CNC PCB milling

-

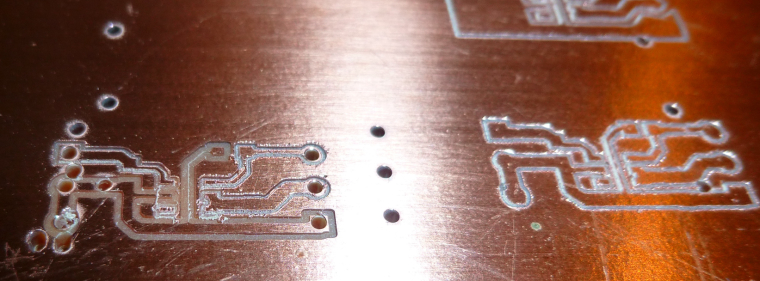

So, I tried a couple more wild guesses, and the last guess was a match. It turns out that the scaling is off by a factor of 10x:

I have no idea why the scaling is in error, but at least now I have an antidote. :)

-

@neverdie why do you use any scaling factor at all? be sure you export the grbl files with proper metrics, then apply the given metrics settings in flatcam (it has global and project specific settings as well), then no scaling is necessary.

@andrew said in CNC PCB milling:

@neverdie why do you use any scaling factor at all? be sure you export the grbl files with proper metrics, then apply the given metrics settings in flatcam (it has global and project specific settings as well), then no scaling is necessary.

I'm using Diptrace. I export from Diptrace an "N/C Drill" file. Then, when in flatcam, I open it as an Excellon file. Perhaps an "N/C Drill" file is not 100% compatible with an Excellon file opened from within flatcam? Perhaps there is some other way?

-

@neverdie why do you use any scaling factor at all? be sure you export the grbl files with proper metrics, then apply the given metrics settings in flatcam (it has global and project specific settings as well), then no scaling is necessary.

@andrew said in CNC PCB milling:

@neverdie why do you use any scaling factor at all? be sure you export the grbl files with proper metrics, then apply the given metrics settings in flatcam (it has global and project specific settings as well), then no scaling is necessary.

It turns out to be a known issue for users of both diptrace and flatcam:: https://muut.com/i/flatcam/usage:diptrace-drill-file-off-sca

-

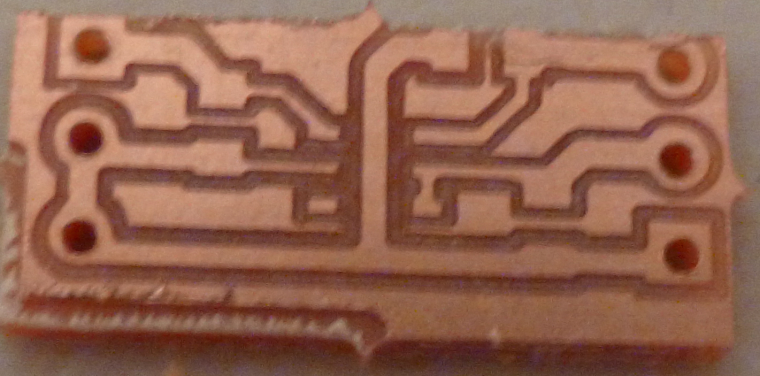

Here's my first milled PCB that's standalone:

-

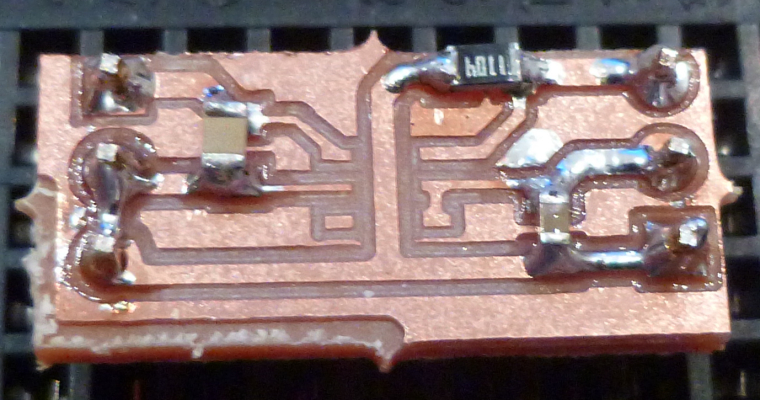

I soldered on three 0805 components, but afterward I was surprised to find that all three were shorted (tested using a cotinuity meter):

I thought I had been reasonably careful soldering them on too, so I'm not sure what went wrong.Scratch that. I found that the faults were measurement error. Re-testing it, it checks out 100%. No shorts. :)

-

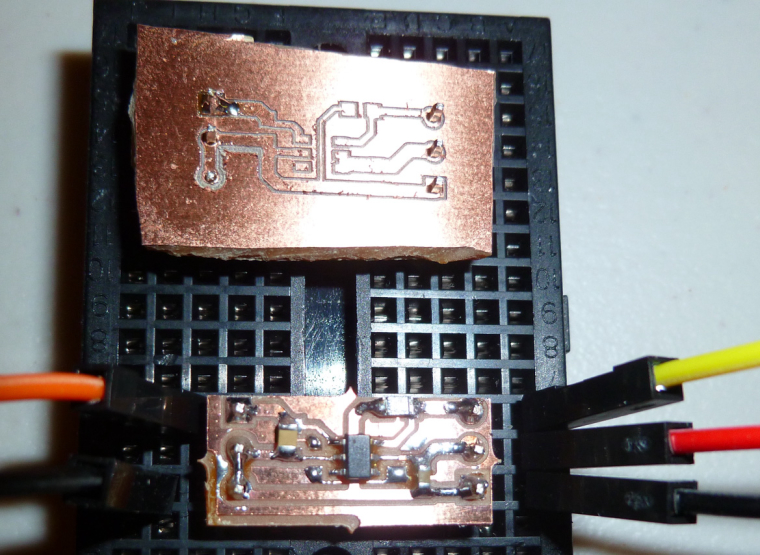

This morning I soldered on the load switch IC. I then tested the circuit, and voilà, it works. :)

Fortunately, solder doesn't seem attracted to the PCB substrate, and it behaves like solder mask. :)By the way, the PCB above it I cut out with tin snips, which is very fast and avoids all the dust generated if using the CNC to route the board outline to release it from the copper clad blank. The result looks crude, but that doesn't matter if it's just for prototyping.

-

@executivul I noticed this youtube video, where they use mineral oil for dust containment:

https://www.youtube.com/watch?v=d9kfzRycQzEHave you tried that?

-

@executivul I noticed this youtube video, where they use mineral oil for dust containment:

https://www.youtube.com/watch?v=d9kfzRycQzEHave you tried that?

@neverdie no, I haven't. I don't have the oil and I don't want to mess with anything non water soluble. To much hassle to clean the machine afterwards in case of splashing.

-

I think if I could upgrade the z-axis to use a ball-screw, I would do that, because I notice a lot of variability in cutting depth from one CNC session to the next. However, I don't see an easy way to upgrade this machine to use a ball screw.

So... alternative might be to add a linear motion tracker to the z-axis. Unlike a rotary encoder, it wouldn't be fooled by backlash. The question then, though, would be: which software to use? I don't know that chilipeppr can take advantage of the closed loop feedback.

-

So, notionially, the height measurement might look like:

https://www.amazon.com/Woodhaven-6015-Digital-Readout-6000-6004/dp/B004BUGW8E/ref=sr_1_16?ie=UTF8&qid=1514743618&sr=8-16&keywords=digital+height+router

but preferably with some kind of known digital interface for reading the height, so it doesn't have to be reverse engineered just to extract that basic information. -

Something like this would probably do the business:

https://www.aliexpress.com/item/High-accuracy-Linear-Scale-5micron-linear-encoder-with-linear-sensor/32827867788.html?spm=2114.10010108.1000013.2.217d28ff67mKcv&traffic_analysisId=recommend_2088_1_90158_iswistore&scm=1007.13339.90158.0&pvid=986e2ba2-43bc-4db4-8edd-f9ca9d1f9b6e&tpp=1It can resolve to 0.001mm.

-

On the other hand, retrofitting with just a ballscrew for the z-axis might be the cheapest/easiest next step:

https://www.aliexpress.com/item/1204-Ball-Screw-SFU1204-L-150mm-Rolled-Ballscrew-with-single-Ballnut-for-CNC-parts-RM1204-without/1998914494.html?spm=2114.search0104.3.138.DFiNws&ws_ab_test=searchweb0_0,searchweb201602_4_10152_10065_10151_10344_10068_5000016_10130_10324_10342_10547_10325_10343_51102_10546_10340_5060016_10341_10548_10545_5130016_10084_10083_10307_5920011_10312_10059_10313_10314_10534_5790011_100031_10604_10103_10594_10142,searchweb201603_25,ppcSwitch_4&algo_expid=e7be0642-ef8c-4a19-ac8b-5c19f850ec57-21&algo_pvid=e7be0642-ef8c-4a19-ac8b-5c19f850ec57&rmStoreLevelAB=5Opinions, anyone? Also, what would be the best ballscrew to get?

Then, if that's still insufficient, adding a more powerful stepper motor would be next I suppose, to avoid skipping steps (assuming that's part of what's happening).

-

No offence but upgrading with dro, ballscrew, stronger stepper, beefier driver, you end up with more cost than buying a real cnc platform like 3020 or 3040 😁

That machine has great results for its price, maybe relaxing tolerances a bit in design and using larger bits would achieve better predictibility.

Happy new year! Happy new toys! -

Not sure why I'd have to buy a bigger machine in order to get quality parts, yet it is true that none of the 2418 kits appear to come with ballscrews. Strange how that is. In terms of just size alone, though, the 2418 seems about right for etching hobbyist circuit boards. If anything, it could be a little smaller. Does the sheer mass of the bigger machines somehow help with accuracy (maybe less vibration for instance)?

The ballscrews themselves, and even the linear scales, don't seem all that expensive, which is why I thought maybe upgrading even just the z-axis might make sense.

If nothing else, replacing the stepper motor with either a larger stepper motor (less skipping) or some kind of servo equivalent might at least put a cap on how far off the z-axis is from what is assumed. In that case, I would think the maximum error would less than or equal to the maximum possible backlash.

Anyhow, any suggestions appreciated.

-

I'll need an adapter plate to go from Nema 17 to Nema 23. Will the existing motor drivers be able to handle a Nema 23?

-

Well, maybe the simplest upgrade would be to upgrade to a higher torque nema 17 motor, such as:

https://www.aliexpress.com/item/Nema17-stepper-motor-60mm-length-1-7A-0-73Nm-7-3kg-cm-104Oz-in-High-torque/32727142878.html?spm=2114.search0104.3.1.RoU5IE&ws_ab_test=searchweb0_0,searchweb201602_2_10152_10065_5000015_10151_10344_10068_10130_10324_10342_10547_10325_10343_51102_10546_10340_10548_10341_10545_5130015_10084_10083_10307_5920012_10312_10059_10313_10314_10534_5790011_100031_10604_10103_10594_5060015_10142,searchweb201603_2,ppcSwitch_5&algo_expid=31255370-90b4-4695-94c0-997d9d68e388-0&algo_pvid=31255370-90b4-4695-94c0-997d9d68e388&rmStoreLevelAB=5or

or perhaps even

Not sure what kind of impact it might have on the feedrate....

The idea is that the higher torque would eliminate missed steps, provided that the feedrate is low enough.

-

Well, maybe the simplest upgrade would be to upgrade to a higher torque nema 17 motor, such as:

https://www.aliexpress.com/item/Nema17-stepper-motor-60mm-length-1-7A-0-73Nm-7-3kg-cm-104Oz-in-High-torque/32727142878.html?spm=2114.search0104.3.1.RoU5IE&ws_ab_test=searchweb0_0,searchweb201602_2_10152_10065_5000015_10151_10344_10068_10130_10324_10342_10547_10325_10343_51102_10546_10340_10548_10341_10545_5130015_10084_10083_10307_5920012_10312_10059_10313_10314_10534_5790011_100031_10604_10103_10594_5060015_10142,searchweb201603_2,ppcSwitch_5&algo_expid=31255370-90b4-4695-94c0-997d9d68e388-0&algo_pvid=31255370-90b4-4695-94c0-997d9d68e388&rmStoreLevelAB=5or

or perhaps even

Not sure what kind of impact it might have on the feedrate....

The idea is that the higher torque would eliminate missed steps, provided that the feedrate is low enough.

-

@neverdie

I think you should start by altering the acceleration/Max velocity settings etc in grbl.

Slow them down a little:grinning:@rmtucker said in CNC PCB milling:

I think you should start by altering the acceleration/Max velocity settings etc in grbl.

I don't see those parameters exposed in flatcam or in chilipeppr either. I guess I have to set them by issuing the grbl commands manually?

-

@rmtucker said in CNC PCB milling:

I think you should start by altering the acceleration/Max velocity settings etc in grbl.

I don't see those parameters exposed in flatcam or in chilipeppr either. I guess I have to set them by issuing the grbl commands manually?