Best CNC for milling/routing wood?

-

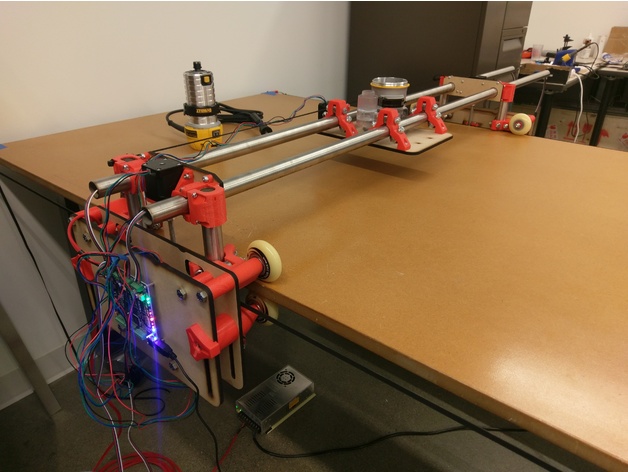

@rfm69 Is this it?

Hmmm. That does look clever. I suppose one could scale it to use whatever bigger/stronger pipe might be needed to make it rigid enough. Pipe/tubing is usually plenty cheap, so I guess it might even be affordable.

If needed, you could maybe even replace the plastic joinery with Kee Klamps or similar: https://www.simplifiedbuilding.com/pipe-fittings/kee-klamp

When will you be done making yours? I'd love to hear how well you like it.

@neverdie Yes thats the one... I'm got it working but am waiting a few things by post to be able to connect the 3d printer. And then I need still to order a new spindle.

There are some modifications people have made on thingyverse to strenghten the Z access to take heavier spindles... you can redesign the connecting corners and just print them out.

I'd like to get a 1.5kw spindle, but might just get a small one to begin with.

-

I bet that diameter of unsupported tube would be a fail, based on what we saw in the earlier videos.

However, if you were to fill those flimsy tubes with self-leveling mortar/concrete, maybe even with a piece of re-bar running down the center of it, I bet they'd become a lot more rigid.... Maybe then you could keep the same size.

Also, would box tubing be more rigid? Seems like the same design idea could be adapted to that. I can imagine that a box geometry might even stabilize the spindle more (keep it from going ring-around-the-rosie like maybe it would on a circular tube).

-

@rfm69 Is this it?

Hmmm. That does look clever. I suppose one could scale it to use whatever bigger/stronger pipe might be needed to make it rigid enough. Pipe/tubing is usually plenty cheap, so I guess it might even be affordable.

If needed, you could maybe even replace the plastic joinery with Kee Klamps or similar: https://www.simplifiedbuilding.com/pipe-fittings/kee-klamp

When will you be done making yours? I'd love to hear how well you like it.

-

@neverdie They've already answered the concrete idea, many people consider that, but a simple center support I think solves the problem. They have nice forums over at the vicious.com link I shared.

-

@rfm69 said in Best CNC for milling/routing wood?:

@neverdie The same web site has a few other designs for larger machines.

Hmm.. That Low Rider MPCNC does looks interesting. They're using just two stainless steel tubes for that. Should be relatively cheap to make, and it can handle large formats. :)

!

-

@rfm69

Ah, OK, that makes sense for the side supports:

The rods that move, though, remain unsupported, especially in the middle. What about those?@neverdie Generally I get the feeling from reading other peoples experience that its a mistake to quickly make the machine too big because of rigidity. But people do make mods to address this issue or to add heavier spindles.

Heres one mod i/d like to do link text

But to change the size just need to get new pipes which even if you use SS they are they cheapest part.

-

same here, a while I'm looking at the MPCNC. It's a nice and affordable project when you want to build a cnc.

Unfortunately never jumped into, because I have different requirements, need something more "powerful" for my job, not only for wood or thin sheets.

I don't think it's comparable with the others machine above (strength, speed, raw material that can be machined..). But if you don't need so much power, it might be pretty cool, you can make lot of things with it :) -

same here, a while I'm looking at the MPCNC. It's a nice and affordable project when you want to build a cnc.

Unfortunately never jumped into, because I have different requirements, need something more "powerful" for my job, not only for wood or thin sheets.

I don't think it's comparable with the others machine above (strength, speed, raw material that can be machined..). But if you don't need so much power, it might be pretty cool, you can make lot of things with it :) -

same here, a while I'm looking at the MPCNC. It's a nice and affordable project when you want to build a cnc.

Unfortunately never jumped into, because I have different requirements, need something more "powerful" for my job, not only for wood or thin sheets.

I don't think it's comparable with the others machine above (strength, speed, raw material that can be machined..). But if you don't need so much power, it might be pretty cool, you can make lot of things with it :) -

@neverdie

no, I haven't yet. still studying :) because i'll built mine, custom I think (inspired from multiple builds), for my job I need stronger than mpcnc (so far asking local subcontractor when I need it).if it would be for personal use, low cost, for soft materials, no speed concern, maybe I would pick the MPCNC as I already have a 3dprinter for printing parts (I think i've maybe just a few missing parts to build one though).

-

This guy took a very different approach, yet he took deflection into account and has supported rails. For its size, it may be the least expensive:

https://www.ebay.com/itm/BobsCNC-E3-CNC-Router-Engraver-Kit-includes-the-DeWalt-DW660-Router/222859180982?epid=530593462&hash=item33e3713bb6:g:HjsAAOSwJvpalajYhttps://www.youtube.com/watch?v=v-e2IVQUh1k

Also, the Y-axis is easily extensible:

https://www.youtube.com/watch?v=k44hWAIadjc -

Yes but can he do this? ;-)

https://youtu.be/Nz8k2MSAasI?t=47s -

Yes but can he do this? ;-)

https://youtu.be/Nz8k2MSAasI?t=47s@bjornhallberg I'm sold! ... except I'm not, because they won't sell a kit to anyone in the United States. Go figure. I don't understand why.

-

Yes but can he do this? ;-)

https://youtu.be/Nz8k2MSAasI?t=47s@bjornhallberg said in Best CNC for milling/routing wood?:

Yes but can he do this?

Something tells me that machine needs some big red E-Stops...

-

Yes but can he do this? ;-)

https://youtu.be/Nz8k2MSAasI?t=47s@bjornhallberg Any estimate on the cost of mechanical parts ?

-

This post is deleted!

-

@bjornhallberg Any estimate on the cost of mechanical parts ?

@rfm69 I think the mechanical stuff is ~$1400 and then ~$600 for steppers and spindle and a few other things.

Of course the machine we're building at the makerspace is the biggest suggested model. Working area ~100x150cm with steel reinforced Y and X and with laser cut steel plates instead of aluminum. So I don't think he ever sold that as a kit internationally because of weight and size. A smaller machine would be much cheaper obviously.

@neverdie Yeah the guy behind the RawCNC has been a bit difficult. This is sort of his side project and he keeps changing his mind on how to proceed. He actually rolled back some of the features to make the machines lighter and easier to ship. But then he didn't sell internationally anyway. At least not for long.

-

@rfm69 I think the mechanical stuff is ~$1400 and then ~$600 for steppers and spindle and a few other things.

Of course the machine we're building at the makerspace is the biggest suggested model. Working area ~100x150cm with steel reinforced Y and X and with laser cut steel plates instead of aluminum. So I don't think he ever sold that as a kit internationally because of weight and size. A smaller machine would be much cheaper obviously.

@neverdie Yeah the guy behind the RawCNC has been a bit difficult. This is sort of his side project and he keeps changing his mind on how to proceed. He actually rolled back some of the features to make the machines lighter and easier to ship. But then he didn't sell internationally anyway. At least not for long.

@bjornhallberg Thanks for the info, I got a bit frustrated trying to find this on the rawcnc website... i was in some loop, very frustrating.

I'm going to learn with the mpcnc and then posisble upgrade if I can justify it, or feel more flush. But thanks for the info...

This shipping costs, can be a big factor, so I do understand, but the openness and transparency or generally communicating well, which you don't get at all from most china suppliers, and some closer is just as important.

-

@rfm69 I think the mechanical stuff is ~$1400 and then ~$600 for steppers and spindle and a few other things.

Of course the machine we're building at the makerspace is the biggest suggested model. Working area ~100x150cm with steel reinforced Y and X and with laser cut steel plates instead of aluminum. So I don't think he ever sold that as a kit internationally because of weight and size. A smaller machine would be much cheaper obviously.

@neverdie Yeah the guy behind the RawCNC has been a bit difficult. This is sort of his side project and he keeps changing his mind on how to proceed. He actually rolled back some of the features to make the machines lighter and easier to ship. But then he didn't sell internationally anyway. At least not for long.

@bjornhallberg said in Best CNC for milling/routing wood?:

I think the mechanical stuff is ~$1400 and then ~$600 for steppers and spindle and a few other things.

Seems like a very good price for the rigidity and such a large format, at least compared to other offerings.

-

The MPCNC is a smart project but I would assume it would struggle with a bigger motor.

The 2.2kW we are going to use weighs A LOT. Around 5kg at least I'd guess. The 1.5kW is not much better. With a smaller spindle, or router like a Kress things would be different. Still I'm glad to have the extra power, and standard ER20 collets up to 13mm. Plus these chinese spindles are really quiet compared to a regular router. And the speed can be set and spindle can be started from the control panel or from the computer. The downside is the low quality VFD I guess, but if it works it works. And you can always use shielded cables everywhere.

@bjornhallberg said in Best CNC for milling/routing wood?:

The MPCNC is a smart project but I would assume it would struggle with a bigger motor.

The 2.2kW we are going to use weighs A LOT. Around 5kg at least I'd guess. The 1.5kW is not much better. With a smaller spindle, or router like a Kress things would be different. Still I'm glad to have the extra power, and standard ER20 collets up to 13mm. Plus these chinese spindles are really quiet compared to a regular router. And the speed can be set and spindle can be started from the control panel or from the computer. The downside is the low quality VFD I guess, but if it works it works. And you can always use shielded cables everywhere.

Thankyou for sharing. i was looking for best cnc router i got alot of information here