CNC PCB milling

-

The adjustment screw on the stepper module allows you to set max allowable current.

Also, in software, you could try setting a lower max acceleration parameter (as discussed earlier in this thread) and lower max velocity parameters, in case either or both are a factor.

You're brave to be attempting this with unknown equipment. If there are multiple factors... it's trickier to troubleshoot with no working baseline to start with.

-

I've changed my modus operandi so that now I use the largest pad and trace sizes that I can get away with. That way, if they get whittled down during the milling, I still hopefully have enough left. :)

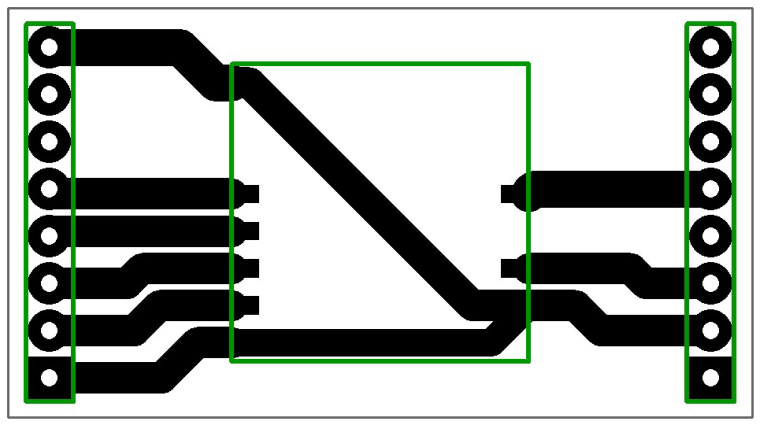

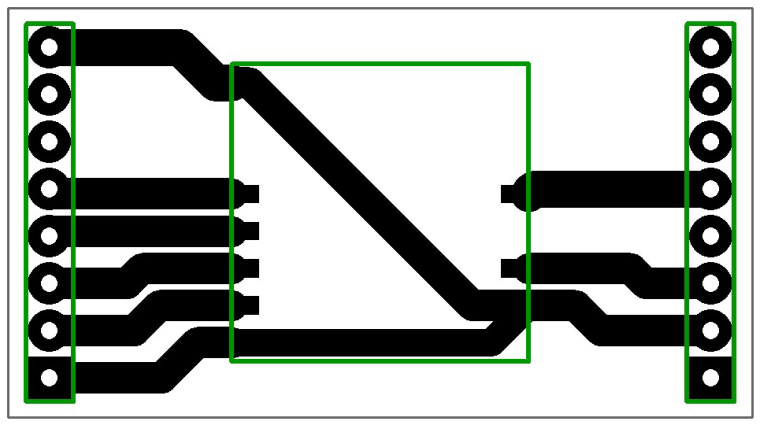

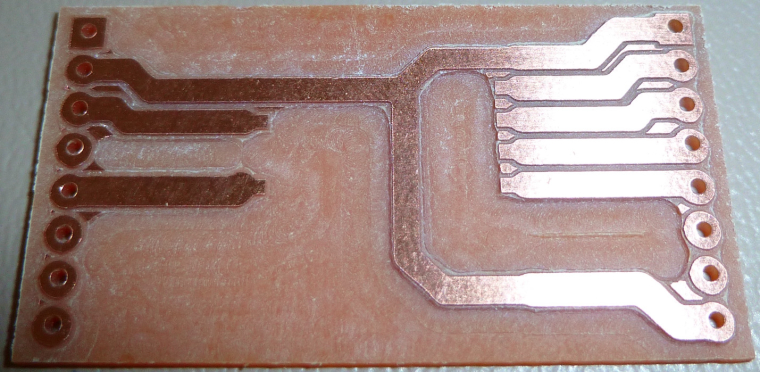

Example:

-

I've changed my modus operandi so that now I use the largest pad and trace sizes that I can get away with. That way, if they get whittled down during the milling, I still hopefully have enough left. :)

Example:

That way, I can also cut deeper and wider, which helps with soldering.

-

So good news. I was able to get the motor turning with some torque. Initially the board was set at full step resolution (no jumpers on M0, M1 or M2). I thought I'd try it at it's lowest microstep resolution which is 1/32, and the motor ran good. I checked the max current and it was set quite high at 2.035 x 2 = 4.07 A. Running some Y axis moves got the motor a bit warm, but I don't think I ran it long enough to do much damage. I now have the current down to 0.254 x 2 = 0.508 A and it seems to be running quiet and good. With it being at 1/32 microstepping it took a lot of revolutions to move the platter mount any distance, so I bumped it to 1/16 microstepping. This is mainly due to the 4.8:1 gear ratio that I have. I think this should give me some pretty good precision on the Y axis at least. Haven't built the X or Z yet, but that is next.

-

The adjustment screw on the stepper module allows you to set max allowable current.

Also, in software, you could try setting a lower max acceleration parameter (as discussed earlier in this thread) and lower max velocity parameters, in case either or both are a factor.

You're brave to be attempting this with unknown equipment. If there are multiple factors... it's trickier to troubleshoot with no working baseline to start with.

-

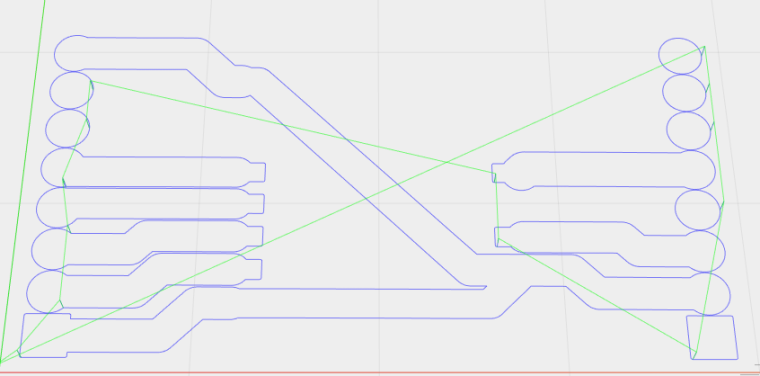

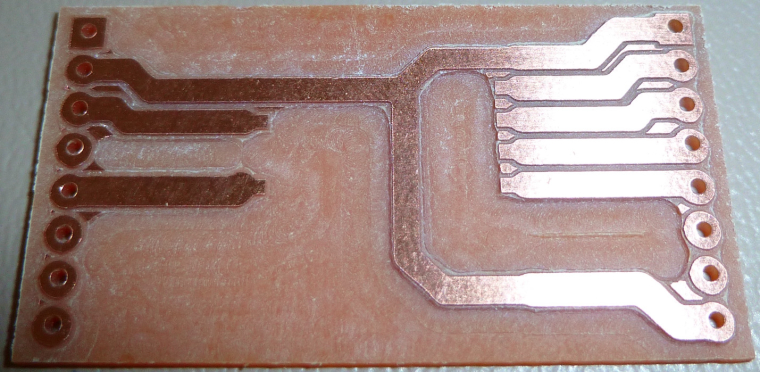

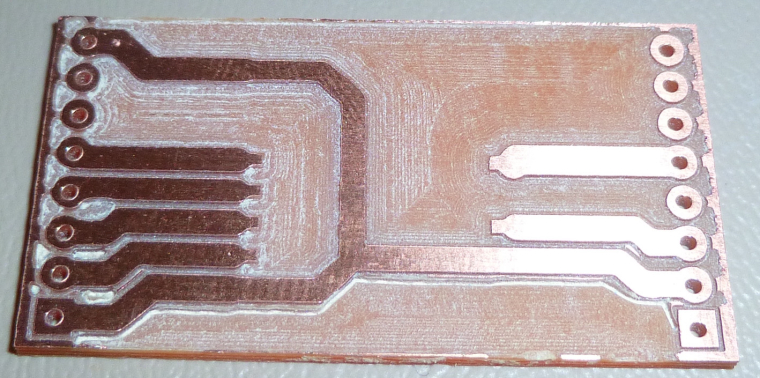

Here's my first attempt at copper removal between the traces/pads:

I used a 2mm endmill to do the work pretty fast. It actually came out pretty good, but the remaining un-removed copper is not what I wanted. I guess it's inevitable unless I use a supper narrow end-mill, or probably a carving bit. But that will take a lot longer.i.e. some kind of hybrid approach would be best, I should think. Is there some way to do the detailed cleanup with a small bit, and then switch to the large diameter bit for the fast cleanup where precision isn't needed?

-

Here's my first attempt at copper removal between the traces/pads:

I used a 2mm endmill to do the work pretty fast. It actually came out pretty good, but the remaining un-removed copper is not what I wanted. I guess it's inevitable unless I use a supper narrow end-mill, or probably a carving bit. But that will take a lot longer.i.e. some kind of hybrid approach would be best, I should think. Is there some way to do the detailed cleanup with a small bit, and then switch to the large diameter bit for the fast cleanup where precision isn't needed?

-

@neverdie Looks like you could raise your end mill a bit (no pun intended). Shouldn't it be the same depth as your other bit?

@dbemowsk said in CNC PCB milling:

@neverdie Looks like you could raise your end mill a bit (no pun intended). Shouldn't it be the same depth as your other bit?

In theory, I suppose maybe so. However, the trouble is I can't preserve and then re-apply the same auto-leveling results. And, after the initial isolation milling, I can't do another to support setting the copper removal depth, because the touchpoints might hit the already removed material, which would seriously skew the results. So, I just set it deep enough to cover the possibilities, and that's why it's deeper.

If anyone has a better solution to that, I'm all ears.

-

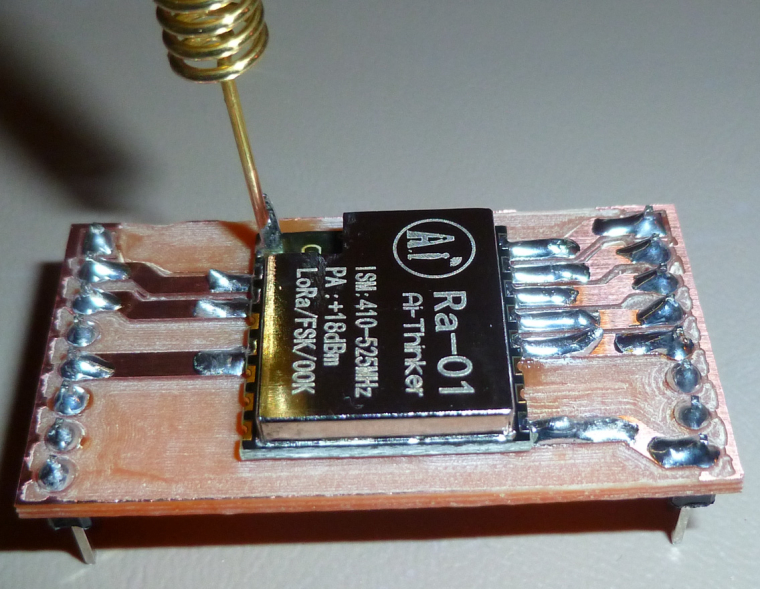

I did get better removal using a carving bit:

-

@neverdie My apologies for near hijacking your thread. I am going to create a new one so I don't mess yours up.

-

Answering my own earlier questin, I forgot to remove the PCB coating using IPA before soldering. I think it probably did make the soldering come out a bit funky looking:

Next time I'll remove it first.Appearances aside, though, it should still work.

-

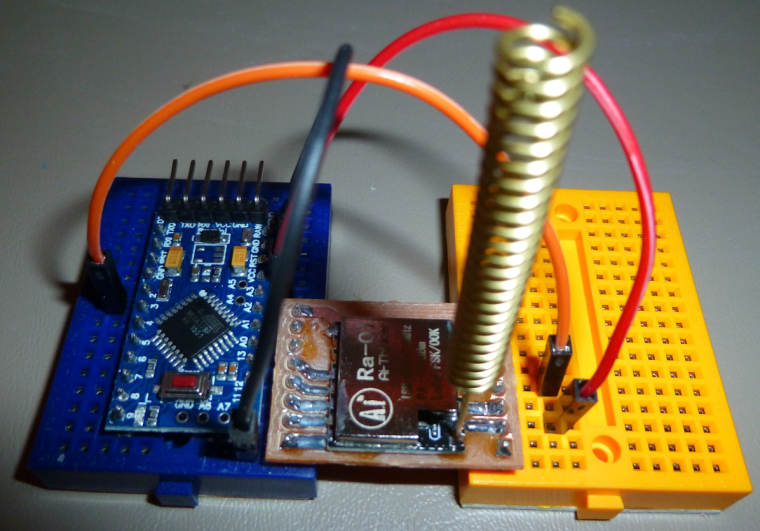

I made the breakout board a bit smaller, and then, since the proof of the pudding is in the taste, I connected it to a pro mini and ran it. Voilà! It works like a charm. :)

-

@andrew What is the widest diameter end-mill bit that this CNC machine can accept and handle? I'm thinking in terms of the mill leveling discussed earlier, and going wide to speed up the process.

@neverdie Pardon my interruption, but I seem to recall my mentioning this near the start of this CNC adventure, and that there was a collet available for that device to accept 8mm standard wood routing bits...

I realise that US traditionally holds to 1/4 and 1/2 inch shafts, but the bigger the size the greater the mass to spin up and motor requirements... Pretty sure you would still be able to find 8mm bits... -

@neverdie Pardon my interruption, but I seem to recall my mentioning this near the start of this CNC adventure, and that there was a collet available for that device to accept 8mm standard wood routing bits...

I realise that US traditionally holds to 1/4 and 1/2 inch shafts, but the bigger the size the greater the mass to spin up and motor requirements... Pretty sure you would still be able to find 8mm bits...@zboblamont I have an ER11 though, so doesn't that preclude using a bigger collet?

-

@zboblamont I have an ER11 though, so doesn't that preclude using a bigger collet?

@neverdie Google it... The ER11 8mm collet indeed exists, although the ads on Ali seem to sell it partnered with a shaft extension.

I'm not familiar with your machine, but well acquainted with wood routers...

Old size bit shafts were 1/4" and 1/2" and probably are predominant in the US, metric were 6mm and 8mm etc... Have only used 8mm personally, but with 1500-2000w routers they make short work of mdf.

For the job you have in mind a 1/4" is probably meaty enough if your motor has the power to handle the cutting rate...There is no reason to go big on the bit diameter, a 1/4" would be plenty strong enough to do what you require and should be readily available stateside... If you have the collet of course...

-

@neverdie Google it... The ER11 8mm collet indeed exists, although the ads on Ali seem to sell it partnered with a shaft extension.

I'm not familiar with your machine, but well acquainted with wood routers...

Old size bit shafts were 1/4" and 1/2" and probably are predominant in the US, metric were 6mm and 8mm etc... Have only used 8mm personally, but with 1500-2000w routers they make short work of mdf.

For the job you have in mind a 1/4" is probably meaty enough if your motor has the power to handle the cutting rate...There is no reason to go big on the bit diameter, a 1/4" would be plenty strong enough to do what you require and should be readily available stateside... If you have the collet of course...

@zboblamont So, indeed, it looks like there is quite a range of collet sizes available for ER11: https://www.maritool.com/Collets-ER-Collets-ER11-Collets/c21_56_60/index.html

It's harder to judge what end-mill diameter the motor can handle though. The motor looks very light duty.

-

@zboblamont So, indeed, it looks like there is quite a range of collet sizes available for ER11: https://www.maritool.com/Collets-ER-Collets-ER11-Collets/c21_56_60/index.html

It's harder to judge what end-mill diameter the motor can handle though. The motor looks very light duty.

Wow, the ER11 collets on Ali Express are incredibly inexpensive--just a little more than $1, with free shipping: https://www.aliexpress.com/item/6MM-SUPER-PRECISION-ER11-COLLET-CNC-CHUCK-MILL-CNC-Workholding-Mill-Lathe-VEC05-P0-25/32795483676.html?spm=2114.search0104.3.44.64385e319AOvIk&ws_ab_test=searchweb0_0,searchweb201602_5_10065_10344_10130_10068_10324_10547_10342_10325_10546_10343_10340_10548_10341_10545_10084_10083_10618_10307_5722320_10313_10059_10534_100031_10103_441_10624_442_10623_10622_10621_10620_10142,searchweb201603_2,ppcSwitch_5&algo_expid=3eb984d6-bba6-4935-8f90-0f6a6da33214-6&algo_pvid=3eb984d6-bba6-4935-8f90-0f6a6da33214&priceBeautifyAB=0

Unless someone here has theory or experience to contraindicate, I guess the only way to answer the question is to buy some end mills and collets and try it out.

-

I think I've found at least one reason for the trouble I've been having: sometimes the double sided scotch tape hasn't been holding the board completely flat against the waste board. Instead, during the milling process, which has a lot of vibration, it can pop up in the area being milled. When that happens, it's effectively the same as having the milling go much deeper, and so traces can be obliterated. Hence, I may try the Shurtape GG-200 that was recommended in the Hackaday article.

It may be that the copper clad boards I'm using just aren't flat enough in the first place. Add to that a waste board that may not be perfectly flat either, and it's not a good formula for keeping everything perfectly flat, which is evidently what it needs to be. The tape itself can't compensate for too large a mismatch.

So, I'd like to try the earlier idea of milling the waste board flat. Just not sure how to do that.

I would't be surprised if single sided copper clad boards are inherently prone to warping. If you think about it, the copper can expand/contract with temperature, and if it's on only one side....Unless the substrate has the same coefficient of thermal expansion, the result will inevitably be warping. The same would be true if the substrate is affected by humidity.

The Hackaday article does mention that it's not necessarily easy to find good copper clad boards. He hints that it has been an ongoing issue over time. He gives a reference for an ebay board vendor in England that he currently likes, but unfortunately that doesn't help me much.

What blank copper clad boards have folks here found that they like?

@neverdie said in CNC PCB milling:

try the Shurtape GG-200 that was recommended in the Hackaday article.

I finally received it, and I tried it yesterday. Definitely has more grip than the regular double sided Scotch tape.