Sensebender Micro

-

@bjacobse Yes and no :-)

Yes 100% is outside of the spec.

And no. 33% with Magnesium Chloride Hexahydrate is inside the spec and I get 40% instead of 33-34%.

Max off should be 3% above or? Means 37% - but fair enough. Should be ok for household use.

@nivoc said:

@bjacobse Yes and no :-)

Yes 100% is outside of the spec.

And no. 33% with Magnesium Chloride Hexahydrate is inside the spec and I get 40% instead of 33-34%.

Max off should be 3% above or? Means 37% - but fair enough. Should be ok for household use.

I hope the Temp measurements are not off by that much.

i don't need .00001 accuracy or anything. but i feel a big difference between 70 and 72 in my house. -

@nivoc said:

@bjacobse Yes and no :-)

Yes 100% is outside of the spec.

And no. 33% with Magnesium Chloride Hexahydrate is inside the spec and I get 40% instead of 33-34%.

Max off should be 3% above or? Means 37% - but fair enough. Should be ok for household use.

I hope the Temp measurements are not off by that much.

i don't need .00001 accuracy or anything. but i feel a big difference between 70 and 72 in my house. -

@bjacobse Yes and no :-)

Yes 100% is outside of the spec.

And no. 33% with Magnesium Chloride Hexahydrate is inside the spec and I get 40% instead of 33-34%.

Max off should be 3% above or? Means 37% - but fair enough. Should be ok for household use.

-

@nivoc

Yes you are right, +-3 from your humidity solution on 33%, then the reading could be in the interval 33-3=30% or up to 33+3=36% and should not show 40%did you get same false readings from other sensebender humidity sensors?

@bjacobse Yes I have 3 sensbener running from 2 different orders. All 3 are very near by each other. So at 33% they all read something near to 40%.

I have 4 more sensbenders to build. However I continue to test tonight with a Boveda-Pack that claims to bring the hum in a containter to exactly 69%. I did 4 test's so far and also used different technics. So i get more and more confident.

But the very good thing is - it looks every reproducible. So the value may be off but reproducable accurate off by about 8%. When I completed my test it will be very easy to correct it within the software.

-

@nivoc said:

@bjacobse Yes and no :-)

Yes 100% is outside of the spec.

And no. 33% with Magnesium Chloride Hexahydrate is inside the spec and I get 40% instead of 33-34%.

Max off should be 3% above or? Means 37% - but fair enough. Should be ok for household use.

I hope the Temp measurements are not off by that much.

i don't need .00001 accuracy or anything. but i feel a big difference between 70 and 72 in my house. -

there are some measurements in the old design thread here http://forum.mysensors.org/topic/510/minimal-design-thoughts

-

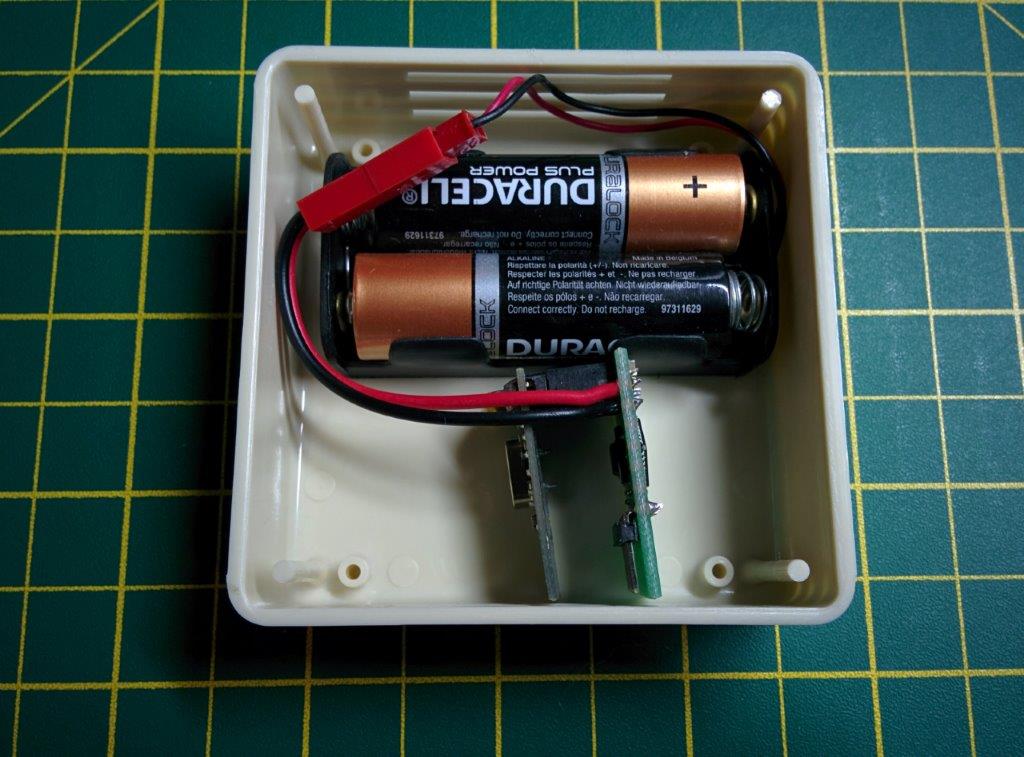

Got it from http://cpc.farnell.com/1/1/57932-evatron-pp42m-case-sensor-ivory-71x71x27mm.html.

Not the cheapest, but definitely worth the money as it is very good quality. There are other colours available (white and black) https://www.jprelec.co.uk/store.asp/c=552/Gas-Sensor-Case -

@tbowmo: I have some of these too, it's nice box. i got these from tme. cheaper :)

http://www.tme.eu/fr/details/box-sens-white/boitiers-dappar-dalarme-et-de-capt/supertronic/ -

Hello @tbowmo

Doesn't the atmega328 has only 2 pins which are D2 and D3 from external interrupts ?

I am wondering why do we waste the usage of D2 since the IRQ pin is not used in the library ? -

Hello @tbowmo

Doesn't the atmega328 has only 2 pins which are D2 and D3 from external interrupts ?

I am wondering why do we waste the usage of D2 since the IRQ pin is not used in the library ?@ahmedadelhosni because it is not in use by the library <yet>. Would be a shame if the library some day gets updated with support for a radio that can enter low power sleep and still wake when needed.

-

What @Anticimex said.. And at the time when I created the sensebender, I didn't know that the interrupt wasn't used (I was relatively new to the project) so I thought that we had to have it connected..

-

@ahmedadelhosni because it is not in use by the library <yet>. Would be a shame if the library some day gets updated with support for a radio that can enter low power sleep and still wake when needed.

@Anticimex @tbowmo This a valid point which I thought of but I needed two interrupt pins. As far as I knew from fast searching is that external interrupts which react to CHANGE in pin state are only valid for pins 2 and 3. Correct ?

Maybe there is another solution which I missed. -

And with a scalpel and a soldering iron you should be able to use both interrupts by disconnecting the one reserved for nrf24. Of course that would disable the use for rfm69 om that board.

-

And with a scalpel and a soldering iron you should be able to use both interrupts by disconnecting the one reserved for nrf24. Of course that would disable the use for rfm69 om that board.

@Anticimex Yeah I could just connect my device to the atmega pin directly as I can see/find any pin header to route the interrupt pin 2. They are all used.

Thanks guys.