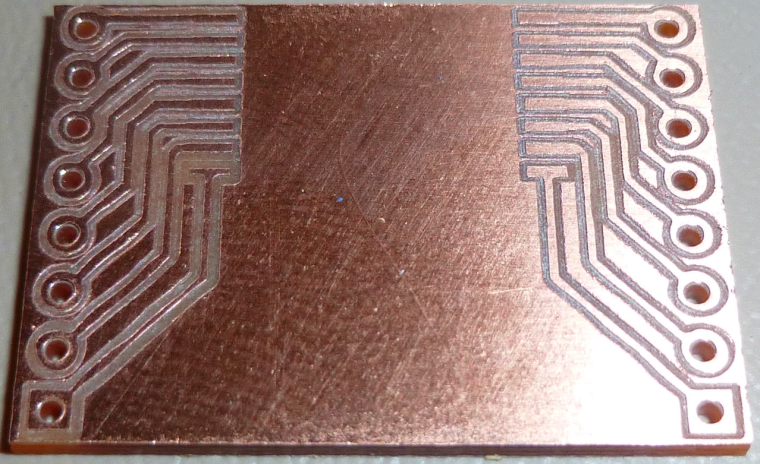

Re-using the alignment holes already drilled, I flipped over the PCB and etched the mirrored bottom. It worked! Some of the traces are only as thick as a hair, but they all conduct and none are broken.

I guess I'll have to flip it again in order to route the board outline. So, count that as yet another reason to start by etching the bottom first.

I had to autolevel at 6mm in order to dodge all the holes I had prematurely drilled, so perhaps that's why this particular etching came out so uneven. -

Re-using the alignment holes already drilled, I flipped over the PCB and etched the mirrored bottom. It worked! Some of the traces are only as thick as a hair, but they all conduct and none are broken.

I guess I'll have to flip it again in order to route the board outline. So, count that as yet another reason to start by etching the bottom first.

I had to autolevel at 6mm in order to dodge all the holes I had prematurely drilled, so perhaps that's why this particular etching came out so uneven.@neverdie the order of the process should be the following:

- drilling the alignment holes (through the PCB into the sacrificial layer)

- fixing the pcb with the alignment pins/headers

- isolation routing on the bottom layer

- flipping the pcb

- isolation routing on the top layer

- drilling holes on the top layer

- milling the pcb outline on the top layer

as I see your results, you could use alignment holes closer to your actual design's border, but it should be definitely out of the pcb's edge + milling tool width area.

the very thin traces are most probably caused by:

- moving and not stable pcb

- improperly calculated tool width

- improper autoleveling on the given side

-

How do I mill a slot? Do I treat it the same as a regular hole, except use a routing bit rather than a drill bit when it comes time to cut the slot?

@neverdie said in CNC PCB milling:

How do I mill a slot? Do I treat it the same as a regular hole, except use a routing bit rather than a drill bit when it comes time to cut the slot?

you can mill holes, which are bigger than your drill bits, you can find a milling section in flat cam when you are working with the drill file.

you can mill slots as well, for this the slot has to be designed properly in the PCB designer software. you have to draw closed shapes on e.g. the edge cuts layer, then basically you have to follow the same approach in flatcam that is used to create the edge milling cnc job, but instead of the edge lines, you have to select the slots.

if you design it that way, then you can do both the slot and edge milling at once. -

I drilled the alignment holes with 0.8mm diameter. I'm using regular male header pins for the alignment, and having tried it, I think 0.8mm is really too tight. Not sure how @andrew is using 0.7mm. Different pins I guess? Anyhow, next time I'll try 0.9mm hole diameter.

@neverdie said in CNC PCB milling:

I drilled the alignment holes with 0.8mm diameter. I'm using regular male header pins for the alignment, and having tried it, I think 0.8mm is really too tight. Not sure how @andrew is using 0.7mm. Different pins I guess? Anyhow, next time I'll try 0.9mm hole diameter.

maybe my pins also have different factors, but indeed, the given holes are pretty tight. this helps to prevent unnecessary pcb movements, which is very important if you work with 6mil traces/isolation, as a small unwanted movement could result in wasted pcb. if you work with bigger traces/clearings then it is not as important.

I would recommend to stick to one size which is good for your selected pins and which does not let the pcb to move.

-

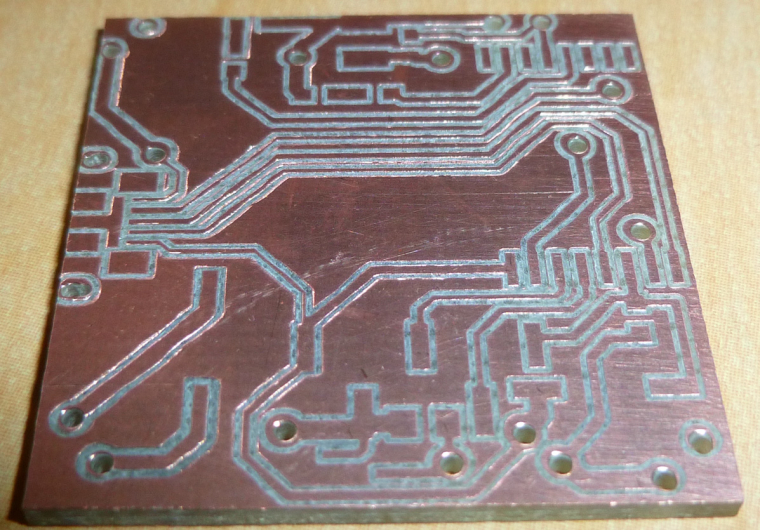

Here's the final product:

Three of the vias are located under an SMD module, so I'll just have to try to minimize any solder bumps over them. -

Here's the final product:

Three of the vias are located under an SMD module, so I'll just have to try to minimize any solder bumps over them.Unfortunately, even a tiny solder bump prevents the module from being soldered. I would have to redesign this so that the vias are not under the module.

-

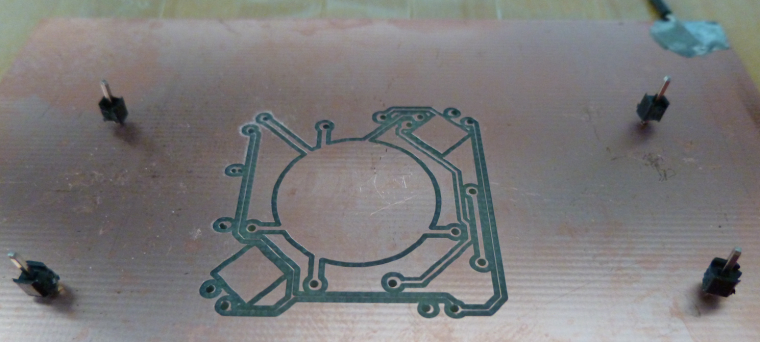

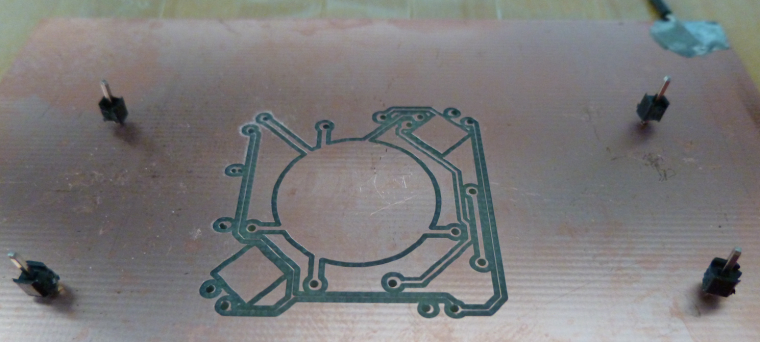

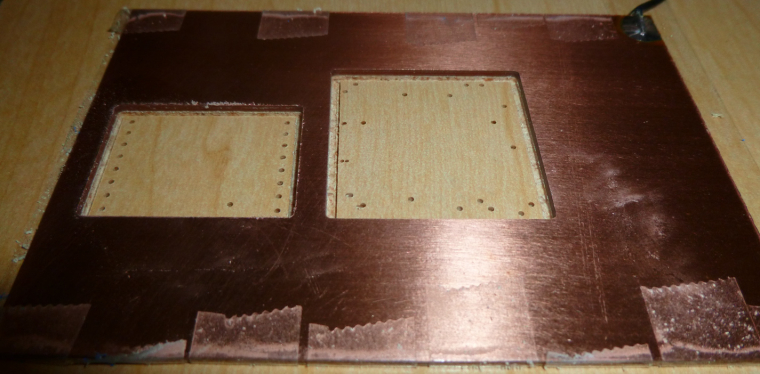

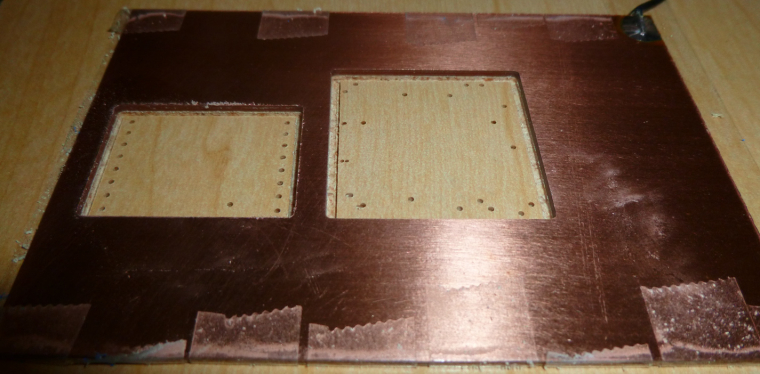

Another good thing for people to know is that you can leave a single-sided blank PCB installed in the CNC and then, as the need arises, cut out additional modules from it:

For instance, this morning I cut this module carrier out of the above, already used, copper clad PCB:

So, for simple small things, it's a handy arrangement, and the incremental cost is negligible.

-

Another good thing for people to know is that you can leave a single-sided blank PCB installed in the CNC and then, as the need arises, cut out additional modules from it:

For instance, this morning I cut this module carrier out of the above, already used, copper clad PCB:

So, for simple small things, it's a handy arrangement, and the incremental cost is negligible.

@neverdie Perhaps a clearer explanation ?

-

One problem I've run into though is that the foil traces can sometimes lift up in the course of ordinary soldering. For instance, the traces connecting the second to the right pin on the Fanstel module seems to have utterly disappeared, leaving that pin unconnected:

Maybe it's the quality of the blank PCB? I just don't know.