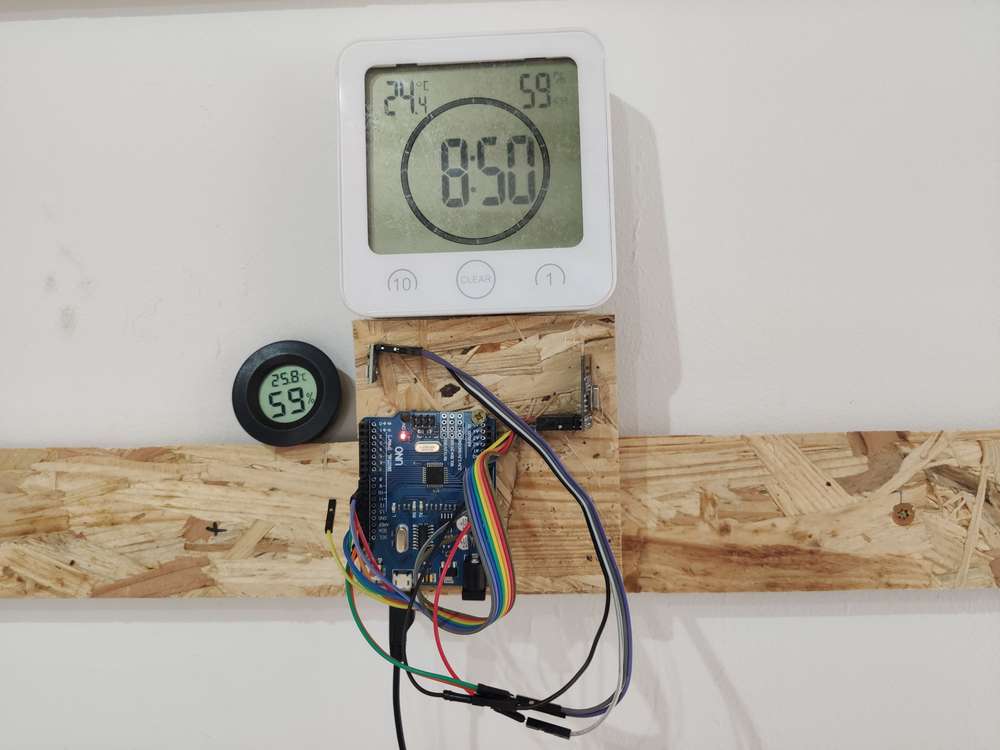

Well, it not really a build I plugged in wires, and copied code. Found a random usb charger and put it all in my workspace to be.

And I absolutely love this thing. Maximum of 3 hours work. I was having fun, so it could be more.

I considered that there could and should be a display on this thing, but not for now. I made this, because I have never experimented with temperature sensors and I just received a few. Now I can just see what happens with the temperature in there.

sensor is a AHT10 temperature and humidity.

http://www.aosong.com/m/en/products-40.html

I used this library: https://github.com/enjoyneering/AHT10

I repurposed Hek's DHT code, and swapped the readings with the AHT's

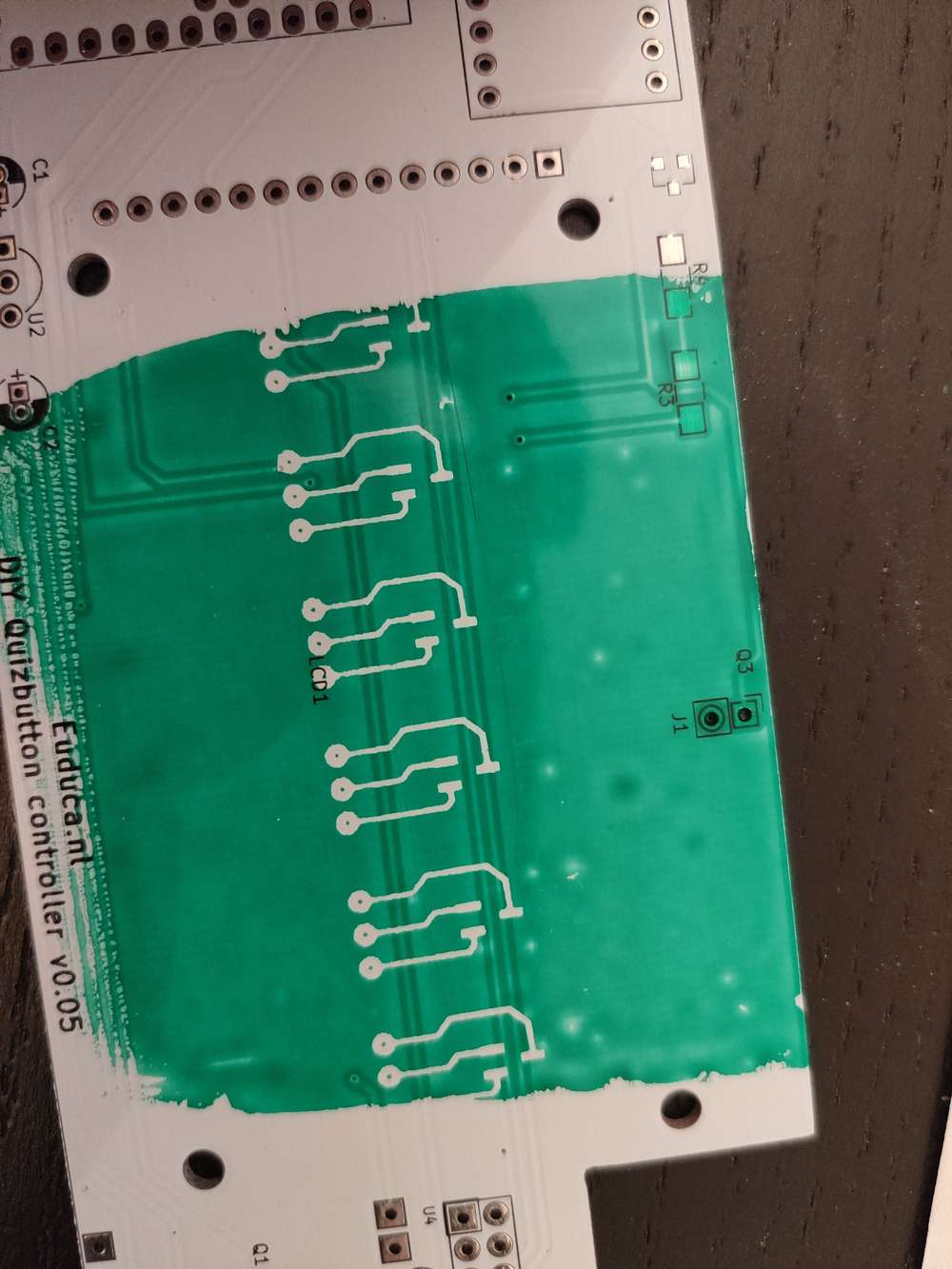

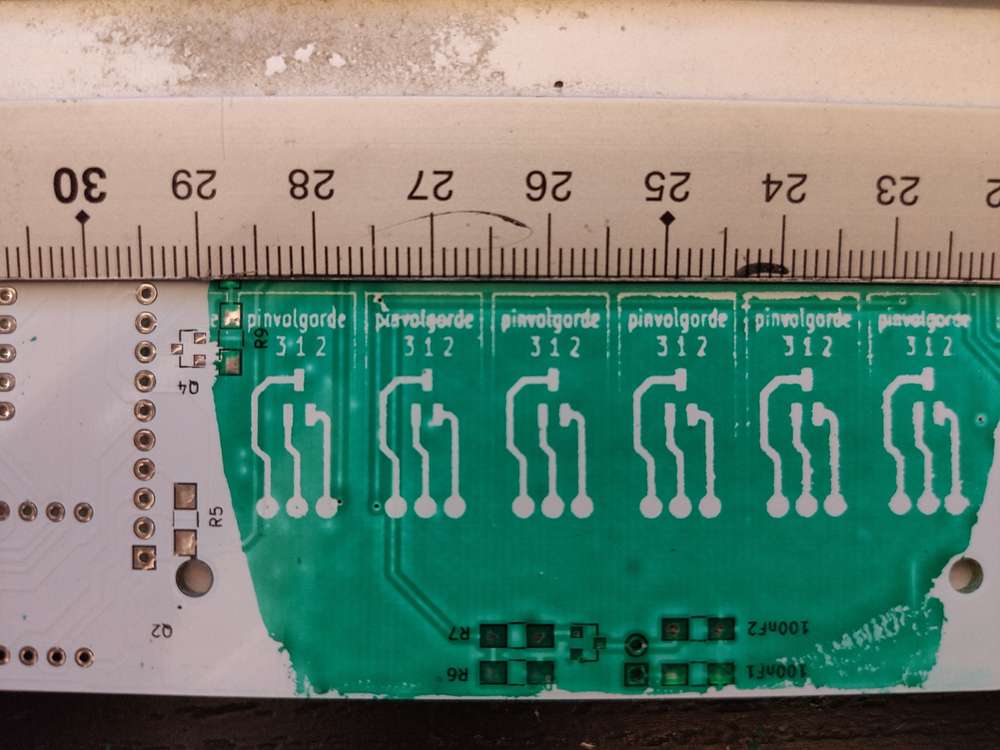

shed before

workspace after but still filling it.