💬 Battery Powered Sensors

-

Ok try to remove the jumper between V+ and AREF

-

Ok try to remove the jumper between V+ and AREF

@tonnerre33 That was it!

I'm getting Battery Voltage: 3.10 V

Battery percent: 92 %Thank you so much :)

Starting sensor (RNNNA-, 2.0.0)

TSM:INIT

TSM:RADIO:OK

TSP:ASSIGNID:OK (ID=101)

TSM:FPAR

TSP:MSG:SEND 101-101-255-255 s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=bc:

TSP:MSG:READ 0-0-101 s=255,c=3,t=8,pt=1,l=1,sg=0:0

TSP:MSG:FPAR RES (ID=0, dist=0)

TSP:MSG:PAR OK (ID=0, dist=1)

TSM:FPAR:OK

TSM:ID

TSM:CHKID:OK (ID=101)

TSM:UPL

TSP:PING:SEND (dest=0)

TSP:MSG:SEND 101-101-0-0 s=255,c=3,t=24,pt=1,l=1,sg=0,ft=0,st=ok:1

TSP:MSG:READ 0-0-101 s=255,c=3,t=25,pt=1,l=1,sg=0:1

TSP:MSG:PONG RECV (hops=1)

TSP:CHKUPL:OK

TSM:UPL:OK

TSM:READY

TSP:MSG:SEND 101-101-0-0 s=255,c=3,t=15,pt=6,l=2,sg=0,ft=0,st=ok:0100

!TSP:MSG:SEND 101-101-0-0 s=255,c=0,t=17,pt=0,l=5,sg=0,ft=0,st=fail:2.0.0

TSP:MSG:SEND 101-101-0-0 s=255,c=3,t=6,pt=1,l=1,sg=0,ft=1,st=ok:0

TSP:MSG:SEND 101-101-0-0 s=255,c=3,t=11,pt=0,l=13,sg=0,ft=0,st=ok:Battery Meter

TSP:MSG:SEND 101-101-0-0 s=255,c=3,t=12,pt=0,l=3,sg=0,ft=0,st=ok:1.0

Request registration...

TSP:MSG:SEND 101-101-0-0 s=255,c=3,t=26,pt=1,l=1,sg=0,ft=0,st=ok:2

TSP:MSG:READ 0-0-101 s=255,c=3,t=27,pt=1,l=1,sg=0:1

Node registration=1

Init complete, id=101, parent=0, distance=1, registration=1

922

Value A0 before force reference: 924

Value A0 after force reference: 923

Battery Voltage: 3.10 V

Battery percent: 92 %

TSP:MSG:SEND 101-101-0-0 s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=ok:92 -

can Li 18650 3.7 batteries be used as they are rechargeable ? knowing the max voltage at full might reach 4.1-4.2v ? maybe keeping the voltage regulator ?

@Meshx86 yes they can be used but as you've already identified the nrf (and maybe other components) will need to be protected from the high voltage when the battery is full.

The self-discharge rate of li-ion is higher than alkaline batteries which might affect how long the node can run before it needs charging.

-

Hi,

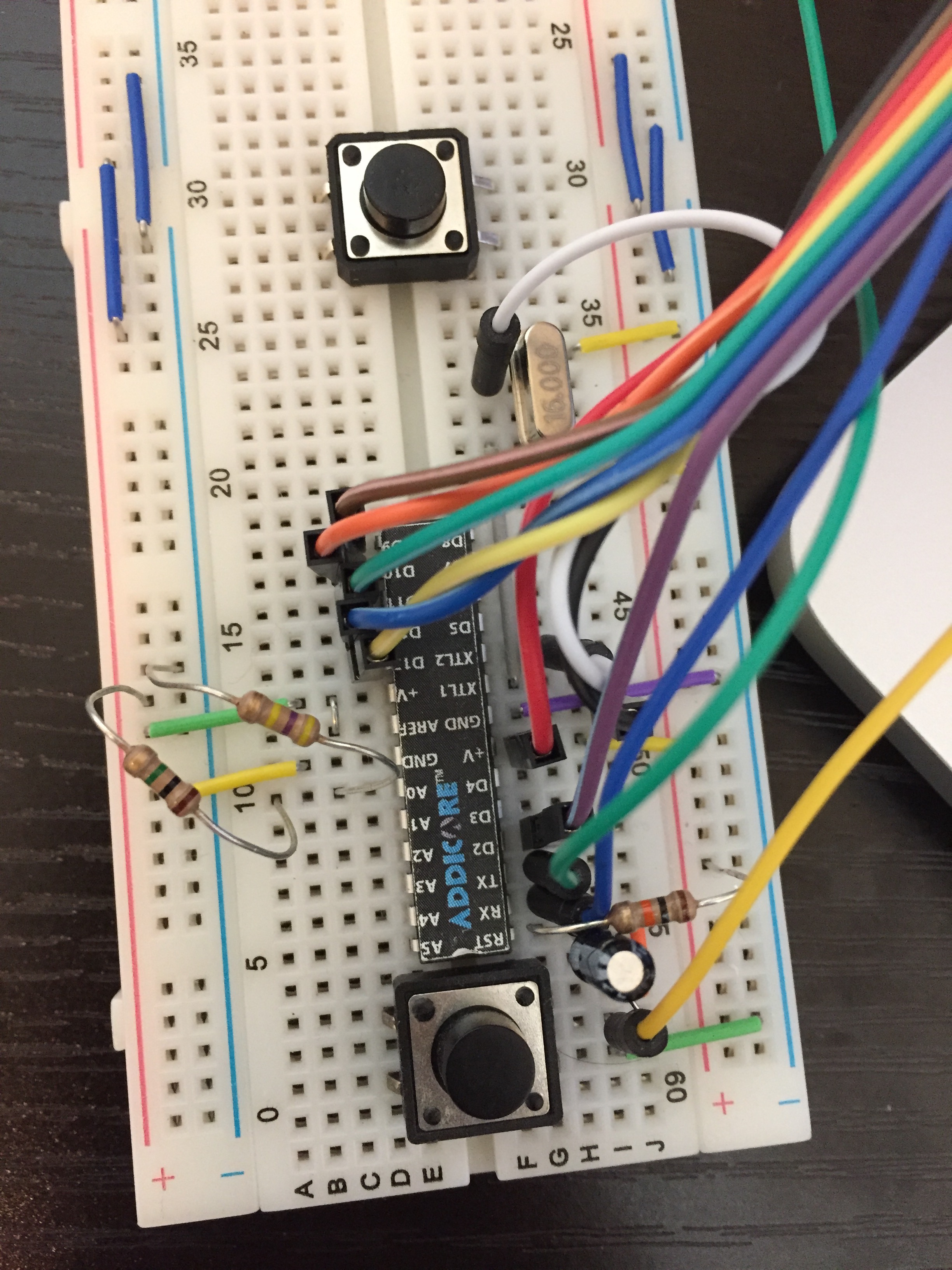

I just built the circuit which is explained in the thread with a Pro Mini 3.3 8 mHz

So far so good, I can read the voltage of the battery etc but my problem is, it consumes about 1.2 mA while in sleep, this is about factor 10 of the findings from the thread.

I just copied the code 1:1

Any glue what could be wrong or what get others with that setup? The Arduino is not modified at all.Thanks

SJ -

Hi,

I just built the circuit which is explained in the thread with a Pro Mini 3.3 8 mHz

So far so good, I can read the voltage of the battery etc but my problem is, it consumes about 1.2 mA while in sleep, this is about factor 10 of the findings from the thread.

I just copied the code 1:1

Any glue what could be wrong or what get others with that setup? The Arduino is not modified at all.Thanks

SJ@parachutesj you have to modify the pro mini. Remove the power led according to instructions!

-

@parachutesj you have to modify the pro mini. Remove the power led according to instructions!

@Nicklas-Starkel thank you. If one could read...

I read the description again and thought that it should be 120uA stock and when removing LED and regulator it will even go down further but thinking about it, how should at base 120 uA and removing LED save additional 1.5mA???? LOL, sorry was a long day.My Fluke reads 0.044 mA in sleep now (without LED). Sweet!

-

Another battery related question that I really do not understand.

Are there different versions on how to read battery consumption?I see some sketches uses:

long readVcc() { long result; // Read 1.1V reference against AVcc ADMUX = _BV(REFS0) | _BV(MUX3) | _BV(MUX2) | _BV(MUX1); delay(2); // Wait for Vref to settle noInterrupts (); // start the conversion ADCSRA |= _BV (ADSC) | _BV (ADIE); set_sleep_mode (SLEEP_MODE_ADC); // sleep during sample interrupts (); sleep_mode (); // reading should be done, but better make sure // maybe the timer interrupt fired while (bit_is_set(ADCSRA,ADSC)); result = ADCL; result |= ADCH<<8; result = 1126400L / result; // Back-calculate AVcc in mV```However some (like the original one in this thread) uses:

int sensorValue = analogRead(BATTERY_SENSE_PIN);Is it due to different libraries or maybe it is the same but just programming wise different?

-

If you are using the first sketch you dont have to use a seperate pin to measure the input voltage. There are also no resistors.

You can run this on a bare ATmega with minimal hardware.

@gloob thanks!

One would think running with no resistors and not using a separate PIN would be better.@hek or @mfalkvidd , any comments as to why the original sketch is preferred over the other 'way' in this article?

-

@gloob thanks!

One would think running with no resistors and not using a separate PIN would be better.@hek or @mfalkvidd , any comments as to why the original sketch is preferred over the other 'way' in this article?

-

@hek , I've read that post several times :)

Since it was so outdated (2 years) I naturally assumed the 'battery powering article' was a newer way to do it (especially since mys2.0).

Also, the post you linked to is attributed if you use no voltage regulator.

And in the article this is also one of the things you are recommended to remove, hence making it even more confusing as to why the article describes another way than the post. -

i just want to get this once and for all, so others coming by gets it directly instead of going through all the 2 threads posts, please correct me if i am wrong:

1- using the voltage divider is needed if there is a voltage regulator / booster where where VBatt != Vcc.

2- using the voltage regulator is not needed if the voltage regulator is removed / no booster is used (powering directly from 2 x AA batteries) where VBatt == Vcc.*I've noticed the 2nd method requires inputting battrie's DMM measured values vs arduino ones for correction, is this a down side if you need to change the battery later on ? or is it just programmed once ? and does the 1st method rquirs these corrections too ?

Cheers

-

i just want to get this once and for all, so others coming by gets it directly instead of going through all the 2 threads posts, please correct me if i am wrong:

1- using the voltage divider is needed if there is a voltage regulator / booster where where VBatt != Vcc.

2- using the voltage regulator is not needed if the voltage regulator is removed / no booster is used (powering directly from 2 x AA batteries) where VBatt == Vcc.*I've noticed the 2nd method requires inputting battrie's DMM measured values vs arduino ones for correction, is this a down side if you need to change the battery later on ? or is it just programmed once ? and does the 1st method rquirs these corrections too ?

Cheers

@Meshx86

actually, you need a voltage divider if the voltage to be measured is above the maximum allowed by the processor at the speed you are running it.If Vcc is 5V, then any voltage above 5V should be measured via a voltage divider.

If Vcc is 3.3V same principle, but you could get away with measuring 5V directly (would not kill the processor), but your values may be off. -

@Meshx86

actually, you need a voltage divider if the voltage to be measured is above the maximum allowed by the processor at the speed you are running it.If Vcc is 5V, then any voltage above 5V should be measured via a voltage divider.

If Vcc is 3.3V same principle, but you could get away with measuring 5V directly (would not kill the processor), but your values may be off.@GertSanders following the instructions of this post suggest using Alkaline batteries (apparently Li-ion aren't a good idea for sensor nodes ?! plus they are expensive), the optimal solution would be using 2 x AA batteries as some ans this post suggested.

I believe there is no way 2 x AA batteries in series would measure anywhere near 3.3v, the max i measured with brand new batteries was 3.2v.

my major concern is:

would i still need to the do the voltage corrections when using the voltage divider ? if so, does that need to be reprogrammed every time you replace the battery ? -

@GertSanders following the instructions of this post suggest using Alkaline batteries (apparently Li-ion aren't a good idea for sensor nodes ?! plus they are expensive), the optimal solution would be using 2 x AA batteries as some ans this post suggested.

I believe there is no way 2 x AA batteries in series would measure anywhere near 3.3v, the max i measured with brand new batteries was 3.2v.

my major concern is:

would i still need to the do the voltage corrections when using the voltage divider ? if so, does that need to be reprogrammed every time you replace the battery ?@Meshx86

No problem to ask. I use the intern measurement method, which uses the internal 1.1V reference of the atmega328, so even if the Vcc value changes from 3.2V -> 2.6V, the reference will always be 1.1V, and the internal method allows you to calculate the actual measured battery voltage based on a difference with the reference, even with a declining value on Vcc (if powered by the same batteries). -

@Meshx86

No problem to ask. I use the intern measurement method, which uses the internal 1.1V reference of the atmega328, so even if the Vcc value changes from 3.2V -> 2.6V, the reference will always be 1.1V, and the internal method allows you to calculate the actual measured battery voltage based on a difference with the reference, even with a declining value on Vcc (if powered by the same batteries).@GertSanders sorry mate, am more of a software guy..

according to the lib i've seen and @Yveaux's example for the internal method, at the begining you need to define a corrective value :

const float VccCorrection = 1.0/1.0; // Measured Vcc by multimeter divided by reported Vcc Vcc vcc(VccCorrection);is this necessary for an accurate reading ? and is the corrective value need to be just entered once (like a calibration per arduino) or need to be reconfigured every time you replace a battery ?

-

Good article/site on why Alkaline is the best way to go for Mysensors nodes :)

http://batteryuniversity.com/learn/article/elevating_self_discharge -

@GertSanders sorry mate, am more of a software guy..

according to the lib i've seen and @Yveaux's example for the internal method, at the begining you need to define a corrective value :

const float VccCorrection = 1.0/1.0; // Measured Vcc by multimeter divided by reported Vcc Vcc vcc(VccCorrection);is this necessary for an accurate reading ? and is the corrective value need to be just entered once (like a calibration per arduino) or need to be reconfigured every time you replace a battery ?

@Meshx86

The corrective value is needed every time you change a battery, AND if you need high accuracy.

On my battery based nodes I do not have a need for absolute accuracy, I just need to see the trend of the Vcc value.

Changing the battery happens every 12-24 months (depends on the use), so I'm not very interested in absolute accuracy. If you need real accurate measuring, I would suggest a real Analog-To_Digital chip.

,

,