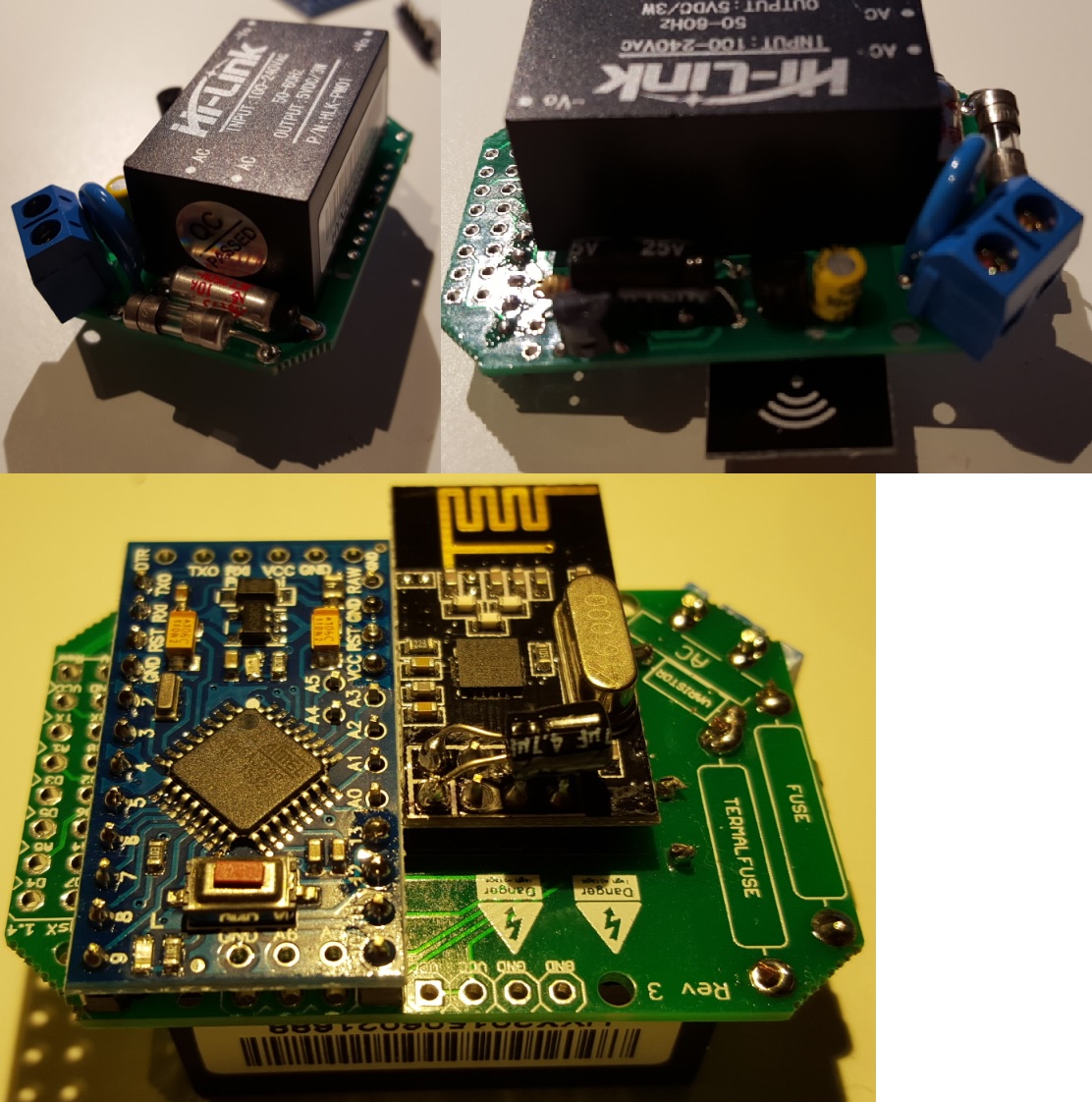

In wall - PCB, (AC to DC 5v)

-

Also, i tested the thermal fuse and that one killed/blew! Couldnt measure the exakt temp because all i had was my barbecue thermometer atm and i fired to much to fast... but it blew pretty much were it was supposed to.,

-

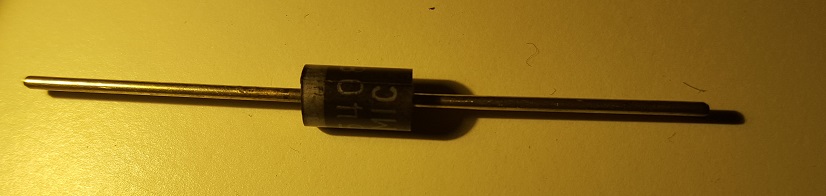

@m26872 It conducts both ways, and there is some voltage depending resistance because the volage drops and its different depending which way i put gnd.

Also, it does not blow :( so its not a fuse.

At the end i connected my vaccumcleaner (1000w) and it didnt blow, all it did was vaccum really slow so i guess its some sort of bidirectional TVS. Good find, thank you!I will keep looking for a 250v 200mA fuse (small) one - you dont happen to know one?

@sundberg84 said:

@m26872 It conducts both ways, and there is some voltage depending resistance because the volage drops and its different depending which way i put gnd.

Maybe a zener diode? Can you read some figures on it?

Also, it does not blow :( so its not a fuse.

:thumbsup: Good job with the testing!

You're welcome.

I will keep looking for a 250v 200mA fuse (small) one - you dont happen to know one?

This far I've only used standard replacable 5x20mm glass fuses and holders (preferably covered). These are safe and proven but quite bulky and hence not as convienient for our PCB designs. I've ordered a few small ones with solderlegs for testing but not yet recieved them.

-

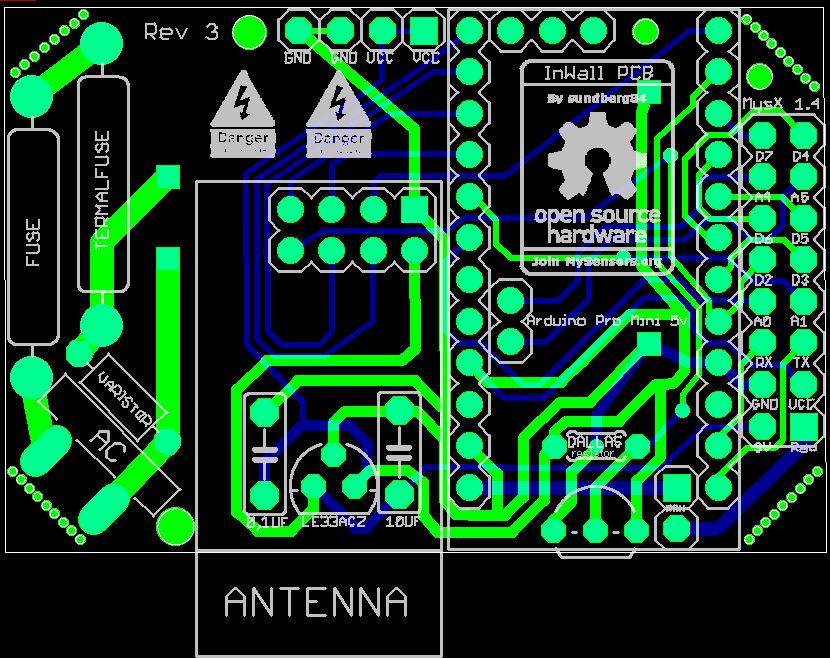

New revision ordered:

and also some new fuses:

http://www.ebay.com/itm/290767404446?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

http://www.ebay.com/itm/231765976267?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AITOf of them is 500mA but that cant matter that much?

Spec of HKL:

Maximum input current ≤0.2 A

Input current surge ; ≤10 A -

@sundberg84 Would you mind posting pictures of your fuses that turned out not to be fuses? I think a few of us ordered from the same store and I'd like to update my original post with a warning. Also, if you don't mind can you post a step by step way for to easily test? If there is another way besides connecting to my vacuum cleaner that would be awesome :)

@m26872 & @sundberg84 can you describe in a little more detail the change of placement of the Varistor? I don't really understand why it's better to change the placement. I'd like to update my first post in this thread with the best/safest method http://forum.mysensors.org/topic/1607/safe-in-wall-ac-to-dc-transformers

Thanks!

-

@sundberg84 Would you mind posting pictures of your fuses that turned out not to be fuses? I think a few of us ordered from the same store and I'd like to update my original post with a warning. Also, if you don't mind can you post a step by step way for to easily test? If there is another way besides connecting to my vacuum cleaner that would be awesome :)

@m26872 & @sundberg84 can you describe in a little more detail the change of placement of the Varistor? I don't really understand why it's better to change the placement. I'd like to update my first post in this thread with the best/safest method http://forum.mysensors.org/topic/1607/safe-in-wall-ac-to-dc-transformers

Thanks!

-

I now have my boards in transit on their way to me as we speak @sundberg84, the next revision will see some development towards some AC/DC conversion i think. However i have a lot of work to do, a lot of learning electronics before i go anywhere near to installing a AC/DC converted board into my wall. Safety first and all that jazz! I love the look of your board layout with the arduino being a add-on board essentially. So as soon as i have my battery version up, working and dialed in for performance, i will be using your board as a learning curve for some AC/DC powering. I actually have printed the above picture of your board out and i'm creating a schematic of it, using it to learn the steps you have taken to get your power to the arduino. I love the fact you have added a temp sensor in there, i'm not too sure why you did that (your personal requirements) but i would love to use this as another trip out sensor to cut the board's power if it detects it getting too hot inside of the socket.

By creating my own i'm not trying to better or improve yours, its simply because for mine to work i would like it to be acceptable into a 29mm depth back box (29mm is with the switch back too, its pretty cramped inside these).

Lastly, is there any chance you could point me in the direction to a copy of your logo/design on the board (The open source, join MySensors.org) so i could include it into mine. I would also like to have the MySensors' official logo on my finished board too, do you know if there is any links/pages/repos to this data or would i just need to create my own as a BMP or Library device?

-

The test I did was just to strip a extension cord, attach "the fuse" to it and apply different equipment with spec from 5W up to my vaccumcl 1000+W Not proffessional but I dont have any other equipment.

I dont think we changed the placement? I made a misstake in my first rev but now my varistor placement is like your post (after both fuse and termal fuse). But @m26872 link describes it good why.

@samuel235 Good luck with your board! Do not take my board as "thats how it should be". My board is the result and my interpretation of the discussions so far in this forum. If that is right or wrong i not able to tell (yet). The tempsensor is to initially be able to measure the temp in that closed box to see that the node doesnt produce to much heat.

Im glad you are creating your own... as i said before, my wish is that we all come together and in the end create a small and safe in wall PCB. And If you want (and use Eagles) ill send over the files for the PCB. I will also post them here when i recieved the boards offcourse.

Here is my bitmap I use as a logo... in eagles you can import that to layer 21 and apply to your board.

-

The test I did was just to strip a extension cord, attach "the fuse" to it and apply different equipment with spec from 5W up to my vaccumcl 1000+W Not proffessional but I dont have any other equipment.

I dont think we changed the placement? I made a misstake in my first rev but now my varistor placement is like your post (after both fuse and termal fuse). But @m26872 link describes it good why.

@samuel235 Good luck with your board! Do not take my board as "thats how it should be". My board is the result and my interpretation of the discussions so far in this forum. If that is right or wrong i not able to tell (yet). The tempsensor is to initially be able to measure the temp in that closed box to see that the node doesnt produce to much heat.

Im glad you are creating your own... as i said before, my wish is that we all come together and in the end create a small and safe in wall PCB. And If you want (and use Eagles) ill send over the files for the PCB. I will also post them here when i recieved the boards offcourse.

Here is my bitmap I use as a logo... in eagles you can import that to layer 21 and apply to your board.

Awesome, yes if you could send me the eagle files I would really appreciate that to allow me to learn how this circuit is working. I completely understand that this is just your interpritation on how it should work. I'm using this as a kind of reference i suppose, just to learn how this is wired out, whats connected in what order etc etc. I will not take this as a 'only way to get ac power to arduino on one board' type of application, don't worry ;)

Thank you for the BMP Image, i will add the MySensors logo to the board too along side of this logo.

The parts for my board have just arrived as I was replying to this. Just waiting on the boards to come from ITead now. Time to get moving!

I have a weird feeling that 2016 will be huge for MySensors and its community!

-

@sundberg84 Thanks for the picture. It's totally different than mine. You said you got it from the same store I linked to in the "Safe in-wall" post? This is what mine looks like:

I will still test it with to be sure but I'm reassured that it at least looks different.

I dont think we changed the placement?

Sorry, you're right, my mistake. I misread/misunderstood the issue as I was reading through this thread. It was still helpful to read @m26872's link though, thanks for that!

-

The test I did was just to strip a extension cord, attach "the fuse" to it and apply different equipment with spec from 5W up to my vaccumcl 1000+W Not proffessional but I dont have any other equipment.

I dont think we changed the placement? I made a misstake in my first rev but now my varistor placement is like your post (after both fuse and termal fuse). But @m26872 link describes it good why.

@samuel235 Good luck with your board! Do not take my board as "thats how it should be". My board is the result and my interpretation of the discussions so far in this forum. If that is right or wrong i not able to tell (yet). The tempsensor is to initially be able to measure the temp in that closed box to see that the node doesnt produce to much heat.

Im glad you are creating your own... as i said before, my wish is that we all come together and in the end create a small and safe in wall PCB. And If you want (and use Eagles) ill send over the files for the PCB. I will also post them here when i recieved the boards offcourse.

Here is my bitmap I use as a logo... in eagles you can import that to layer 21 and apply to your board.

@sundberg84 Your 'fuse' looks very much like a regular diode, e.g. 1N4007:

You can easily verify by using a multimeter, or even the printing on the component could reveal its real identity.

Some sellers ship both clothes and electronic components, so maybe the seller just shipped the wrong parts? -

@Yveaux Yea, could be - its not a 1n4007 because i have those as well, and also it conducts in two ways. Anyway, you are probably right - they shipped the wrong item. @petewill I ordered from the link in safe-in-wall thread: http://www.ebay.com/itm/111433875797?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT&rmvSB=true

-

I finally had a spare minute to test my fuse. Good news, it worked! I plugged in a 13 watt florescent light bulb and it turned on. I then plugged in a 32 Watt florescent light bulb and it blew the fuse. @sundberg84 sorry you got the wrong ones! Hopefully other people who ordered got the ones that I did.

-

This post is archived!

Please use this thread to post questions:https://forum.mysensors.org/topic/2783/in-wall-ac-dc-pcb-for-mysensors

Project can be found here:

https://www.openhardware.io/view/13/In-Wall-ACDC-Pcb-for-MySensors

Hi!

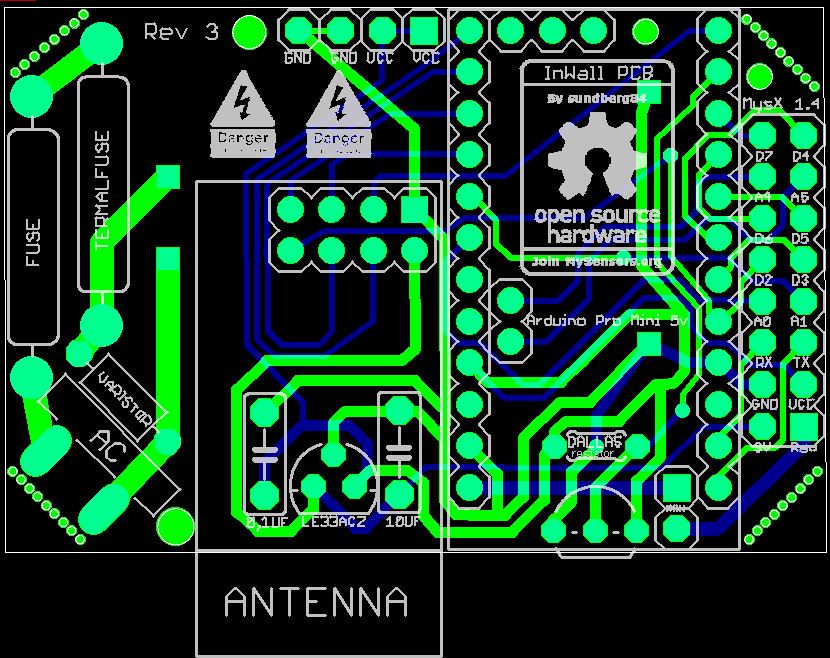

As i mentioned in another post i had this idea to stack two PCB on top of each other to fit inside a wall appliance box. This idea has evolved (see below).

Im aware of the big security risk here, and have tried to read:

- http://forum.mysensors.org/topic/1607/safe-in-wall-ac-to-dc-transformers

- http://forum.mysensors.org/topic/1540/110v-230v-ac-to-mysensors-pcb-board

EDIT 03/1/2016

After discussion on this here are the findings of this thread (as of now):I will update this post with BOM and eagles files as soon as i get a node running.

...............................

BOM/README: http://1drv.ms/1kCzue5

GERBER: InWallMySensor3.0.rar

EAGLES: InWallMySensor3.0Eagles.rar

Build images: http://1drv.ms/1lsleox

...............................If you are using this design, please know about the risks when you work with high power. This design has no guarantee s so use it on your own risk!

@sundberg84, gr8 job done....really amazing to see this one. i want to make few sensors for my home. Is the design of the board is final? Kindly guide me for the placement of LE33 and Dallas Temp as mentioned in your BOM that placement "solder Le33 + Caps (1,0, 10uf) on the pcb underside. Note the directions of the LE33 (not as silk mask!)"

Also, will it be possible for you to upload the design to http://dirtypcbs.com, as i don't have any knowledge about PCB manufacturing. it will be very easy for me to order and get the PCBs for assembly.

I am very new to all this and learning from you guys.....

Thanks

Brijesh -

@Brijesh-Mishra Thank you! Im waiting for Rev3 to arrive. It was manufactured a week ago so i guess it will arrive on 1-2 weeks. I will post and let you know the status here.

I will also update the BOM with better instructions. LE33 should be soldered on the back side which reverse the direction of the pins (VCC/OUT). This means that the nice print on silkmask (white markings how the LE33 should be mounted) is not correct.

Its a nice idea at dirtypcb, I can do that i guess!

-

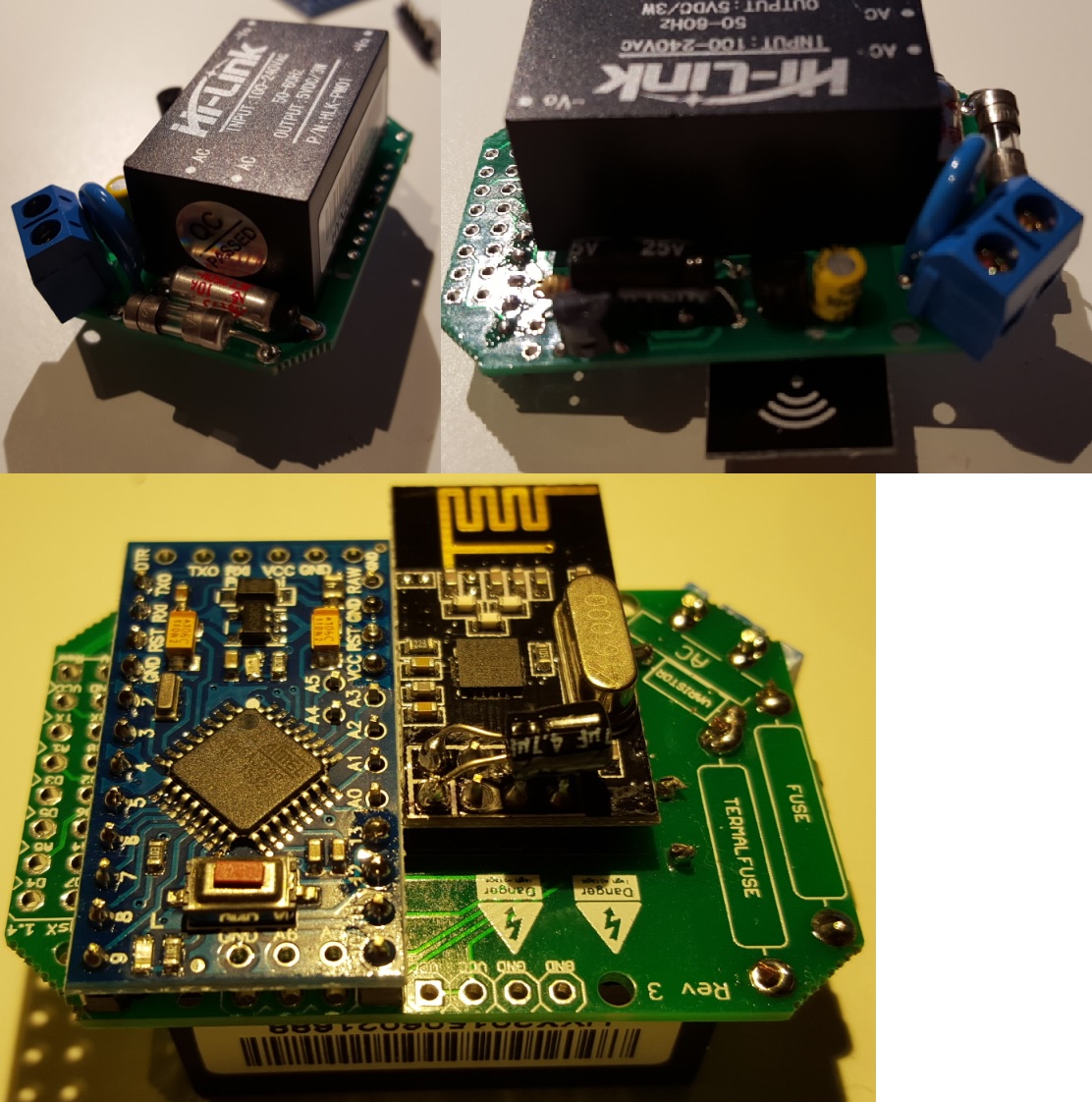

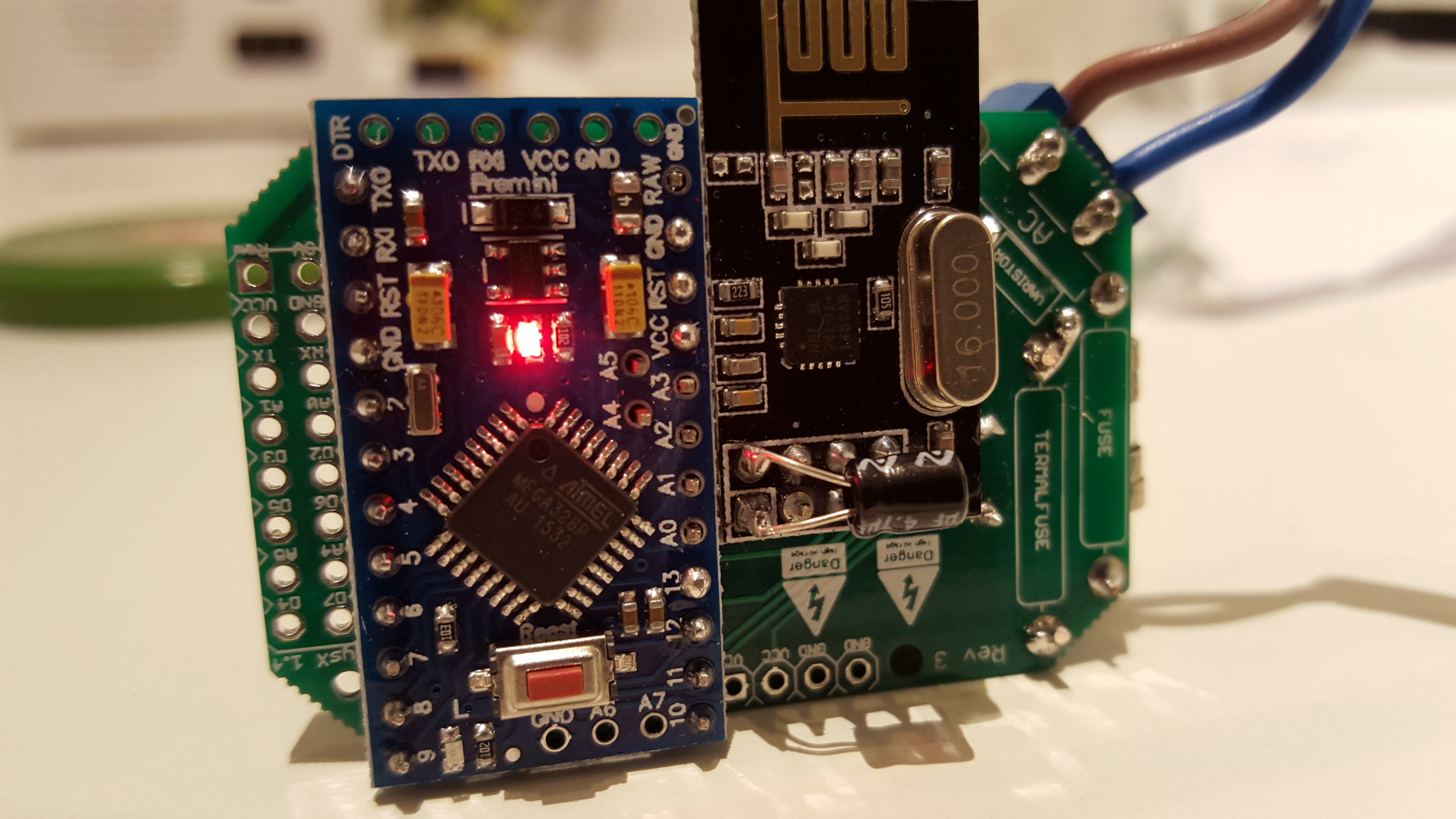

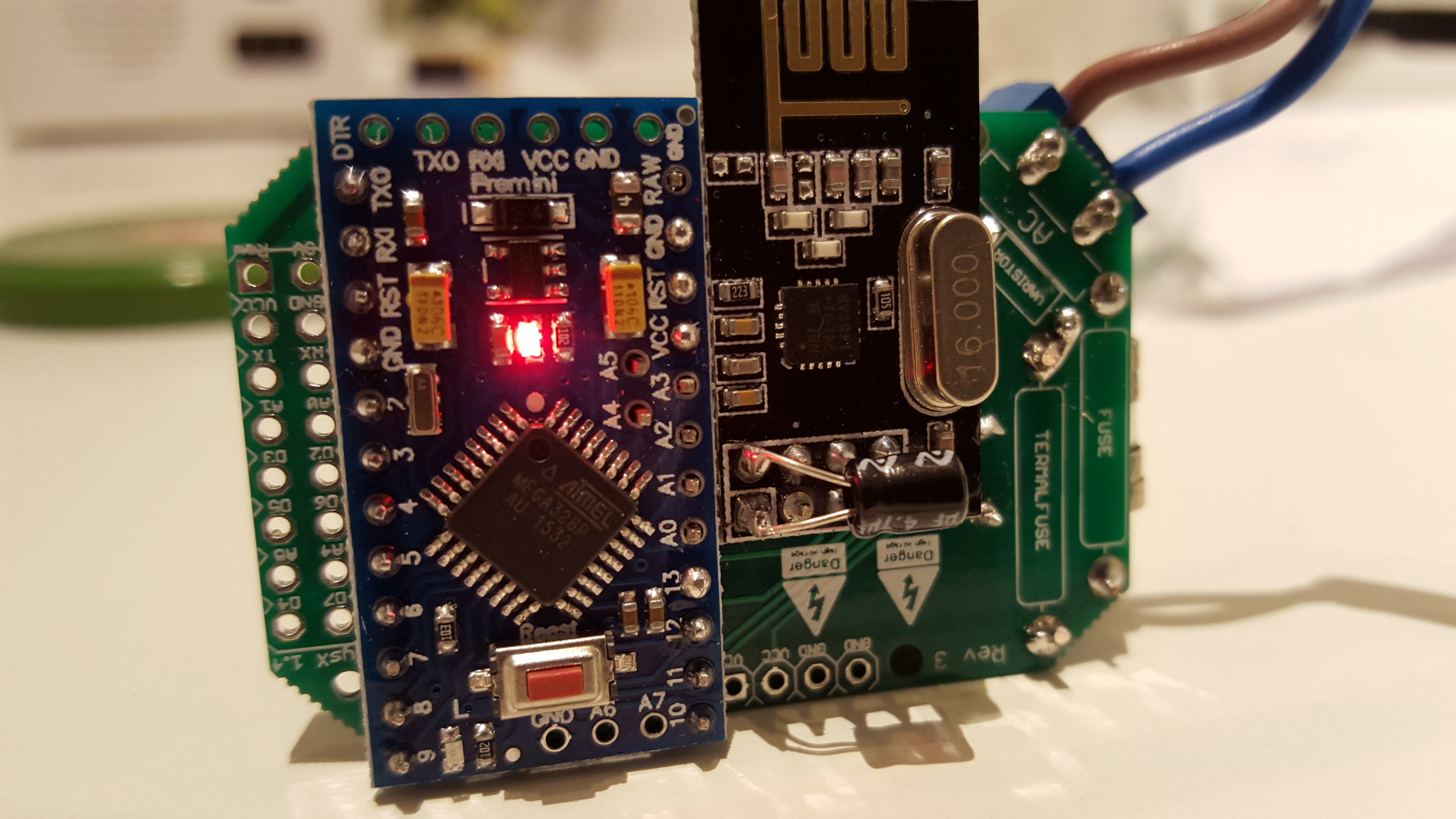

Rev 3 arrived today and its working, nice.

I soldered it togheter and uploaded a dallas temp sketch and ran it with AC power.Next step is a long time test in a small space, measuring temp.

Also it would be nice to get some tips how i can test it more... (safety check).Files and readme can be found in the first post.

Also this image for where i assemble the pcb (build).

-

Rev 3 arrived today and its working, nice.

I soldered it togheter and uploaded a dallas temp sketch and ran it with AC power.Next step is a long time test in a small space, measuring temp.

Also it would be nice to get some tips how i can test it more... (safety check).Files and readme can be found in the first post.

Also this image for where i assemble the pcb (build).

@sundberg84 This is awesome progress dude!

So in my honest opinion, from a professional tradesman plastering, tiling, stud walls, plaster boarding are my specialties, I would firstly test this inside of a back-box, outside of a wall with the front attached (like it would be in a real-life situation). Then once that passes your expectations and requirements, I would then test it inside of a back-box located inside of a wall but without the front plate screwed on. Then once that passes, I would connect the front plate and manually monitor the temps inside of the controller.

If your question was aimed more towards how to test it electronically, then i'm sorry i can't help in that department, as you already know, I'm pretty weak at electronics at the moment still.

Its awesome to see your project coming on, very swiftly too. Keep up the good work!

-

@sundberg84 - Correct me If i'm being a complete NOOB here....

Your fuses, if they are the same function as what i feel to be a 'general household fuse', could you not use a removable fuse in a holder. This way if a fuse blows/trips all you would need to do is change out the fuse. This is all depending on what caused the fuse to blow, if it was an environment issue (spike of power draw, etc) then you could just change the fuse and power back up... Rather than having to get the soldering iron out.

Again, If I have incorrectly understood the principle of the fuse in this application, please notify me.

-

@samuel235 You are right - the only problem is size.

If you find a removable fuse as small as this axial fuse please let me know!

Most are 2x20mm and the holder are bigger. -

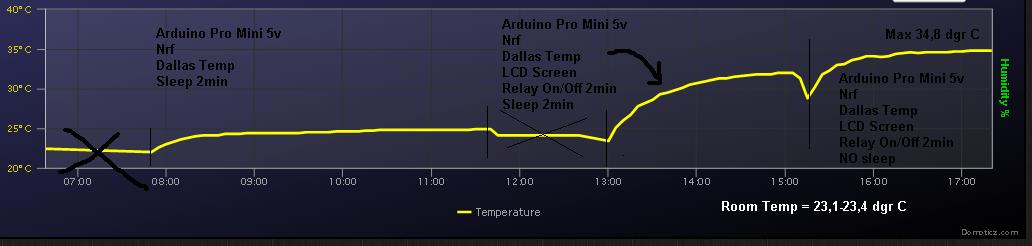

So today I have been testing temperatures inside a closed compartment with my PCB.

I drilled a hole in a metal cap to a glass bottle, put AC main through the metal cap and wrapped everything up inside. I then found some insulation material and wrapped the glas bottle up.- First test was only minimum components and sleep for two minutes.

- Second test was the same but i added a LCD screen on maximum background lights and also a relay which switched on and off every 2 minutes sleep cycle.

- Third test was to remove the sleep and used wait instead so the node was powered all the time.

No problems so far, max temp during last test was 34,8 dgr C. Here is my numbers:

Any other ideas or components i can use to try - write a post!

-- Next

So... there are some (important) questions ahead i dont know how to answer though...

- Reliability, when will it fail? (compared to a commersial product?)

- How will it fail? What is it weakest point?

- Will my safety components be enough and prevail damage... ?

- What will happen when it fails?

Anyone having thoughts... let me know.

-

@samuel235 You are right - the only problem is size.

If you find a removable fuse as small as this axial fuse please let me know!

Most are 2x20mm and the holder are bigger.@sundberg84 said:

@samuel235 You are right - the only problem is size.

Ahh okay, indeed you're right. However, what is going on the front of the in wall box? Is it still being mounted inside of a wall box, or are you have it concealed away behind the wall where you can't really get to it easily? It isn't behind a light switch/socket?