CNC PCB milling

-

Once I find my dragon, I'll burn a new atmega328p with the grbl 1.1 and replace the suspect atmega328p. Hopefully it will work then. If not, then I'm guessing it's the the usb-to-serial chip gone bad. Anyhow, one way or another I'll get to the bottom of it. And if I don't, a replacement board is on its way.

-

Once I find my dragon, I'll burn a new atmega328p with the grbl 1.1 and replace the suspect atmega328p. Hopefully it will work then. If not, then I'm guessing it's the the usb-to-serial chip gone bad. Anyhow, one way or another I'll get to the bottom of it. And if I don't, a replacement board is on its way.

-

@neverdie don't stick to you missing dragon programmer. use an arduino as an isp programmer instead. also, if you burn the bootloader, next time you can use the usb connector for update.

-

I extracted the atmega328p chip that was on the woodpecker and attempted to read it. Fail. Normal voltage is 5v on a fresh chip, but it was reading only 4.8v. Also, it got quite hot. So, I think it is defective.

-

I've established that the GRBL1.1f firmware assumes it's running at 16Mhz. So, I guess I'll try the following fuse settings, typically used on a 16Mhz Pro Mini:

pro5v328.bootloader.low_fuses=0xFF <<< same as 8 MHz pro5v328.bootloader.high_fuses=0xDA <<< same as 8 MHz pro5v328.bootloader.extended_fuses=0x05 <<< same as 8 MHzBODLEVEL = 2V7 RSTDISBL = [ ] DWEN = [ ] SPIEN = [X] WDTON = [ ] EESAVE = [ ] BOOTSZ = 1024W_3C00 BOOTRST = [X] CKDIV8 = [ ] CKOUT = [ ] SUT_CKSEL = EXTXOSC_8MHZ_XX_16KCK_14CK_65MS EXTENDED = 0x05 (valid) HIGH = 0xDA (valid) LOW = 0xFF (valid) -

I soldered in the replacement atmega328p, after burning its firmware with GRBL 1.1f, and Bingo! That fixed it:

Grbl 1.1f ['$' for help]Because of the upgraded firmware, I'm actually better off now than I was before. :)

-

@neverdie I still use my default settings (see below). I re-applied these settings after I flashed the board to grbl 1.1f.

to be honest, after I found the right parameters for the PCB milling jobs I did not went further to fine tune the CNC settings, due to the lack of time. maybe later of the year, but currently I'm more than happy with the results.$0=10 (step pulse, usec) $1=25 (step idle delay, msec) $2=0 (step port invert mask:00000000) $3=5 (dir port invert mask:00000101) $4=0 (step enable invert, bool) $5=0 (limit pins invert, bool) $6=0 (probe pin invert, bool) $10=3 (status report mask:00000011) $11=0.010 (junction deviation, mm) $12=0.002 (arc tolerance, mm) $13=0 (report inches, bool) $20=0 (soft limits, bool) $21=0 (hard limits, bool) $22=0 (homing cycle, bool) $23=0 (homing dir invert mask:00000000) $24=25.000 (homing feed, mm/min) $25=500.000 (homing seek, mm/min) $26=250 (homing debounce, msec) $27=1.000 (homing pull-off, mm) $100=800.000 (x, step/mm) $101=800.000 (y, step/mm) $102=800.000 (z, step/mm) $110=800.000 (x max rate, mm/min) $111=800.000 (y max rate, mm/min) $112=500.000 (z max rate, mm/min) $120=10.000 (x accel, mm/sec^2) $121=10.000 (y accel, mm/sec^2) $122=10.000 (z accel, mm/sec^2) $130=200.000 (x max travel, mm) $131=200.000 (y max travel, mm) $132=200.000 (z max travel, mm)```@andrew said in CNC PCB milling:

@neverdie I still use my default settings (see below). I re-applied these settings after I flashed the board to grbl 1.1f.

to be honest, after I found the right parameters for the PCB milling jobs I did not went further to fine tune the CNC settings, due to the lack of time. maybe later of the year, but currently I'm more than happy with the results.$0=10 (step pulse, usec) $1=25 (step idle delay, msec) $2=0 (step port invert mask:00000000) $3=5 (dir port invert mask:00000101) $4=0 (step enable invert, bool) $5=0 (limit pins invert, bool) $6=0 (probe pin invert, bool) $10=3 (status report mask:00000011) $11=0.010 (junction deviation, mm) $12=0.002 (arc tolerance, mm) $13=0 (report inches, bool) $20=0 (soft limits, bool) $21=0 (hard limits, bool) $22=0 (homing cycle, bool) $23=0 (homing dir invert mask:00000000) $24=25.000 (homing feed, mm/min) $25=500.000 (homing seek, mm/min) $26=250 (homing debounce, msec) $27=1.000 (homing pull-off, mm) $100=800.000 (x, step/mm) $101=800.000 (y, step/mm) $102=800.000 (z, step/mm) $110=800.000 (x max rate, mm/min) $111=800.000 (y max rate, mm/min) $112=500.000 (z max rate, mm/min) $120=10.000 (x accel, mm/sec^2) $121=10.000 (y accel, mm/sec^2) $122=10.000 (z accel, mm/sec^2) $130=200.000 (x max travel, mm) $131=200.000 (y max travel, mm) $132=200.000 (z max travel, mm)```Looks as though GRBL1.1f has exposed some additional registers than GRBL0.9 did:

$0=10 $1=25 $2=0 $3=5 $4=0 $5=0 $6=0 $10=3 $11=0.010 $12=0.002 $13=0 $20=0 $21=0 $22=0 $23=0 $24=25.000 $25=500.000 $26=250 $27=1.000 $30=1000 $31=0 $32=0 $100=800.000 $101=800.000 $102=800.000 $110=800.000 $111=800.000 $112=500.000 $120=10.000 $121=10.000 $122=10.000 $130=200.000 $131=200.000 $132=200.000namely, registers 30, 31, and 32. Not sure what their values should be, or if it even matters.

Interestingly, the stepper motors have a distinctly different sound to them when running Chilipeppr with GRBL1.1f (as contrasted with GRBL0.9).

-

I am having a serious problem, though, which is that no matter whether I use Chilipeppr to jog the x-axis to the left or to the right, it always veers to the left. It never goes to the right. Y and Z seem to be working OK however.

-

I am having a serious problem, though, which is that no matter whether I use Chilipeppr to jog the x-axis to the left or to the right, it always veers to the left. It never goes to the right. Y and Z seem to be working OK however.

-

@andrew said in CNC PCB milling:

@neverdie I still use my default settings (see below). I re-applied these settings after I flashed the board to grbl 1.1f.

to be honest, after I found the right parameters for the PCB milling jobs I did not went further to fine tune the CNC settings, due to the lack of time. maybe later of the year, but currently I'm more than happy with the results.$0=10 (step pulse, usec) $1=25 (step idle delay, msec) $2=0 (step port invert mask:00000000) $3=5 (dir port invert mask:00000101) $4=0 (step enable invert, bool) $5=0 (limit pins invert, bool) $6=0 (probe pin invert, bool) $10=3 (status report mask:00000011) $11=0.010 (junction deviation, mm) $12=0.002 (arc tolerance, mm) $13=0 (report inches, bool) $20=0 (soft limits, bool) $21=0 (hard limits, bool) $22=0 (homing cycle, bool) $23=0 (homing dir invert mask:00000000) $24=25.000 (homing feed, mm/min) $25=500.000 (homing seek, mm/min) $26=250 (homing debounce, msec) $27=1.000 (homing pull-off, mm) $100=800.000 (x, step/mm) $101=800.000 (y, step/mm) $102=800.000 (z, step/mm) $110=800.000 (x max rate, mm/min) $111=800.000 (y max rate, mm/min) $112=500.000 (z max rate, mm/min) $120=10.000 (x accel, mm/sec^2) $121=10.000 (y accel, mm/sec^2) $122=10.000 (z accel, mm/sec^2) $130=200.000 (x max travel, mm) $131=200.000 (y max travel, mm) $132=200.000 (z max travel, mm)```Looks as though GRBL1.1f has exposed some additional registers than GRBL0.9 did:

$0=10 $1=25 $2=0 $3=5 $4=0 $5=0 $6=0 $10=3 $11=0.010 $12=0.002 $13=0 $20=0 $21=0 $22=0 $23=0 $24=25.000 $25=500.000 $26=250 $27=1.000 $30=1000 $31=0 $32=0 $100=800.000 $101=800.000 $102=800.000 $110=800.000 $111=800.000 $112=500.000 $120=10.000 $121=10.000 $122=10.000 $130=200.000 $131=200.000 $132=200.000namely, registers 30, 31, and 32. Not sure what their values should be, or if it even matters.

Interestingly, the stepper motors have a distinctly different sound to them when running Chilipeppr with GRBL1.1f (as contrasted with GRBL0.9).

@neverdie said in CNC PCB milling:

namely, registers 30, 31, and 32. Not sure what their values should be, or if it even matters.

I found out what they mean:

$30=1000. Max spindle speed, RPM $31=0. Min spindle speed, RPM $32=0 Laser mode, boolean -

@neverdie

Is it working correctly if you just issue a G0 x10 then x-10?

did you switch to the jpadie workspace for v1.1?

sounds like you have a short on pin 5@rmtucker said in CNC PCB milling:

Is it working correctly if you just issue a G0 x10 then x-10?

No, it goes left in both instances.

@rmtucker said in CNC PCB milling:

did you switch to the jpadie workspace for v1.1?

yes

-

@rmtucker said in CNC PCB milling:

Is it working correctly if you just issue a G0 x10 then x-10?

No, it goes left in both instances.

@rmtucker said in CNC PCB milling:

did you switch to the jpadie workspace for v1.1?

yes

@neverdie sorry, I'm abroad, with very limited availability, so cannot answer too quickly.

based on the mentioned facts it seems to me, that the X axis direction pin is sticked to one position, maybe it has a solder bridge to another pin, or vcc / gnd directly.

-

@neverdie sorry, I'm abroad, with very limited availability, so cannot answer too quickly.

based on the mentioned facts it seems to me, that the X axis direction pin is sticked to one position, maybe it has a solder bridge to another pin, or vcc / gnd directly.

@andrew said in CNC PCB milling:

@neverdie sorry, I'm abroad, with very limited availability, so cannot answer too quickly.

based on the mentioned facts it seems to me, that the X axis direction pin is sticked to one position, maybe it has a solder bridge to another pin, or vcc / gnd directly.

Thanks! You nailed it. It turns out the solder connection on the atmega328p pin corresponding to D5 just wasn't good enough. I resoldered it, and now the X-axis works in both directions. :)

-

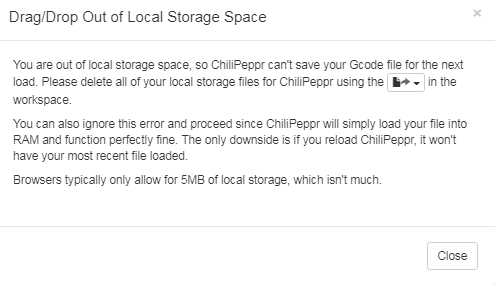

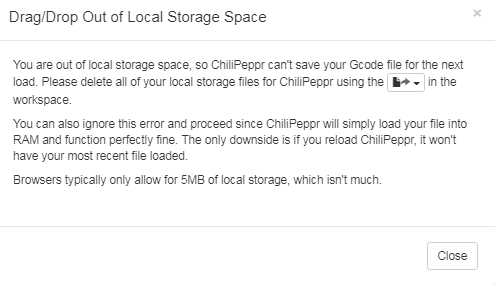

I'm receiving this error message now:

However, it's not obvious how to delete the files it's referring to. Anyone know how? -

I'm receiving this error message now:

However, it's not obvious how to delete the files it's referring to. Anyone know how? -

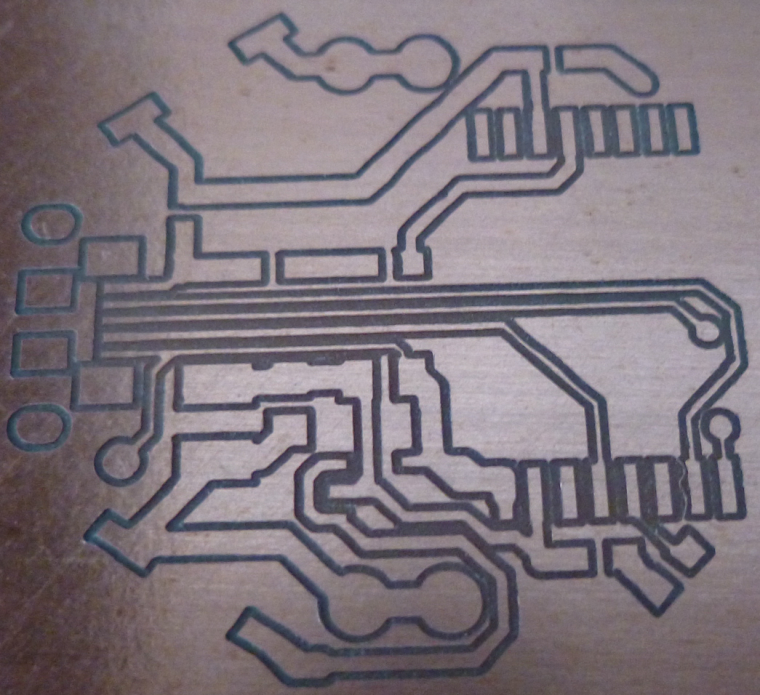

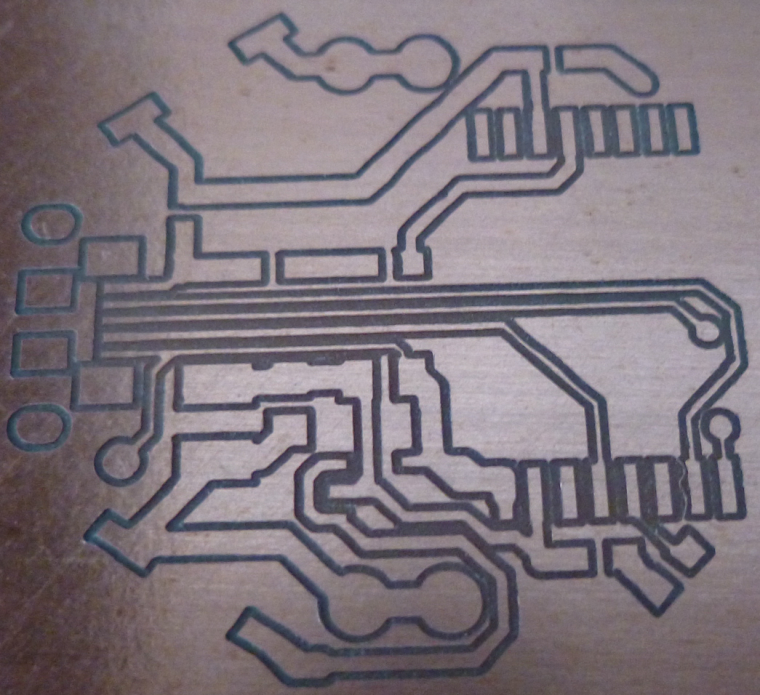

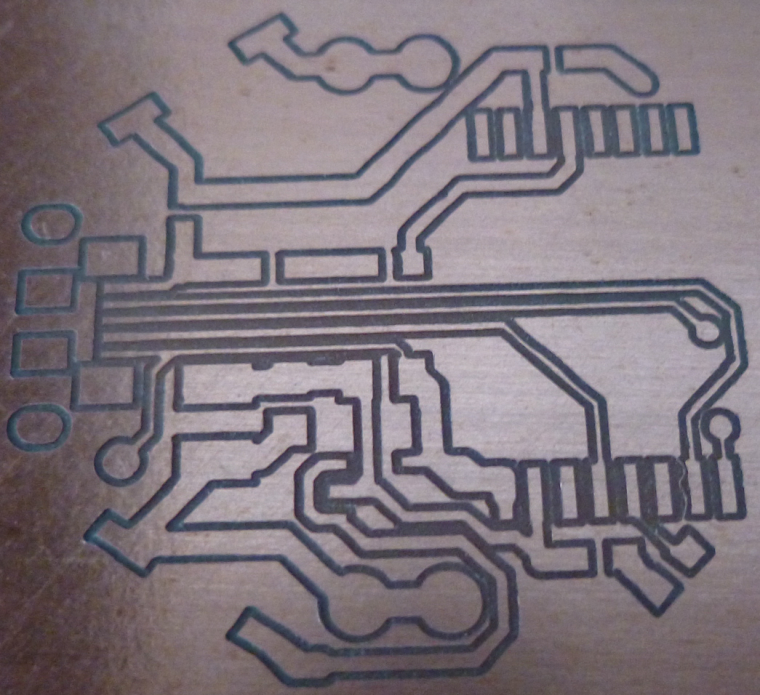

Great news! Grbl1.1f makes all the difference. I tried milling at 6 mil separation using the upgraded grbl1.1f, and it works!

There's a huge difference between being able to evolve a single PCB design to perfect it rather than having to work on a "dumbed down" design (for a CNC or some other DIY etching process) before being able to get "the real deal" from a PCB fabricator. So, I'm very relieved that the first option now seems possible. :) -

Great news! Grbl1.1f makes all the difference. I tried milling at 6 mil separation using the upgraded grbl1.1f, and it works!

There's a huge difference between being able to evolve a single PCB design to perfect it rather than having to work on a "dumbed down" design (for a CNC or some other DIY etching process) before being able to get "the real deal" from a PCB fabricator. So, I'm very relieved that the first option now seems possible. :) -

Great news! Grbl1.1f makes all the difference. I tried milling at 6 mil separation using the upgraded grbl1.1f, and it works!

There's a huge difference between being able to evolve a single PCB design to perfect it rather than having to work on a "dumbed down" design (for a CNC or some other DIY etching process) before being able to get "the real deal" from a PCB fabricator. So, I'm very relieved that the first option now seems possible. :)@neverdie as I see from the picture, you can decrease the cutting depth. this could help you to soften the force against the carving bits and it could also help you to use faster feed rates without risking a missing step or bit damage.

btw, what are your currently used parameters?

also, for the best results please be sure, that when you set up the tool width in flatcam, then it is originated from the previously mentioned formula, which uses the carving bit properties (end with + angle) and the cutting depth.

-

@neverdie as I see from the picture, you can decrease the cutting depth. this could help you to soften the force against the carving bits and it could also help you to use faster feed rates without risking a missing step or bit damage.

btw, what are your currently used parameters?

also, for the best results please be sure, that when you set up the tool width in flatcam, then it is originated from the previously mentioned formula, which uses the carving bit properties (end with + angle) and the cutting depth.

@andrew

In this particular instance I had used a dull bit to do the autoleveling at 4mm and then switched to a Jack bit (nominal 0.1mm, 30 degrees) which I re-zeroed before starting the cutting.

Cutting depth: 0.03

Tool width: 0.12mm (just a guess as to the actual width)

Feedrate:80mmIt does seem that the actual cutting depth came out deeper than 0.03mm, so I'm not sure what's up with that. My guess is that the re-zeroing with the sharp bit came out wrong.

-

@neverdie I use a wood screw in the sacrificial board holding a piece of metal as a "clamp" I slide it over the board (1mm overlap) and clip one alligator clip to the screw, the other to the bit. After probing I slide it out of the way. The metal piece is about 10cm long and it's left in place for the life of the wood board.

@executivul said in CNC PCB milling:

The metal piece is about 10cm long and it's left in place for the life of the wood board.

Do you have a photo of that?

Also, are you using double sided tape at all, or is this all that you're doing as far as holding the PCB flat against the sacrificial board?