Hey @NeverDie, everyone,

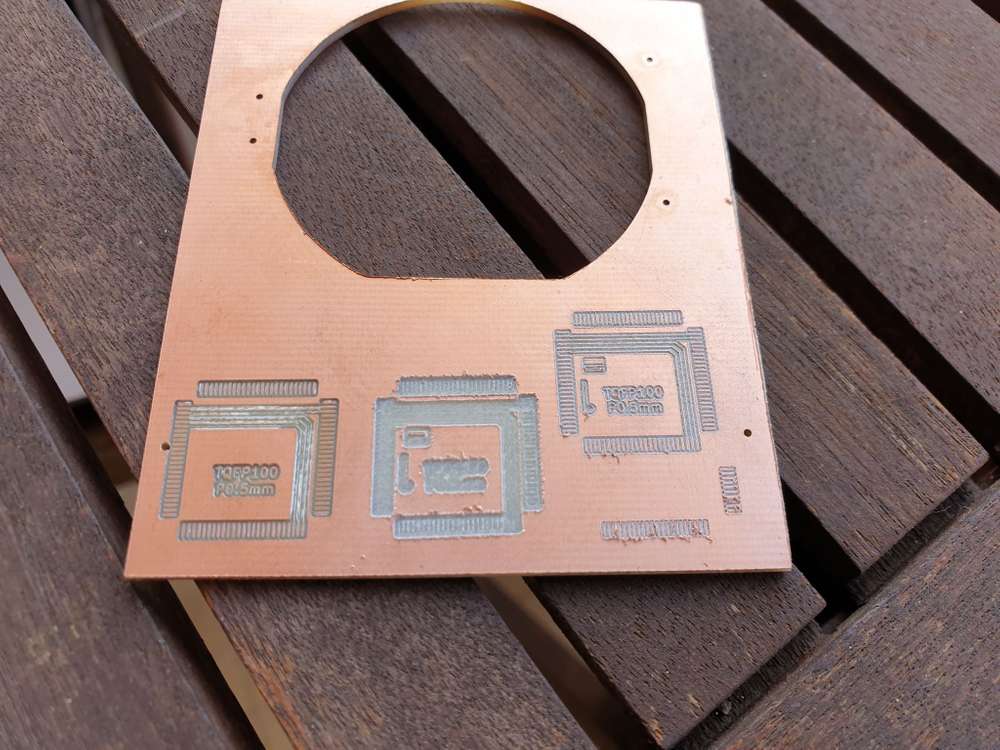

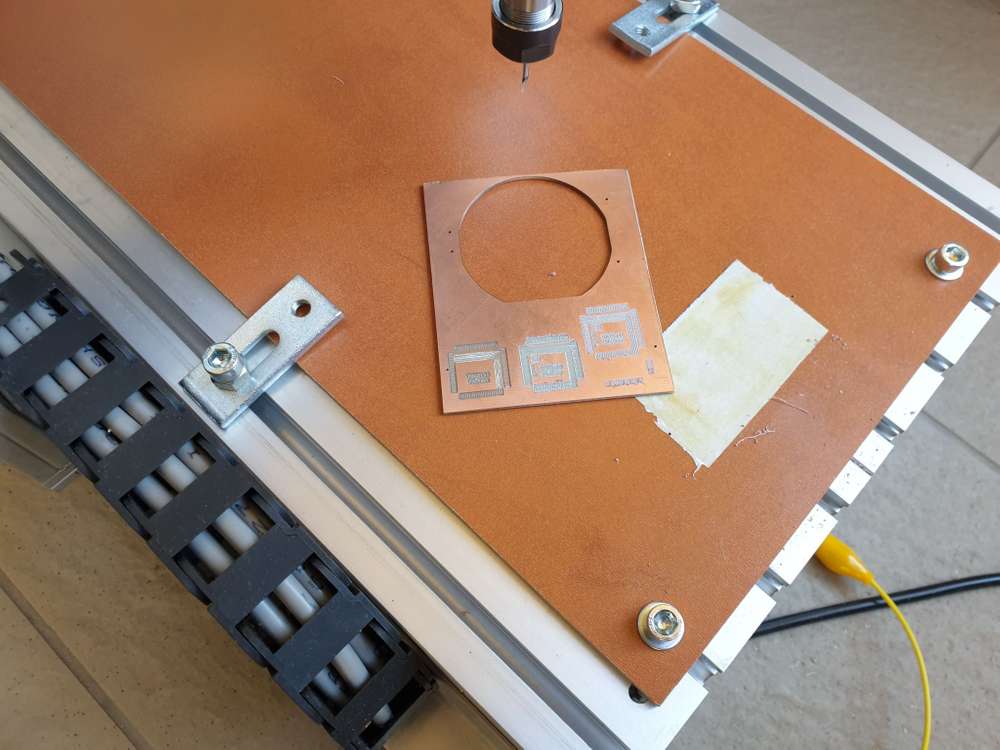

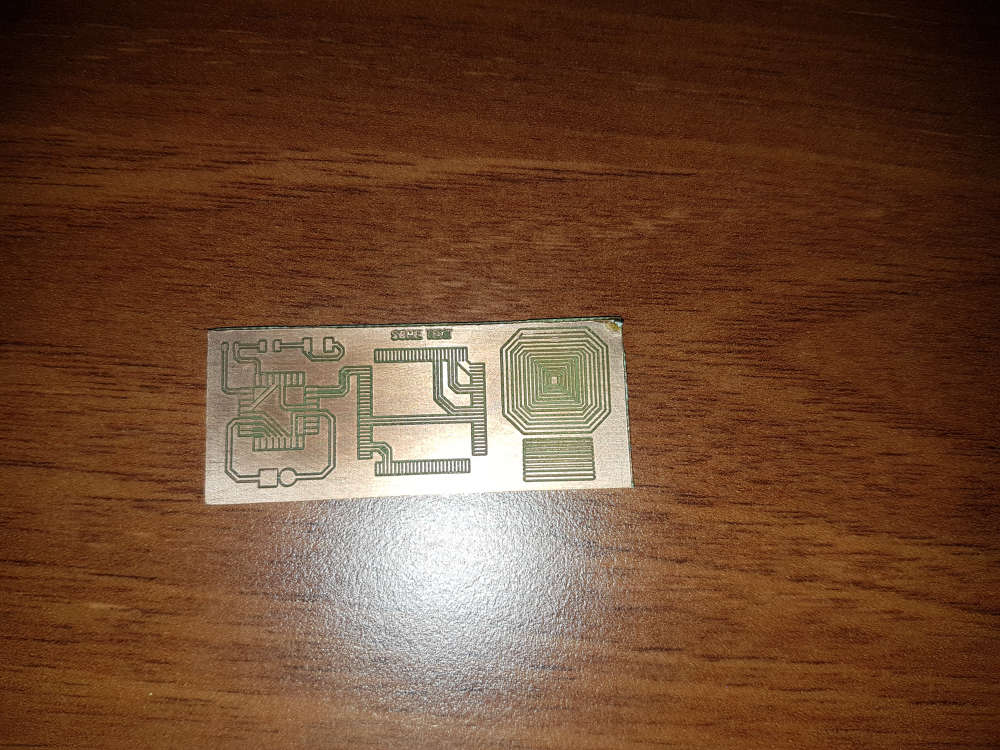

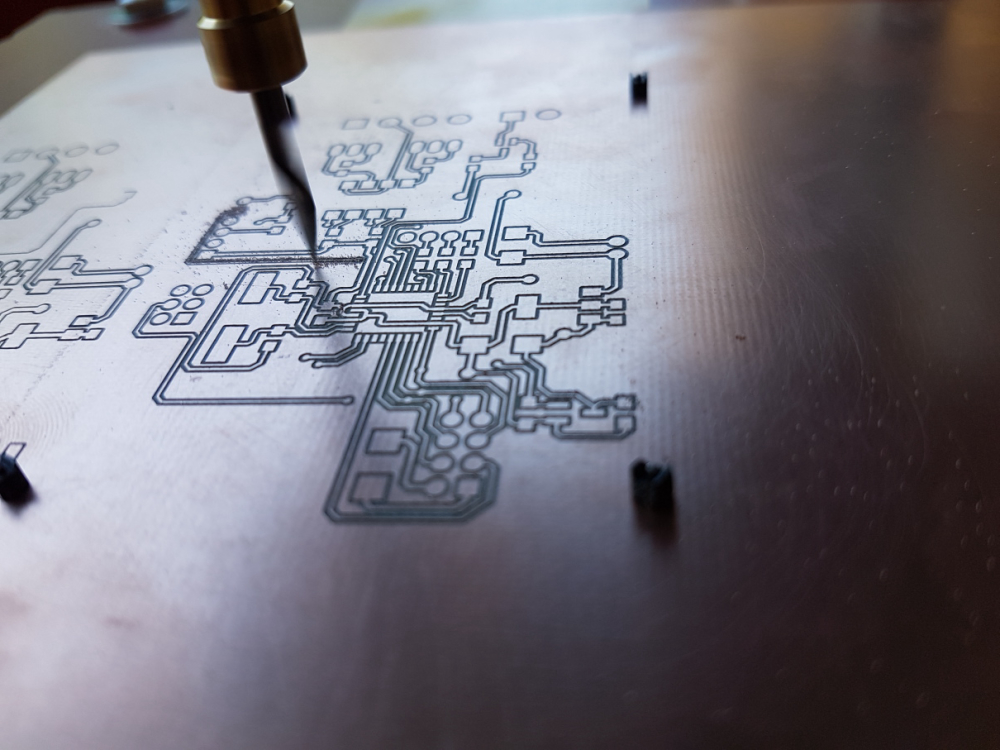

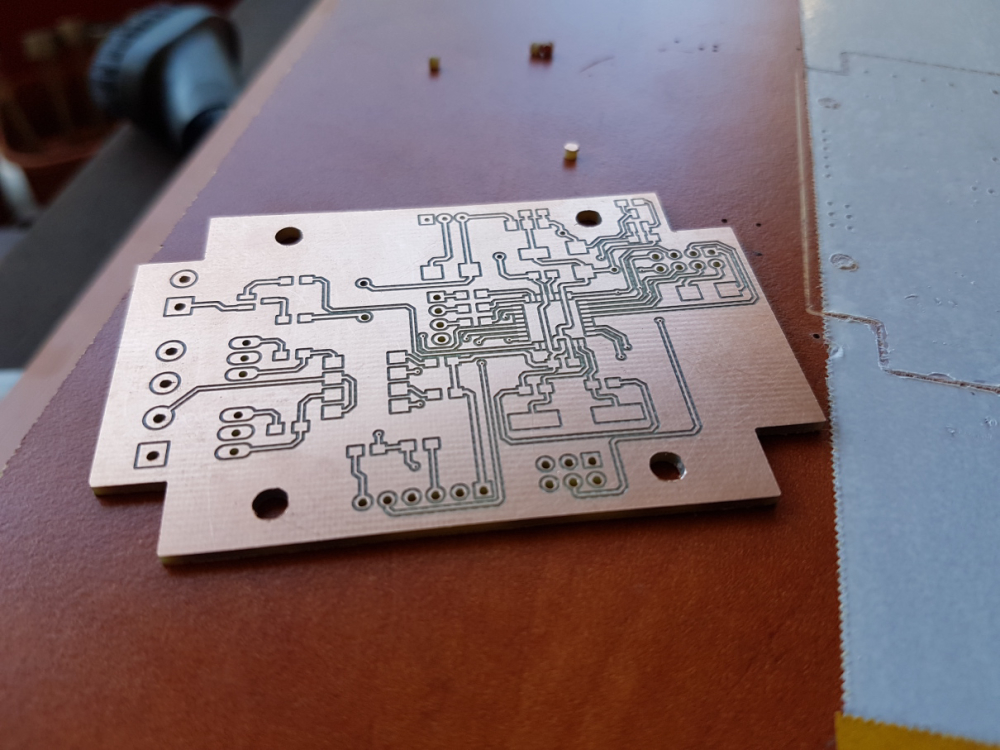

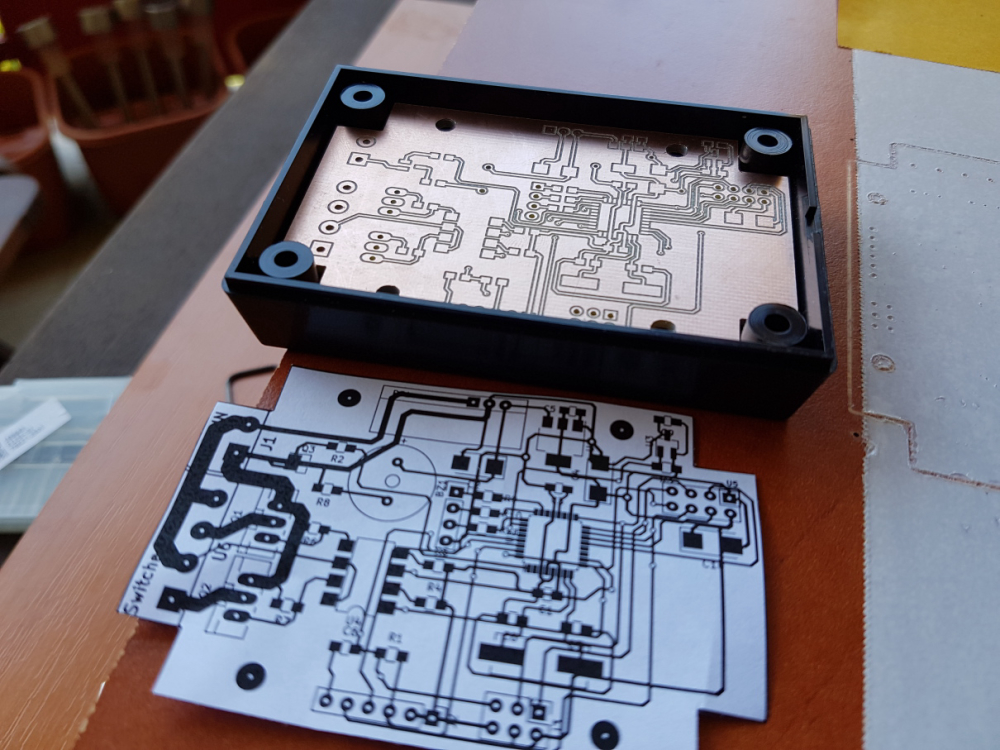

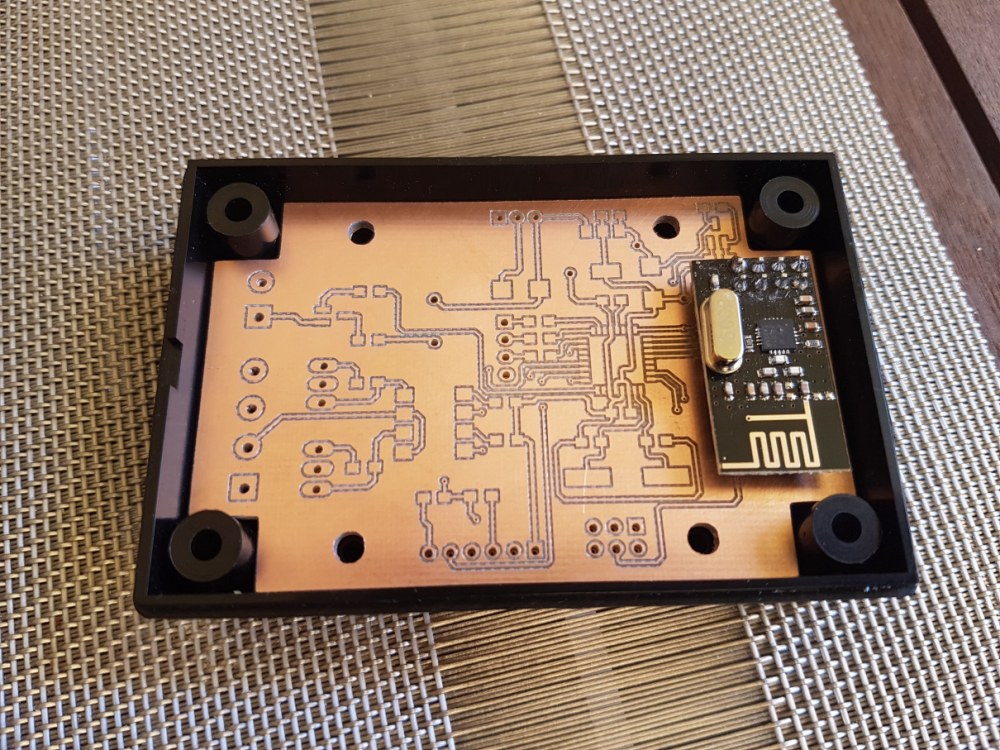

It is good to see how this thread developed over the time and you guys are enjoying the PCB milling.

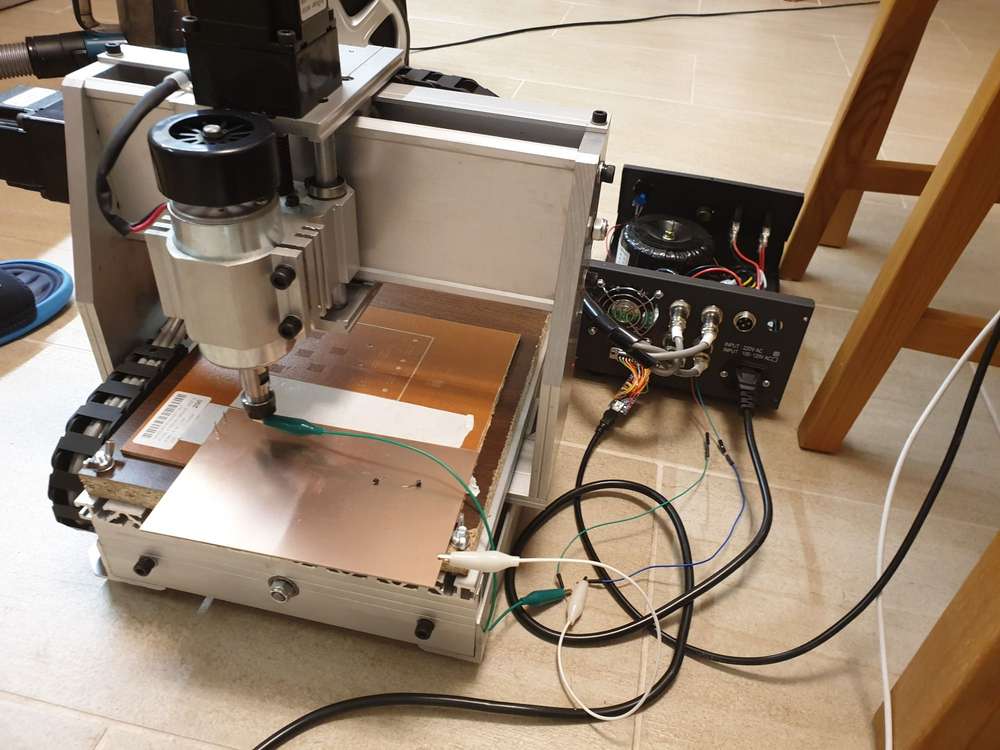

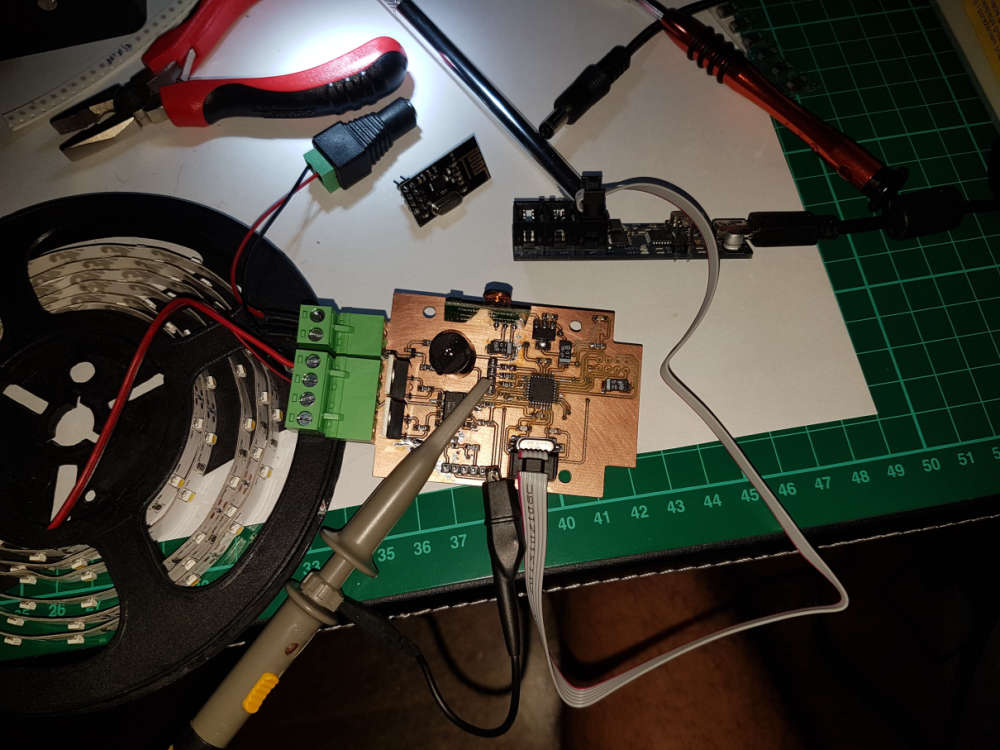

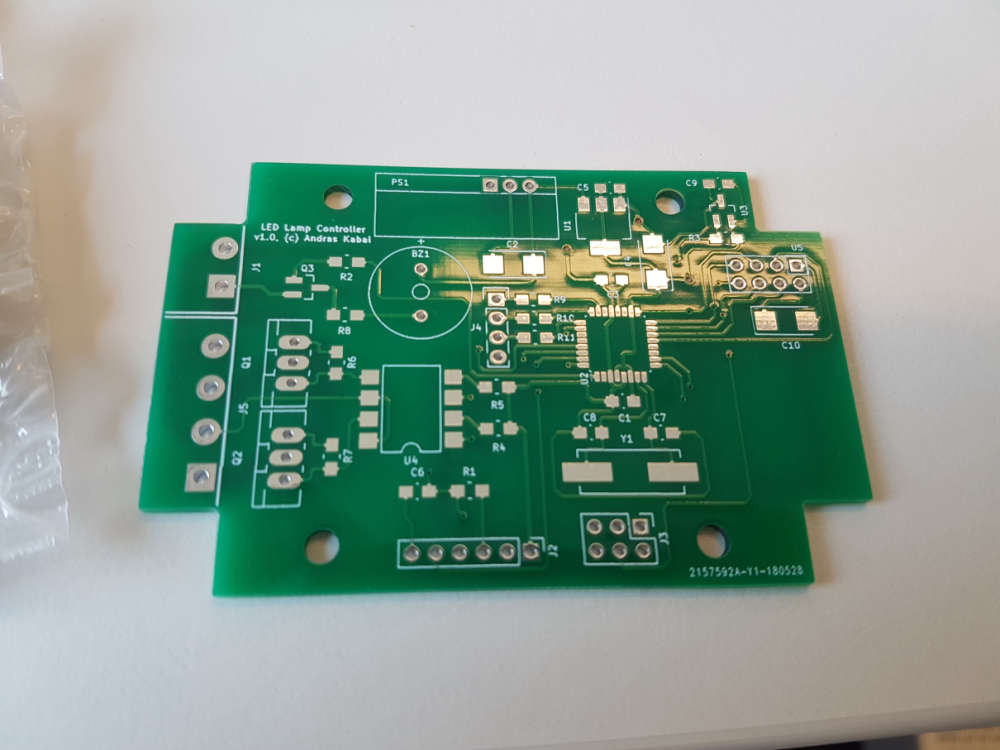

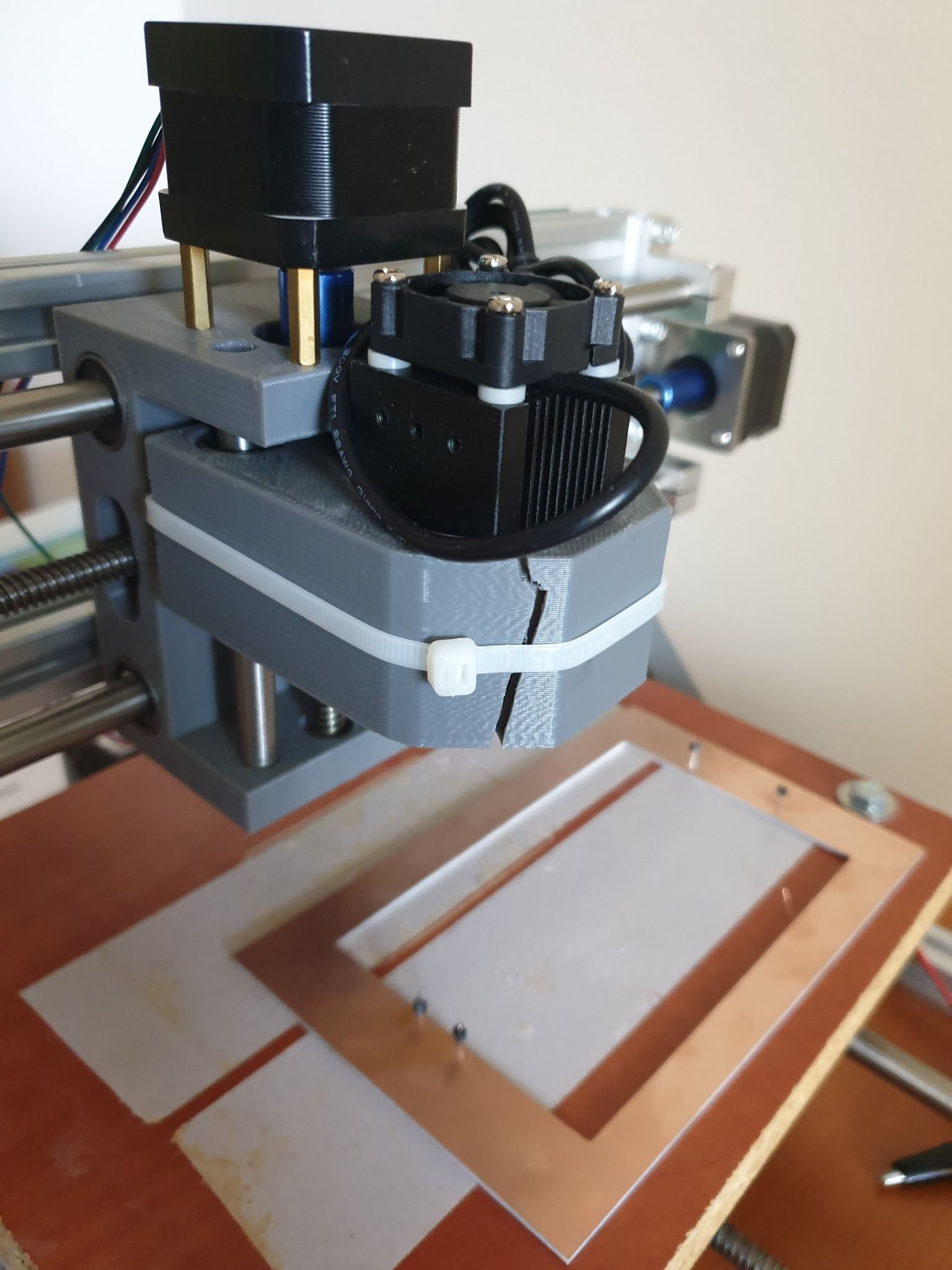

Unfortunately I had many other responsibilities and was super busy, so a lot from my projects had to be postponed. Nevertheless I'm still working with my CNC.

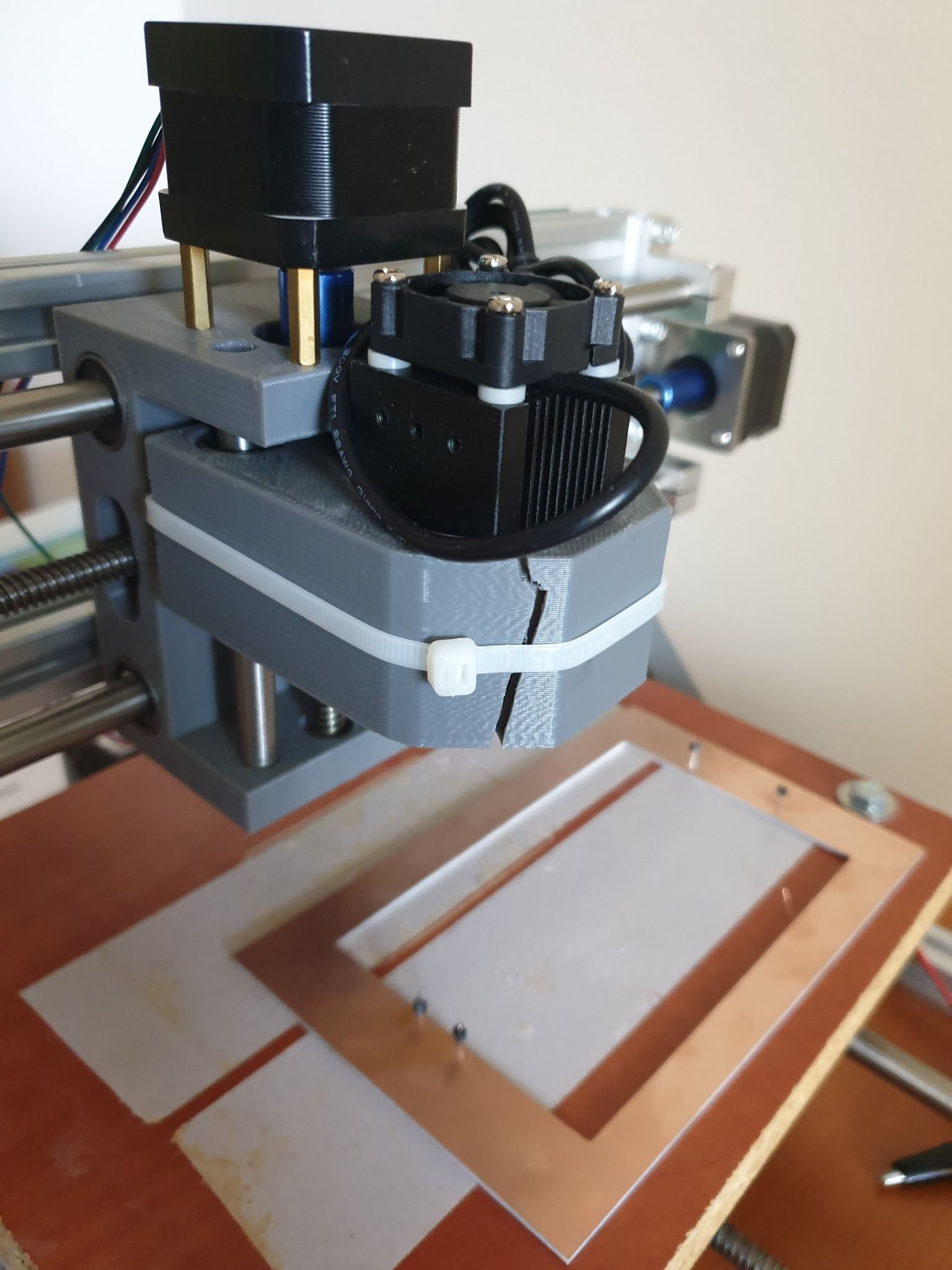

A few days ago I replaced the spindle to a laser module to make same plywood engraving, and the original spindle motor holder (the 3D printed stuff) broke during the unscrew...

I managed to fix the laser module with cable tie. :)

It is ok for the laser, but of course not for the spindle and for the PCB milling.

Replacement parts are available mostly in packages (e.g. https://www.ebay.com/itm/Replacement-Parts-DIY-Kit-for-CNC-1610-2418-3018-Spindle-Holder-Screw-Polish-Pod/112382449851), but it is possible to print your own version too.

Some guys already came up with an enhanced design, such as https://www.thingiverse.com/thing:3586273

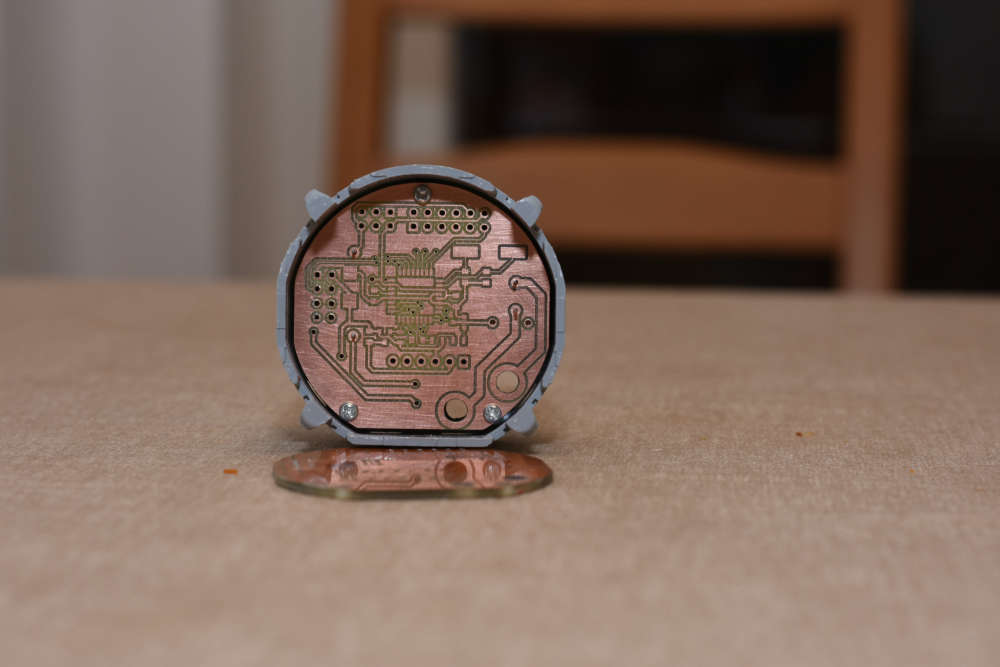

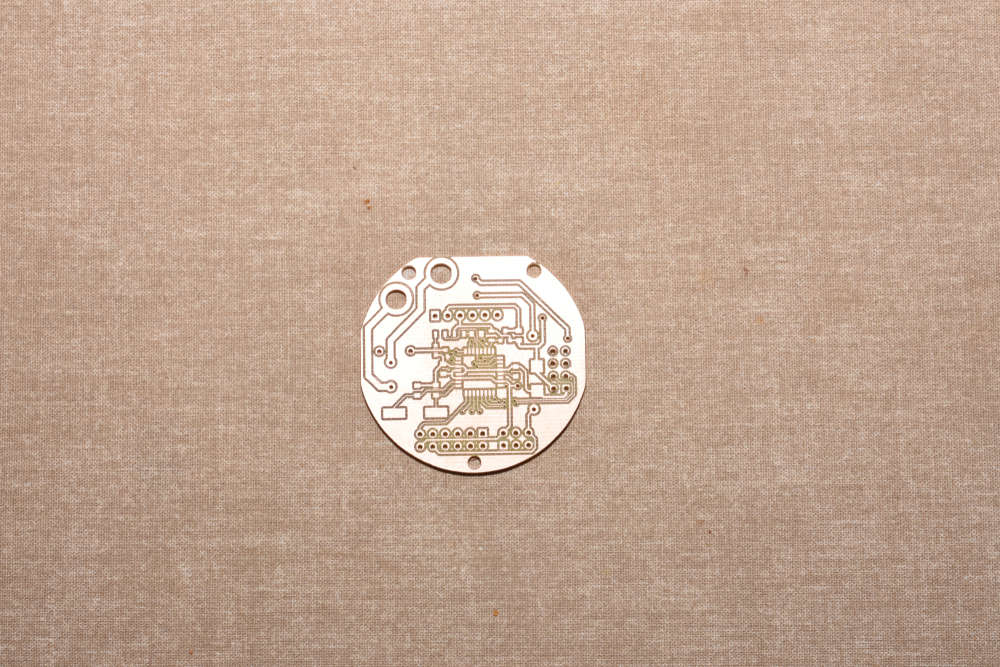

I already wanted to make an upgrade on the CNC, so I came to a conclusion, that I will fix the broken part with a custom 3D printed one, then sell the machine.

I already ordered my new toy, a CNC3020T (EUR 325 + shipping EUR 25):

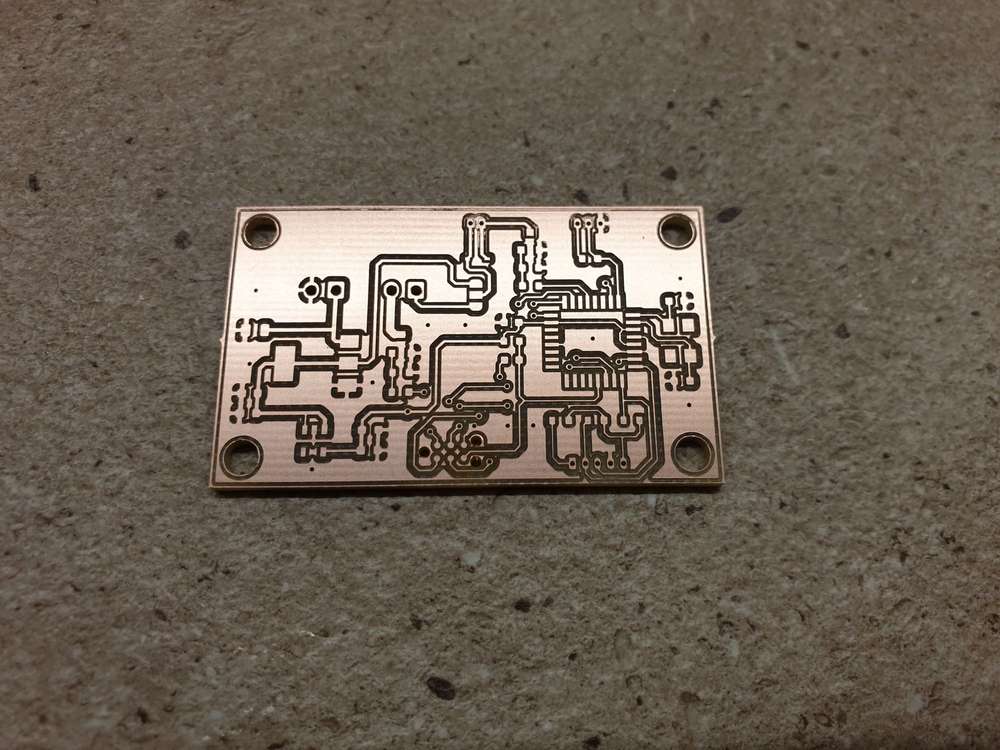

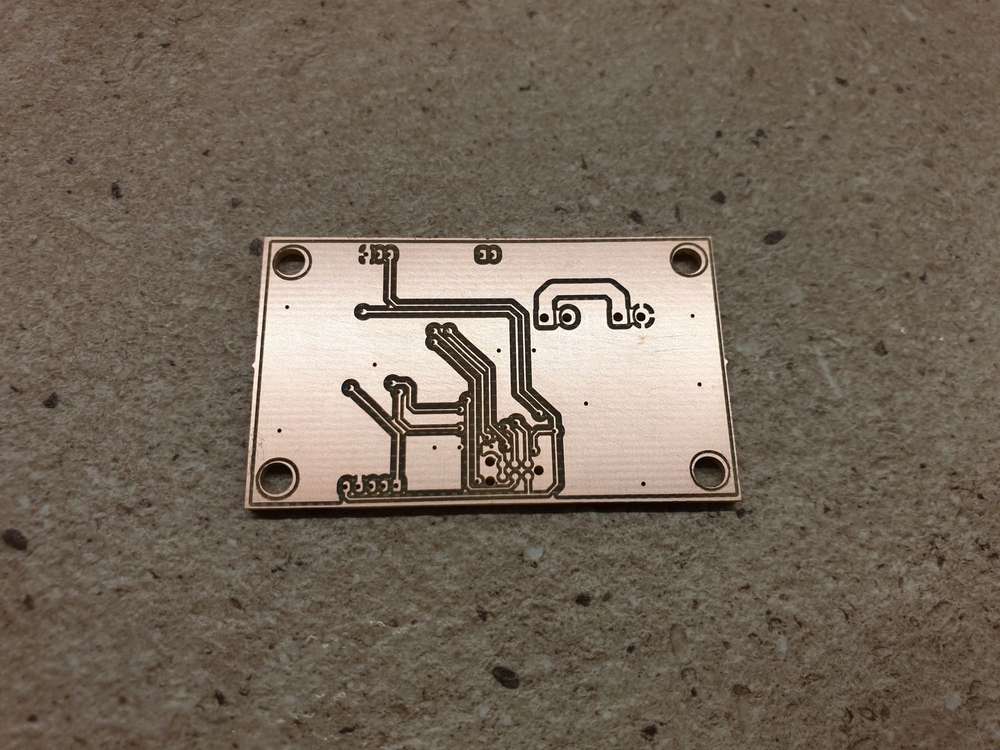

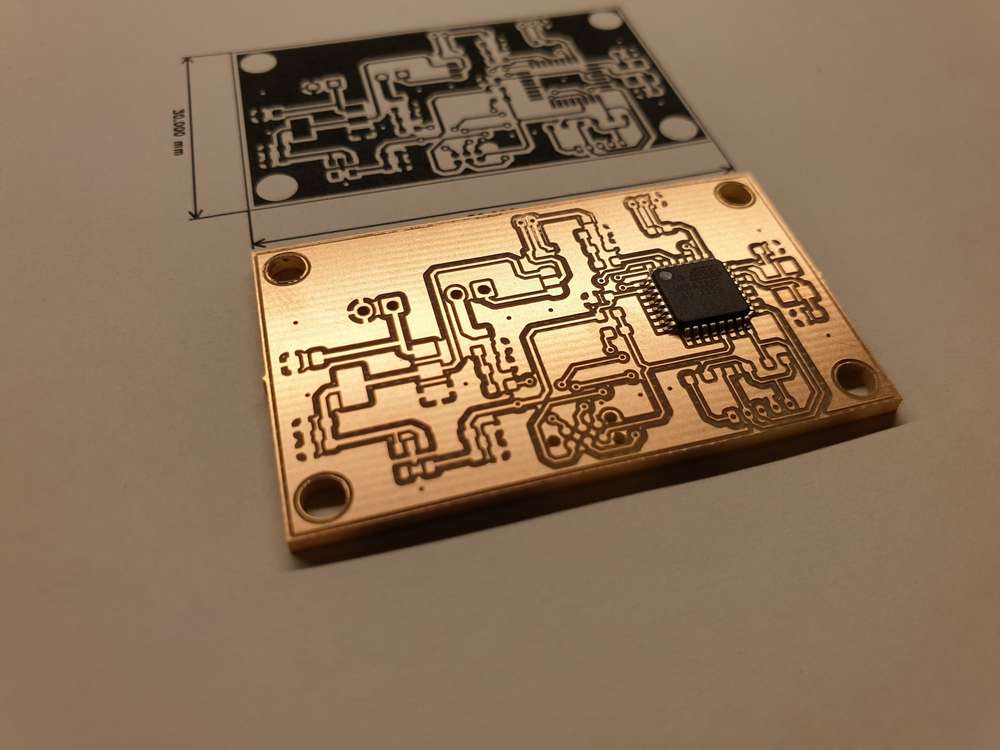

Well, I hesitated a lot and almost bought a CNC3040Z-DQ (bigger, better, ball screw), but as currently I really don't have enough space for it (and to be honest, no reason to buy a better/bigger) I sticked with the 3020T. The quality I achieved with my 2418 will be definitely reproducible and this is enough.

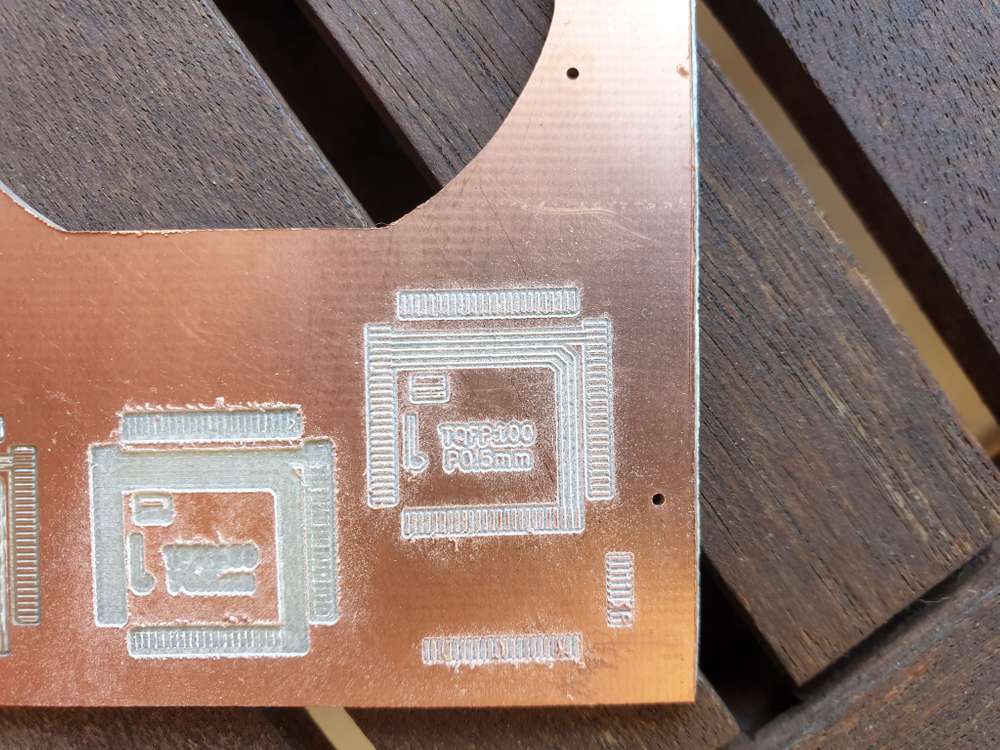

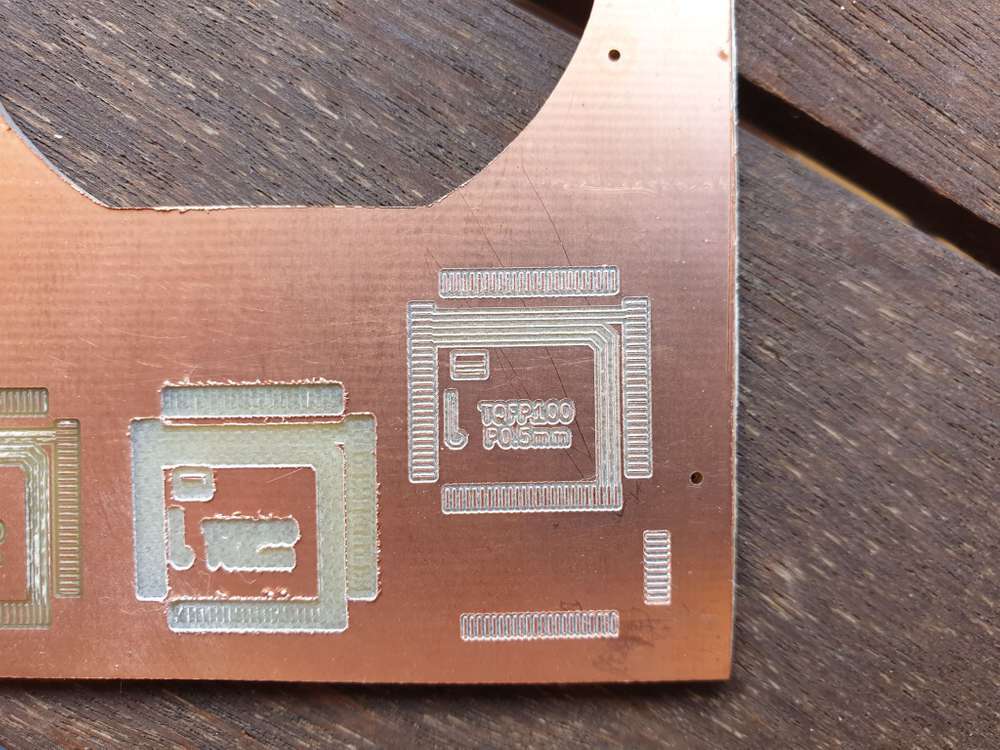

I just read the endmill isolation routing posts. Interesting stuff.

I'm curious whether you can use smaller ones to deal with the 6mil/6mil trace/isolation sizes.

Happy milling and cheers!