@user2684

Tried again with adafruits library and got it working changing the address.

But still can't get any useful data from it using NodeManager.

Did a bit of copy/paste and got this code working (with adafruit and the alternative library):

#define MY_RADIO_NRF24

#include <MySensors.h>

#include <SPI.h>

#include <BH1750.h>

#include <Wire.h>

#include <BME280I2C.h>

#define BARO_CHILD 0

#define TEMP_CHILD 1

#define HUM_CHILD 2

#define CHILD_ID_LIGHT 3

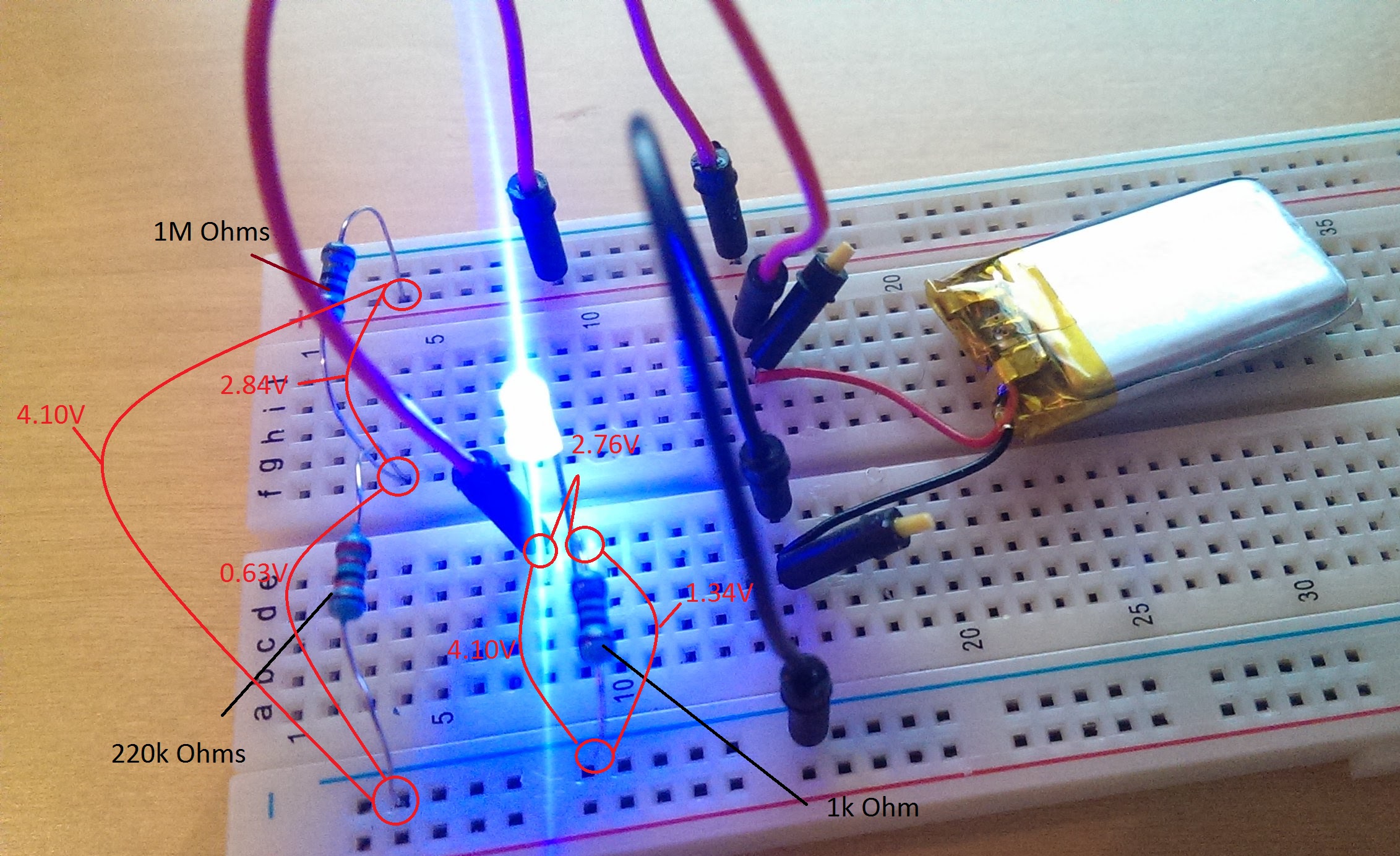

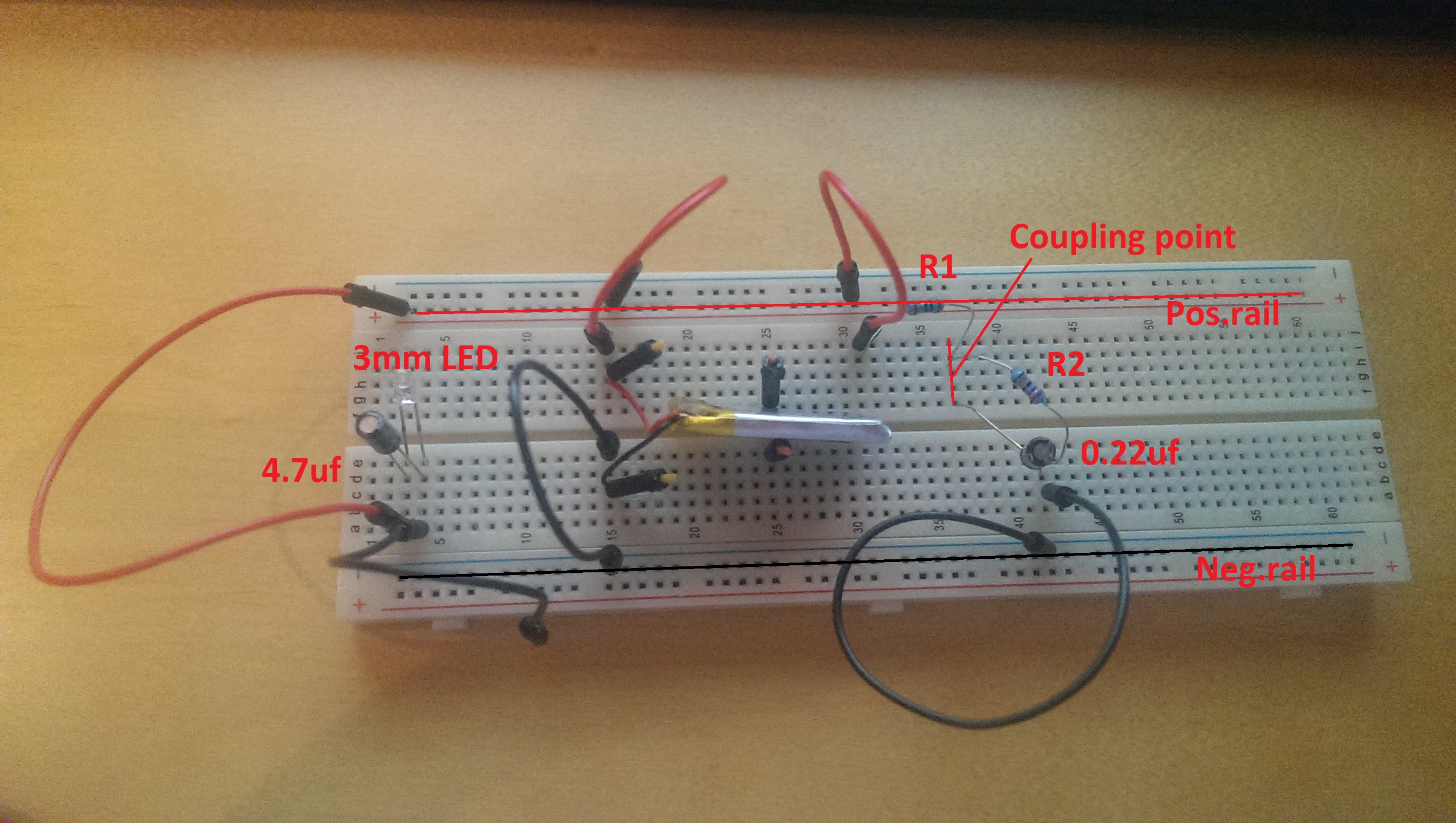

#define R1 687000

#define R2 222000

#define VMIN 3.30

#define VMAX 4.18

#define ADC_PRECISION 1023

#define VREF 1.107

unsigned long SLEEP_TIME = 300000;

const float ALTITUDE = 10;

BME280I2C bme;

BH1750 lightSensor;

MyMessage pressureMsg(BARO_CHILD, V_PRESSURE);

MyMessage tempMsg(TEMP_CHILD, V_TEMP);

MyMessage humMsg(HUM_CHILD, V_HUM);

MyMessage lightMsg(CHILD_ID_LIGHT, V_LEVEL);

float lastbaro = -1;

float lasttemp = -1;

float lasthum = -1;

float lastlux = -1;

float oldBatteryPcnt = -1;

int BATTERY_SENSE_PIN = A0;

void setup()

{

lightSensor.begin();

bme.begin();

analogReference(INTERNAL);

pinMode(BATTERY_SENSE_PIN, INPUT);

delay(100);

}

void presentation()

{

sendSketchInfo("BME280_BH1750", "1.1");

present(BARO_CHILD, S_BARO);

present(TEMP_CHILD, S_TEMP);

present(HUM_CHILD, S_HUM);

present(CHILD_ID_LIGHT, S_LIGHT_LEVEL);

}

void loop()

{

float baro_local = bme.pres() / 100.0;

float baro = ( baro_local / pow((1.0 - ( ALTITUDE / 44330.0 )), 5.255));

if (baro != lastbaro) {

send(pressureMsg.set(baro,2));

lastbaro = baro;

}

float temp = bme.temp();

if (temp != lasttemp) {

send(tempMsg.set(temp,1));

lasttemp = temp;

}

float hum = bme.hum();

if (hum != lasthum) {

send(humMsg.set(hum,1));

lasthum = hum;

}

float lux = lightSensor.readLightLevel();

if (lux != lastlux) {

send(lightMsg.set(lux,0));

lastlux = lux;

}

float batteryPcnt = getBatteryPercentage();

if (oldBatteryPcnt != batteryPcnt) {

// Power up radio after sleep

sendBatteryLevel(batteryPcnt);

oldBatteryPcnt = batteryPcnt;

}

sleep(SLEEP_TIME);

}

float getBatteryPercentage()

{

delay(500);

int inputValue = analogRead(BATTERY_SENSE_PIN);

float voltageDividerFactor = (R1 + R2) / R2;

float maxValue = voltageDividerFactor * VREF;

float voltsPerBit = maxValue / ADC_PRECISION;

float batteryVoltage = voltsPerBit * inputValue;

float batteryPercentage = ((batteryVoltage-VMIN)/(VMAX-VMIN))*100;

return batteryPercentage;

}