Most reliable "best" radio

-

@Larson said in Most reliable "best" radio:

My problem today is bootloading the brand new 328's with my old USBASP. The IDE says something about “cannot set SCK period” and then “initialization failed”.

If you have a second USBASP or an Arduino of some sore lying around, you could try to update the firmware on the USBASP. I recommend this edition, latest release and a Google search for "how to update usbasp firmware". You may see that with release v1.06 of that repository, there was an improvement that "Includes automatic SCK slowing".

Of course, the problem may be more rudimentary. Can you read the fuses? Are they set to use an external oscillator that doesn't exist?

@alphaHotel Still working on getting my USBASP reprogrammed. After googling I found this site: https://www.electronics-lab.com/project/usbasp-firmware-update-guide. That program says to create a new programmer; I used a Nano and uploaded the ArduinoISP successfully. Next I combine the avrdude.conf, avrdude.exe, and the update hex file in one file as suggested. I used your latest release link to find the update hex file to be main.hex for the Atmega8 that lives on my USBASP. The readme files in your link lead me to that conclusion.

After connecting everything together I enter “avrdude -C avrdude.conf -P COM9 -p m8 -c avrisp -b 19200 -U flash:w:usbasp.atmega8.main.hex:I” in the windows command line.I get these errors:

avrdude: error at avrdude.conf:1133: programmer type jtagice3_updi not found

avrdude: error reading system wide configuration file "avrdude.conf"I found jtagice3 in the config file to be a defined programmer. I feel that I’m close. Any ideas? I continue to work on it.

-

@alphaHotel I'll try the firmware update. Thanks. I suspect my problem is the SCK speed. I get immediate failure. I don't think I can reach the fuses if the 'target' chip doesn't have a bootloader. Do I have that wrong? The wierd thing is that I used my USBasp to bootload an extra Nano I have on hand. That worked fine. On the bare bones board, I've double/triple checked the connections and I've rechecked the 328 chip for solder bridges & solid connections with pins. I have downloaded your recommended link. The 2011-05-28 Thomas Fischl Readme.txt file looks complicated. I'll see if I can manage that. Thanks again.

@Larson said in Most reliable "best" radio:

I don't think I can reach the fuses if the 'target' chip doesn't have a bootloader. Do I have that wrong?

You can reach (read/write) the fuses with a USBASP regardless of whether there is a bootloader. If you have any troubles, shoot me a message in the chat or start a new thread somewhere and I'll help you through it.

-

@Larson said in Most reliable "best" radio:

I don't think I can reach the fuses if the 'target' chip doesn't have a bootloader. Do I have that wrong?

You can reach (read/write) the fuses with a USBASP regardless of whether there is a bootloader. If you have any troubles, shoot me a message in the chat or start a new thread somewhere and I'll help you through it.

@alphaHotel Chat sent. My apologies to NeverDie for the distractions to a very fine thread.

-

Reporting back on Piezo buzzers discussed earlier in this thread: I just now tested out a ceramic disk piezo, and, indeed, it appears they more or less require a resonate cavity of some kind to get loud enough. Putting a 3.8KHz square wave into one that already has a resonate cavity to go with it, it appears to consume about 400ua at 3v and around 260ua at 1.8v. Interestingly, it appears you can identify the frequency of maximum loudness by selecting a frequency that gives rise to the maximum current draw. A steady tone sounds like a hearing test though, so for a more pleasant effect, I guess you have to dial-in some creative frequencies.

Anyhow, despite the cheap price for ceramic disks, I don't feel like designing a suitable resonate cavity for one, so I guess I'll look more into the premade surface mount buzzers that have resonate cavities already built into their modules.

I had thought that I wouldn't need a particularly loud buzzer, and maybe that's still the case, but since I will be putting these into sealed plastic boxes as a locator beacon, I guess maybe the louder the better in terms of finding it by ear. The trade-off is that louder mostly seems to also mean bigger.

The premade buzzers fall into two camps: actively driven by some kind of built-in circuit vs. externally driven. Since the above initial test appears to indicate that current drain won't be much, I'm leaning toward driving it "externally" with an MCU pin so that I can make R2D2 sounds if I want to. Well, I'm joking about R2D2, but I would much prefer something that doesn't sound like a hearing test.

BTW, I had thought that changing the duty cycle on the square wave used to drive the piezo would change the volume, but in the tests I performed so far, the duty cycle length actually seems to have almost no effect.

-

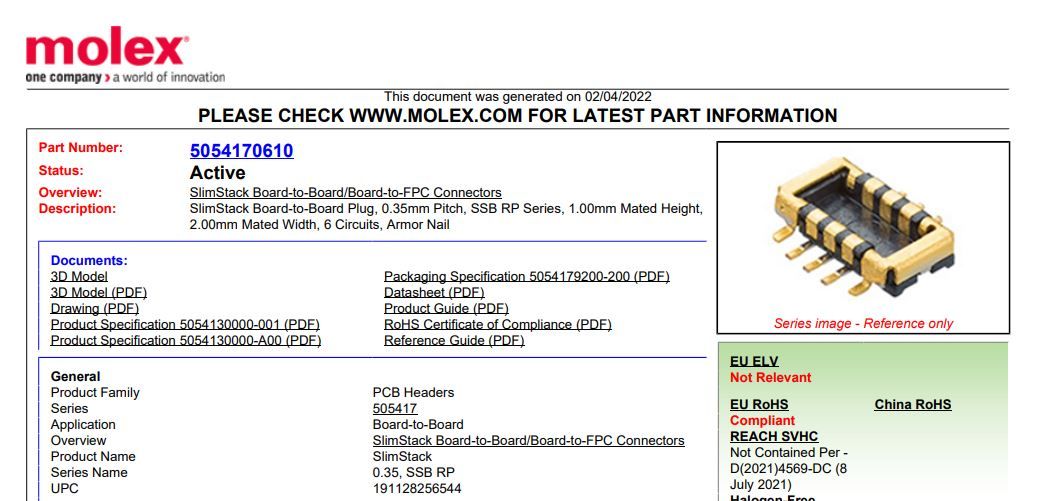

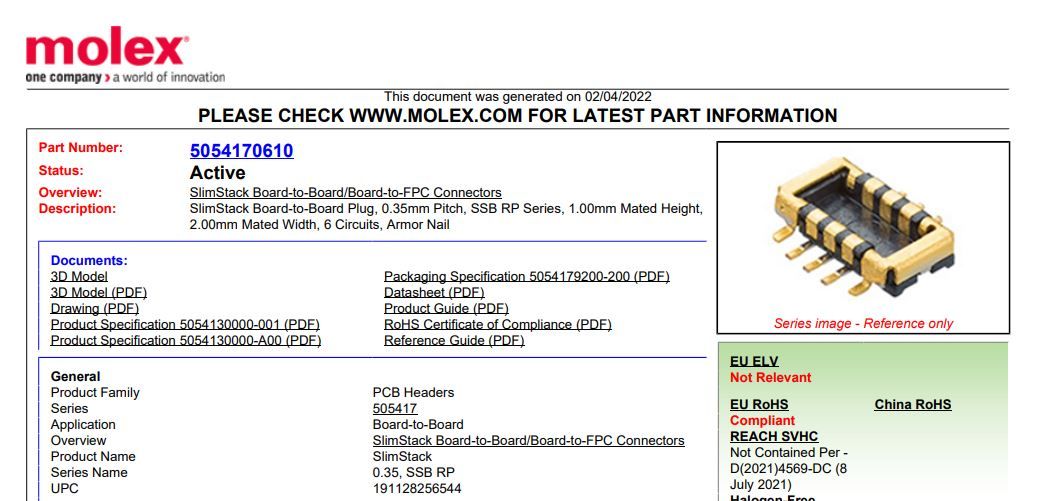

Reporting back: I finally found a name for some "press-fit" board-to-board connects: Molex slimstack.

For instance, it could maybe be used for connecting a "compute module" to a backplane. Pitch is just 0.35mm, and they come in all sizes from 6 pins up to 60 pins:

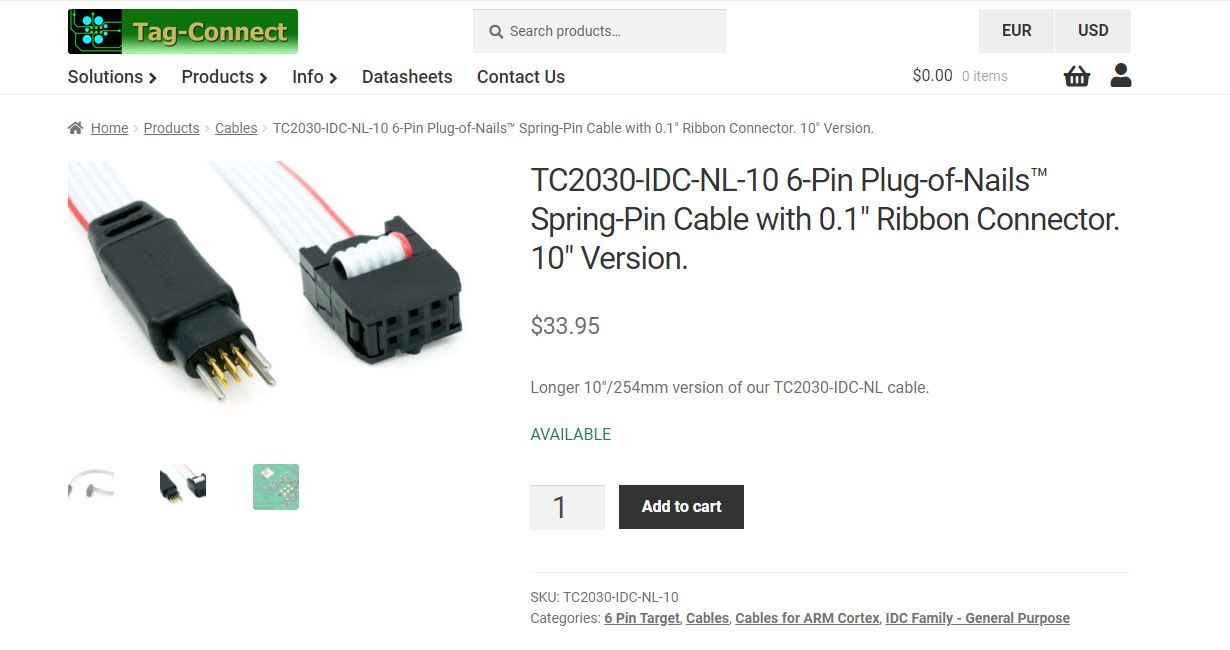

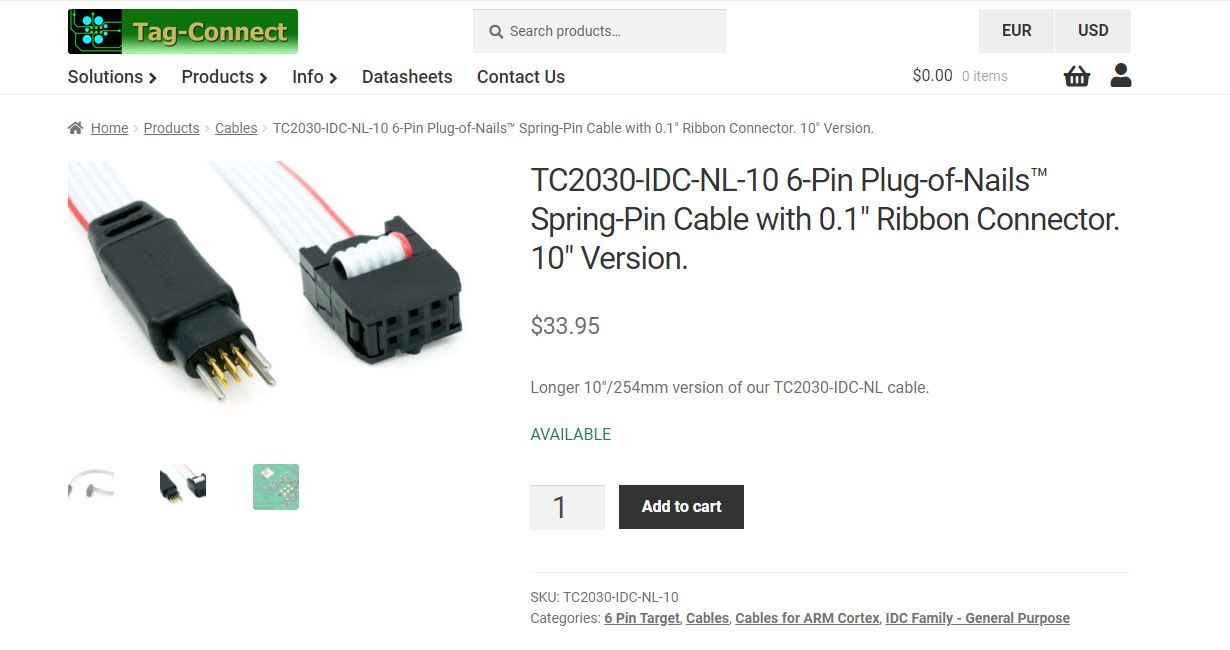

On the other hand, for a temporary programming connection, the 6 pin tag-connect might be a good idea:

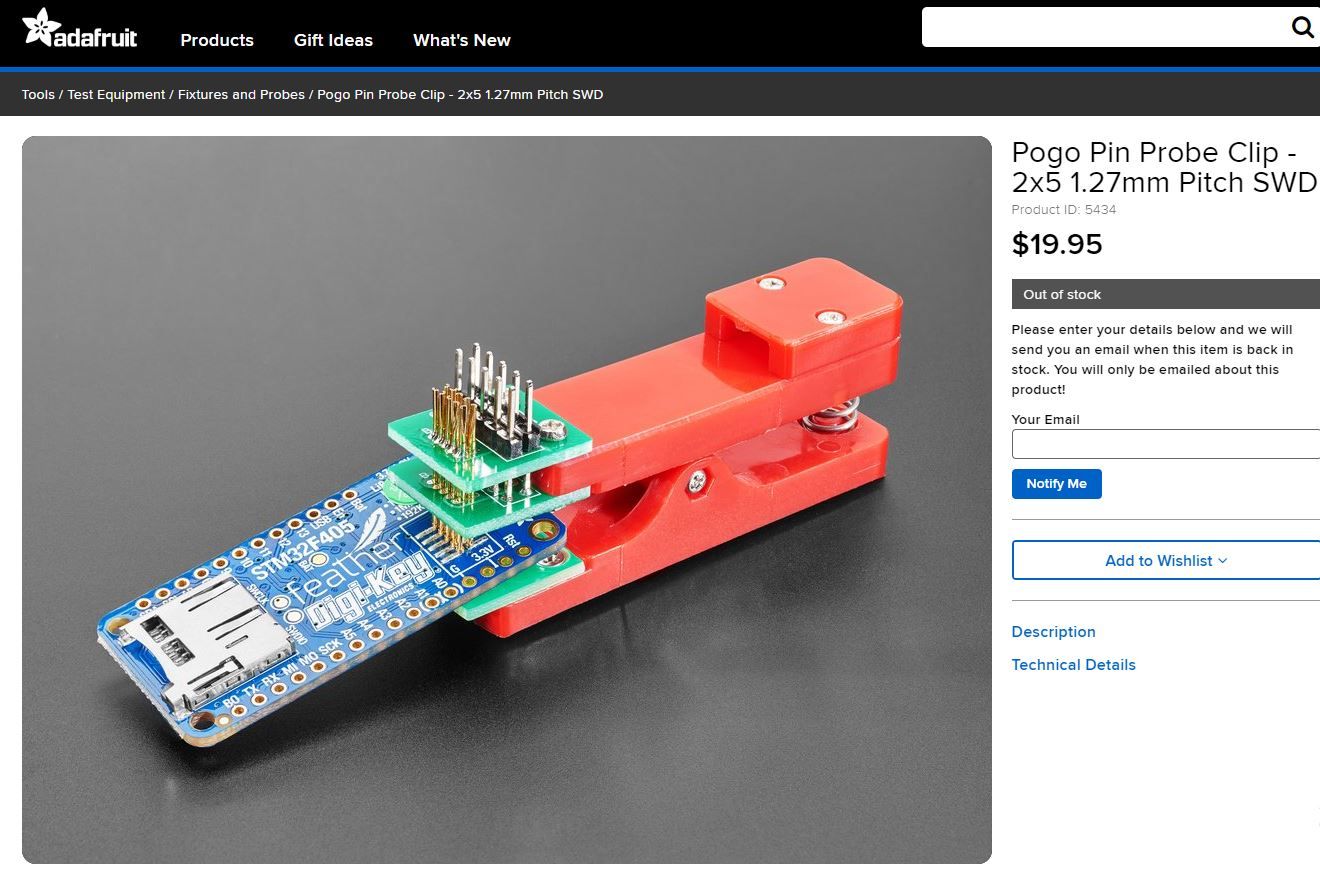

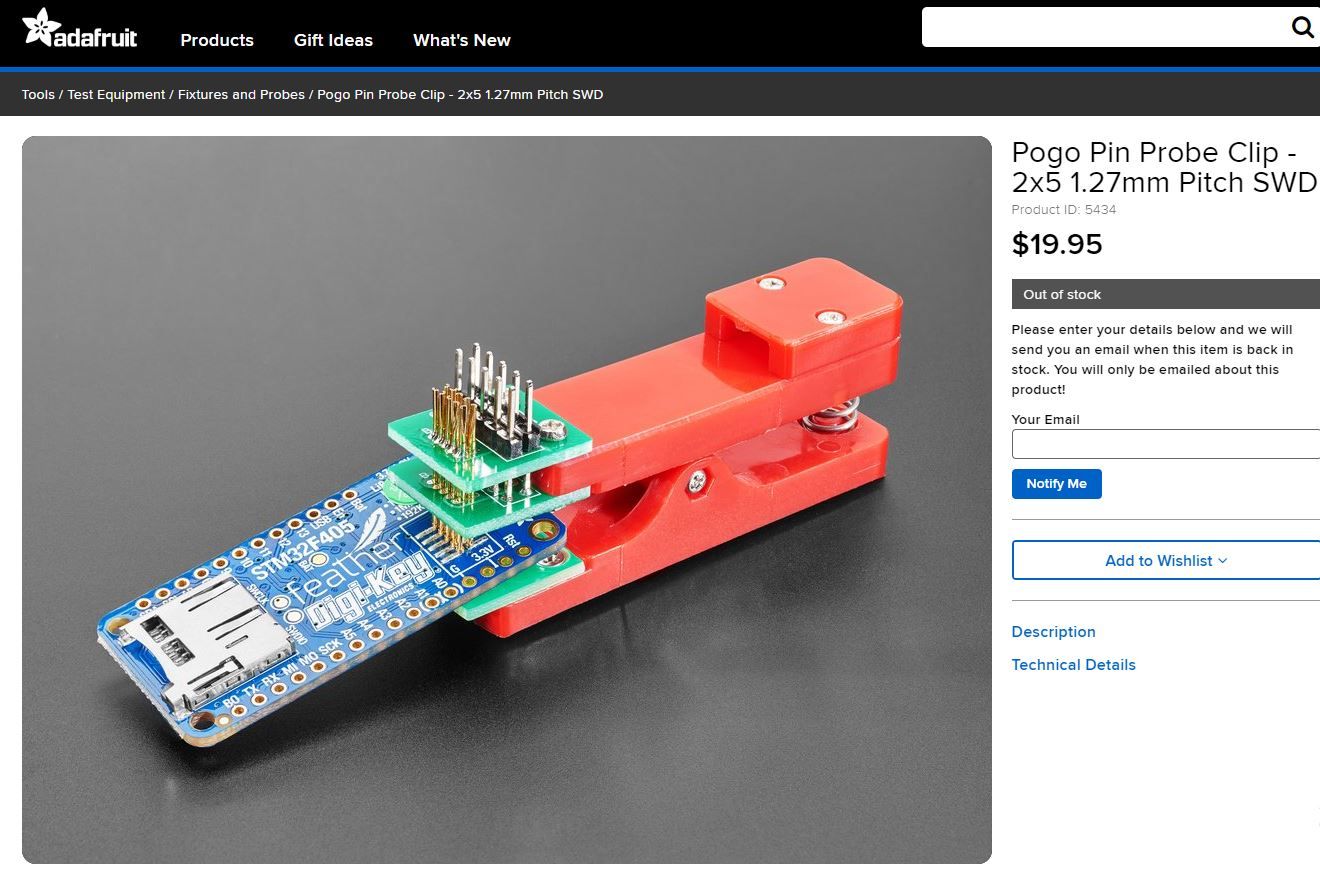

Or you could possibly use a pogo-pin clip:

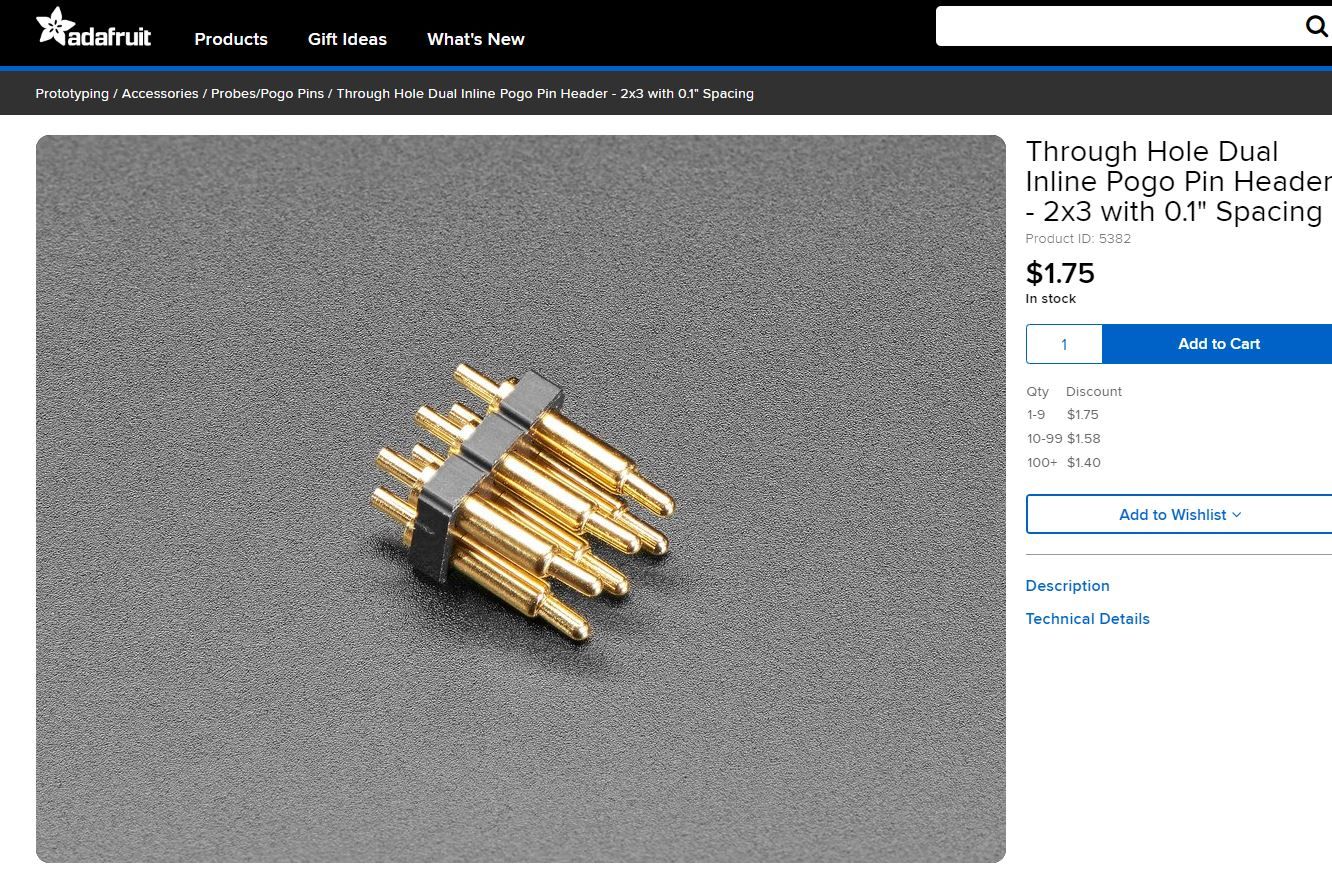

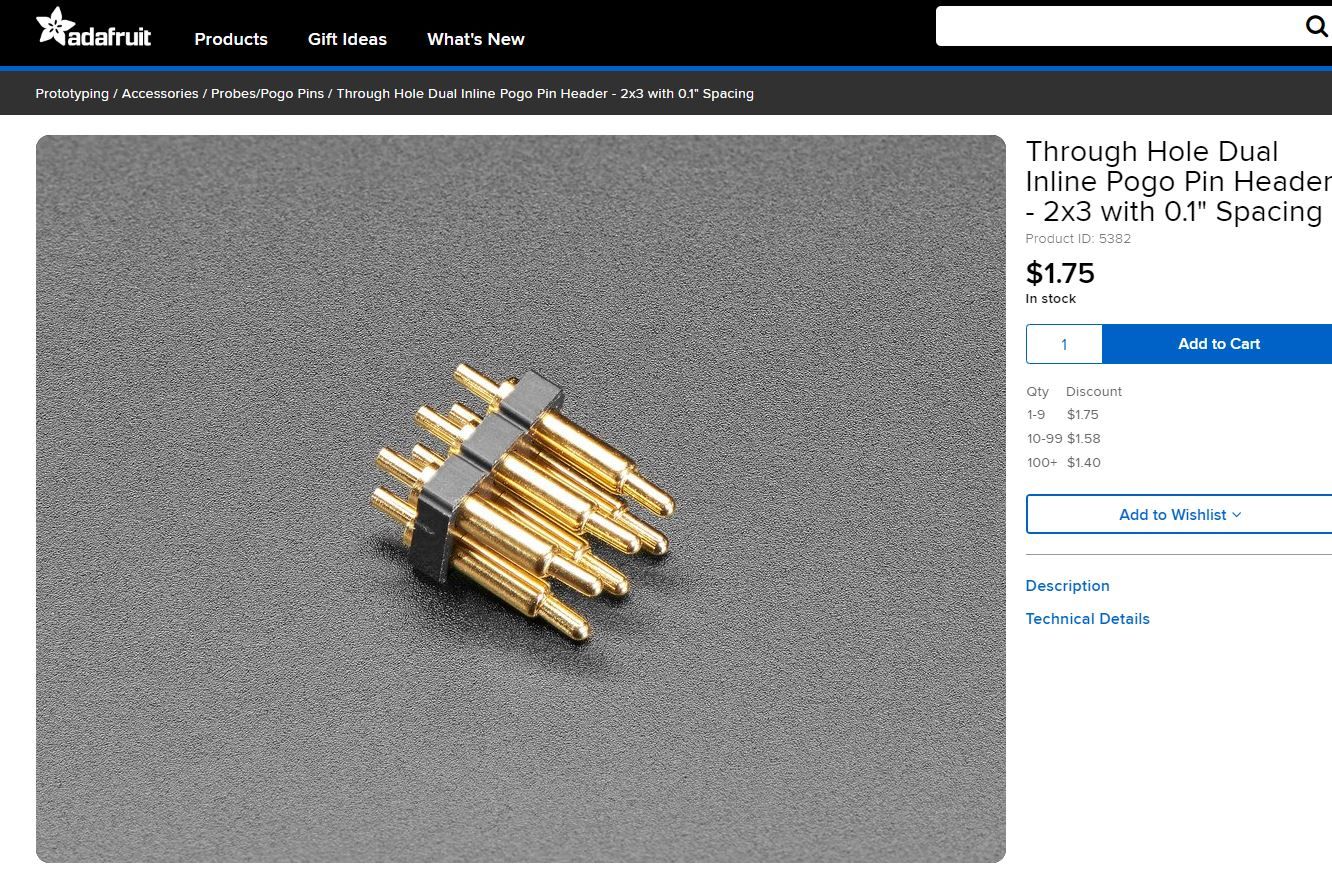

or possibly DIY your own using an inexpensive pogo pin header:

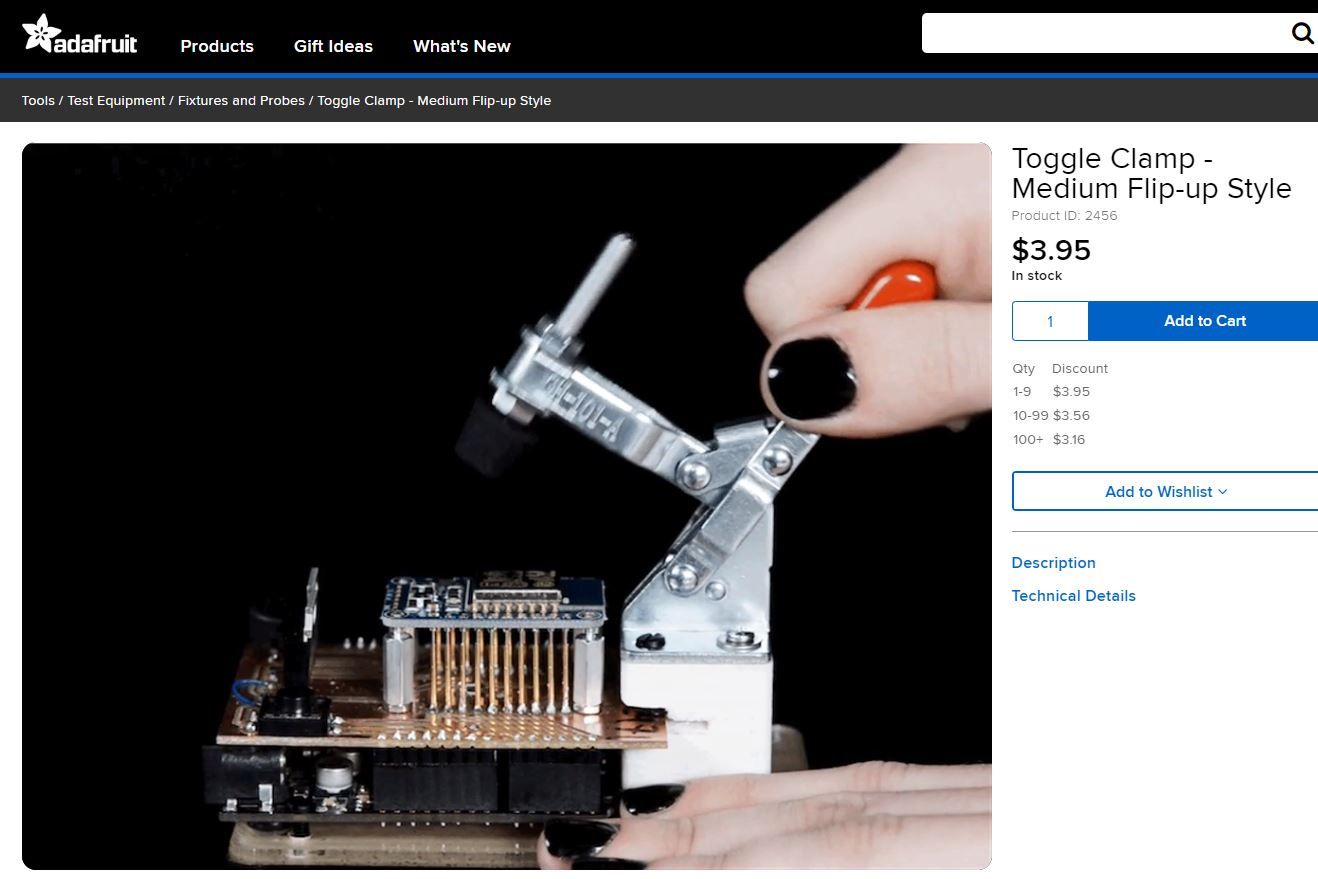

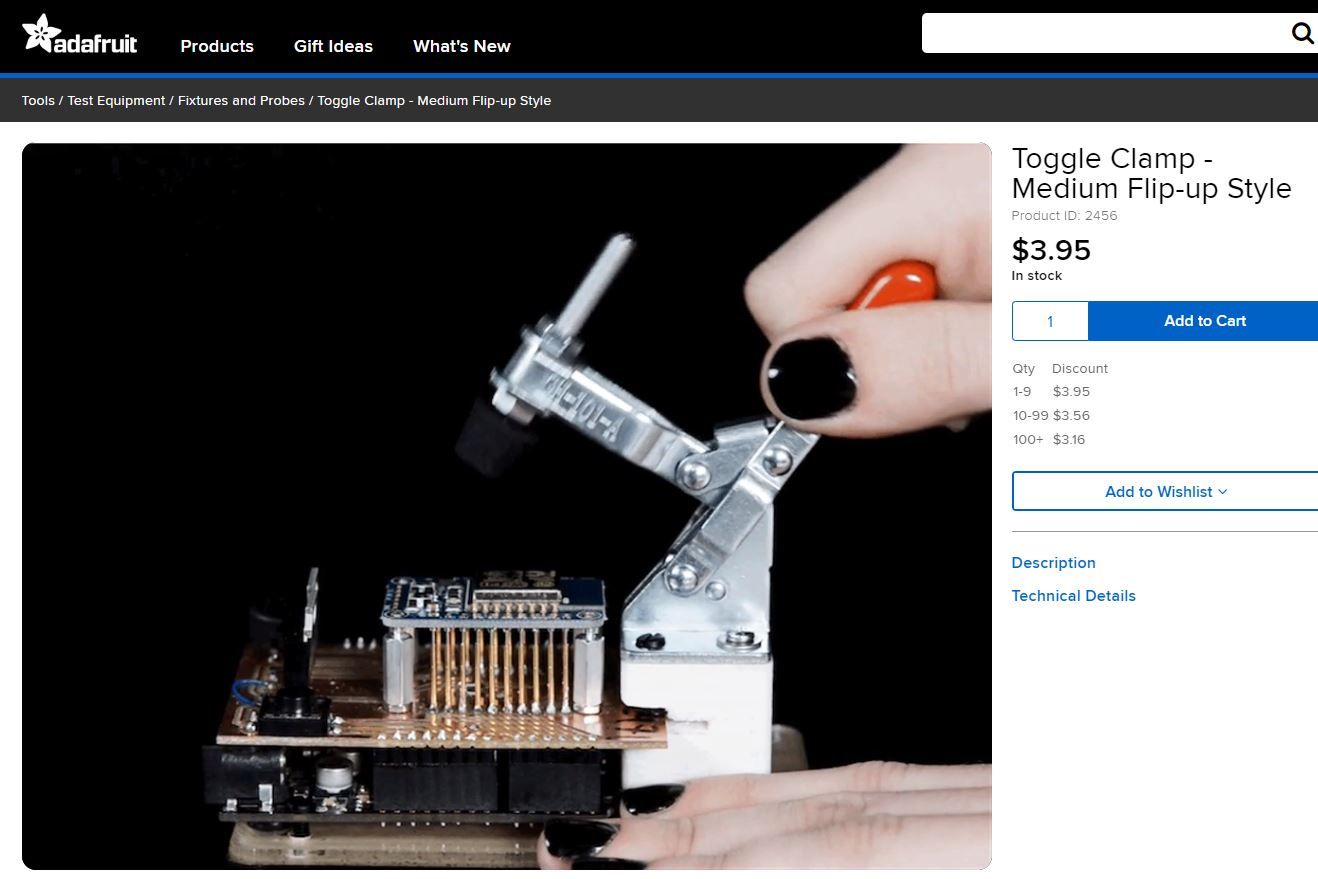

For that matter, with a few registration holes and a toggle clamp, it looks to me like you could have a darn good connection for either one-off programming or for more extended debugging:

I think I may move in that direction, because then you can spread out your pogo pin pads and fit them wherever there's extra a little extra space on your PCB rather than having to bunch them all together, as in the case of the other solutions. In that sense, I suppose it's more or less a conventional custom-built bed-of-nails. -

Reporting back: I finally found a name for some "press-fit" board-to-board connects: Molex slimstack.

For instance, it could maybe be used for connecting a "compute module" to a backplane. Pitch is just 0.35mm, and they come in all sizes from 6 pins up to 60 pins:

On the other hand, for a temporary programming connection, the 6 pin tag-connect might be a good idea:

Or you could possibly use a pogo-pin clip:

or possibly DIY your own using an inexpensive pogo pin header:

For that matter, with a few registration holes and a toggle clamp, it looks to me like you could have a darn good connection for either one-off programming or for more extended debugging:

I think I may move in that direction, because then you can spread out your pogo pin pads and fit them wherever there's extra a little extra space on your PCB rather than having to bunch them all together, as in the case of the other solutions. In that sense, I suppose it's more or less a conventional custom-built bed-of-nails.@NeverDie said in Most reliable "best" radio:

I suppose it's more or less a conventional custom-built bed-of-nails.

:joy: :sunglasses:

-

@NeverDie said in Most reliable "best" radio:

I suppose it's more or less a conventional custom-built bed-of-nails.

:joy: :sunglasses:

Unfortunately, it also looks like it's the most work. I tried the picoblade on Version 1.0 of the Barebones, but I found that although picoblade makes the connection easily, the disconnection process is hard because it locks into place when you plug into it. So, for small projects, I'm looking into JST-SH connections, which have 1.0mm pitch and maybe (?) don't lock as well, which in this instance would be a good thing. I found some on amazon:

https://www.amazon.com/dp/B01DUC1M2O?psc=1&ref=ppx_yo2ov_dt_b_product_details

but the sockets are vertical. For right-angle sockets, I may may have to order from Aliexpress, because even Mouser just doesn't seem to stock them.I was faced with this same problem previously when I did this project: https://www.openhardware.io/view/510/Multi-Sensor-TempHumidityPIR-LeakMagnetLightAccel

My "solution" at the time was, in future versions, to use a micro-usb connector, which indeed was much smaller, but there was nearly universal pushback on that from people saying that anything which looks like a micro-usb connector would be mistaken for an actual USB connector, and at some point end-users would hook it up wrongly on that assumption and basically destroy the system with 5 volts. Thinking about it now, that grim outcome could be avoided by the addition of just a single diode, but then again that's yet another extra part and more board real estate.

-

Unfortunately, it also looks like it's the most work. I tried the picoblade on Version 1.0 of the Barebones, but I found that although picoblade makes the connection easily, the disconnection process is hard because it locks into place when you plug into it. So, for small projects, I'm looking into JST-SH connections, which have 1.0mm pitch and maybe (?) don't lock as well, which in this instance would be a good thing. I found some on amazon:

https://www.amazon.com/dp/B01DUC1M2O?psc=1&ref=ppx_yo2ov_dt_b_product_details

but the sockets are vertical. For right-angle sockets, I may may have to order from Aliexpress, because even Mouser just doesn't seem to stock them.I was faced with this same problem previously when I did this project: https://www.openhardware.io/view/510/Multi-Sensor-TempHumidityPIR-LeakMagnetLightAccel

My "solution" at the time was, in future versions, to use a micro-usb connector, which indeed was much smaller, but there was nearly universal pushback on that from people saying that anything which looks like a micro-usb connector would be mistaken for an actual USB connector, and at some point end-users would hook it up wrongly on that assumption and basically destroy the system with 5 volts. Thinking about it now, that grim outcome could be avoided by the addition of just a single diode, but then again that's yet another extra part and more board real estate.

@NeverDie Jonathan Oxer a little while back went through a similar process with programming headers for ESP8266/ESP32 boards. He discusses some of the challenges and tradeoffs in his video(s).

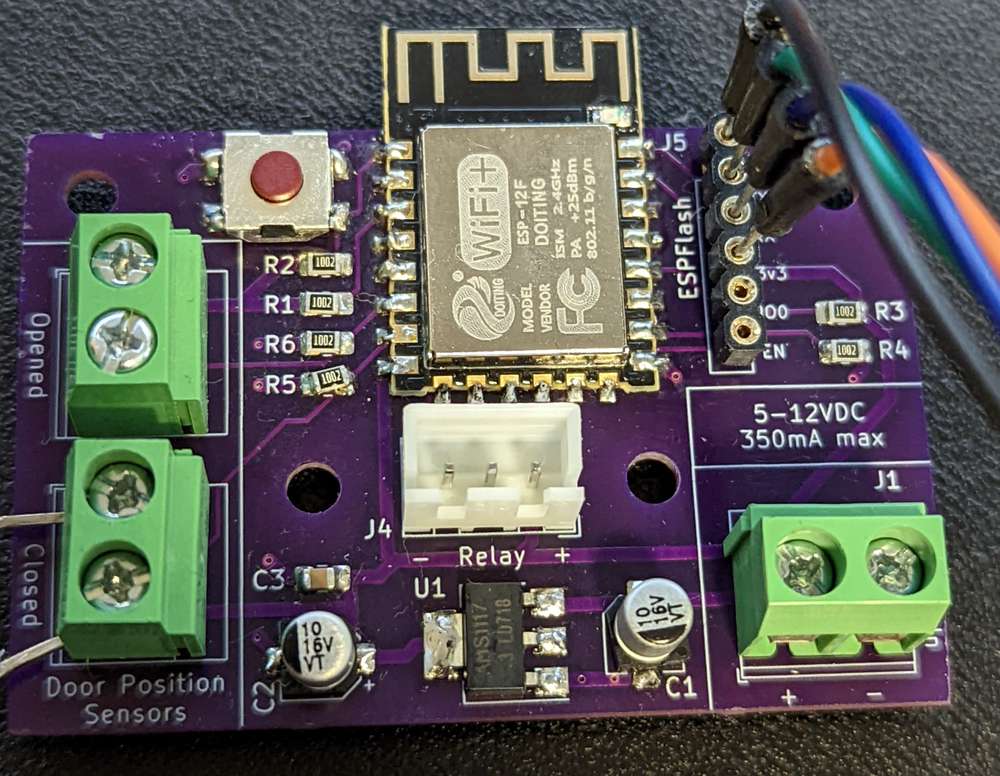

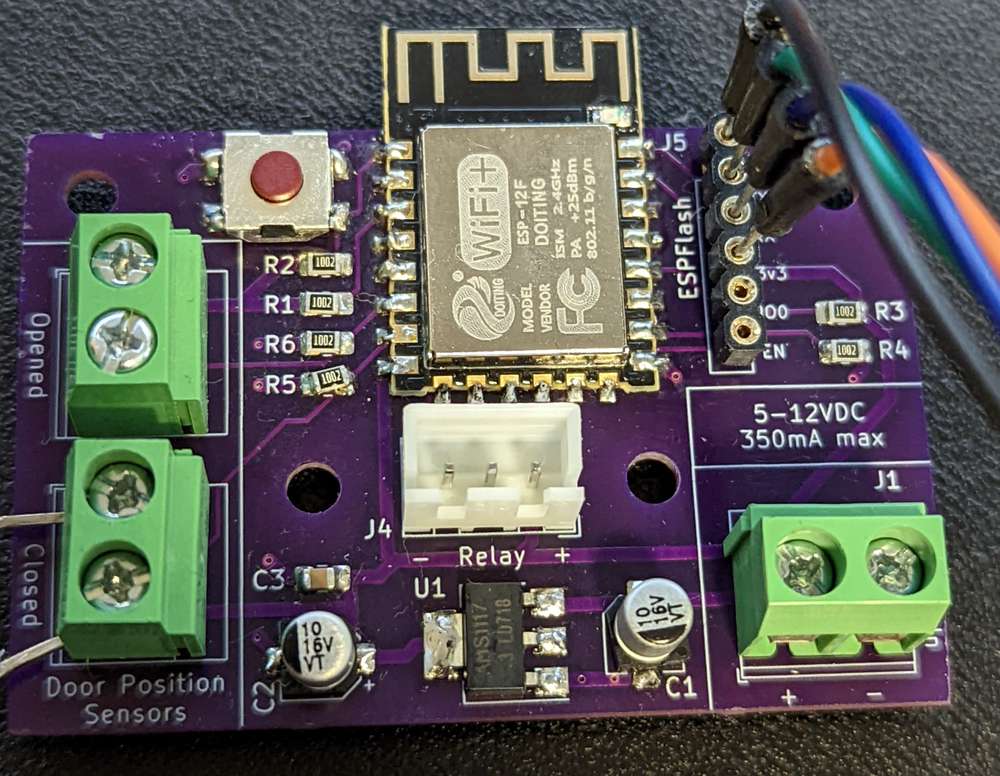

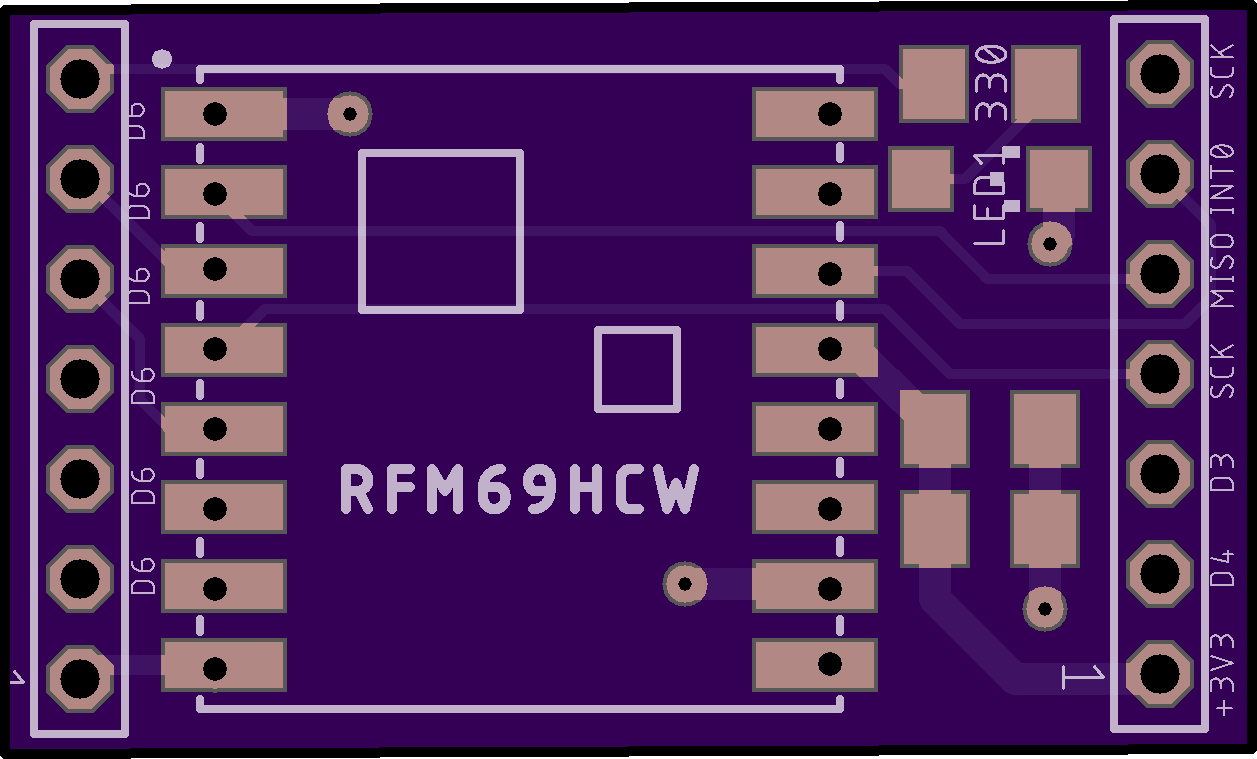

My personal opinion on trying to shrink them down is to keep with pin headers and just make them smaller. It's easy enough to find 1.27mm pitch IDC connectors. Your JST connector idea is good too. In the end, this is mostly a target audience scenario, it seems to me. My most recent board (still working on it), employed Oxer's ESPFlash header but I kept it with a 2.54mm pitch package because I have a ~million headers with that spacing and I wasn't cramped for space. (pic below)

If it's board-to-board as in connecting a radio module to an MCU backplane, then it's more of a use-case and dealer's choice scenario, in my mind. Those Molex SlimStack connectors look interesting.

I don't know if that helps or if I'm blowing smoke in the wrong direction. Just adding my voice.

-

@NeverDie Jonathan Oxer a little while back went through a similar process with programming headers for ESP8266/ESP32 boards. He discusses some of the challenges and tradeoffs in his video(s).

My personal opinion on trying to shrink them down is to keep with pin headers and just make them smaller. It's easy enough to find 1.27mm pitch IDC connectors. Your JST connector idea is good too. In the end, this is mostly a target audience scenario, it seems to me. My most recent board (still working on it), employed Oxer's ESPFlash header but I kept it with a 2.54mm pitch package because I have a ~million headers with that spacing and I wasn't cramped for space. (pic below)

If it's board-to-board as in connecting a radio module to an MCU backplane, then it's more of a use-case and dealer's choice scenario, in my mind. Those Molex SlimStack connectors look interesting.

I don't know if that helps or if I'm blowing smoke in the wrong direction. Just adding my voice.

@alphaHotel Thanks for your post. It reminded me that for one-time programming, all one really needs is just the through-holes on the board. You can then bend the pins on a male header to create a kind of "weave" pattern, and that alone is enough to hold it into place during the programming, after which you can simply remove it. I've confirmed this works at 2.54mm pitch, and so I'll try it at 1.27mm pitch. I expect it should work well with that too.

I did find this video, which makes it seem fairly straightforward to set up a custom bed of nails:

https://www.youtube.com/watch?v=_ILqQ1kpqEQbut he did say during the Q&A that it took him 4 days to design it. However, with the benefit of knowing his solution, I don't think it should take anywhere near that long to design just the PCB part of it. Maybe an hour, give or take? Someday I'm going to try it. His approach to the push-pin alignment seems quite simple and, I would think, should be easy to adapt to a whole range of different targets.

-

@alphaHotel Thanks for your post. It reminded me that for one-time programming, all one really needs is just the through-holes on the board. You can then bend the pins on a male header to create a kind of "weave" pattern, and that alone is enough to hold it into place during the programming, after which you can simply remove it. I've confirmed this works at 2.54mm pitch, and so I'll try it at 1.27mm pitch. I expect it should work well with that too.

I did find this video, which makes it seem fairly straightforward to set up a custom bed of nails:

https://www.youtube.com/watch?v=_ILqQ1kpqEQbut he did say during the Q&A that it took him 4 days to design it. However, with the benefit of knowing his solution, I don't think it should take anywhere near that long to design just the PCB part of it. Maybe an hour, give or take? Someday I'm going to try it. His approach to the push-pin alignment seems quite simple and, I would think, should be easy to adapt to a whole range of different targets.

@NeverDie My personal preference is the Tag-Connect. It costs a bit upfront to get into it, but then there's zero ongoing BOM cost per board, and the connectors are very sturdy, so I don't get bad connections, even while doing extended troubleshooting.

Of course, if I hadn't needed them for a customer project, I might never have sprung for the upfront cost, as the cables are somewhat spendy for the what they are. But they are very well made, and have been great for me. The board footprint is pretty tiny, so that has yet to have ever been an issue in my projects. The footprint is also keyed, so you can't put the cable on backwards. Always a good thing. Also, since the connection points are not through-holes, you still have the back and interior of the board for routing traces. Of course the alignment pins are still through-hole. I prefer the type without the locking pins, and then there's a little board that you slide on the alignment pins from the back to hold everything together.

If I were to go with a standard, I wouldn't be excited about his ESP Flash one, simply because I don't see a need for it. Yet another 'standard' just fragments things worse. I would use the ESP-Prog one if needed, and use the .05" pins if I needed tiny.

-

@NeverDie My personal preference is the Tag-Connect. It costs a bit upfront to get into it, but then there's zero ongoing BOM cost per board, and the connectors are very sturdy, so I don't get bad connections, even while doing extended troubleshooting.

Of course, if I hadn't needed them for a customer project, I might never have sprung for the upfront cost, as the cables are somewhat spendy for the what they are. But they are very well made, and have been great for me. The board footprint is pretty tiny, so that has yet to have ever been an issue in my projects. The footprint is also keyed, so you can't put the cable on backwards. Always a good thing. Also, since the connection points are not through-holes, you still have the back and interior of the board for routing traces. Of course the alignment pins are still through-hole. I prefer the type without the locking pins, and then there's a little board that you slide on the alignment pins from the back to hold everything together.

If I were to go with a standard, I wouldn't be excited about his ESP Flash one, simply because I don't see a need for it. Yet another 'standard' just fragments things worse. I would use the ESP-Prog one if needed, and use the .05" pins if I needed tiny.

@ejlane said in Most reliable "best" radio:

I prefer the type without the locking pins, and then there's a little board that you slide on the alignment pins from the back to hold everything together.

Aha! Thank you. So that's how it's done with the so called "legg-less" connector. I had worried that without the legs it would be flapping in the breeze whenever I wasn't applying hand pressure to guarantee the connections.

Another thing I like about the tag-connect is that there's no soldering involved. With the JST_SH, it's one more thing to solder, not to mention the cost of the JST connectors themselves. So, I agree with you: the amortized cost of the Tag-Connect seems reasonable to me.

-

@ejlane said in Most reliable "best" radio:

I prefer the type without the locking pins, and then there's a little board that you slide on the alignment pins from the back to hold everything together.

Aha! Thank you. So that's how it's done with the so called "legg-less" connector. I had worried that without the legs it would be flapping in the breeze whenever I wasn't applying hand pressure to guarantee the connections.

Another thing I like about the tag-connect is that there's no soldering involved. With the JST_SH, it's one more thing to solder, not to mention the cost of the JST connectors themselves. So, I agree with you: the amortized cost of the Tag-Connect seems reasonable to me.

@NeverDie Yes, though sometimes you have to dig a bit on their site to find them. Here's the one for use with the 6 pin tag-connect: https://www.tag-connect.com/product/tc2030-retaining-clip-board-3-pack

They don't automatically come with the cables, which could be a pain if you didn't know to add them to the order. Though this way I guess if they wear out it's easy to just buy the one without the other...

-

@NeverDie Yes, though sometimes you have to dig a bit on their site to find them. Here's the one for use with the 6 pin tag-connect: https://www.tag-connect.com/product/tc2030-retaining-clip-board-3-pack

They don't automatically come with the cables, which could be a pain if you didn't know to add them to the order. Though this way I guess if they wear out it's easy to just buy the one without the other...

@ejlane said in Most reliable "best" radio:

They don't automatically come with the cables, which could be a pain if you didn't know to add them to the order.

Uh, which cables do I need to add? I thought the Tag-Connect came with a cable already built into it. Unfortunately, none of them seem to come with Dupont wires on the other end of them, so it looks as though I may need to build some kind of adapter board to make use of the cable-connectors it does come with.

-

Apple's AirTag measures in at 1.26 inches in diameter, and it has a height of 0.31 inches, or 32mm and 8mm respectively.

Part of that is going to be due to the inevitable bulk of the surrounding enclosure, yet I think I might be able to get in the ballplark to the same dimensions with a DIY solution that leverages inexpensive sample containers as the enclosure:

https://www.amazon.com/gp/product/B00YOS7N4A/ref=ox_sc_saved_image_4?smid=AS7VB9OCJNT4I&psc=1

I say that because a surface mount CR2032 holder needs a footprint of around 25mm in diameter. That allows for a little extra space for the module antenna to overhang without hovering over the GND plane. That means I can craft a solution that's close to the one I had already done 5 years ago:

https://www.openhardware.io/view/510/Multi-Sensor-TempHumidityPIR-LeakMagnetLightAccel

but this time it can be just an MCU (nF52805 this time around) with a buzzer and LED, without the need for all the other bells and whistles. I'll try to see whether I can fit a Tag-Connect footprint onto it. I'm fairly sure it can be done. By the way, I've looked at a lot of nRF52 "beacons", and none of them come with a buzzer, nor would it be easy to add one, so that's what necessitates this as a DIY project. The only reason the earlier project had the big 10pin box connector was that it was very easy to plug it into an nRF52-DK for J-TAG using just an IDE ribbon cable with that particular connector. With time comes better options, and so this time it'll be ixnay to the box connector. -

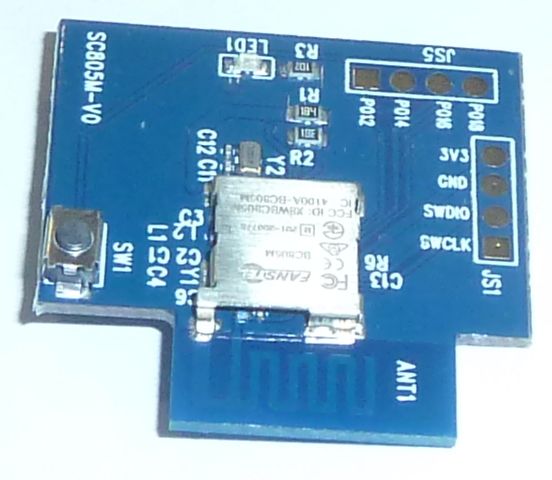

I had to open one up to get this photo, but this is what the inside of a Fanstel beacon looks like:

Obviously it's meant to be programmed with pogo pins. Interestingly, although the case is black, it has some translucency to it, so maybe the LED can shine through it enough to be visible.

It has one intriguing feature though that none of the aliexpress beacons have, which is that they also expose 4 other pins along the JS5 connector outline. This opens the possibility that with the right ultra-thin buzzer, the right resistor, some UV glue, and some solder, it just might be possible to kludge a buzzer onto this board and still fit it back in its case, which looks like this:

which has dimensions: 30x31x10mm (9300 mm^3) , which is just a tad narrower than the Apple AirTag but 2mm thicker. Assuming that the apple airtag is fully optimized for size, I'd say that's pretty good. As a further datapoint, my el cheapo keyfinder tag that I took apart earlier in this thread is 47x31x6mm (8,742 mm^3), so thinner than either than either the AirTag or the Fanstel, but obviously 50% longer. Being circular, the airtag has the least volume, at just 6,430 mm^3, whereas the sample case I linked above has a radius of 31mm but a thickness of 15mm, giving it a volume of 11,114 mm^3, so hopefully I can find a thinner sample jar with less volume to repurpose for my DIY enclosure, although given the cheap price for sample jars I could certainly live with 15mm if I can't find better. I do like that the sample jars appear to be very clear, and since they're acrylic, I assume (?) they won't yellow if kept away from UV light sources like the sun.Anyhow, I estimate that a 2mm thick buzzer might not exceed the height limitation imposed by the casing, so today I ordered a few different 2mm thick buzzers from mouser to try and see if I get lucky. :face_with_rolling_eyes: If that fails, then there does exist at least one buzzer that's 1.9mm thick that might be able to squeeze in, but that appears to be the minimum possible buzzer thickness, at least for what's available on Mouser. In general thinner means both less loud and more expensive, so there's that as a trade-offs.

-

@NeverDie Yes, though sometimes you have to dig a bit on their site to find them. Here's the one for use with the 6 pin tag-connect: https://www.tag-connect.com/product/tc2030-retaining-clip-board-3-pack

They don't automatically come with the cables, which could be a pain if you didn't know to add them to the order. Though this way I guess if they wear out it's easy to just buy the one without the other...

@ejlane said in Most reliable "best" radio:

They don't automatically come with the cables, which could be a pain if you didn't know to add them to the order. Though this way I guess if they wear out it's easy to just buy the one without the other...

I ordered this one: https://www.tag-connect.com/product/tc2030-idc-nl-10-6-pin-plug-of-nails-spring-pin-cable-with-0-1-ribbon-connector-10-version

and it looks to me as though the cable will be baked right into it. I ordered the 2.54mm pitch cable connector because it should be relatively easy to create an adapter board for it using 2x3 male pin header that I already have.I also ordered the little holder pieces that you mentioned: https://www.tag-connect.com/product/tc2050-clip-3pack-retaining-clip though I didn't buy their $1 paper clip for holding it. Sheesh! The audacity.

-

@alphaHotel Thanks for your post. It reminded me that for one-time programming, all one really needs is just the through-holes on the board. You can then bend the pins on a male header to create a kind of "weave" pattern, and that alone is enough to hold it into place during the programming, after which you can simply remove it. I've confirmed this works at 2.54mm pitch, and so I'll try it at 1.27mm pitch. I expect it should work well with that too.

I did find this video, which makes it seem fairly straightforward to set up a custom bed of nails:

https://www.youtube.com/watch?v=_ILqQ1kpqEQbut he did say during the Q&A that it took him 4 days to design it. However, with the benefit of knowing his solution, I don't think it should take anywhere near that long to design just the PCB part of it. Maybe an hour, give or take? Someday I'm going to try it. His approach to the push-pin alignment seems quite simple and, I would think, should be easy to adapt to a whole range of different targets.

@NeverDie said in Most reliable "best" radio:

@alphaHotel Thanks for your post. It reminded me that for one-time programming, all one really needs is just the through-holes on the board. You can then bend the pins on a male header to create a kind of "weave" pattern, and that alone is enough to hold it into place during the programming, after which you can simply remove it. I've confirmed this works at 2.54mm pitch, and so I'll try it at 1.27mm pitch. I expect it should work well with that too.

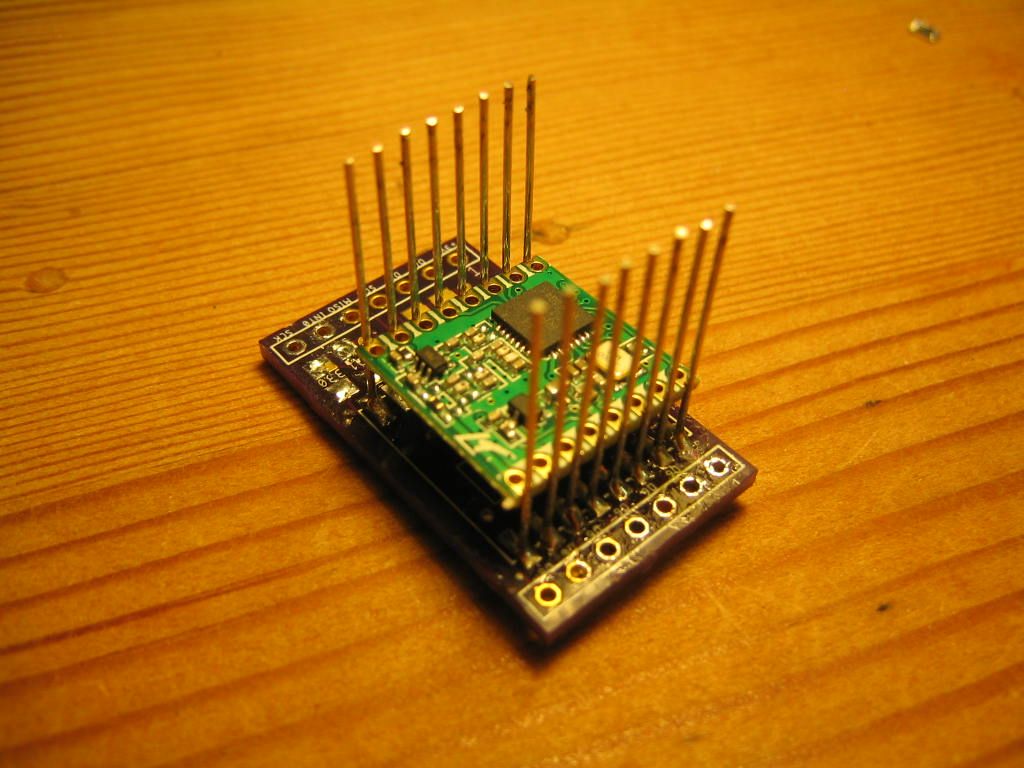

Those castellated notches of the RFM69XXX radios and ESP12 radios appealed to me as an opportunity to use springs in a different way. I think I talked about that in an earlier post. Well, I designed one based on NeverDie's radio boards and the picture below is how it turned out. For the springy things I used high-carbon-wire (guitar strings.) I had to cut the wire with a Dremel grinder because shears would bend the wire at the cut. The springs don't need to be nearly this long, though it does allow for a lot of flex when entering the jig at the top. At the pads on the board I used large via's (about 21 mills, I think) so that I could solder both sides of the board for rigidity. This would all for the rapid testing of dozens of radios if necessary.

As you know, I am having trouble with bootloading so I haven't implemented the idea yet. But I'm really pleased at how the dimensions worked out and the spring tightness. I got this idea from looking at RJ45 connectors and thinking that I could do something like that.

I tried a few pogo-pin designs for ESP programming, and they work... but not easily. This design is a snap. I think I left behind the design files.

-

Clever! Thanks for your post. Exactly which type of guitar strings do you buy that work the best? i.e. do you try to match the castellation diameter with the diameter of the string? Also, regarding your layout for them on the PCB, how do you decide where to position them? i.e. do you use a formula or something, or do you eyeball it and take a WAG? And how do you keep them perpendicular to your PCB while you solder them? Or do you just fit a bunch in, force in the part, and then use the tension to hold them in place while you solder?

-

@alphaHotel Thanks for your post. It reminded me that for one-time programming, all one really needs is just the through-holes on the board. You can then bend the pins on a male header to create a kind of "weave" pattern, and that alone is enough to hold it into place during the programming, after which you can simply remove it. I've confirmed this works at 2.54mm pitch, and so I'll try it at 1.27mm pitch. I expect it should work well with that too.

I did find this video, which makes it seem fairly straightforward to set up a custom bed of nails:

https://www.youtube.com/watch?v=_ILqQ1kpqEQbut he did say during the Q&A that it took him 4 days to design it. However, with the benefit of knowing his solution, I don't think it should take anywhere near that long to design just the PCB part of it. Maybe an hour, give or take? Someday I'm going to try it. His approach to the push-pin alignment seems quite simple and, I would think, should be easy to adapt to a whole range of different targets.

@NeverDie said in Most reliable "best" radio:

Exactly which type of guitar strings do you buy that work the best? i.e. do you try to match the castellation diameter with the diameter of the string?

The brand is D’addario, I think. It measures 22 mills, and yes, I was trying to fit the diameter of the castellation. Looking online I see there are many different types, but I just asked for high carbon steel at the local music store.

@NeverDie said in Most reliable "best" radio:

Also, regarding your layout for them on the PCB, how do you decide where to position them? i.e. do you use a formula or something, or do you eyeball it and take a WAG?

It was a calculated WAG, but it worked. I wanted the rows of vias to be about 10 to 20 mills closer than the radio’s two rows of castellated pockets. The distance between the radio's castellated surfaces measures 616.5 mills. The distance between the via centers is 622.0 mills. Subtracting the 23-mill hole diameter would result in the via surface-to-surface distance on the board of 599 mills. The 17.5 mill difference (616.5 - 599) means the radio would not be able to slide all the way to the bottom. When engaged, the radio slides down within 1/4 inch of the board while the springs tops splay outward slightly.

@NeverDie said in Most reliable "best" radio:

And how do you keep them perpendicular to your PCB while you solder them?

You are asking all the right questions. Since OSH Park gave me 3 boards, I used one at each end of the wire. I think I used some blue-tac under the target board and maybe some blue-tack, or tape, to hold the place-holder board at the other end of the springs. Then I soldered top pads of the target board, flipped the assembly over, remove the target blue-tac, and soldered the bottom via surface.

To do this again, I would add SMD pads on the bottom of the board that would give more soldered rigidity to the spring base. I also had some slight alignment problems as the vias are not exactly straight. It was my first KiCad project; thank you for encouraging me to try. KiCad probably has an alignment tool. The other change I might make is to cut the wires down to about 0.5-inch, or less. The existing 0.9-inch length was helpful for assembly and soldering access, but my fear is that each of these longer wires form a potential antenna. I wouldn't change any of the other dimensions.

You are welcome to 'my' KiCad file based on your design. Is there somewhere that I can drop it. I can't do it here.