Re: This posting about merging sensors.

I did exactly as I said in there:

- Removed the Node and Children from Vera. At this point I have only the MySensors Plugin visible in Vera

- Cleared EEPROM on the Sensor

- Uploaded the new sketch to the Sensor

- Ran Inclusion on Vera

When inclusion ran it found 4 new devices (I assume Node, Temp, Hum, Light)

But Vera does NOT display the new devices even after multiple restarts. The Serial Monitor on the Sensor shows that it is indeed sending data and receiving ACK OK from the Gateway. Subsequent attempts at Inclusion do not find any devices so the GW at least knows they are there.

Looking at the SysLog there is no sensor data being reported since I started this so apparently it isn't getting through.

I'm going to Clear EEPROM again and fallback to the Temp/Hum sensor in case there is a problem with the new sensor code.

Well, that's interesting. After reverting to he 2 sensor node Inclusion found 3 new devices and Vera now displays them. Yet when the 3 sensor code was running the serial monitor showed transmission and ACK for all three sensors. Now I'm confused.

[UPDATE]

I sorted it out, i had several problems.

- It appears the it is necessary to RESET the Node prior to Inclusion. Vera will then find the devices and display them. Absent the Reset it looks like Vera found them but that was all.

- When it finally displayed the LIGHT, it was showing as an ON/OFF Switch not a level. In the Setup routine i had

gw.sendSensorPresentation(CHILD_ID_LIGHT, S_LIGHT);

rather than

gw.sendSensorPresentation(CHILD_ID_LIGHT, S_LIGHT_LEVEL);

and similarly in the sending of the data I had left off the "_LEVEL" not realizing that that told the GW how to display the device. Now I know :)

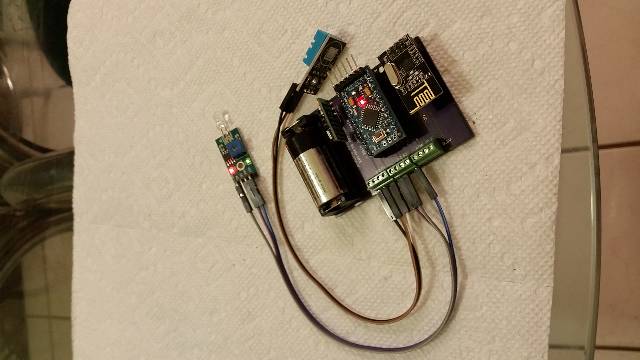

Anyway, the three input sensor is working. In the process of making the conversion I changed the Light Level to a floating number for consistency on the display .I've also implemented a simple Keepalive; every "N" times through the loop it resends the last temperature reading. i have this set to 30 times (and I adjusted the basic data cycle from 30 seconds to 60 seconds) so the keep alive occurs every 30 minutes whether the sensor sends any data in that time or not.