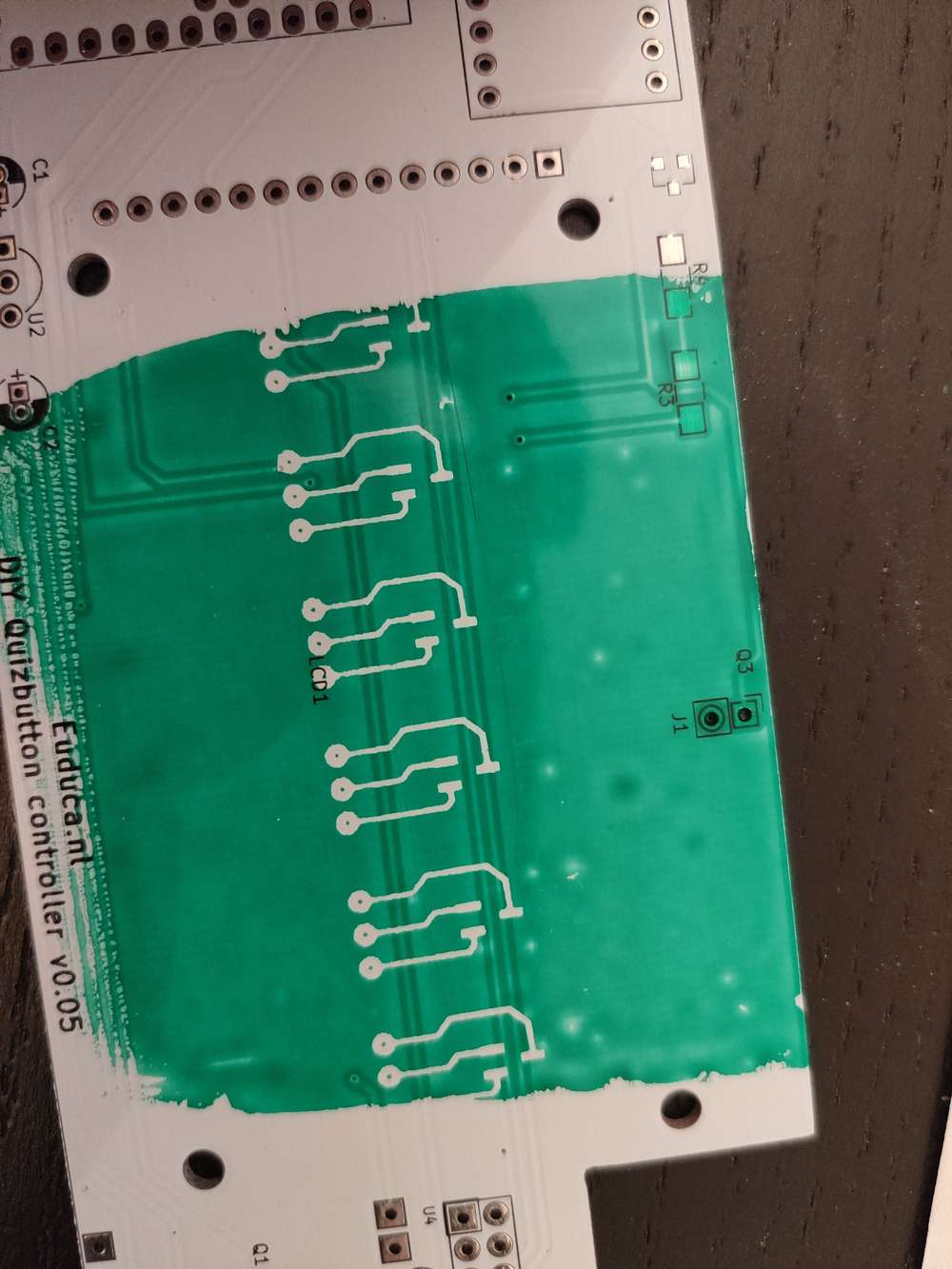

I just started with my first UV mask experience.

Following a YouTube video about how to apply the paint. I use a transparent sheet anyway to put the paint on. If I had printed the pads on there before exposing than my only task would have been to rinse it after a minute.

Either way, first test to apply it failed. Better cleaning next time.

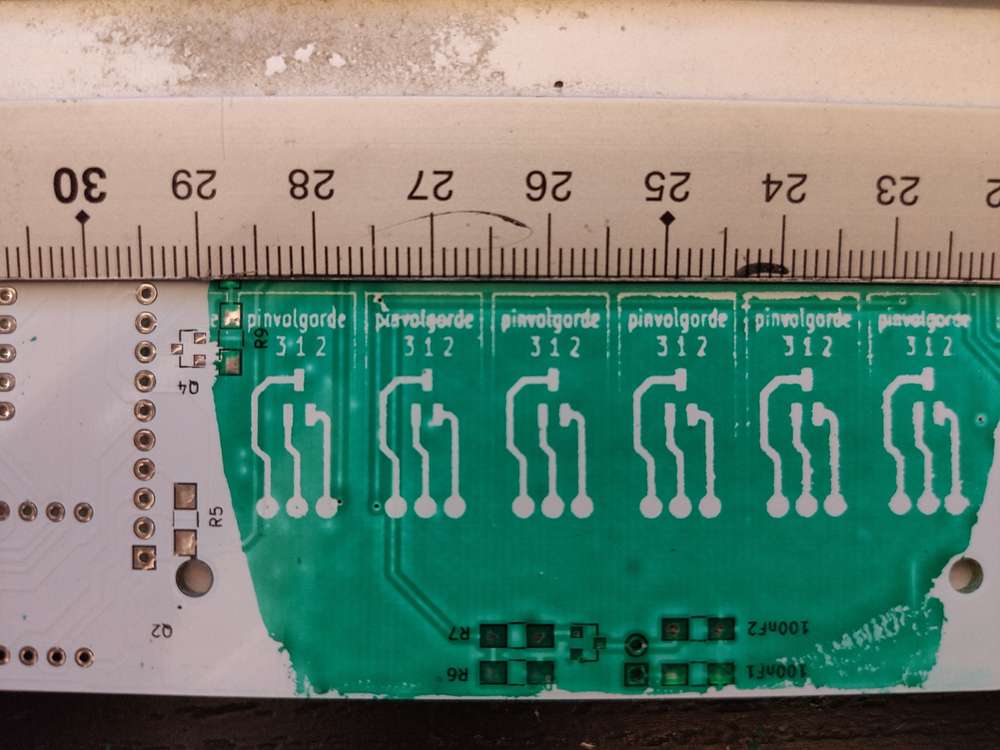

So far... I find it difficult to apply the paint. And I find it difficult to expose the paint and then remove it again.

Edit: I have already reached the tenth test. So I am starting to root for the laser. although aligning will be very difficult.

Edit again: Exposing uv paint is problematic. It worked a bit, but I think I will have to experiment with curing times. It is far less forgiving than exposing pcb's. On the other hand... I now understand why they use there mill for this.

I am a bit out of material to put the paint on, and out of patience. The laser will have to come later. I am not so experienced yet using that thing. It takes a bit of time to set it up.