CNC PCB milling

-

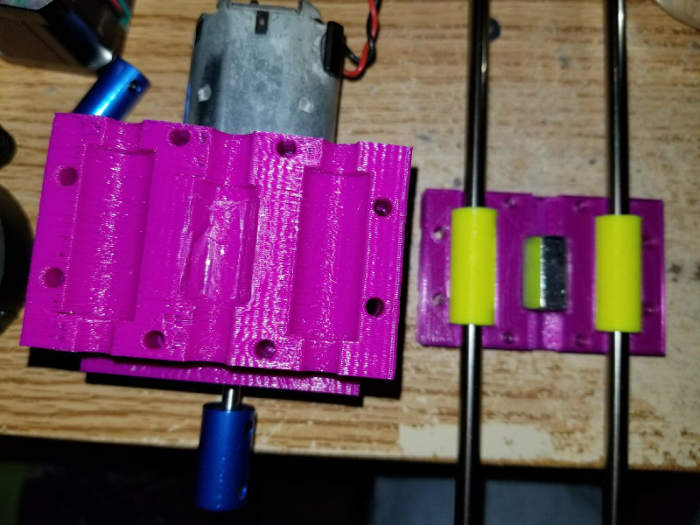

@neverdie FOr starters I am trying 3D printed rod bearings. I';ll see how that goes. The beauty of designing this myself is that I can alter the design whenever I want.

@dbemowsk said in CNC PCB milling:

I am trying 3D printed rod bearings

What are those? Is it like this?

or this?

-

@dbemowsk said in CNC PCB milling:

I am trying 3D printed rod bearings

What are those? Is it like this?

or this?

-

@neverdie I just printed them in PLA and they seem to slide pretty smoothly on the rods, but someone told me that printing them in nylon is better.

@dbemowsk said in CNC PCB milling:

printing them in nylon is better.

It would seem so: http://www.craftechind.com/top-5-materials-for-plastic-bearings-used-on-metal-surfaces/

If you had a multi-filament printer, I wonder if you could print the nylon bearing within another plastic piece (e.g. the part that holds the spindle to the z-axis)? That would would be pretty cool and would also save assembly time.

-

@dbemowsk said in CNC PCB milling:

printing them in nylon is better.

It would seem so: http://www.craftechind.com/top-5-materials-for-plastic-bearings-used-on-metal-surfaces/

If you had a multi-filament printer, I wonder if you could print the nylon bearing within another plastic piece (e.g. the part that holds the spindle to the z-axis)? That would would be pretty cool and would also save assembly time.

-

Anyone tried Trinamic drivers, such as the TMC2130? They seem to produce superior 3D prints, and so I would guess they would yield some improvement for CNC as well.

So far I've only found two boards that appear to be made for them, a ramps and a rumba:

https://www.aliexpress.com/item/MKS-Gen-V1-4-control-board-5PCS-TMC2130-V1-0-And-Heatsink-stepper-motor-compatible-with/32836389832.html?spm=2114.search0204.3.2.3e5a8105IWdaWH&ws_ab_test=searchweb0_0,searchweb201602_5_10152_5711320_10151_10065_10344_10068_10130_10324_10342_10547_10325_10343_10546_10340_10548_10341_10545_10084_10083_10618_10630_10307_5711220_5722320_10313_10059_10534_100031_10103_10627_10626_10624_10623_10622_10621_10620_10142,searchweb201603_2,ppcSwitch_5_ppcChannel&algo_expid=875aa997-05fe-4eda-9d76-0aaefcaeff83-0&algo_pvid=875aa997-05fe-4eda-9d76-0aaefcaeff83&priceBeautifyAB=0I have no experience with either board, so I don't know if either would be desirable.

The pinout of the TMC2130 is different than the A4988 driver currently used in my Woodpecker. However, I could perhaps make an adapter board to re-route the pins so as to be compatible. In that case, maybe I could plug them into my Woodpecker board. A video by Sanladerer seems to imply that might actually work:

https://www.youtube.com/watch?v=sPvTB3irCxQNote: from what I've read, the v1.1 TMC2130 modules are much better for adapting than the v1.0 modules.

-

I'm unsure what kind of firmware runs on the Woodpecker board, so I have doubts whether it could exploit the Trinamic features. Anyone here know?

So.... I'm looking at a Smoothieboard as perhaps one possibility, although I'm not sure yet as to whether Chillipepr will talkto it.

https://www.panucatt.com/azteeg_X5_mini_reprap_3d_printer_controller_p/ax5mini.htm

-

I'm unsure what kind of firmware runs on the Woodpecker board, so I have doubts whether it could exploit the Trinamic features. Anyone here know?

So.... I'm looking at a Smoothieboard as perhaps one possibility, although I'm not sure yet as to whether Chillipepr will talkto it.

https://www.panucatt.com/azteeg_X5_mini_reprap_3d_printer_controller_p/ax5mini.htm

Are you looking at this for a 3D printer or for your CNC? If you are looking at it for a 3D printer, have you looked at the RAMPS 1.4 boards? I like their modular design over a fully integrated board for the simple fact that if a part dies, you are only replacing the one part and not an entire board. This make repairs cheaper if something goes wrong.

-

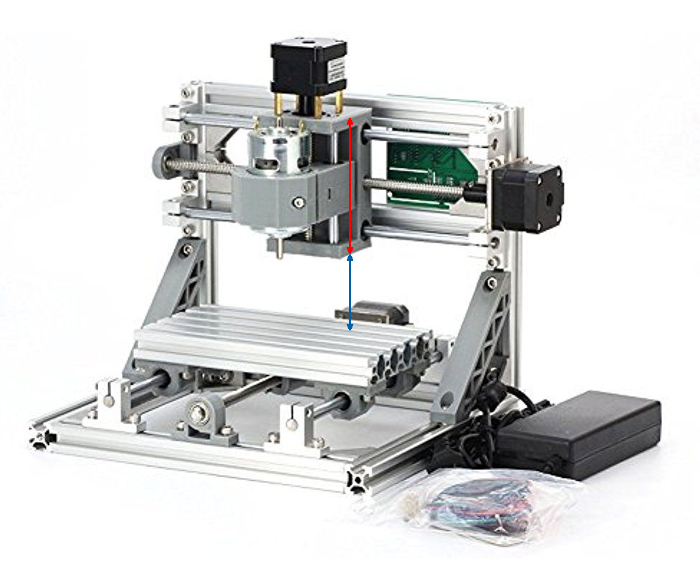

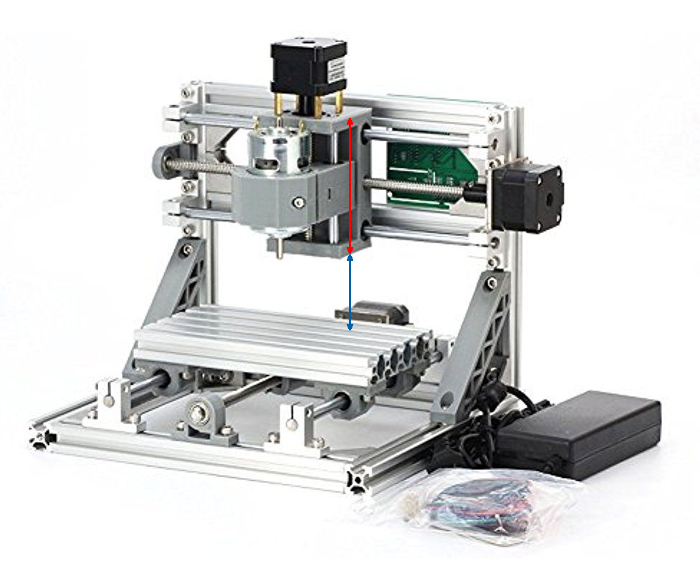

@NeverDie I have one more question of measurements on your CNC. If you look at the pic, can you tell me the measurements of the red and blue arrows on your machine? I have some idea of how tall I want my bracket for the red arrow area, but you were mentioning that you wish you had more travel in that area and I am curious if I have enough room.

-

@NeverDie I have one more question of measurements on your CNC. If you look at the pic, can you tell me the measurements of the red and blue arrows on your machine? I have some idea of how tall I want my bracket for the red arrow area, but you were mentioning that you wish you had more travel in that area and I am curious if I have enough room.

-

Perhaps slightly off topic but I wanted to share very interesting youtube channel of FRANK from Germany link text who's been working on a PCB pick and place module along with a CNC tool changer in the video above.

Very inginious, and clever work if you've not come accross his videos and work yet.!

-

Perhaps slightly off topic but I wanted to share very interesting youtube channel of FRANK from Germany link text who's been working on a PCB pick and place module along with a CNC tool changer in the video above.

Very inginious, and clever work if you've not come accross his videos and work yet.!

@rfm69 said in CNC PCB milling:

PCB pick and place module along with a CNC tool changer in the video above.

Imho, it's certainly a fun project.. but I think you can go faster by hand ;)

Only a thousands more expensive machine will be faster for assembling, and they are more precise, have a lot more features (cam driven features, more feeders etc.).Pick And Place is not plug and play at all :) there is lot of calibration, preparation. So it's useful and save time, only if you plan volume production. This is why there is often fees when you ask for a pcba, they spend time for calibrating each new board, parts in database etc.

There are multiple different diy pnp, most of them are slow, not enough precise for <0402 etc..

If it's for 0603 size with some dfn, low volume, you don't need this kind of investments I think.. but if you want to tinker it's fun I imagine.For example, if I remember well, someone said he can assemble an easypcb in 30mn, trhough hole. Good but that's the time I need to get assembled&soldered one of my compact smd multisensors boards, no PNP, no handsoldering..

PNP is just for placing, it won't fix test, soldering shorts etc, that still need some agility :)No need of a solder paster dispenser, I use stencils. I like freedom for placing parts, but you can also build a simple manual pick&place in case you shake when placing (no shaking here). With a good magnifier, easy! (I have a big one like dentists, + another one with a cam). Finally, the reflow oven cook it. When I need a repair/reflow -> flux + hot air or fine solder tip. Well organized, you're faster like that. Not the same, if you want to assemble 50 boards, agreed.

So, I've no real xp on PNP, but I'm not new at assembling smd boards. Saying this because I already digged in forums, diy builds, reviews, as I need to invest in a cnc router, and PNP this year. and I'm lucky I can talk with local professionals.. I always "try" to get a good ratio between the need/time/ROI . I'll build the cnc router, but I'll buy the PNP. there are a few interesting but it's still a few thousands dollars.

-

Perhaps slightly off topic but I wanted to share very interesting youtube channel of FRANK from Germany link text who's been working on a PCB pick and place module along with a CNC tool changer in the video above.

Very inginious, and clever work if you've not come accross his videos and work yet.!

@rfm69 Thanks! I've already learned something potentially very useful: instead of doing his etching with an etching bit, he uses a V spiral endmill 30 degrees. Unfortunately, he didn't say the diameter. :(

Interestingly, he didn't even bother with autoleveling.

-

Perhaps slightly off topic but I wanted to share very interesting youtube channel of FRANK from Germany link text who's been working on a PCB pick and place module along with a CNC tool changer in the video above.

Very inginious, and clever work if you've not come accross his videos and work yet.!

-

@rfm69 Thanks! I've already learned something potentially very useful: instead of doing his etching with an etching bit, he uses a V spiral endmill 30 degrees. Unfortunately, he didn't say the diameter. :(

Interestingly, he didn't even bother with autoleveling.

-

@neverdie said in CNC PCB milling:

Interestingly, he didn't even bother with autoleveling

Are you sure? What's happening from 3:25 then?

@yveaux said in CNC PCB milling:

@neverdie said in CNC PCB milling:

Interestingly, he didn't even bother with autoleveling

Are you sure? What's happening from 3:25 then?

You're right. I guess he edited most of it out, or else he did just a partial.

-

Looks as though StepCraft makes a tool changer that you can buy:

https://youtu.be/pCMdPF39Uts -

@rfm69 said in CNC PCB milling:

PCB pick and place module along with a CNC tool changer in the video above.

Imho, it's certainly a fun project.. but I think you can go faster by hand ;)

Only a thousands more expensive machine will be faster for assembling, and they are more precise, have a lot more features (cam driven features, more feeders etc.).Pick And Place is not plug and play at all :) there is lot of calibration, preparation. So it's useful and save time, only if you plan volume production. This is why there is often fees when you ask for a pcba, they spend time for calibrating each new board, parts in database etc.

There are multiple different diy pnp, most of them are slow, not enough precise for <0402 etc..

If it's for 0603 size with some dfn, low volume, you don't need this kind of investments I think.. but if you want to tinker it's fun I imagine.For example, if I remember well, someone said he can assemble an easypcb in 30mn, trhough hole. Good but that's the time I need to get assembled&soldered one of my compact smd multisensors boards, no PNP, no handsoldering..

PNP is just for placing, it won't fix test, soldering shorts etc, that still need some agility :)No need of a solder paster dispenser, I use stencils. I like freedom for placing parts, but you can also build a simple manual pick&place in case you shake when placing (no shaking here). With a good magnifier, easy! (I have a big one like dentists, + another one with a cam). Finally, the reflow oven cook it. When I need a repair/reflow -> flux + hot air or fine solder tip. Well organized, you're faster like that. Not the same, if you want to assemble 50 boards, agreed.

So, I've no real xp on PNP, but I'm not new at assembling smd boards. Saying this because I already digged in forums, diy builds, reviews, as I need to invest in a cnc router, and PNP this year. and I'm lucky I can talk with local professionals.. I always "try" to get a good ratio between the need/time/ROI . I'll build the cnc router, but I'll buy the PNP. there are a few interesting but it's still a few thousands dollars.

@scalz Agreed... the P&P is beyond my knowledge level, but what I found fascinating in what and how he was doing the project to make something himself, how he evolved the project was very interesting.

He's got something similar for a tool changer on a 3d printer which is very nicely designed... along with the software and controllers.

mine are similar 3D printed ones

mine are similar 3D printed ones