💬 Roller Shutter Node

-

Hi, there is something similar available although without an ac712. So you can't check the percentage o the shutter.

See https://github.com/JanGoe/esp8266-wifi-relay

I had one at home and it is working well. Because of the esp8266 it is directly connected to any controller using udp or MQTT or other protocols.

The only problem is the missing box. I have to admit I wouldn't put this in my wall without a proper box using AC 240 V!!!

The project you proposed is of course the most advanced. Do you think there is a smaller version available perhaps less parts on the BOM and easy to build?

Thank you very much, kduino -

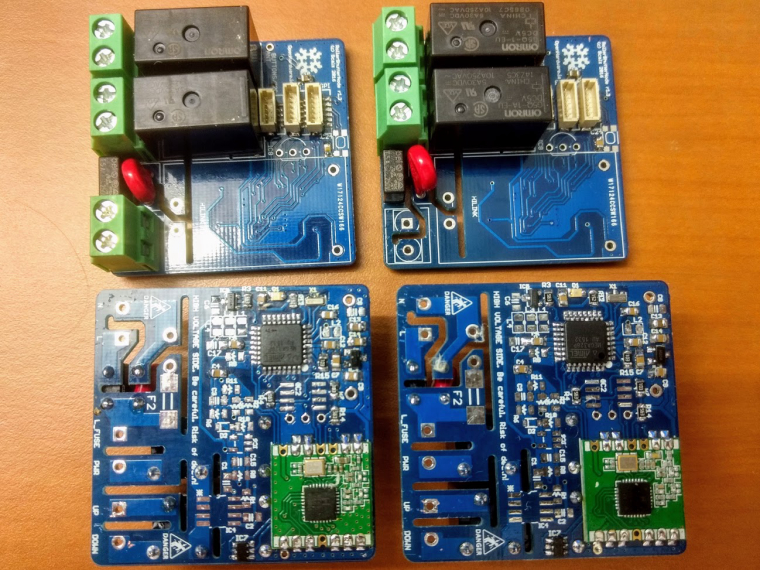

Hi, I make this project, pretty cool.

How I can upload the firmware? What I need to do?

-

@Sergio-Rodrigues

It's better to talk about this here instead of private, so other people can learn or help you ;)it's "like" programming an arduino board.

- in arduino ide, program bootloader (for these, i used the sensebender board in Board manager).

- Then, with a FTDI adapter, program the rollershutter sketch.

For more infos on programming arduino:

- see official docs from arduino website

- https://www.mysensors.org/about/fota for a bootloader programming example

What do you need to know exactly ??

-

Finnaly I find a solution with a very good WAF !

I want to keep a sort of manual command (not gateway or controller dependant) and I don't want an expensive solution (my ODACE schneider button are quite expensive and I don't want to buy other button).

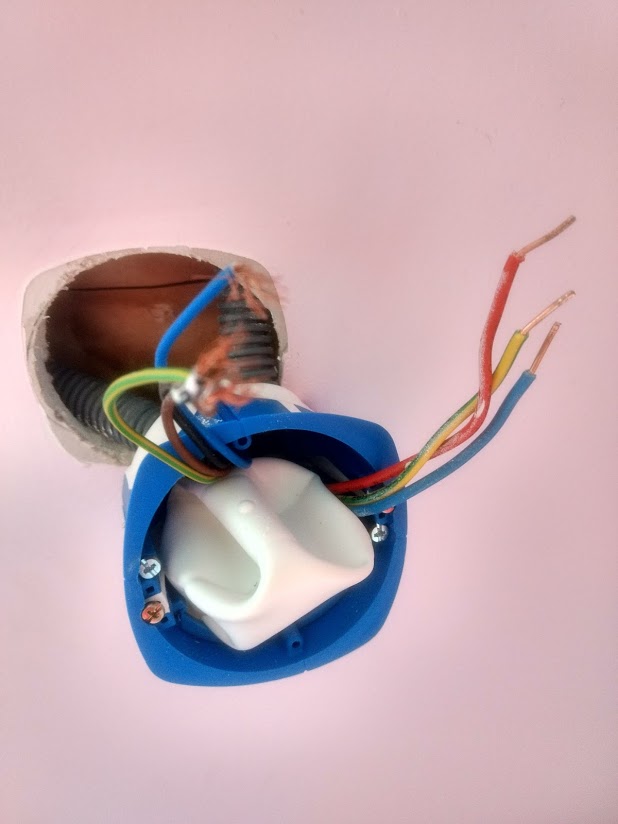

But these button measure 38mm depth and @scalz board is about 20mm. My wall boxes are 50mm !

Si I find some special wall boxes with an enclosure for home automation module. It's cheap (about 3€) and very well designed (french RT2012 compliant). I update the sketch with MY_TRANSPORT_WAIT_READY_MS so node can work alone. And I update sketch to work with bistable button. Works well on 2 windows since yesterday.

Here is a photo before :

-

Almost looks like this type type of part-rubber box that can be mounted without tearing down the wall:

https://www.eldirekt.se/elmaterial/elinstallation/infallda-dosor/multidosa-big-box

-

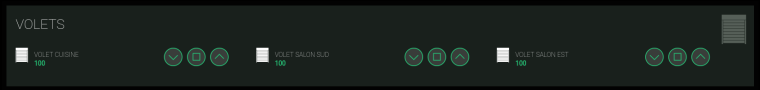

One test screenshot (not definitive) of my habpanel (openHab 2.0 part).

I'm using OpenHAB mysensors binding (from @TimO), node-red for rules, habpanel for UI, Tasker on android (for example open all RollerShuter just after morning alarm !).

I can access OpenHAB via nginx reverse proxy with https and on my LAN, home automation have a separate VLAN (for security reasons). Thanks a lot to @scalz for this module.

-

@scalz great work, sorry to dig up the topic, but good topics never die ( :) ). Can you clarify some questions?

- Way did you used 2 different relays? Way not only one type?

- What is the Amp consumption of your motors? I know that 10A is overkill, but just to get one idea. Would 2A do it? (at 220V)

- I see that you added a 8Mhz Cristal, way not use the internal clock? It's 8Mhz

- I see that you use a relay driver, correct me if I'm wrong, that is because the rated coil consumption to those relays is 80mA.

Thank You

Great Work -

@Soloam

2 relay for interlocking system and add more security.

I never mesure my current but it's low ... not 10A !

Internal clock is not very precise and can vary with external parameters like temperature. And for this project it's better to have good precision.

It's always better to use relay driver and not directly arduino pin. -

@Soloam

2 relay for interlocking system and add more security.

I never mesure my current but it's low ... not 10A !

Internal clock is not very precise and can vary with external parameters like temperature. And for this project it's better to have good precision.

It's always better to use relay driver and not directly arduino pin.@fabien said in 💬 Roller Shutter Node:

@Soloam

2 relay for interlocking system and add more security.

I never mesure my current but it's low ... not 10A !

Internal clock is not very precise and can vary with external parameters like temperature. And for this project it's better to have good precision.

It's always better to use relay driver and not directly arduino pin.Thank you @Fabien all very clarifying, only one thing that I don't understand (sorry, but I like to use this projects to learn and improve my personal knowledge) I still don't understand way the relays are different model numbers, from what I can see, one is 4 pins, and the other 5 pins, or I'm miss interpreting?

Thank you

-

@Soloam

about relays, imagine there would be two same relays:-

two SPDT would not make sense here, plus it would add more pins.

-

two SPST wouldn't be secure, there could be a moment where you could have both relays activated (for example in case pins are not well set on startup, or of bad sketch). That would not be great for motor.

So there is one (SPST) to enable power flowing to the SPDT which toggle between UP or DOWN. -

there are parts on my schematic which could be optional. I always put as much footprints as I can, for reference, and especially when I need to fix something it's handy.

Sure crystal could be optional, and you could burn sensebender bootloader for example, or like fabien said it's good to have. It's an AC powered node, so not really needed to try saving something. And also, if you're paranoid about sourcing cheap, and why not out of specs, atmel on aliexpress, then you have the footprints available. -

the relay driver is nice because it helps protecting atmel and improve reliability. It integrates all parts for relays in one package (transistors, diodes, resistors etc.) so it simplifies schematic and takes less place on pcb too.

-

10amp omron relays, better oversize, so you're sure they won't suffer :) and the board can be used for other stuff needing more power than rollershutters in case.

-

-

@Soloam

about relays, imagine there would be two same relays:-

two SPDT would not make sense here, plus it would add more pins.

-

two SPST wouldn't be secure, there could be a moment where you could have both relays activated (for example in case pins are not well set on startup, or of bad sketch). That would not be great for motor.

So there is one (SPST) to enable power flowing to the SPDT which toggle between UP or DOWN. -

there are parts on my schematic which could be optional. I always put as much footprints as I can, for reference, and especially when I need to fix something it's handy.

Sure crystal could be optional, and you could burn sensebender bootloader for example, or like fabien said it's good to have. It's an AC powered node, so not really needed to try saving something. And also, if you're paranoid about sourcing cheap, and why not out of specs, atmel on aliexpress, then you have the footprints available. -

the relay driver is nice because it helps protecting atmel and improve reliability. It integrates all parts for relays in one package (transistors, diodes, resistors etc.) so it simplifies schematic and takes less place on pcb too.

-

10amp omron relays, better oversize, so you're sure they won't suffer :) and the board can be used for other stuff needing more power than rollershutters in case.

@scalz this is a great work, I'm planning on ordering a couple to use on my system.

Besides that, I'm most interested in the integrated Current Sensor, and planning on use it on my one PCB. I've been studding your PCB layout and reading regarding the ACS712 and is integration with the LM321. Way didn't you use the schematic on the ACS712 DataSheet (http://henrysbench.capnfatz.com/henrys-bench/arduino-current-measurements/acs712-current-sensor-user-manual/ page 12) to integrate with the LM321? I see that you use a lot more resistors and caps, and the values are not the same. Was this intencional or you did it to reuse a footprint? Would the layout on the DataSheet also work in you board? (From what I can tell it changes the sensitivity).

Also I see a couple 0 Ohm resistor, I think that that is to reuse footprints correct?

Thank you for your help and contribute to the community.

-

-

@Soloam

Your link is about DC. He has another howto for AC, which is based on sampling adc but i was not interested in this one. I didn't want the current measurement dependant on sampling reliability and misses.

So I used part of datasheet schematic, and I adjusted it to my application. If you use it in another projects, you may need to adjust resistor divider etc.

0ohms needs to be soldered. -

Hi,

I have been searching for a longtime for some decent rollershutter solution. I have about 12 of them and i am currently using a sonoff relay solution which works but i never really know the position if it is open or closed or pourcentage position.

What your solution seems to do.

Is it possible to interface this with amazon echo or google home to ask to open/close the shutter but also ask the status. Are my shutters open or closed? Or open window shutter 1 at 50%?

Also there is a link to purchase 10 pcb at 21$ is the the complete solution (plug &play, including relays, connectors,,,) or is it just the board and do i need to solder everything my self?

Thank you and great job at doing this! :)

-

Hi,

Where could i buy a finished version of this hardware?