💬 EFEKTA Temperature & Humidity mini sensor

-

@berkseo

my comments were not about pulse power, but about rf radiation, gnd counterpoise size regarding monopole (on batt, less gnd = less range & possible freq detuning), meandered antenna prone to detuning.. (and on pic looks like you have a route behind it).

In some usecase (more range needed, or when board is enclosed etc), these details, combined, could create retransmission for example and more power used etc.

Well, I bet you could get better range if you tested different design vs range. But, no matter, great if it's working well enough for you. That's most important point ;)

Keep the good work!@scalz

Partially agree. Ideally, the ground distance from the antenna should be > 30mm. This condition is not feasible :). In my case, as far as possible... Generally a big issue to the most printed antenna. How well these printed antennas are calculated on all these radio modules :)). But this already the twists and turns... However, thanks for the advice, not in my rules to give up reasonable, kind and free advice :)

-

@instrumentsmeco

perhaps it will be more interesting extended version ... coming soon ;)

E-paper Temp&Hum sensor | First prototype test | MySensors -

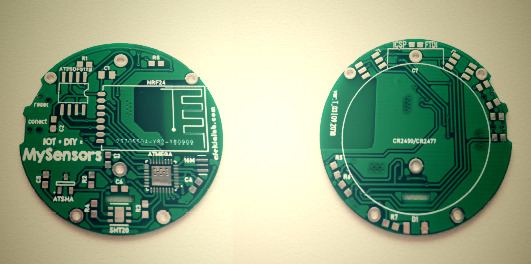

The second revision of the pcb. Added mounting holes for mounting to the device body. Added cutouts for the buttons. Added temperature barrier for temperature and humidity sensor. The lines are moved as far away from the antenna as possible. The empty areas on the Board are filled and connected to the ground.

-

@mika said in 💬 EFEKTA Temperature & Humidity mini sensor:

Hi,

exist some enclosures for your sensors?

MiKaHi, this is a problem, for now, I do it, but I practically have no time for it. But I will definitely make them myself. Maybe I will do them on industrial equipment, if some people like my devices, now they are testing them :)

-

@mika said in 💬 EFEKTA Temperature & Humidity mini sensor:

Hi,

exist some enclosures for your sensors?

MiKaHi, this is a problem, for now, I do it, but I practically have no time for it. But I will definitely make them myself. Maybe I will do them on industrial equipment, if some people like my devices, now they are testing them :)

-

@berkseo do you have a 3d Model of the Sensor? I could support with designing a housing if you want!

-

Started the development of the case...

Remember to support the project with your likes !!! :)

-

@berkseo

Update, the hull prototype is ready. Developed at SOLIDWORKS. It was printed on a 3D printer type SLA. Trial printing on opaque resins has been started. This case cannot be reproduced on the printer type FDM. -

One button is reset, the second button is multifunctional. Depends on how many seconds you hold this button. In my program, I use this button to connect via air to other devices and to transfer the device to receive settings (data transmission intervals, led operation and so on). This button is not used in my test sketch

An example of direct connection between devices (without the use of controllers, without changing the SOFTWARE) is my development, which is in the testing stage is the controller of Underfloor heating. This device controls the five contours of the Underfloor heating. Up to 10 such temperature sensors can be connected to this device simply by pressing the connect button. Maximum of two temperature sensors per one relay channel.

Examples of direct connections (micro-networks) based on MySensors can be found here:

-